In a previous life, I was pretty committed to being a scientist. Well, an engineer actually. A minor distinction to some, but the cardinal sin is to confuse the two among a certain group of my friends. I entered college bright-eyed and bushy-tailed, ready to learn what I needed to so I could go work for an Italian or Japanese MotoGP team making the next generation of fast motorcycles. Fast forward a few years to a bitter college sophomore curled up in the fetal position broken under the weight of abstract math and an electronics class that beat me up and took my lunch money . . .

Sitting in front of my advisor signing the paperwork that would transfer me to the business administration department, I heard something that stuck with me forever. “Tyler, you would have been a fantastic engineer. You’re just a very poor engineering student.” And with a flourish of the pen, that dream went poof. It turns out that the chalkboard wasn’t really for me. I really only did well in labs and practical applications of classroom work. Proof of this is my name on the wall for winning a truss-building competition and an academic record that reflects needing two attempts to get through Calculus 2.

Luckily, TTAG has provided me a really solid outlet to scratch the itch for the rigors of scientific testing. It further pleases me that my former engineering classmates spend a great deal of time in front of Microsoft Excel calculating budgets and not out in the field building, testing, and collecting data.

Recently, I posted an article detailing The Rehn Test, a standardized way of viewing pistol performance. As usual, there was a lively debate in the comments section. It gave me a lot of feedback on what was right and what was wrong with the way I was approaching this. But you can only sit in your living room arguing on the internet for so long before you have to take action. So I grabbed a bone stock M&P 9 that I recently acquired, an Apex Duty Carry Enhancement Kit, and a set of Trijicon sights. Figuring that the trigger and the sights are two known “weak” points of the M&P 9 pistols, I figured it might be fun to take a somewhat mundane review and add a bit more scientific rigor to it.

A few changes to the overall protocol had to happen first. Several of our commenters pointed out that if I wanted to be truly scientific, I should lose the holster draw portion. I agree completely, so all my testing was done with the gun indexed to the chest. Second, I declined using tests four through seven as I felt they were better suited for testing elements of the shooting process than sight acquisition and split times. For this test, I used tests one through three which I felt best evaluated sight acquisition and fast shooting.

My data collection methodology was fairly straightforward. Using a Competition Electronics shot timer, and starting from an indexed point on my chest, finger on the trigger, I attempted to shoot all A Zone hits. After the string was over, I recorded where my shots hit along with my time to first shot, and split times between shots. I started by running the stock M&P through ten repetitions of drills one, two, and three. Then I swapped out the trigger, ran it again, and then made the change to the sights running the same drills again. Once I got home, I put the data into Excel, and scored each rep using Comstock scoring.

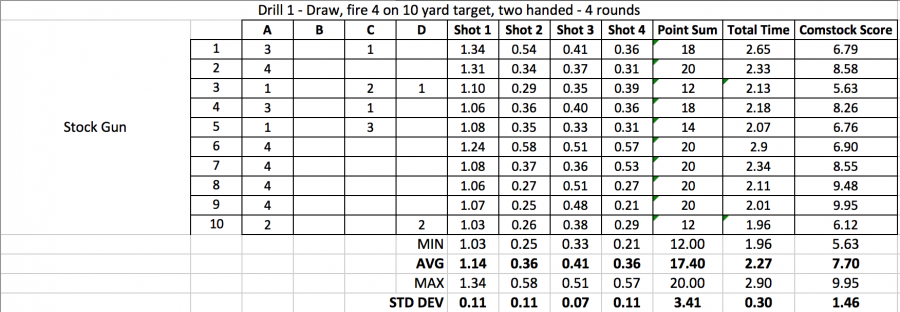

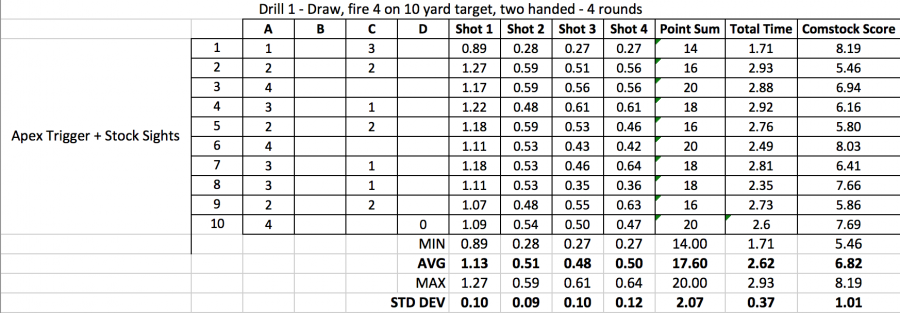

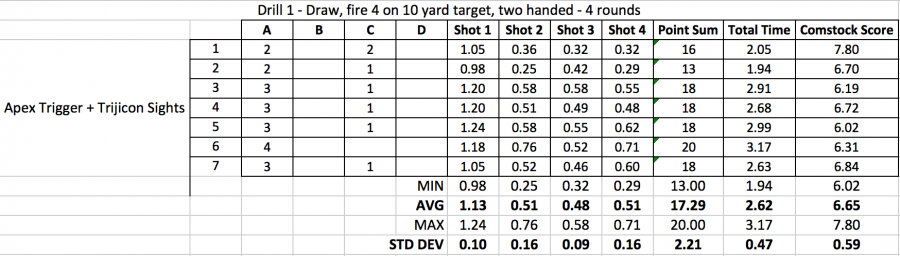

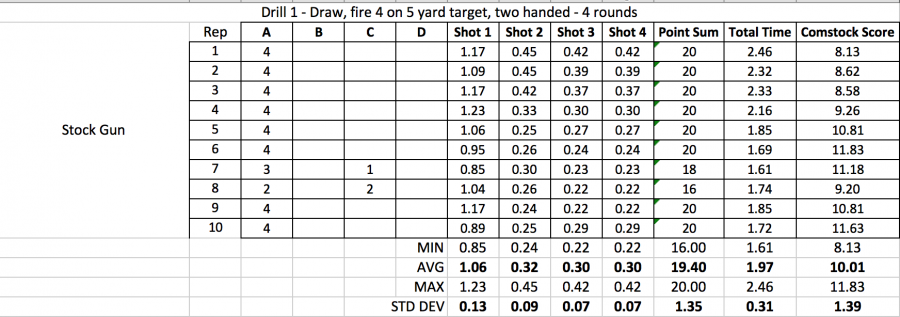

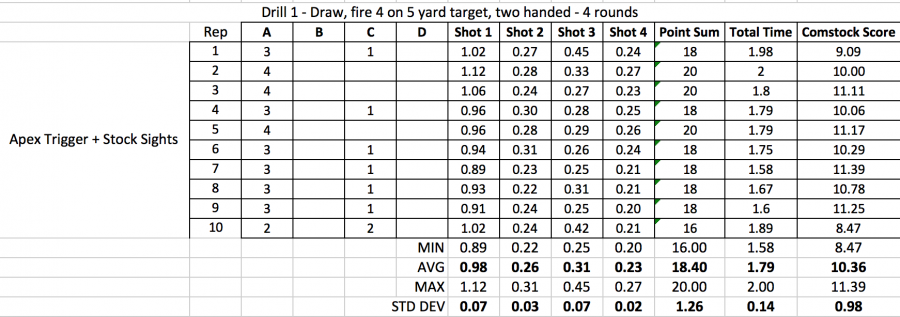

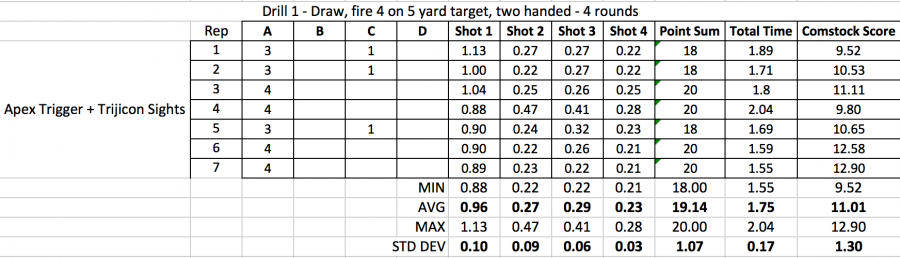

The scoring is as follows. 5 points for A zone hits, 3 points for B/C zone hits, 1 point for D zone hits. You then sum all the points and divide that by the total time to get a normalized score. A higher Comstock score is better. During this process, there was a variety of interesting data that started to trickle out. Below is a screenshot of Excel with the relevant and interesting data points bolded for the first drill.

I really wish I’d been able to collect more data, but our budget is not endless and each one of those data points costs about a quarter. Though limited in data availability, some interesting data emerged. For the first drill with the completely stock gun, the ten runs yielded an average time to first shot of 1.06 seconds with the second shot coming at .32, the third at .30, and the fourth .30 seconds later. This yielded an average total time of 1.97 seconds for the drill. My average raw score was 19.40 (perfect is 20), and my average Comstock score for the stock gun was 10.01.

Once I installed the Apex Trigger, my average time to first shot went down below one second to .98, my second, third, and fourth shots coming .26, .31, and .23 later yielding an average time of 1.79. However, my accuracy suffered as my average raw score dropped a point to 18.40. This loss is accuracy was offset by the drop in speed as my Comstock score went up ever so slightly from 10.01 to 10.36, an increase of 3.5%

Making the final parts swap for the Trijicon Night Sights, my times dropped even further with my first shot coming at .96 followed by .27, .29, and .23 for the rest of them. This yielded an average total time of 1.75 AND my raw score went up to 19.14. Still not as accurate as the stock gun, but definitely an improvement. With the increase in accuracy and the very slight decrease in total time, my average score broke 11 with a score of 11.01. This represents a 10% increase in score over stock and a 6.3 % increase over stock sights with the Apex Trigger.

You’ll also notice that I bolded the standard deviation rows for each data set. As Nick has explained in his ammo consistency testing, standard deviation is one of a few good ways to assess the overall consistency of the data. A lower number is better, and while standard deviation isn’t the end all be all of statistical formulas, it does give a quick and dirty look at how “good” the data is. Broadly speaking, all of the standard deviation numbers are smaller with the Apex trigger and Trijicon sights in place over the stock trigger.

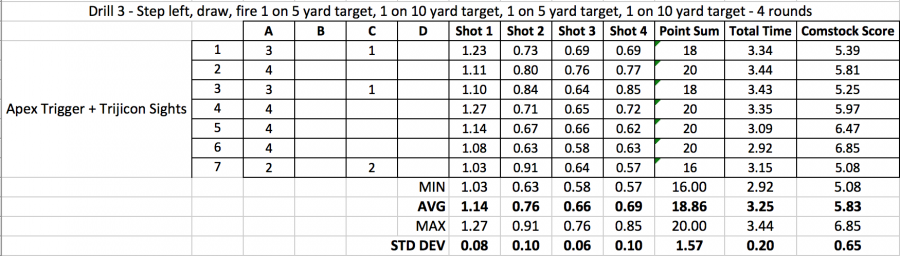

As a sidenote, you’ll notice that the Apex Trigger + Trijicon Sights group of data only has seven reps associated. This was due completely to a dwindling supply of ammo. I made the decision to lower the total reps for drill three so that I could collect as much data on all three drills as possible.

All of this data was very encouraging as it seemed to validate that spending the money to install an aftermarket trigger and set of sights would result in an increase in performance. The counter argument that familiarity with the course of fire is responsible for the increase in score is easily just as possible. The unfortunate fact is that eliminating that bias would take much more ammo than I had available for this test. I figure that running twenty five reps would be a good place to start with the goal of reaching a point where the accuracy and time numbers plateau. It wasn’t always rainbows and kittens as the data from the second drill proved.

Broadly speaking, the second drill shattered any hopes I’d had that trigger + sights = perfection across the board. And honestly, that’s a good thing. The point of this testing is to root out underlying bias with something approaching a scientific method.

Broadly speaking, the second drill shattered any hopes I’d had that trigger + sights = perfection across the board. And honestly, that’s a good thing. The point of this testing is to root out underlying bias with something approaching a scientific method.

With the stock gun, my average time to first shot was 1.14 and my second, third, and fourth shots came at .36, .41, and .36 yielding an average run time of 2.27 seconds with a standard deviation of .30. My average raw score with the stock gun was 17.40 (20 is perfect) with a standard deviation of 3.41. This yielded an average Comstock score of 7.70 with a standard deviation of 1.46.

Switching out the trigger yielded a slightly better raw score of 17.60 with an even better standard deviation number of 2.07. However, the average time to run the course rose to 2.62 seconds and yielded a Comstock score of 6.82, an 11.43% decrease in score. This increase in time was driven completely by the difference in split times between the two runs as the time to first shot remained almost identical.

The addition of a set of sights didn’t help either as the average total time remained identical (CONSISTENCY!), but the raw score number fell from 17.60 on average to 17.29. The standard deviation numbers shuffled slightly but overall the addition of Trijicon sights seemed make things slightly worse.

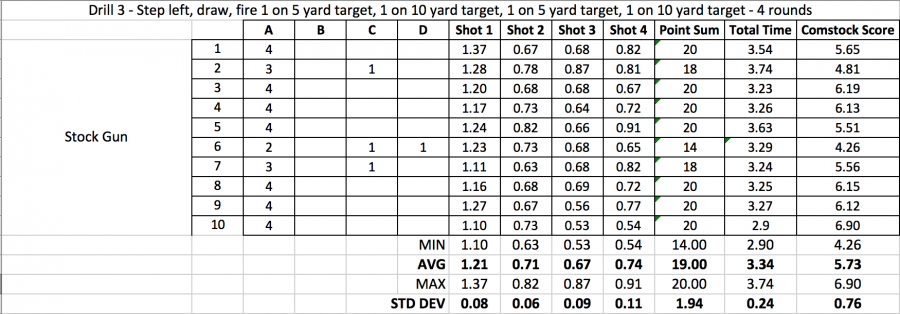

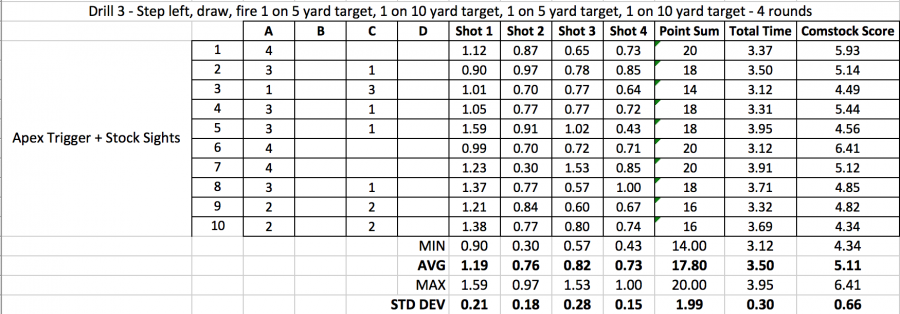

Where drill two was an unmitigated disaster in terms of shattering my preconceived notions, drill three seemed to be a blend of both. With the stock pistol, my time to the first shot average 1.21, my second, third, and fourth shots coming at .71, .67, and .74 seconds later to yield an average run time of 3.34 with a standard deviation of .24. My raw score was nearly perfect on average at 19 with a standard deviation of 1.94.

With the installation of the Apex Trigger, my run time got slower on average by .06 seconds with my first shot coming at 1.19, my second, third, and fourth coming at .76, .82, and .73 for an average time of 3.50 witha standard deviation of .30. My raw score also fell to 17.80 on average with a standard deviation of 1.99. This yielded a drop in score from 5.73 with the stock gun to 5.11 with the Apex equipped gun.

The addition of the Trijicon sights seemed to make things better as the average time to first shot, and split times fell bringing the average run time to 3.25 seconds with an average raw score of 18.86. This yielded a Comstock score of 5.83, a 1.7% increase over the stock gun.

Final Conclusions

If nothing else, usage of this test provided a more defined way to tell you that this gun with an Apex trigger and Trijicon sights seemed to be an absolute machine at “fighting distances” but was a bit harder to work at longer distances and yielded no significant difference at transitions back and forth from five to ten yards. It also made me as a reviewer take a step back to reconsider my previously held opinions. I left the range thinking that my performance at the ten yard line just needed a lot of improvement when the data showed me that the gear I was using was pretty consistently having a negative impact on my performance.

What this also showed me is that we can only really start to tease out story the data wants to tell us doing ten runs of a test. Realistically, something like twenty five runs (100 rounds) should be the norm to establish a plateau in performance. Either way, my hope is that this has added something to your knowledge bank as mine increased substantially over the course of a day out at the range with a shot timer and a copy of Excel.

Math: as soon as you use it, everyone stops paying attention to what you say no matter how important or true it is.

Seriously. Put that shit on battered deep fried krispy kreme donuts stuffed with bacon and watch me back away in fear…

Not true. I was quite interested in Tyler’s data. But I did make it through all 4 years of engineering…

Ditto. And, I survived more than 4 years of engineering school (8.5 to be exact) and I have worked as a test engineer for a while now.

I was impressed and excited that Tyler at least considered a possible bias based on order of tests. I was thinking to myself most of the way through reading about the first test that he was introducing a learning error to the data that would correlate directly with the expected effect of improving the trigger and sights. Randomize the order of the trials… that would take care of it, LOL. That’s a whole lot of time spent swapping the trigger and sight parts though; the test would take a year to complete.

If you are interested in or enjoy stats (I can barely imagine that), this is an excellent handbook on engineering statistics.

http://www.itl.nist.gov/div898/handbook/index.htm

And as to your test design, search the linked text for “design of experiments”. Lots of rules for building optimum (most results for fixed assets) or meaningful experiments

So, shooting the same target sequence three times in a row didn’t have a discernible impact on your target acquisition? It seems you may have a bit of bias introduced by improving your gear with each successive attempt. (First test.)

Also, what is the statistical significance of a variance of, say, 0.06 seconds? Are you really seeing any meaningful differences among the various configurations of gun, trigger, and sights?

To be really scientific… START with the modified firearm, and downgrade it for the subsequent tests and see if the score is lower.

Actually, have a partner and have them either modify the gun or not for each round, so you aren’t mentally skewing the results (i.e. thinking “this round is going to suck with the stock trigger…”)

I was going to recommend doing the test several times, mixing in the other tests, and varying the order of configuration each time.

Also, do the same test, same configuration, multiple times. See if sight acquisition improves when repeating the test with the same configuration.

College is a sham. All it does is it excludes people who do well in the real world and bases their intelligence on tests and grades alone. I hate how much of a priority society has placed on “college”.

Now you need a two year degree to be a plant operator. And I’ve been one. That PTech plan is worthless.

Depends – some college degrees are definitely a sham and unnecessary for work in a field : I would rather higher a high school drop put who ran a successful business than someone with a business degree but no experience in the “real world”

That said, as an electrical engineer I would STRONGLY prefer to hire people who have engineering degrees for engineeing positions. Yes, I’ve met some very brilliant self-taught programmers and circuit designers, but “engineering” is not a trade/craft. An EMT with lots of field experience may be able to stitch you up better than your podiatrist, but that doesn’t mean they’re qualified to work as a physician.

Why? A lot of engineering involves understanding, analyzing, and creating new solutions, and this requires a broad and deep understanding of many aspects of a field (and often a fair amount of math). After many, many years as an engineer, I’m still amazed when I come across an issue at work and suddenly discover an application for that “useless” abstract concept I learned at college.

Good points Tim. As I viewed your post, I thought I’d like to add some additional flesh to these things from a learning-by-doing perspective if I could.

I’ve been a manufacturing engineer at a well known high tech company for a lot of years. Did machining for several years before that. …and I did them without a mechanical nor a machine tool tech degree. …not even any shop classes. I kind of fell into the industry actually, as i found the work very intuitive and it made sense. I guess I had a bent for that kind of work and didn’t know it. It was fun and I enjoy the journey of learning this stuff to this day.

I went to school for a couple years in late 80’s for computer information science, like my high school school guidance councilor recommended along with my parents, as I was kind of the techy-nerdy type. Graduated with a degree in “abstract” things that happen inside a computer and I learned that I didn’t want to do that for a living.

The stuff I had a natural bent for understanding, along with the schooling, came together full-circle once some applications revealed themselves. I loved making stuff, problem solving, developing detailed step by step processes to control outcomes etc… even writing software that improves our CAD/CAM technology came into the picture eventually. I have to credit God for my career path. I certainly didn’t plan it.

I find the young guys with their shiny new mechanical engineering degree really aren’t particularly useful for quite a while yet. Sometimes they don’t make it, regardless. Its more about how your built and what a person can learn and understand, than the necessarily the content a person studies. Its obviously both to some point.

I still have holes in my understanding like anyone else, but its not like we work alone in these kinda of things.

“Now you need a two year degree to be a plant operator. And I’ve been one. That PTech plan is worthless.”

That degree is only an indication you’re trainable.

One company I was at years back decided they wanted to require a bachelor degree to do benchtop analytical chemistry.

I warned them a bs degree candidate won’t be happy in a rotating shift environment.

Sure enough, the college kids kept that job only long enough to get a much better one. We couldn’t get them to stick around more than a year, tops.

The folks that were our best bench techs were the local high school grads where that would be about the best job they would ever get.

A degree — or at least the knowledge that goes into earning one — is also very helpful for work in a field that requires collaboration with others, a common understanding of terminology and methods, and a shared base of knowledge.

I understand and agree with the backlash against over educated elitists and their culture war against those they consider inferior. And God knows that many college campuses have become cesspools of political correctness, off-the-charts liberalism and white male guilt. Education can and often does suck, but an education can still be a good thing.

So basically what you said is…

Blah, blah, blah, numbers. I shot a little better with mods. Blah, blah, blah, more numbers, and I need to get better at 10yds.

So, you went to the range, burned through some ammo then?

‘All of this data was very encouraging as it seemed to validate that spending the money to install an aftermarket trigger and set of sights would result in an increase in performance.’

If you had run the tests in the reverse order, ending on the stock gun, would that difference have disappeared? Doesn’t running the test in the your order cause the performance improvement from repetition to compund any positive results or mask and negative ones?

Truss building is necessary but not sufficient to be an engineer. Anyone can make a truss in a silly competition. It’s just a matter of spending the time on it. Understanding the math to build a truss that cars and trucks will drive on at their peril is an entirely different animal.

Continuing from above. And I think employers use college as a form of legal discrimination but I won’t go into that.

They do, because the SCOTUS disallowed employers from administering their own tests for IQ and competence at the skills the employers found important.

So the four-year degree became the litmus test of “can you read, write and reckon well enough we don’t need to teach you basic stuff to work here?”

Well the labor department should do something about that, as well as something about employers asking otherwise qualified candidates “why did you resign” “do you have kids” “are you married” and such questions.

But they don’t. All they do is fine companies who don’t hire the right amount of minirities, women, illegals, and Muslims for the labor departments liking.

Employment of illegals is…..illegal, isn’t it?

The problem comes back to the human /handgun interface.

No two people will interact with the same gun exactly the same, and the “learning curve” property means shooting a drill the second time will result in numerically superior times versus the first time. Alter the drill to compensate for that, and we destroy the compatibility.

The closest we can come to an objective performance measurement is each person running their own individual stats and controlling the variables for their own circumstances with firearms, ammo, and target configurations ideally suited for the users specific needs.

The math won’t be comparable to others, but that’s a better path to take then trying to establish ‘one drill to rule them all’. Way too many variables to make an SAT for handguns, and there’s even evidence to suggest the real life SAT fails at truly being standardized.

Fully agree.

In the end it is impossible (from a practical perspective) to compensate for all variables. How about fatigue — both mental and physical? At what point during an extended set of drills to collect data does fatigue alter the shooter’s performance? How about the shooter’s circadian rhythm … if the testing takes the better part of a day, is the shooter better in the morning versus afternoon or vice versa?

And as others pointed out, how about potential bias in the shooter? Does the shooter believe that the aftermarket trigger and sights are better and thus mentally choose to run faster?

Exactly. Way too many uncontrolled variables. You might be able to call this testing “scientific,” but it doesn’t really tell you anything of value.

There’s a reason that prospective population studies are slow and expensive. There are ways of compensating or at least mitigating external influence, but it takes a lot of thought in study design. You see studies put together as multi-phase where the initial phases may look very unrealistic. Risk analysis is essential. And you want to have a good statistician if the target is a 95% confidence interval.

The night sights may be great for shooting in the dark, but they aren’t helping you much here. If you want faster target acquisition with sufficient precision at these ranges, install a Warren Tactical rear and a Dawson Precision 0.1″ wide fiber optic front.

Although that 5yd target may be close enough for target focus instead of front sight focus depending on how much you practice that an how solid your grip is.

Don’t feel bad about the engineering thing. I got my bachelors in mechanical engineering three years ago and still can’t get a job.

I don’t know where you live, but you should look into Biotech/Pharmaceuticals. We hire ppl with engineering degrees all the time to spec equipment and handle installation/qualification. I know there are even consulting companies we hire engineers from on contract. Biotech is where it is at. I have worked for one of the largest Biotech companies for the last 9 years since I graduated college with a BS in Biology and we didn’t lag at all when the recession hit because people always need life saving medicine.

“I got my bachelors in mechanical engineering three years ago and still can’t get a job.”

There are temp companies that specialize in tech people. The companies like to use them because it allows a prospective employer to ‘try before you buy’ your next employee.

I’ve done that several times over the years when the mass layoffs hit.

And vice-versa, you get to see if the company will be a good fit for you.

One of them is Kelly Engineering, it’s the tech side of Kelly staffing.

http://www.kellyservices.us/US/Contact-Us/Request-Staff-Engineering/?cid=google#.Va7577UzKSo

Bunch of others, just Google ’em.

One thing to be aware of is some companies want to use temp workers exclusively.

The ones you want are an understanding of temp-to-perm positions.

“…needing two attempts to get through Calculus 2.”

WHAT?! You made it through Calculus 1?!?! How in the heck….

Calc 1 is easy. Calc 2 is the real nut cracker. And don’t even get me started on calc 3. I don’t even think the professor knew what exactly we were supposed to be learning.

Calc? No prob. Combinatorics? Graph theory? Diff EQ? 400 level Stats? Real Physics (ie, using calculus). No big deal.

Me? I had to retake damn Linear algebra. The single easiest advanced math course on the bloody planet and it still give me trouble.

I can design multidimensional array to build my own OO subsystems with 4+ levsels of indirection. But I choke on basic matrix transformations.

To be fair, linear algebra is just plain tedious.

I hear you. Linear algebra is tough, but the one that really got me was vector geometry.

“A lower number is better, and while standard deviation isn’t the end all be all of statistical formulas, it does give a quick and dirty look at how “good” the data is. Broadly speaking, all of the standard deviation numbers are smaller with the Apex trigger and Trijicon sights in place over the stock trigger.”

This is wrong, at least as far as your datasets are concerned. Stddev here will just tell you something about the variability of your performance – it tells you NOTHING about the quality of your data.

If you still maintain that stddev is significant here, how do you explain that the stock gun results have the lowest standard deviation of all tests in “total time”? If you think about this a bit more you’ll see why this is not a valid measurement of anything for this test.

(Now, using stddev to measure the variability in muzzle velocities is something else entirely and there are likely many valid uses for this type of test.)

About 95% of what I learned at my big 12 university I never used again as an actual engineer. What was used, was the person who I transformed into having entered the university thinking I was the most intelligent person on the planet, and repeatedly mentally and emotionally beat down by the professors and curriculum. After five years, I was an engineer – but was not the person who was admitted five years before. As an electrical engineer, I give you an engineering salute. By the way – I took differential equations three times.

Speak not of thou which must not be named!

I got a C in Differential Equations…

I don’t know how, because I still don’t understand them.

At least calculus could usually be translated into some real world situation to help understand the concept.

Don’t feel bad Tyler, I read an article that likened getting an engineer degree to Special Forces training. It’s washout city, because most students had no idea of the regimentation required to attain the degree.

Engineering school done right will teach you how to teach yourself. The tactics you learn (for example, how to program a PDP-8 in machine code in my case) didn’t ever earn me a cent; understanding how to figure out some arbitrary architecture and program it … pretty good money. Knowing how to architect something useful … priceless (and pretty good coin too). Graduated in the early 1980s, retired a coupe of years ago. Being an engineer also helped me learn other stuff later – and some of that turned into my 2nd career.

I recall realizing that the professors didn’t care if you passed or failed (they wanted to do research); it was up to you. Great lesson in life and self reliance.

PDP-8?

You must be old.

At least I used an 11

I first thought a DEC referred to the stack of cards I fed into the Univac

I feel really old.

First machine I messed with was on an S-100 bus.

*sob*

Ummm… Honeywell DPS-9. Missed punched cards by one semester. We just got several TI Silent 700’s. We even had 2 with acoustic couplers you could check out. Ran at an incredible 300 baud.

Ahh, the memories. I wrote my first program on a PDP8e in Focal in 1969. I was a Junior in high school. Focal was a proprietary to DEC programming language. Also did Basic and Assembler in HS. Didn’t touch another computer until the IBM PC came out.

By the way, I really appreciate that difference between a scientist and engineer. It’s a real distinction. Often subtle but very real.

I know because I’m both a clinical cardiovascular scientist and a software engineer. It’s not hard to borrow the knowledge base of the one to aid the other, but to truly change mode takes a solid day.

It doesn’t help your argument when you do no comparative statistics and then pull a conclusion out of nowhere. This data is screaming for an ANOVA and tukey’s hsd.

Your investigation seems to point to the need for a double blind, multi-center, placebo controlled randomized trial. With a lot more power. And I don’t mean a .40 cal.

Anectodally, I love the apex trigger and trijicon sights on my M&P.

As long as there not doing an animal study on the same 7 dogs in Italy…

(Old joke from ACC and AHA abstract sessions.)

I’m slightly ashamed to admit this, but I’m a physicist (yup, I spent way too much time in school). Consequently, I’ll start by applauding the desire to be quantitative and objective; that’s awesome! Woohoo! Unfortunately, when a human plays a critical role in a test such as this, any hope of absolute objectivity and rigor is pretty much hauled out behind the woodshed and flogged to death… and then flogged some more.

Nonetheless, there is hope! There are measurements that can be made and numbers that can be reported that are objective (and quantitative and unbiased…) and tell us readers at least a little about the “shootability” of a handgun. I’d love to see em reported in future reviews.

I’m omitting many, but here are a few.

Weight. Assuming identical chamberings, a heavy gun is generally going to recoil more gently than a light gun.

Bore height. How high is the axis of the barrel above the web of your hand? Super low will generally beat super high if you need to take more than a single shot.

Grip dimensions. A big part of perceived recoil is the fit of the gun to the user’s hand. What’s the distance from the back of the grip to the trigger? How wide is the grip? How tall is the grip? Are there finger grooves? If so, what is the spacing? What’s the grip angle? (For years I would have sworn that I couldn’t care less about grip angle… then I took my Ruger MkIII to the range for the first time and discovered my wrists didn’t want to point it anywhere other than the sky.)

Trigger weight and travel. In my most sordid physicist fantasies, I dream of a plot of trigger movement versus applied force. That could be wildly informative, but you’d likely have to build a custom contraption to measure it. A less sexy substitute would simply be to tell us that you’ve got to pull the trigger x inches and apply y pounds of force to make the boom stick go boom. That should be supplemented with some basic description of the feel (gritty, smooth… it ain’t super objective, but it’s better than nothing).

Sight details. What’s the sight radius? How wide is the front post? How wide is the notch in the back? Are there any fancy features… dots, tritium inserts, fibers…? This is one of those times where a good picture could be worth a thousand words. (Pictures should of course be taken under fixed lighting at a fixed distance using a camera with fixed settings while the boom stick is pointed at several different test patterns… maybe a black target, a white target and some sort of striped target…?)

I’ll admit that many of the numbers wouldn’t be particularly useful in isolation, but over time a database of such numbers could be compiled for many guns. Eventually, a shooter could look up the numbers for a gun they’ve tried, and then easily identify guns that are perhaps heavier, or narrower, or have a lighter trigger…

It would be glorious!

Well, putting this in the performance shooting realm, from the holster, six shots at 10 yards all A zone hits should be done in 2 seconds or less if you’re “good”. Most guys who make a habit of competition shooting can hit that mark within a year or two of starting if they take it seriously and dry practice. You’ve got a lot of room for improvement as a pistolero so comparing data collected today and a year from now may not be quite as valid, especially if you get into USPSA or IDPA, (which you should IMNSHO, anyone reading this should). No I’m not some GM, or even play one on TV, but this data will probably be most interesting to the square ranger sect rather than the gamer sect of hand gunners. That all said, it takes balls to vid yourself and put it up on the internet for jokers like me to armchair QB.

I also think “from the holster” is important comparing guns of various stripes, it is hard as hell to get a good grip on a subcompact or single stack that’s not a 1911 in the holster and come on target quickly. If you were rating a guns defensive capabilities this seems like something that’s mighty important. If you can get your less comfortable M&P out in 2 seconds from concealment with good A zone hits, and your more comfortable shield with a heavier trigger out in 3 seconds with 2 A’s and 2 C’s, then that speaks to the practicality of that design. Running similar types of drills I have pretty well sworn off subcompacts and skinny 9’s.

Further, Fobus makes 2 sizes of IWB holsters that accept almost any fire arm. Seems like a really great way to standardize the holster variable by using the large or small Fobus IWB. I have no idea if it’s any good, I’m guessing it’s just barely “good enough” like the rest of their products, but you could normalize that variable across any gun you test with it.

Would it make sense to do like 5 dryfire reps for each drill with a new gun prior to any live fire to get used to the sight index, trigger etc? Or maybe do a benchmark with whatever your primary gun you’re most familiar with is each day you go out to see how a foreign handgun rates that day against a known platform?

It might be cool to throw in some Mozambique’s at whatever distance you feel comfortable as a 4th test since the first two shots test the speed on a rough index while the final shot requires you to see the sights and get a quality trigger press in a hurry.

Many students dreams died pierced on Calc2.

I didn’t bother pursuing that dream, haha. It was something I wanted to do for a long time. I did take some EE classes while getting my CS degree, but it was terrible and rigid compared to CS. I was kind of glad I did CS instead. Even landed one of my dream jobs making vidya games for a couple years! 😀

While some might like the numbers it all comes down to how proficient with you are with your gun and your equipment.

One thing I though of as I yawned through the match & numbers was this – how proficient was the shooting with all the mods? I know that when I try some new sights, triggers, etc there is a learning curve associated with each. I imagine that would play a part in this as well.

In the end, the end user needs to practice and get good with their firearm. I know my split times were rough so I practice and instead of .24-.30 they are now around .16 if I’m doing well and that is with a stock trigger. I think too many (BTDT) where I thought if I purchased the next newest mod it would make me a better shooter. However I found that there has to be a lot of perfect practice before those things really take effect.

Thats my 2 cents.

BTW did I say I yawned a lot when I was going over the numbers?

Opps – forgot to add the familiarity of the test itself.

When you try a new drill one is usually slower then as they get more familiar their performance usually improves. BTW I am wary of any firearms classes that do not have a way to show improvement – if you dont’ have that your only putting rounds down range and I can do that by myself.

Anyway I think the only real test for accuracy and precision is bench testing. Everything else depends on the shooter’s skills, abitity (with firearm, drill, mods, etc) and amount of training they do.

It’s not just training, it’s practicing. You can take 5 training classes a year and still suck badly compared to the guy who watches YouTube training videos and actually practices dry/live fire.

Sounds like Technology would have been a good major for you, instead of Engineering. After failing Calculus 2, I made the switch from Electrical Engineering to Electrical Engineering Technology, which had a less rigorous mathematics requirement, but still covered all the essentials of circuit design, power controls, etc. They had an equivalent for ME, Mechanical Engineering Technology that likewise covered the more practical aspects. Although getting our foot in the door was a lot more difficult compared to regular engineering students (and there is definitely a stigma that Technology grads are not as “smart”), for most of my classmates, there was no distinction in job title/salary a few years into work.

Comments are closed.