The AR-15 bolt carrier group, or BCG, is a critical and often misunderstood piece of the AR-15/M16 upper receiver. Here I will give a brief breakdown of the BCG’s components, how it works, problems to look for and what to consider when buying.

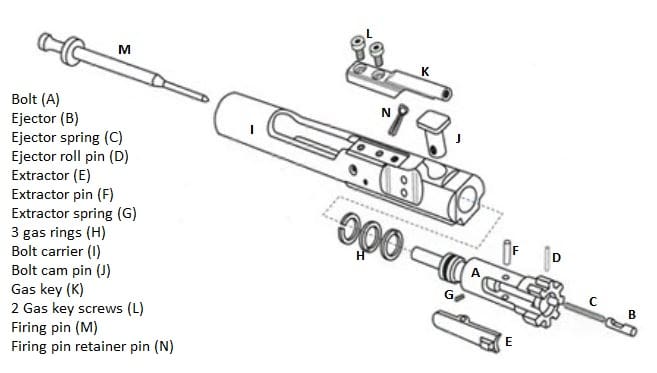

The image below gives a nice breakdown of the parts in a typical BCG.

We won’t get into a lot of detail here, but this is a good illustration of how the BCG operates when an AR-15 type rifle is fired:

When the round is fired, the redirected gas from the cartridge is funneled back into the bolt carrier. The gas fills the chamber that’s created by the bolt’s gas rings and the bolt carrier and forces the bolt carrier back against the recoil spring.

As the bolt carrier moves rearward, it acts on the cam pin, which twists the bolt. This unlocks it from the chamber allowing the BCG to cycle rearward.

As you can see, the BCG itself has a number of parts and there’s a lot going on every time the rifle goes bang. Now that we have a basic understanding of the parts and how they work, we can talk about some common problems you might run into with the parts in your bolt carrier group.

Loose Gas key

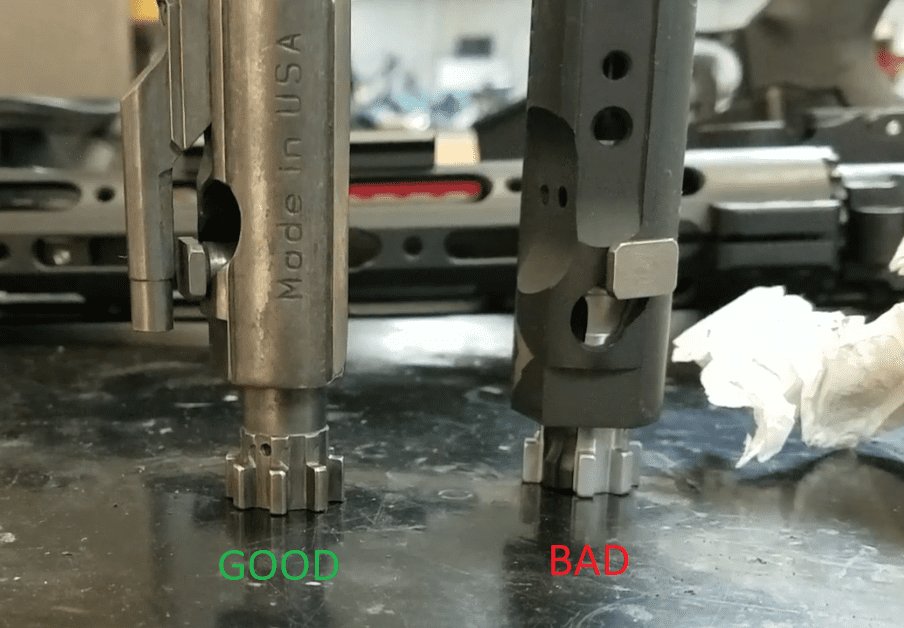

Gas keys can come loose. The screws are (or should be) staked in place. If that’s done correctly, it will take a lot for the key to loosen…but it can still happen.

A loose key creates a poor seal so gas can escape. Depending on the degree of looseness, this can cause cycling issues due to a leaky, under-gassed system. That can mean failures to eject and short-cycling of the bolt.

My first issued M4 had a loose gas key. It was loose for quite a while. At the time I didn’t know any better, so I figure that’s just how they were. I eventually learned it was a problem and got it fixed, but I was lucky…I never had a malfunction due to the loose key. You may not be so lucky.

The internet is full of stories about Bushmasters and the malfunctions caused by their loose gas keys, but those were in the old days. If you have one, however, they’re not hard to fix. Re-tighten the screws and re-stake them. If you’re absolutely sure you’ll never ever want to remove the gas key, you can even use JB Weld or some other heat-resistant epoxy to fix them down. Red Loctite may work for a while, but it isn’t heat-resistant.

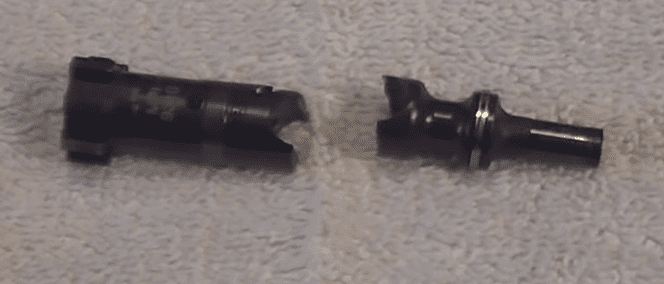

Staking works just fine, though. The image above shows two AR-15 bolt carriers — a Bushmaster on the left and a Colt on the right — both with properly staked screws. If you don’t want to worry about loose screws, a BCG design like this one from Voodoo Innovations eliminates the problem completely.

Bad rings

The gas rings create a seal between the bolt and the bolt carrier. This tight seal is what contains the gasses and drives the whole system. If those rings get damaged or worn to a point where gasses escape, malfunctions like those listed above can occur.

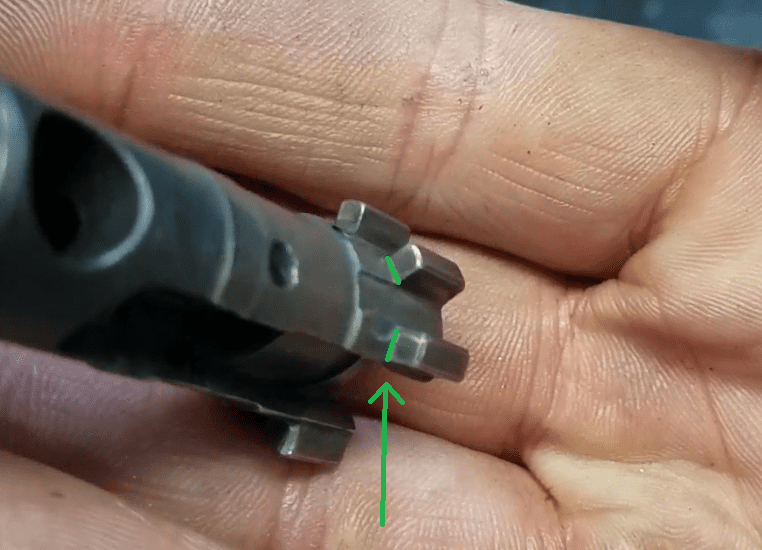

Unless the rings are obviously damaged, you can confirm the seal on your bolt is good by standing the BCG on the bolt face like in the image below.

If the rings make adequate contact with the bolt carrier and form a good seal, it will stand tall. You should check this even with brand new rifles.

Especially check it if the BCG is made from mismatched parts. The BCG on the left above is a Spike’s Tactical complete bolt carrier group with roughly 1000 rounds through it. It’s working just fine. The BCG on the right is brand new with a JP bolt and Rainer bolt carrier. It failed the test, but it’s easy to fix. Throw some new gas rings in and you should be good to go.

Broken locking lugs

This is what a normal, healthy bolt face looks like:

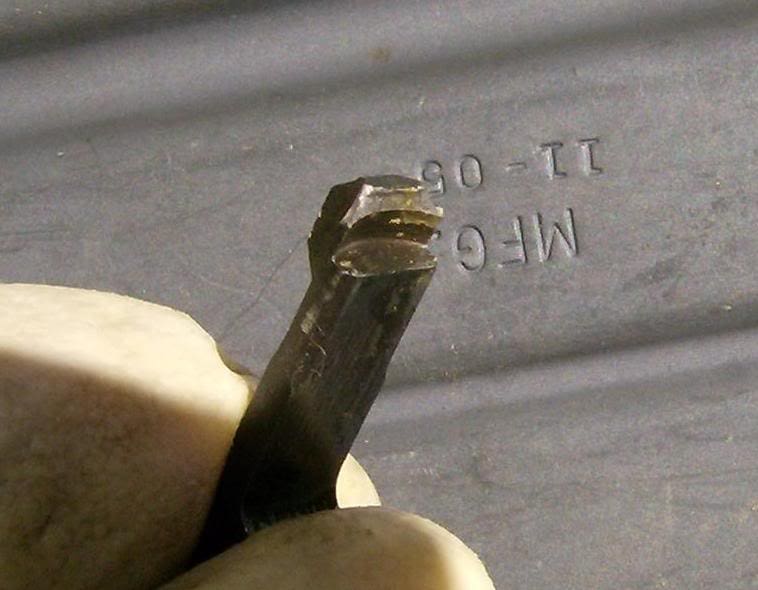

But bolts can get damaged, like this one:

Yes, this one’s a little extreme. Still, the more you shoot and as your AR-15 ages, make sure to check the locking lugs on your bolt.

Look for signs of wear along the back in the corners. Stress fractures can develop and the lugs can eventually break completely off. Not good.

The rifle may still function if only one lug breaks. I’ve seen this a few times after a long day of live fire drills when guys were cleaning their rifles. They had no idea anything was wrong until then.

Check your bolt every couple of thousand rounds for stress fractures so you can replace the bolt before something like this happens. Or go with an upgraded JP Bolt and don’t worry about it unless you shoot over 60,000 rounds.

Split Bolt

The cam pin hole is a weak point in the bolt. It has the least amount of material to handle the stresses of firing and cycling. It is the pivot point for the bolt.

As a result, the bolt can break here. This is definitely a catastrophic failure. Your rifle will not run if that happens. When you’re checking your bolt lugs (above), also check the cam pin hole for signs of stress fractures or excessive wear. HM Defense makes a bolt designed to eliminate this problem.

Broken firing pin

It happens. With every firearm. You’ll pull the trigger and no bang. Have a spare lying around. They’re not expensive and it could keep you going in a pinch.

Broken extractor

This is another piece that also wears with time. The front edge can shear off, the pin hole can break or the pin itself can break.

The spring will also wear with time. Any of those issues can cause a complete or occasional failure to extract casings depending on its severity.

Maintenance Schedule

If your AR-15 platform rifle is just used for plinking and fun, I wouldn’t stress out much about a regular maintenance schedule. Check it when you feel like it and be prepared to replace parts as they fail. If you’re a competitive or combat shooter, meaning you really can’t have something break while you’re using the rifle, you’ll want to inspect and replace your bolt carrier group parts on a schedule.

Replacing parts on a BCG is similar to changing the oil in your car. Do it too often and you’re wasting money. Don’t do it at all, and you’ll eventually screw yourself. The schedule you’ll want to follow will be based on your round count, so keep a record of how much you’ve shot.

The schedule needs to be based on how many rounds each part is rated for. For example, if your extractor spring has a minimum service life of 3500 rounds, then replace it at around 3500 rounds. Call the manufacturer that supplied your BCG so they can tell you what your parts’ minimum round life should be.

I recommend contacting the manufacturer because the ratings may not be the same across the board. There’s no point in replacing a JP bolt every 10,000 or 20,000 rounds when it’s good for 60,000.

Dig through enough forums and you’ll find general recommendations that can work fine for you. But if you really care about your rifle absolutely never failing, get the facts straight from the manufacturer. If you don’t know your manufacturer, or they don’t know how to answer your question, you should probably invest in something of better quality.

There are plenty of good AR parts manufacturers on the market right now. JP Enterprise, Spike’s Tactical, Aero Precision, Radian, Daniel Defense, Faxon, Failzero and Lantac, just to name a few. All of them make mil-spec bolts that should serve you very well.

My nickel boron bolt carrier group from Spike’s Tactical works great. I recommend staying away from the super-cheap options. I also recommend buying a complete bolt carrier group from one manufacturer. The chances of you getting a complete bolt with bad rings are far less than if you piece the BCG together from different manufacturers. Take my JP bolt and Rainier bolt carrier failure (above) as an example…first-rate parts that don’t fit together well.

Coatings

Getting a BCG with higher-end coatings will improve its service life. Nickel boron, TiN nitride, black nitride finish, and other similar coatings improve wear resistance, lubricity and corrosion resistance. The bolt carrier group should run better and last longer. Which coating to get is the shooter’s preference. Functionally I don’t see enough difference in them to really care. Visually, each finish has its own distinct look.

Skeletonized BCGs

Skeletonized, low mass or lightweight bolt carrier groups are for people who like to tinker with adjustable gas blocks, buffer weights and recoil springs to have the absolute softest, fastest-shooting AR possible. Other than that, they look cool, I guess. If that’s what you’re after, go for it.

The AR-15 or M16 bolt carrier group is the heart of your rifle, and therefore not something you should go cheap on. Certainly not bottom of the barrel cheap, anyway. Don’t get attached to yours and don’t neglect it, either. Definitely, share any stories of BCG failures that highlight any issues I didn’t address as well as your go-to BCG supplier.

Matt Sandy is an Arizona-based gunsmith who competes in both USPSA and PRC matches.