Ken asks:

Over the last several months, I’ve had trouble finding ammunition at my usual carriers. I use popular calibers (.45acp and .223rem) and live in the SF Bay area, so it could be due to small market/high demand forces. In either case, I’ve recently started thinking about reloading–not just to potentially save money, but limit my dependency on the supply chain. I think this might be of interest to other readers, too. Could we see a “Fundamentals of Reloading” installment?

With apologies to the dozens of other Ask Foghorn articles waiting for response, let’s talk about rolling your own . . .

It’s true: reloading can save you a ton of money. It can also render unto thee match grade ammunition precisely tuned to your specific firearm or purpose. The process is relatively simple.

Modern self-contained ammunition is composed of four main parts (from left to right): the primer, the case, the powder and the projectile. These components come together to form a single round of ammunition called a cartridge. But only three of these components are “used up” during the firing process: the primer, powder and projectile. The case can be re-used over and over again. The process of turning that used case into a fresh round of ammunition is called “reloading.”

When you pull the trigger on a firearm, the firing pin strikes the primer at the rear of the case. When it’s struck, the primer is emits a small spark. That spark travels through a small hole in the rear of the case to the main chamber. Smokeless powder waiting in that main chamber reacts with the spark and begins to burn, producing expanding gases.

These gases are trapped by the projectile (a.k.a., bullet)— which is seated in the top or “mouth” of the case and held in place by friction. When the pressure overcomes the force of friction keeping the projectile in the case, the two separate. The bullet heads down the barrel. The gasses dissipate. All that’s left is the spent brass case.

The spent brass has lost two of the components in the firing process (the powder and the projectile) but the primer remains. (You can see the indentation the firing pin made in the primer here.) Primers are self-contained components. We can swap out the used one for a fresh one. But first we need to get the used one out of the case.

Brass is a fairly malleable metal; given the right pressure it will readily expand or bend. When the gunpowder starts burning the pressure inside the cartridge forces the case to expand and even stretch slightly, changing the case’s dimensions. Before we can add fresh powder and projectiles we need to resize the case back to its original dimensions so that it will fit in the gun (magazines and chamber).

So, in short, to reload this cartridge we need to do the following:

- Remove the spent primer.

- Resize the brass case to the original dimensions.

- Insert a fresh primer.

- Add gunpowder.

- Press a new projectile into the mouth of the case.

- Apply the finishing touches.

These steps require some specially designed tools. So before I dive into the play-by-play of the reloading process let’s talk about the equipment (don’t worry — there’s a shopping list at the bottom of the article).

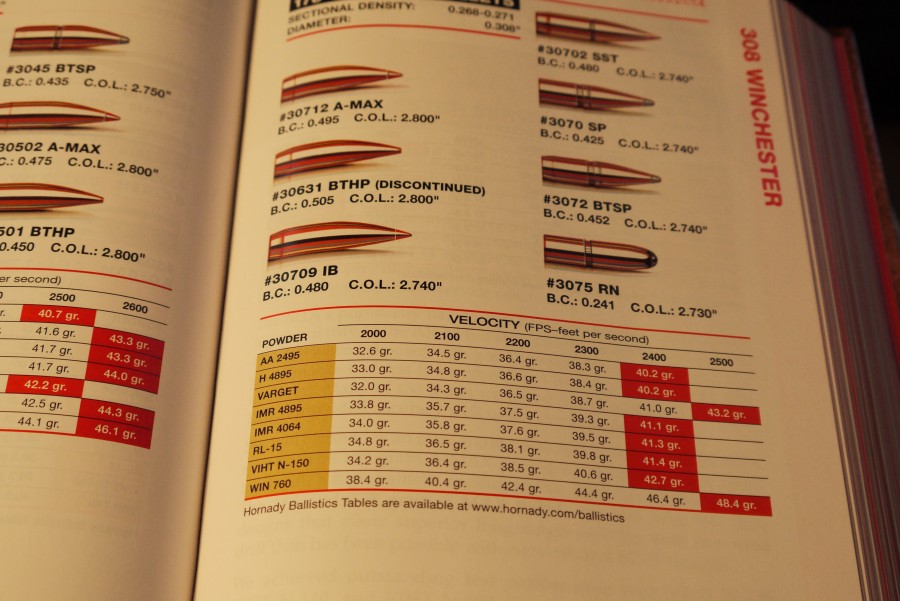

The first thing on any aspiring reloader’s shopping list: a reloading manual. I use Hornady’s. It provides a great overview of the reloading process and offers page after page of handload “recipes”: how much of a specific powder you should use in a specific cartridge with a specific bullet weight. Hornady’s manual also lists “ideal” loads for reloaders looking to create the best balance of speed and accuracy for a given cartridge for a given application (hunting, self-defense, target shooting, etc.).

WARNING! The proper (i.e. safe) powder charge will differ based on the weight of the bullet you use. Heavier bullets have a lower maximum charge than light bullets. While the reason is fascinating and complex (and scheduled for an upcoming Ask Foghorn) the bottom line is critical for new reloaders.

Pay attention to bullet weight so that you never exceed the recommended maximum charge for that bullet weight.

Failure to comply usually forms a direct line between your shooting bench and the emergency room. You have been warned.

The first required piece of equipment: a press. A press makes most of the tasks associated with sizing and pressing the ammunition easier. This is a Lee Hand Press (or Thighmaster, as I’ve come to call it). It’s unique in the reloading world. Most of the presses mount to a counter or workbench. The Hand Press, well, you know. Considering the device’s low price, it’s a good place to start before you invest in a monstrosity of a reloading press (especially true for apartment dwellers like myself).

Next on the list: reloading dies. A set of dies includes three bits: a deprimer / resizer, a seater and a shell holder. We’ll get into these a bit more in a second, but all you need to know right now is that dies are standardized across the industry. So no matter which brand you pick they will work with any other brand of press.

Just be sure to buy the set of dies for the caliber you want to reload (you’ll need a new set of dies for each new caliber). I recommend you get “full length” sizing dies; they do a better job of sizing the entire case. [Note: this article assumes you have full length dies.]

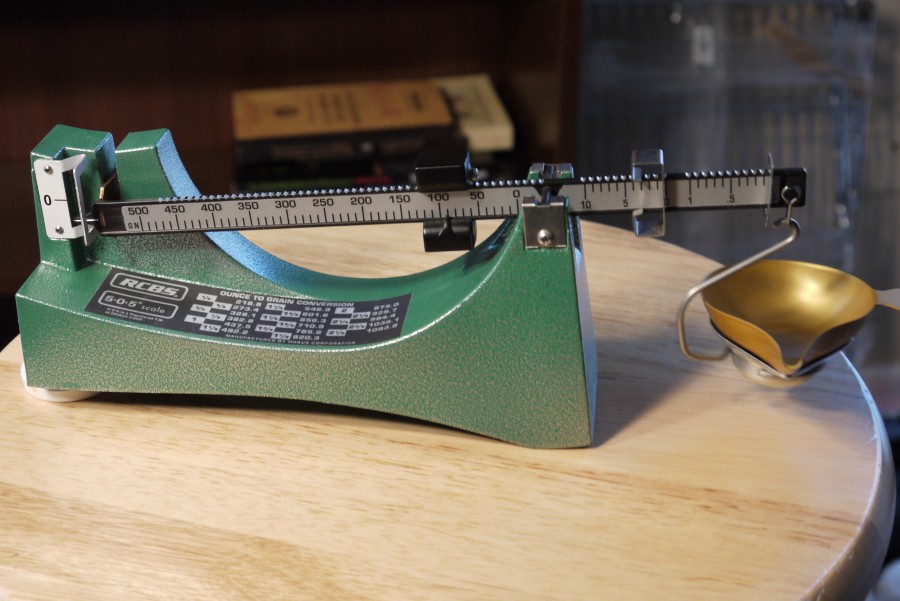

Also of great importance: a scale. We’re working with gunpowder in a confined space (the chamber of your firearm). Getting the weight of that charge of gunpowder is essential not only to the accuracy of your ammunition but also your personal safety.

If you put too much gunpowder in a cartridge your gun could explode in your face, possibly killing you and/or someone you love. It has happened before and it will happen again Don’t let it happen to you.

A good scale is the best step you can take to keeping yourself alive and your rounds on target. It will allow you to accurately—and thus safely—measure out each and every load. Digital scales are fine for reloading, but a simple beam balance scale is the best tool for the job.

Next up: a case trimmer. Remember how I said the case stretches as well as expands when it deforms? This tool will precisely trim-down the case back to the factory specifications.

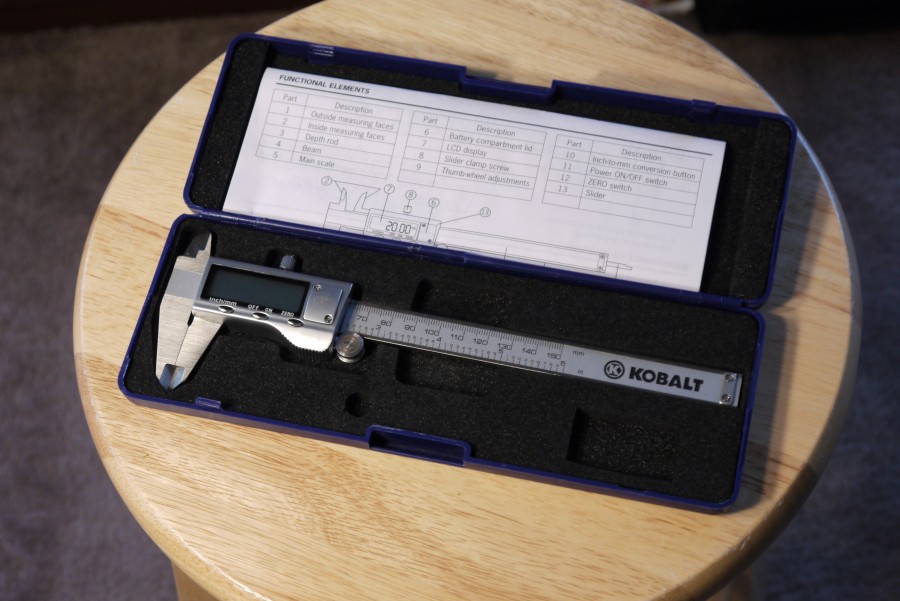

The last piece of equipment: a set of calipers. These precisely measure the size of the case and the length of the finished cartridge. This is an important measure; a good set of calipers is a must.

Now that we have the required equipment we can start collecting brass and reloading ammunition.

This is where the process starts—a box full of spent cases. After every range trip I pick up my spent brass and put it in a pocket on my range bag. I sort it into a set of boxes back at home based on caliber. This box holds 7.62×51 NATO brass.

Heads-up! Only certain types of brass can be reloaded. “Boxer” style cases have a single central hole for the primer vent that allows the machinery to remove the primer. Other types of primers may have the hole on one side off-center. Steel or zinc cases are also not considered reloadable due to the forces required to form them back into shape. Be aware of the kind of brass you are picking up and whether it can be reloaded.

Check the manual or phone a friend. If in doubt, don’t.

As you empty your brass into the collection box (or bag or whatever) inspect every piece of brass. You’re looking for signs that the brass has begun to degrade, including cracks and holes in the side of the case. These will most likely appear near the base (head) of the cartridge where the pressures are greatest. If you see any stress marks on your cartridges discard them immediately.

Before we can start adding new components we need to remove the last remnants of the spent ones from the cases, specifically the primers. Your die set should include a sizing and depriming die (one single die that does both, often also called a “decapper”). It will remove the old primer by pushing it out and resize the brass to the proper dimensions at the same time.

Look for a small metal rod coming out of the sizing / depriming die. This metal rod will travel through the small hole in the base of the case (where the spark from the primer travels when the gun goes off) and push the primer out of place. The primer will fall through a hole in the shell holder and into a small tube in the bottom of the press. Remember to periodically empty that primer catching hole.

Let’s take a second to setup the press with the sizing die.

First, position the shell holder plate, which should come in the die kit. (If not you can order them individually online.) These plates grip the rim of the case—much like the extractor on your firearm—and hold them in place. They will also pull the cases free of the dies once they have been pressed.

The plate slots onto the bottom of the press. The rod is held in place by friction, applied through the nut at the top of the die. If you ever need to adjust the length of the rod (if it stops pushing out primers, for example) all you need to do is loosen that nut, re-adjust the rod and tighten it back down.

Notice that the die is threaded, and there’s a nut on the outside of the die. To begin, move that nut up and out of the way as you thread the die onto the upper portion of the press. Screw the die into place far enough where the bottom of the die contacts the holder positioned on the bottom when the die is closed. Then turn it 1/4 to 1/2 turns further. Once in place tighten the nut all the way down on the die to hold it in place.

Now that the press is all set up (yes?) we can start running brass through it.

Lightly apply lubricant to the exterior of the case to keep it from becoming stuck in the die. (I have three dies sitting behind me with cases stuck in them.) Lee makes a wax-based lubricant that comes in a paste tube. I highly recommend it; you can see when you have enough or too much lube on a case. The case should be slick, but you shouldn’t be able to see much lube visible on the case. There are other “quicker” ways of lubing your case but I like the slow and steady method. Try to keep the lube away from the neck (the skinny part at the top) of the case.

A properly lubed case can be positioned on the shell holder and run through the press easily. Slow and steady pressure is the best method, making sure that the bottom of the sizing die touches the top of the shell plate. This can take significant force, but the mechanism of the press is doing most of the work for you.

With necked cartridges (e.g., 5.56x45mm NATO, 7.62×51 NATO, 300 AAC BLK) the sizing process as well as the firing process has slightly extruded the case and made it longer than it was when it started life on the factory floor. This extruding process causes the wear that we looked for when we poured the brass into the collection bucket back at home. Take a second look; an unhealthy case could lead to an equally unhealthy situation on the range. It happens with straight-walled cases as well (e.g., .45-70 government, 45ACP, 9mm para) but not as quickly.

Anyway, because the case has become longer we need to trim the neck down to the proper size.

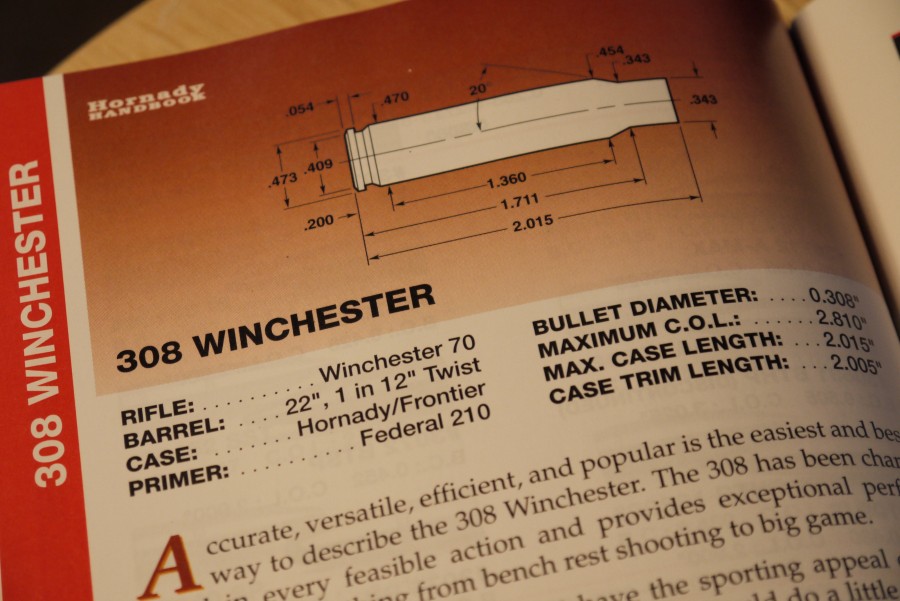

We determine the proper size for a case by looking it up in our reloading manual. There are three measurements which are extremely important on this page: Maximum C.O.L., Max Case Length and Case Trim Length.

Maximum C.O.L. or Cartridge Overall Length is the maximum allowed length of the entire completed cartridge (including projectile) to fit the cartridge into the magazine and chamber of your gun. COL also has an important role to play in velocity and chamber pressure, but that’s another story for a more advanced look at reloading. All you need to know right now: never exceed the listed COL, measuring from the tip of the projectile to the rear of the case.

Max Case Length is the maximum length of the case for the cartridge to fit in the chamber. If the case is too long then it could get stuck or potentially cause the chamber pressure to rise to a dangerous level (see a theme here with the death and destruction?). You do not want to exceed the maximum case length, as measured from the back of the case to the top of the mouth.

The Case Trim length is the ideal length to which you should trim the cases once they exceed the maximum case length. Somewhere between the max length and the trim length is good enough. But be aware that trimming too short could lead to accuracy issues.

How do you trim the case so precisely as to not anger the reloading Gods? Using one of these, of course!

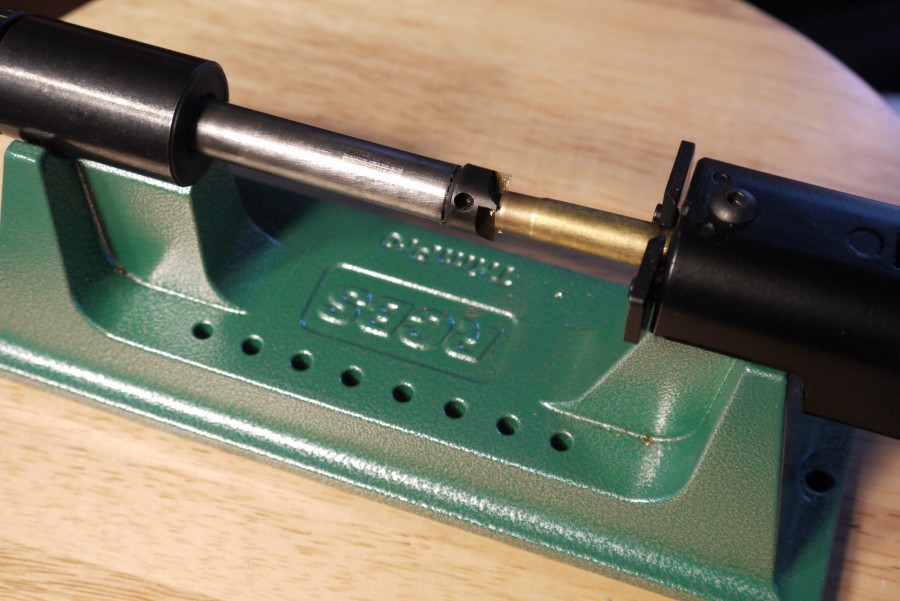

What we have here is a miniature hand-cranked lathe. It can be precisely tuned to trim off exactly the required length of brass. In other words, it’s my favorite tool of all time. This one is produced by RCBS; there are other versions available. It takes some trial and error to set up a mini-lathe (expect to throw away some brass). Once it’s been locked down you can happily trim for hours on end.

After trimming, the case is usually ragged around the freshly trimmed mouth. This piece of kit—a chamfering and deburring tool—smooths out the edges. It’s not required equipment, but it helps make things nice and shiny. Check the cartridge length once you’re good to go.

The last step of the prep process is completely optional, but I like to do it. The brass comes out of the reloading process a little dirty (second to right). With a little polish the rounds will look factory new and probably feed better in your gun (right). Brass tumblers are available from a number of different manufacturers.

Congratulations! You now have a “prepped” piece of brass. The most time consuming and annoying parts are over. Now we can actually load a fresh round of ammunition. As we go through this section I’ll throw in a little something about the consumables you’ll need to purchase at each step, starting with the primers.

Primers come in all shapes and sizes; you need to figure out which ones are right for your ammunition of choice. The reloading book (well, Hornady at least) will happily tell you the primers they used in their loads. Primers are usually sold in lots of 1,000 for small primers or 100 for large primers.

Putting a new primer into cartridge = inserting it into the empty “primer pocket” at the rear of the case. Here you can see the primer pocket, and the flash hole where the spark enters the main chamber as the gun goes off (also where the deprimer rod punched out the primer). The primer is held in place by friction. The new primer needs to be “press fit” into the hole.

Before fitting a new primer check to see if there’s been a crimp fitted around the previous primer hole. [NB: military ammunition usually has a primer crimp.] Look for a recessed ring around the primer pocket.The crimp makes fitting the new primer slightly more annoying, but certainly not impossible. You’ll need to remove the crimp before the new primer can be seated. Otherwise, the primer may not function properly. Extract the prime using what’s called a primer pocket swage (or something similar).

Now that the primer pocket is ready we can press-in a new primer. I like to use the Lee hand prime, which allows me to prime lots of brass quickly. Be aware that the hand prime needs its own special shell plate to work. Also: wear safety glasses.

NEVER prime brass which already has gunpowder in it. That could end very, very badly.

Speaking of gunpowder, that’s the next step in the process.

There are a number of different types and blends of powder, and it can be a little overwhelming choosing the right one. never fear: Hornady is here! Well, their book at least.

The reloading manual will describe a number of “recipies” of powder charges for the given bullet weight and type you’re using. Naturally Hornady has hand crafted their book to fit their own bullets. But as long as the weight is the same the charges indicated will be safe to use. As I said before, the powder charge will vary depending on the weight of the bullet, so be sure to pick out a bullet weight and stick with it for that specific run of ammunition.

A little powder safety first:

- Never place the powder near an open flame.

- Never mix powder from different bottles, even if it’s the same company and the same name.

- NEVER exceed the maximum indicated charge (shown above in red) for a recipe.

- Never use pistol powder in a rifle cartridge unless specifically instructed to do so by a trusted source (like a reloading manual).

Now that we’ve picked a powder and charge we can start loading-up some primed cases. Powder weights are usually given in grains. The RCBS scales are calibrated in grains as well. Be sure to zero your scale before you start using it. Be wary of any air conditioning or fans in the area as the breeze will throw off your measurements. No, really.

You now have a primed and charged piece of brass. It’s time to cap off the reload by pressing the projectile into the mouth of the case.

The first thing we need to do: swap out the die on our reloading press. The sizing die has done its job and can be unscrewed. The seating die can now take its place.

The bullet seating die installs the same way as the sizing die, only this time once the die is screwed-in to the point where it contacts the shell plate back it out 1/4 turn. After adjusting the die position and locking it into place with the nut, back out the seating adjustment knob (at the top of the die). This thingie will precisely seat the bullet so that you get the right COL on the cartridge. But we need to start way back so that we don’t accidentally seat a projectile too far.

Once the press is set up simply pop a primed and charged case onto the shell holder, balance a new projectile on top and then close the press. This stage requires some finesse; you don’t want to pound the thing home. Apply just enough pressure to pop the bullet into the mouth, then stop pressing when you feel the press starting to give resistance. Check to make sure your round meets the right COL, adjust and re-press as required.

Congratulations! You’ve made a single round of ammunition! Now to do it again and again and again and again…

http://www.youtube.com/watch?v=Z90W9WJb8FA

Reloading 300 AAC BLK is only slightly more complicated, but the basic steps are the same. Here’s a video I did a while back illustrating how to reload.

I hope that answers any questions you have about getting started, but I get the feeling I’ll be updating this post as the comments come rolling in. Here’s the new reloader’s shopping list:

SHOPPING LIST

One-Time Costs:

- Reloading Manual

- Press

- Dies

- Scale

- Trimmer

- Hand Primer

- Calipers

- Bullet Puller

Consumables:

- Primers

- Powder

- Bullets

- Lube

For those about to comment, I salute you! I’d really love to hear your favorite loads for different calibers. Please feel free to post them below.

[Email your firearms-related questions to “Ask Foghorn” via [email protected]. Click here to browse previous posts]

Caveat Lector: I’m not a pro; use this data at your own risk.

.45 Auto: Remington case, Winchester Large Pistol primer, Suter’s Choice 185gr LSWC, 5.6gr of Unique, 1.19″ COaL. Makes major for USPSA/IPSC, shoots to point-of-aim out of my Kimber, easy on the wrist, easy on the cases. I’ve yet to recover one of my cases that needed trimming.

Have you chrono’d your load? It might run faster than what you need to make major. Depending on how many standards of deviation you’re looking at.

230gr lead round nose (Mo Bullet Co or Roger’s Better Bullets) and 5.4gr of Unique and CCI primers do 730-750 fps out of a 5″ bbl Kimber.

On your typical spring day here in Minnesota, these average around 920-925 fps. As I need 892 to make major with a 185gr pill, I think this gives me a nice cushion should the weather on range day be unusually cold.

Ahhh, I haven’t found Unique to vary too much in velocities from 50-90F.

Probably true. However, my local club has a match called the “Blizzard Blast”, usually held end of February or beginning of March. It’s the official start of the season for us. I’m told that they’ve been shooting at temperatures as low as -20F. At the other end of the season is a 3-gun match, in October. You’ll forgive me if your 50-90F data does not match my situation. 😉

Haha, yeah I know… I used to live in the UP. So I’m well aware of the winters. 😀

This may sound unusual but I collect and crack black walnuts in my vise, very difficult . I was looking online for nut crackers and thought what about my RCBS Rock Chuck-er. With different screw in top die and bottom die made in machine shop, do you think this would double as a nut cracker ? Don’t yell at me. I worked as a Millwright all my life and know a good thing when I see it. I just wanted your opinion. Don

For some great reloading info and quality videos check out:

http://ultimatereloader.com/

Nick,

You mention brass tumblers, but you aren’t recommending tumbling the entire cartridge after it is complete, right?

I usually do this with the brass cases before the whole reloading process, or put them in the tumbler before storing the spent cases.

You want to be careful with tumbling completed cartridges as it can cause the powder to “break down” inside the case (although it’s not very likely). This can cause erratic and potentially dangerous burn characteristics when fired.

Yeah, like Adam points out, tumbling the loaded rounds is generally considered to be a bad idea.

The explanation that I’ve heard is that the powder grains in the loaded round might change geometry (e.g. grains of a “stick” powder might break into smaller sticks).

Anyway, great post Nick. I always enjoy the Ask Foghorn installments. Keep ’em coming.

You want to tumble/clean brass before reloading. As it can break down the powder, causing a change in burn rates. And as Nick likes to emphasize can lead to injury or death.

There’s another method you can use, like ultrasonic cleaners (using a liquid solution). The idea behind cleaning is to not only make the brass pretty, but to remove carbon fouling and dirt. Which can scratch and ruin your dies. Using the ultrasonic method and solution can cause powder fouling, resulting in no bang, and bullet lodged in barrel.

Expanding on recommended reloading gear and the bullet puller is good to have. Whether it’s a collet or inertia/hammer type. Which is great for when you seat a bullet too deep, or forget to charge a cartridge with powder.

“or forget to charge a cartridge with powder.”

—–

There are two types of reloaders: those who have forgotten to charge a case, and those who will. Thankfully, I don’t know of anyone who has done it more than once. Having to clear your barrel of the result usually leaves a distinct impression on the reloader.

Haha, I’ll admit to doing it. From time to time. Usually when setting up a new load/caliber on my AP press.

Usually happens when I short stroke my press, and don’t seat a primer. And put it back under the wrong turret. Powder check/lockout dies are great for preventing this.

Powder check/lockout dies are great

Using progressive presses, emphatically yes. The powder cop die has saved me several times.

I use RCBS’s lock out die. Keeps you from advancing the press if over/under charged. That way you don’t have to look at it. Only downside is that it’s primarily for handgun calibers.

I should probably move that section a little higher in the article…

Note to future writers: the Shiner Bock is delicious, but don’t try to write after four of them.

That’s my problem! I always believed that good scotch made me a poet laureate…

…and smart, good looking…hell, you get the picture.

WELCOME TO TEXAS! Home of the worlds greatest Bock beer.

This world you speak of – it doesn’t include Germany?

My favorite .308 “Match” load is as follows. It has shot well in EVERY single .308 that I’ve shot it out of.

– Lapua brass

– Fed 210M Primers

– 168-grain SMK (Sierra MatchKing)

– 43.5 grains of IMR 4064

– TTL=minimum

– COL = 2.800″

– Primer pockets cleaned and uninformed.

About how many rounds per hour do you think you crank out with the hand press?

What are the other options for presses?

I’m planning to get into reloading when I get back from basic and this article was excellent in getting me more informed.

Thanks!

I use an RCBS Partner press, and it was/is my first and only press. Got it used for about $40. It works well if you have a bench to mount it to (I used an old workbench I built and don’t use for woodworking anymore). I am not sure about the handheld presses, but I find the basic single stage press to work fine for my needs. I don’t think you need a progressive press to start (in fact it may lead to mistakes if you aren’t careful), and I can load about 100 basic handgun (.38 spc) rounds per hour and a half or so. Then again, I take my time at every step to minimize the chances of a mistake. I really enjoy the process of doing it and find it relaxing. YMMV depending on your scale, powder dispensing method, and pace…

Dan,

In total, it takes about a minute per round to perform all of the steps not including setup. The hand press doesn’t slow things down compared to a bench press, it just requires more energy to get the job done.

I just did some follow up after asking the above question…

It seems most of the internet concludes tumbling loaded ammo is fine.

I was just curious because I never thought about doing it that way. Are there any benefits, or is it because you load your rifle rounds with case lube and want to get that off?

Great article, thanks.

Great starter article Nick. I’ve only just joined the ranks of reloaders, but instead of baby steps, a Dillon XL650 somehow found it’s way into my apartment.

Since I was starting from basically 0 (except for a few thousand pieces of range-pickup), I did have to make a major cash outlay to get really going. I’d cry i did the real math, but using “kentucky” arithmetic, I’m at about $1800 including 2k bullets, 7k primers, 5lbs of various powder to run test loads.

It may sound like a lot, but since I’m shooting mainly .45ACP, and cases of even bulk ammo are easily $400 + shipping, I’ll start saving money right around 8-9k rounds.

Given that I’ve shot 3k since the beginning of the year, I’ll be about even by 2013.

What makes it even more affordable is getting a couple shooting buddies to kick-in on the consumables (either buying components or cash donations). If my loads meet their standards, I can easily expect to be even on $1800 by summer’s end.

What goes without saying is that the calculus of satisfaction of developing, testing and scoring your *own* loads is a HUGE return on investment; I don’t believe I’ve ever had so much fun shooting at static targets.

After reading this I realized there isn’t yet an “Ask Foghorn” on making Bullets. I think it would be a good idea for a future Ask Foghorn.

Non-reloader here.

How many times can you typically re-use a brass shell, for say .223 or .308, before you would have to dispose of it? I assume there are many factors but there must be a practical limit, even under the best conditions.

putting my shopping list together to heading to the store!!!

I will never buy ammo again!

Oh one question..

Will ranges get upset if you are picking up brass off the floor that isn’t yours? I mean if you put together a ton of 9mm and sell it to friends it could fund your trips to the ranges at minimum.

Yeah yeah I know lots of laws regarding ammo sales and such, but I won’t go there..

Depends on the range. Some ranges won’t let you pick up brass, even if its your own. As they resell it. Also, some ranges won’t let you fire reloaded ammo. It doesn’t hurt to ask the rangemaster if it’s ok. But if not, and it’s on the ground… Fair game is a safe assumption.

With picking up range brass do so at your own risk. You don’t know if it was factory loaded, how many times fired, etc. I like to keep track of how many times I’ve fired my brass, because of wear from extraction.

Also if you’re trying to squeeze every bit of accuracy out of a cartridge, you’ll be more discriminating with brass. You’ll only use brass that’s been fired from a particular chamber. This is more prevalent with rifles than handgun cartridges. Where the case will form to the chamber eliminating “play.” In place of using a full-length sizing die you’ll use a neck sizing die.

picking up range brass do so at your own risk

Some folks feel that this is especially true for .40 S&W. Glocks, or at least older Glocks, don’t support the brass completely leading to the dreaded “Glock bulge.” Full length sizing dies are supposed to deal with this.

Some ranges get pissy, but most won’t. One range I go to encourages you to pick up after yourself (it’s a sportsman club), one prefers you sweep up but leave stuff in their buckets, one indoor one has brass catchers that ferret your brass away in the first place. So just ask around.

Thanks for the feedback. I am assuming you could also ask to buy brass too and then hand pick rounds, and buy them by weight. I do understand about being picky and agree! For those who do this as a business I could not imagine that they only reload rounds they fired themselves, or had a complete history on. None the less I am sure if we as individuals do this our rounds could potentially be much better. Plus if you collect lets say you and your friends go to the range, pick up all 200 + rounds, you know it is fresh ammo, and then you can track it’s history so you know the casing is clean.

This was exactly what I was looking for Nick, thanks! I’ve already got a reloading manual on the way.

One other question. Do you tumble your brass post primer removal pre rebuild? I know it was mentioned as a last step but I would figure you wouldn’t tumble live ammo.

In Nick’s setup, and most others that I’m aware of. You tumble with the used primer(s) still in place. If you were to remove the primers and then tumble what can happen is that media (what cleans the brass – often corn cob or walnut shell based) will clog the flash hole. This of course will depend on the size of the media.

Yup I totally didn’t think about that, so get back from the range, pop the box of rounds into the tumbler and watch some baseball or hockey while they clean up..

Then relax and De-prime everything.

Put on some smooth jazz and start lubing and resizing lol

The process sounds as much a meditative hobby as it is a cost savings!

Put on some smooth jazz and start lubing and resizing lol…..

Are we still talking about reloading?

You get a better reloading experience after wining and dining…

I know with the setup I use (Hornady Lock and Load Auto Progressive press and dies) the handgun dies use a titanium nitride finish; which don’t need lube. I don’t know about other brands of dies though. But dies for rifles or anything that isn’t a straight wall benefits from using some lube.

Nick doesn’t mention it, but I’ve found that using a dry lube like mica powder for the case neck will help prevent a mess from being made when charging. What happens from liquid case lubes is they become “gummy” and causes the powder to stick to it preventing all the powder from going into the brass. This really becomes a problem with smaller diameter calibers.

Tumbling with stainless steel pins, a wet process, is supposed to totally clean the insides of the case and the primer pocket. Unfortunately this is also a messy operation and more expensive to buy into.

That sounds really interesting… But I’m skeptical on how it won’t shot-peen and harden the cases.

I use a little Dillon Square Deal B pistol caliber only progressive press and will use the depriming/resizing stage and then clean and polish the deprimed brass. Sometimes a little help is needed from a primer pocket brush. If the range brass is just too dirty to get near my dies, I will do a quick clean then deprime and a full clean and polish. I use walnut media due to the issues Ken mentions regarding corn cob media.

Bravo Mr Leghorn I requested a post like this a few months ago you pretty much covered everything in this post, good job. I have been “rolling my own” for a few years now and nothing makes you feel more independent from “the man” than this hobby….well making your own beer is right up there also but that’s a different story (and blog site)

So if you are reloading, brewing and throw in wine making to boot then you are independent? 🙂

Nick, great timely article. An older friend of mine is getting out of reloading and has agreed to sell me his two presses (one is a Lee and the other a RCBS Rock Chocker, I think) plus three sets of dies ( 45ACP, 44, and 9MM) and all of the stuff that goes with it for $250.00. I’d love to have a progressive like a Lee or Dillon, but the cost is out of my reach. So, once again thanks for the info.

Progressive presses, aren’t that expensive. Yeah, there’s more outlay versus the thighmaster. But a 3 station press from Lee starts at $150 on Midway. I have a Lock-n-Load from Hornady which is comparable to a Dillon 650 but less expensive. When I bought mine, there was also $100 in bullet rebates.

To me the extra turrets are great. As it lets me run other dies as well, instead of trying to get it all done in 3 stations. I use a powder check and lockout die, separate crimping dies, collet puller, etc.

Ken, I’m only going by info the guy at a very reputable reloading store told me. I was looking at the Dillon which was around $399.99, and asked him about cost outlay, and he said that by the time you bought everything you needed, it would probably end up around $800.00. Which if true, I’d rather know the total cost upfront, then get shocked after I bought the initial press and found I needed all this other stuff. Hopefully he was being truthful, for I am just getting interested in this, and don’t have all of the info.

That $800 figure is probably a little high, but not by much. Back when I started, I had to spend about the same amount as the progressive press for all the support accessories needed to reload: Scale, flip tray, case gauge, calipers, tumbler and media, etc…

If you start with your friend’s single stage kit you can still upgrade to a progressive later and probably only need to buy the press itself since you will already have the dies and many other needed accessories.

Mike’s pretty spot on with his comment. The only additional cost you’ll probably have with an AP setup is needing the press specific plate. But it really depends how complicated of a setup you want to get. Most of the things that come with a starter kit will be pretty good at producing a consistent product. Especially if you’re only loading one type of round and aren’t continually fiddling with things. Things might start getting expensive when you start getting more things to make changing over to different setups easier. But things like super fine metering inserts may be overkill depending on the powder, and tolerance.

When I got my LnL AP press I ended up getting $150 in free bullets from Hornady. I think I spent maybe 500-600 in reloading stuff to get setup (press, .45 dies, .45 plate, tumbler, caliper, scale, inertia puller, and flip tray). So it’s not too bad.

Just a heads up for those living in apartments, check first.

In some place (example:Maryland) it is illegal to store and have bulk powder (including black powder) in a rental property. Other places it may be express forbidden by your lease or condo association, so unless you want your stuff on the curb, quietly check first.

Yeah, explosives are forbidden in my lease, so no reloading for me unfortunately. I’m trying to talk my brother into going halves on a reloading press so we could keep in his basement. We’ll see if he goes for it.

I stumbled upon this site and approve! Heartily!

Having reloaded my first .45 Auto round in 1980, and having continued to do so ever since (plus another 18 calibers), I will have to say Your article on the beginner’s reloading process is perhaps the finest I have ever read in so few column inches. Well done, Sir!

“Loading in the shadow of the Alamo ennobles the pursuit of ballistic perfection!”

Nice article. I appreciated it and the comments.

I had a friend who had a deluxe reloader in his basement; but it was for shotgun shells.

Nick, something of a nitpick here: Early in the article you list bullet point items which you expand upon later and one of them could be dangerous if taken at face value as written: “Fill the case with gunpowder.” You fully explain the correct process later on, but that one point might be better if written along the lines of: “Add the proper amount of powder.” /end nitpick

Noted and updated. Thanks!

Great article, Nick! I have been reloading since 1977, both pistol and rifle cartridges.

I use a Lee Turret Press (Progressive 3-dies) for Pistol and RCBS “Rockchucker” (single stage) for Rifle.

New reloaders should check online with RCBS, Dillon and Lee, as they often have package deals where you get a Press, Dies, Scale, Powder Measure, Dial Caliper and so forth at a good price (cheaper than buying the equipment piece-by-piece).

I use Lee Carbide Sizing Dies for pistol, as they do not require lube. Many manufacturers make Carbide Sizing Dies and they last for years. Rifle cartridges (except in pistol calibers) require lube because of the case shoulder and neck down.

I strongly would advise against Tumbling loaded rounds. Due to powder degradation, friction and the wild chance of somehow igniting a round, this could be very dangerous. Even a .223 round igniting inside a Tumbler with other loaded rounds could cause a life-changing disaster.

Reloading is fun, money-saving, and relaxing. I think the best part is that you CAN tailor cartridges for optimal performance to each Pistol or Rifle you own and the results are satisfying and sometimes surprising. Specifically, a firearm that does not seem to shoot well with whatever manufactured brand you can find in the stores or online suddenly becomes a great-shooter with the right handload. I have seen this happen for myself and others I have shot with over the years.

For all who decide to take up this great pastime, best wishes and ENJOY!

RCBS offers ‘second’ presses for half off.

These are presses that have painting flaws,

a nick on the handle ball and things like that.

Purely cosmetic.

Got my Rock Chucker for something like $85.

Works great.

I’ve tumbled my brass as the first step in the process of reloading.

This keeps the dies cleaner and prevents them from becoming scratched inside due to any grit that may have been picked up along with the brass.

Ultrasonic cleaners anyone?

There is a long thread on the M1911 board about tumbling finished rounds.

I Love My Country!

Excellent basic article.

Couple of points I’d add:

In addition to bullet weight, composition changes the recommended powder load. More important in pistol calibers, but loads for jacketed bullets do not transfer to plain lead slugs or vice versa.

You explain the process for a typical bottle neck rifle cartridge. Straight wall ammo whether rifle or pistol is a tad more complicated and requires belling the case mouth slightly to prevent case or bullet damage during the seating process.

I always recommend that a new reloader start with a heavy duty single stage press. Many want to leap straight into high end progressives, but I really want them to get a full understanding of each step in the process first.

You can still get a solid press, beam scale, and set of dies for under $200. Sure, you’re going to spend a lot more on tools and other goodies that make the process better and easier, but it’s best to get the basics under your belt first, then you’ll know what you really need to enhance the experience.

+1 for a solid press to start with. My first press was an RCBS Rockchucker and 25 years later I still have and use it exclusively.

For those who would like to hand deprime a brass case before cleaning, & without using a press I whole heartedly recommend the Harvey Deprimer. Another advantage is that you do not have to send a dirty case into your resizing die possibly scratching & damaging it, which will shorten it’s useful life. I have used the Harvey Deprimer to hand deprime my current crop of 12 calibers .380 ACP to 300 WSM, along with many other calibers at the range to show interested people.

Contact info: http://www.harveydeprimer.com

(541) 401-1835

[email protected]

Roger Harvey

115 Airport Rd.

Lebanon, Oregon 97355

Note: I do not receive any money or benefits from praising this product, nor am I in business with or related to Mr. Harvey.

One thing that can never be said often enough: never overcharge a cartridge with powder. Don’t trust your process. Know what a properly filled case looks like and do a visual check before seating a bullet. Especially on progressive presses.

I got lucky. My 1911 is equipped with steel reinforced rubber grips. When a case breech occurred from unnoticed overfilling, the gases were vented through the mag, not my hand.

Every remaining cartridge I had made to that point was weighed and about half disassembled and rebuilt.

Eyeballs work better than lockout or powder check dies. They’re cheap and readily available too. Use them.

“do a visual check before seating a bullet”

+1,000. That can’t be emphasized enough.

Great article, I’ve just started reloading so this was a good read. One thing I wonder is you and others online mention to look for signs of cases degrading, and I have also heard of looking for signs of high pressure. Any chance you can post some photos of what those coditions look like?

On straight wall cases, they will eventually get thin. Fortunately, they’re small enough that you’ll likely lose them before they wear out. You should inspect them for flaws all the same. Look for cracks, deep scratches, dents that won’t come out in the sizer, etc. (you’d be surprised what the sizing die will fix)

Get the Hornady Reloading Handbook if you want to see horror pictures with bottle-neck cases. Cracking is the usual problem. The neck gets thinned down and eventually splits. I’m not yet loading bottle neck rounds, so I can only report third hand.

Oh, and to comply with the request above, I use the following recipe for 45ACP:

– Winchester case, deprimed, ultrasonically cleaned and inspected

– Winchester Large Pistol primers

– Winchester 231 Powder, 4.5 gr ± 0.1 gr

– Hornady 230gr FMJ-FP bullet

Mix in your favorite Hornady LNL AP or other progressive press and you get 100 rds in about 40 minutes to an hour depending on setup. Yes I read about people assembling rounds at higher rates than that, but after the aforementioned case breach, I’m persuaded to be slow and careful.

For what it’s worth, I’m saving about 7 cents a round over Winchester White Box at Wal Mart which is roughly the same round. It’s not much, but if you shoot 3000-4000 rounds a year, it adds up.

Rawles…where the the baby eating cannibals come out to play. Who is heading to the new america when the SHTF? Oh yeah, only for God fearing people. Not those who are good natured…have to be a bible thumper.

I have a question I noticed on some 30/30 rounds I have reloaded and shot the primer was extended. So I tried a couple of 45 ACP reprimed with no powder or bullet to see if I found the same thing and I did. I redjusted the primer rod to crush the primer same result. Any suggestions by the way I am shooting a colt 1911 nearly new

Fantastic news for iPhone and Ipad people! Do u want to have Kamen rider in just your hand?. You’ve seen heroes several times on morning shows, finally It’s the moment to think&guessing them

kamen rider wizard koyomi dead http://apple.co/293e5r0

Very useful, thank you. I’ve only reloaded with black powder so far and I feel somewhat uncomfortable at the thought that a big case like the .45 Long Colt is less than half filled with smokeless powder. Does it matter? Should (and can) I use a paraffin wad to hold the powder towards the bottom of the case? Thanks for your help.

Vincent

I read your whole content it’s really interesting and attracting for new reader.

Thanks for sharing the information with us.

https://gunsvalley.com/product/winchester-large-pistol-primers/

Great post! i appreciate it.. thanks for sharing!

You can also visit my page

https://armoryanchor.com/product/large-rifle-primers-100/

I read your whole content it’s really interesting and attracting for new reader.

Thanks for sharing the information with us.

I read your whole content it’s really interesting and attracting for new reader.

Thanks for sharing the information with us.

https://gunsvalley.com/product/7-62x39mm-ammo/

I read your whole content it’s really interesting and attracting for new reader.

Thanks for sharing the information with us.

Comments are closed.