Everyone wants to use match grade ammunition, but no one wants to pay match grade prices. Know what Wilson combat charges for their 5.56 ammo (which currently tops our charts)? A buck fifty a round. Yeah. Hurts, doesn’t it? But what if there were a way to get the same quality without the pants-browningly high prices? Turns out there are one or two manufacturers trying to do just that. But how good is their ammo really? . . .

What we have today are two brands, each trying to meet the same goals, but doing it in two different ways.

Hornaday’s Steel Match goes the same route as Tula, Wolf and the various “Bear” ammunition manufacturers — namely, its all steel cased ammo. But inside that case is the same loving and caring manufacturing process that makes Hornaday’s ammo some of the best in the world. Well, not THE best, but pretty darn close.

HPR, on the other hand, decided to recycle some old components. Just the cases though, not any of the other parts. The cases are all once-fired Lake City brass, and each round is inspected by hand before being packaged and shipped. They believe that allows them to make some amazing ammo without having it cost an arm and a leg. But just how good is it really?

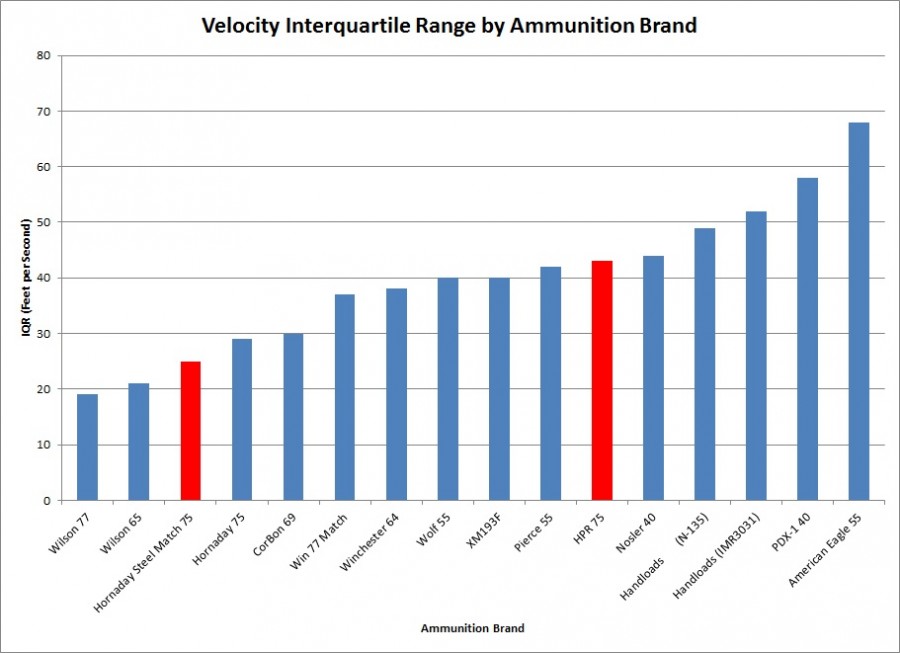

Brief note here to remind everyone of the testing methodology: we run 20 rounds of each brand through a chronograph and look at the IQR or InterQuartile Range to get an idea of how tight the group is going to be downrange. There are plenty of other factors in accuracy, but velocity is the only one that’s “clean” enough to calculate and compare (as everything else can be influenced by the shooter, equipment, etc.). For the full methodology check out this article. Just remember LOW = GOOD and we’ll be on the same page.

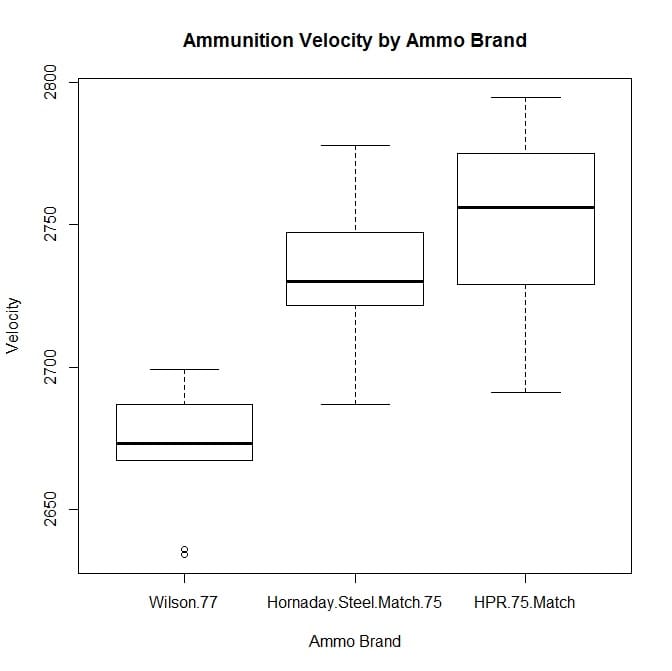

So, how did things turn out? let’s compare the numbers we got with the current reigning champ.

That’s, uh, well, hmm. Hornaday seems to be doing pretty well, but I can already tell this won’t end well for HPR. On to the normalized graph….

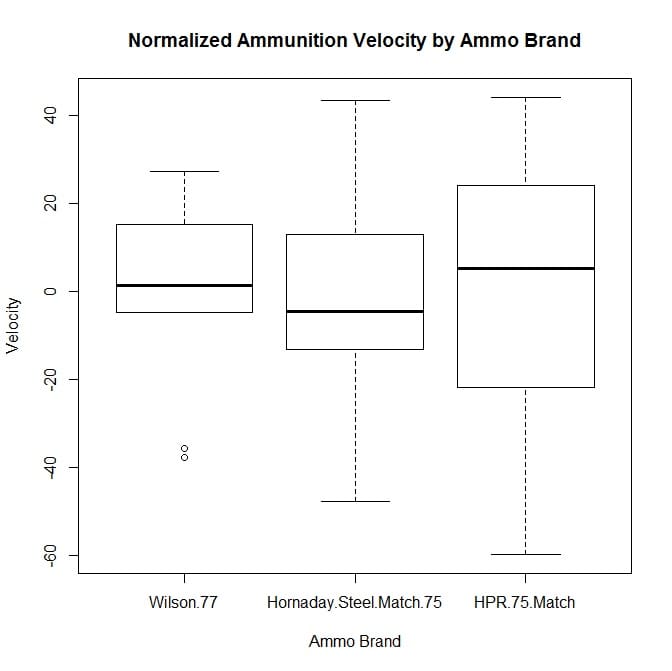

Yeah, not so good for HPR. The maximum observations for Hornaday don’t look so hot either, but the IQR is still pretty solid. Let’s see how these newcomers stack up on the chart.

For Hornaday, things actually look pretty rocking. Their El Cheapo option for ammo has landed them squarely in third place on our scoreboard in terms of consistency, and actually seem to be BETTER than their brass cased compatriots. Which seems odd. I’ll have to re-test that and double check, but having followed the procedures to the letter, what you see is what you get.

HPR, on the other hand, is ranked just below Wolf. But as increased velocity does have a tendency to improve velocity consistency we’ll have to give their 55 grain flavor a try and see if we get the same results.

So what’s the verdict? Hornaday’s Steel Match is all that and a bag of chips. If you need match ammo on the cheap, have no fear.

| Brand and Weight | Caliber | IQR | $/round |

| Wilson Combat 77gr Sierra HPBT Match |

.223 Rem | 19 | $1.52 |

| Wilson Combat 65gr Sierra SP BT |

.223 Rem | 21 | $1.52 |

| Hornady Steel Match 75gr BTHP Match |

.223 Rem | 25 | $0.44 |

| Hornady 75gr BTHP Match |

.223 Rem | 29 | $0.79 |

| CorBon 69gr HPBT |

.223 Rem | 30 | $1.18 |

| Remington Premier Match 77gr BTHP |

.223 Rem | 36 | $1.50 |

| Winchester 64gr “Power Point” SP |

.223 Rem | 38 | $0.82 |

| Wolf 55gr FMJ |

.223 Rem | 40 | $0.21 |

| Federal XM193F 55gr FMJ |

.223 Rem | 40 | $0.32 |

| Pierce 55gr HP-BT |

.223 Rem | 42 | $?.?? |

| HPR 75gr BTHP Match |

.223 Rem | 43 | $0.50 |

| Nosler Varmint 40gr Ballistic Tip |

.223 Rem | 44 | $0.86 |

| Handloads – 20.8gr N-135 75gr Hornady HPBT Match |

.223 Rem | 49 | $?.?? |

| Handloads – 21gr IMR 3031 75gr Hornady HPBT Match |

.223 Rem | 52 | $?.?? |

| Winchester PDX-1 60gr SC-HP |

.223 Rem | 58 | $1.45 |

| American Eagle 55gr FMJ-BT |

.223 Rem | 68 | $0.30 |

| Brand and Weight | Caliber | IQR | $/round |

| Remington UMC 115gr | .300 BLK | 20 | $0.52 |

| Remington AccuTip Premier 125gr | .300 BLK | 20 | $1.39 |

| CMMG 147gr | .300 BLK | 26 | $0.78 |

| Remington Subsonic 220gr | .300 BLK | 27 | $0.92 |

| PNW M 155gr | .300 BLK | 28 | $0.90 |

| PNW D 220gr | .300 BLK | 54 | $1.08 |

| Brand and Weight | Caliber | IQR | $/round |

| Hornady Superformance Match 150gr SST |

.308 Win | 26 | $1.21 |

| Wilson Combat 168gr Sierra HPBT Match |

.308 Win | 28 | $1.99 |

| PMC Bronze 147gr FMJ BT |

.308 Win | 39 | $0.50 |

| SetPoint – 44gr Varget 150gr Hornady FMJ BT |

.308 Win | 52 | $1.74 |

| Prvi Partizan 150gr FMJ |

.308 Win | 54 | $0.82 |

| Remington “Managed Recoil” 125gr CORE-LOKT PSP |

.308 Win | 125 | $1.40 |

I suppose that works if your time is too valuable to spend reloading.

I have shot a lot of the hornady steel Match I do like it and I also reload my own ammo I like the consistancy that I find in the ammo. The one thing though that I stress to folks is that because it is steel cased you have to clean the gun before switching over to brass. Also because of the lacquer on the case if you fire a few rounds through the barrel and then allow a round to just sit in there it can cause that round to have issues with FTE as the case sticks after the lacquer heats up. I use hornady TAP for work and it is nice to use something similar for practice at a cheap price.

If that’s the result you’re getting with handloads, you have lots of room for improvement.

BTW, if you study on loads and ballistics for awhile, you’ll learn that you almost never achieve the best groups with the highest velocity loads. Read through an old Lyman book and they’ll call out box accuracy loads and highest velocity loads – and you’ll notice that they’re very rarely the same. Usually the accuracy loads are 10 to 12% lower in velocity than the max velocity loads.

First place I’d be looking to improve your handloads for the AR would be to switch away from IMR3031 and possibly move to a powder like Varget, which is less temperature sensitive. Next, I’d check your seating length, or crib the seating length from the loads that your AR performs well with.

Dyspeptic Gunsmith, I’ve seen you post a lot of very detailed responses in the comments on this site. Why don’t you submit an article or three to TTAG? I think what you have to offer would make a fine addition to the posted content here. I’d love to see you write something comparing and explaining different propellants or giving an overview of what modifications could (or should?) be done to various stock firearms.

I might do that in the future, but not right now. I see how much work RF, Dan, Nick, et al put into their pieces and responding to questions afterwards, and I can’t commit that amount of time at the moment.

That’s the crucial difference between blogging and writing for a magazine or writing a book – the amount of time as well as the timeframe of responses from readers.

eg: When you write a book, people might write you letters, which your publisher will gather up and send on to you every so many weeks. You’ll consider them, maybe write a bunch of responses once/quarter and you’re done.

A magazine article requires a more timely response, perhaps before the next edition of the magazine hits the shelves – ie, within a couple weeks.

In the short-turnaround time of the blog world, blog editors would like some responses within a half day.

While this is a good basic comparo that beats the hell out of “what is says on the side of the box”, I am curious what corrections, if any you made to correct your data points.

Atmospherically speaking, for the sake of short-range velocity testing humidity is of negligible effect, so we can eliminate that. But ambient air temp and barometric pressure can have a good deal of influence over the velocity of a bullet as well as the burn rate of the powder in the shell.

If the ambient temp changes 10C during the course of a day-long shoot that can produce a velocity change of 25FPS (.308Win). Did you correct for ambient?

Assuming you used only one gun, which rounds were fired in what order? Did you do a batch of one brand(AAAAA), then a batch of the next (BBBBB) or was it (ABCDABCD).

Barrel temperature and fouling will have a some impact on velocity of the bullet down the pipe. Not much, but 5 or 6 FPS per effect can compound error rather quickly when looking at a narrow spread like 40 FPS. Beyond that, what’s the accuracy of the chrono used?

Just curious, because while the data presentation seems well laid-out, we are talking about unit spreads of only 40-ish FPS. As such, the other relevant factors have to be accounted for somehow. In other words, the math looks great, but if the underlying data isn’t corrected, frankly it’s kinda meaningless.

Atmospheric influences don’t really matter in these tests. All that would do is raise or lower the observed velocity, and we’re using a calculation made based on the spread. So no, I don’t believe the air temp or humidity has any impact on the testing whatsoever.

As for the barrel temp, that is something that I do monitor. I start each batch from a cold barrel and fire at a rate of about one every 30 seconds. The process has been the same for each and every load tested.

In short, I see no correction being necessary to the data.

Atmospherics impact not only the flight velocity of the bullet, but the burn rate of the powder, which also affects velocity. Both of which impact measured velocity at the resolution you’re studying. Same thing with barrel fouling. All of these factors will vary over the course of a day long test.

Aberdeen had lengthier tomes somewhere, but this is a quick, easy read.

http://www.kestrelmeters.com/blogs/news/3457002-temperature-effects-on-zero

It would appear by the work you put into the graphs and the math that you are trying to do good science. However, ignoring basic environmental factors that are known to play a role at the granularity you are studying, really leaves a lot open.

Right, but again, we’re not measuring the REAL velocity. If i was worried about getting a good “true” reading on the actual velocity of the rounds there are a ton of factors I would have to account for. But since all we’re looking at is the variability of the velocity from one round to the next, we can safely ignore those factors.

Since each round for a given brand is fired under the exact same conditions and with the exact same equipment in the exact same state of repair that will give us a good read on consistency. Air temp, humidity, altitude… all of these things do indeed impact the velocity of the ammo. But since each brand of ammo is fired under identical circumstances we can assume that they were all affected equally.

Like I said, we’re looking at the relative differences in the consistency of the velocity. We’re not looking for a “true” read on the actual speed the round leaves the barrel. All we care about is how well it does compared to other rounds form the same box fired under the same circumstances. And for that, this test is perfect.

I get what you’re saying, and I understand your concerns, but I don’t think they apply given the parameters of the test. But if you want to convince me otherwise (as I’ll probably stop checking the comments here soon) there’s an “Email” button on the right side and I’m more than happy to continue this conversation that way.

I’m surprised enough by the results for the Hornady steel that I’m going to pick up a box and see if my rifle likes it.

I understand that you are using the consistency of velocity as a measure of accuracy, but do you also look at the bullet itself as to it’s design ballistic coefficient? Are the bullets concentric? Are the bullet tips true and square to the bullet’s centerline? My point being that you might find some cheap ammo with a tiny velocity spread, but loaded with bullets of poor quality that won’t fly straight.

I asked pretty much the same thing. The variance of velocity is a relatively easy metric to measure, whereas some of the other variables are not. Nick is essentially trying to take the shooter and equipment out of the equation, so to speak. One of the benefits of these studies could be that manufacturers take additional steps to increase the consistency of their velocity.

As we’re out of “replies”…

Apparently you’re not understanding what I’m saying at all. This has nothing to do with “true” or “absolute” velocity. As there’s no raw data shown, and you have yet to reveal anything significant of your methodology, I have to interpolate how you gathered your samples. Either way you did it, there are raw data issues that are unaddressed.

Presuming now you shot all of “A”, then all of “B”, then “C”, as the atmo conditions change throughout the day, you are pulling data point groups from a different environment. Powder “A” may burn more consistently at one temp, but not at another. Bullet “B” will travel more consistently at one baro pressure than another.

So, while round “A” was tested under it’s optimal temp, round “B” which would perform fine at the same temp as “A” wasn’t. Who has the tighter velocity spread? Who knows? Was the gun cleaned between brands? No? Then the 1% fouling on group A may not matter, but the transition from 2% to 3% in the middle of test D may matter. See how these pile up, especially if you do one brand at a time?

The fact that “B” performs more consistently than “A” at the same temp/press/barrel condition is useful data. At different temp/press/bblcond it becomes nothing but noise or, at most generous, a rough approximation of data.

When you say “Since each round for a given brand is fired under the exact same conditions and with the exact same equipment in the exact same state of repair that will give us a good read on consistency.” I’m afraid “exactly the same” really doesn’t mean what you think it means in terms of ballistic science. If you don’t control for all known variables, you might as well just dry lab it.

(If you performed all this indoors in a temperature and pressure controlled range environment, with temp stabilized ammo, firearm, with staged cleanings between brands, mea culpa. All you had to do was attach your methodology.)

Are the individual sensitivities of different powder loads (as they burn, NOT the flight of the bullet) to temperature and the effect that those sensitivities may or may not have on the variance in velocity really significant enough to completely or partially reorder this list if the comparison is reorchestrated in extreme hot or cold environments? Is the relationship between temperature/pressure and the powder’s performance (in terms of consistency) really direct, or is it irrelevant information that can simply be applied as a uniformity to all tested loads on an equal basis? Wouldn’t the latter be a flawed analysis based on the limiting belief that ambient conditions are only an element of external ballistics and have no relevance internally? …are the bolt face and muzzle working in tandem to create a magical barrier barring the influence of the outside world and all of its silly little variables from varying the…er, explosions themselves that happen to be spitting out the business end?

These are all relevant questions (save for the smart-ass bit at the end, hah), and I would be very interested in having a look at the results of the exact same testing performed in a very very cold controlled environment…say below zero somewhere. If we then have similar individual consistencies among the different loads between the provided chart and data gathered in a controlled follow-up test or tests in varying conditions (disregarding actual velocities, of course), I would be pleasantly surprised by the simplicity of it all…but I suspect there isn’t a soul curious enough to fork over the $114.10 (for the 5.56mm data alone sans handloads and Pierce, judging from amounts provided) worth of ammo needed just to find out.

Rambled on enough I think.

Liked the article: decent data point.

Considering a trial box of steel match: low expectations.

The factors I noted are long established ballistics science. Our educational system has failed to the point that when people don’t understand, don’t want to understand, or are simply unaware of science, they just deny it when it suits them. That doesn’t change the science.

If you are really interested in how those factors matter, I have a link to a very relevant, clean, straight-forward one pager Kestrel did that illustrates the variables I noted up above. It shows what proper controls and methodology look like when you want to generate conclusions which are actual science, not just some raw data thrown on some pretty charts.

There’s nothing wrong with ignoring variables when one can prove that they don’t matter. But, when the science says they do matter, then ignoring them makes all the conclusions irrelevant.

So basically American Eagle 55gr FMJ-BT is total garbage? I’m a little confused reading these charts and the IQR.

Not at all. There is just more variance in velocity than some of the other loads. Accuracy is affected by a multitude of ammunition / gun / shooter / atmospheric variables. One of the variables is velocity variance, and it is objective, measure able, and quantifiable. I’ve got 2 – 5 MOA with with it using peep sights at 50 yards and a single stage trigger, and less than 2 MOA shooting a gun with a Tijicon 4X scope at 100 yards.

So how about an actual “next step” test and see what kind of groupings you get. I see where you are going with your math – but how does it turn into actual results at 100-200-300 yards?

How about the variations in your chrono? This is why I’m interested to see actual groupings. Would be fun!

Hey guys…..give me a break…will ya?

The info presented here is useful and provides good guidance. End of story. To do a test as some of you sugest, taking all of the variables out is imposible. Lets just take one element:

POWDER.

Could it be that brand X had a bad lot? Could it be that the dispensing at the manufacturing line was missadjusted or sabotaged by a pissed off employe?

Could it be that the AC at the Dupond was not working right? Could it be that the extruder at Dupont was missdjusted by a bad operator? Could it be that one of the components in the powder was faulty?

ETC, ETC, ETC….you got the drift….

Comments are closed.