Australians making 3D printed guns have came up with an interesting way to get around the durability problem: interchangeable disposable barrels.

Criminal Groups Squad detectives have charged a man and seized five pistols following an investigation into the supply of 3D-printed firearms across Sydney’s west. https://t.co/fJpfckuhQS pic.twitter.com/bEACdtyLX2

— NSW Police Force (@nswpolice) August 11, 2020

The frame appears to be based on the Songbird design that’s floating around the internet. Originally chambered in .22 with a plastic barrel and break-open action, the design was eventually upgraded to use a barrel liner and fire .357 Magnum rounds. The design definitely wasn’t great compared to commercially-built guns, but it worked and left the user with all their digits.

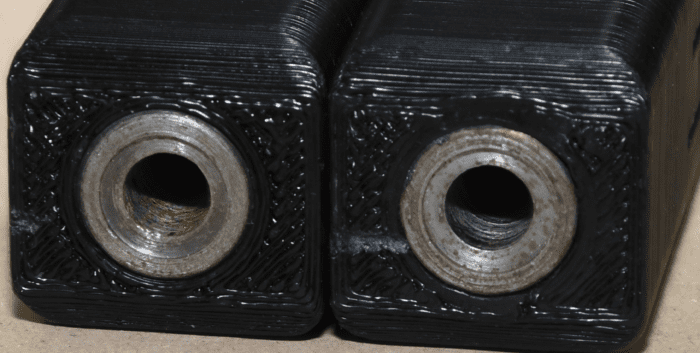

Instead of operating as a break-open action, this variant has a thicker barrel built into a removable piece. The rear appears to be made to accept rimmed cartridges like the .357 Magnum or .38 Special, as you can see a recessed space at the back of the chamber for a rim.

This allows the cartridge to headspace on the rim, but be flush with the back of the barrel so the action can still close up.

When the NSW Police Force seized the guns, there were multiple barrels per gun, implying that the barrel was designed to be disposable and/or quickly replaced with another. This may be due to limited durability of the barrel itself (only firing one or two shots). Or it may be that the sleeve that holds the barrel may melt with too much use in a short period.

By switching out the barrel and let it cool, the assembly’s duty cycle is reduced by 50%, allowing for more durability. If one or two shots is all it takes to melt down, then replacing the whole barrel assembly makes a lot of sense.

Like any older Songbird, the frame has a trigger assembly that drives a firing pin into the primer. We don’t see a place for a rubber band, so it likely has a spring inside to accomplish all this like other newer Songbird designs.

Ways This Could Be Improved

If one were unable to get cases for ammunition somehow, this design could be modified to allow for muzzle loading. If one could get a pipe for the barrel that was closed up at one end, a primer pocket could be drilled directly into the rear of the chamber, followed by a flash hole.

Powder could then be poured into the muzzle and a cast bullet pushed back until seated on the powder. This would allow for a way to keep spare ammunition in a pocket or pouch, replacing the whole loaded barrel for follow-up shots, and possibly retained for subsequent reloading later.

Powder and even primers could be made without regulated parts, using procedures outlined in this old Army field manual.

Whether cartridge-fed or muzzle loaded, this design could be turned into a revolver. Instead of replacing a whole barrel, the disposable/replaceable part could include just a chamber and forcing cone, and include 5 or 6 of them. Cylinders could be swapped in for more shots, like a speed loader. It would need to be mounted to the frame in such a way that the barrel doesn’t melt the frame down, but that would allow for a more usable firearm.

If only a forcing cone were included with the chamber, the package would be much smaller, probably not much bigger than a regular cartridge. It would probably be possible to load these forcing cone/chambers into a magazine, and then line them up with the back of a barrel similarly to a revolver. If these assemblies were muzzle loaded, bolt-action or possibly semi-auto firearms would be possible without cartridges. This would be definitely be chunky and ugly, but would at least work.

Obviously modern cartridges are preferable to any of this, but if you’re desperate enough to be relying on a Songbird-derived design for armed defense, you’ll do what you can. Either way, it’s clear that, increasingly, gun banners can’t stop the signal.

A two by four and pipe can be bought at the hardware store. 3d printers get you in trouble.

3D printers and printing your own guns (at the risk of your hands and eyes) is not illegal. Better quality firearms are produced with milling machines and lathes. Those aren’t illegal either. making 100’s of your own guns isn’t illegal either. Selling one without adding a unique serial number is illegal, and you might face heavy fines and lifetime ban on firearm ownership. Selling many homemade firearms without a manufacturing FFL will get you a few decades in a federally funded gated community.

It is illegal in my part of the world. I’m lucky I have no need for a 3D printer at this time and I have no “files” for firearms or parts.

“ Selling one without adding a unique serial number is illegal…”

In some cases, yes, but for the average guy who does a home build for himself to keep & use, and later decides to sell it or give it away, no. So long as he doesn’t do it often, or with the intent to sell, he is not a manufacturer for this purpose. See:

https://www.youtube.com/watch?v=DRnjM_t4kho

Well that’s interesting…like the homemade Kyber Pass or the Filipino gats. Can’t stop the signal😏

Cool

The principle of operation is similar to one or two of my own (metal) simplified / “Liberator” ideas. The fact that they used a metal liner puts them a cut above many who seem so infatuated with 3D printing technology that they forget other (equally unrestricted, less suspicious, and more suitable) materials and methods exist. They could take it a step further and use thicker wall tubing (or drill a hole in a bar) for a non-disposable barrel. Since there’s no magazine, they can also make it stronger, simpler, more compact / concealable, and less obviously “gun” shaped by moving the barrel back while still retaining ample space for a striker or hammer.

Exactly.

I remember commenting here on TTAG years ago when 3D became a thing that the main problem was trying to make things from plastic that NEEDED to be metal. I suggested then that a printed plastic sleeve could be drilled out and a metal barrel inserted to keep the thing from exploding in your hand since getting it past a metal detector was not the purpose.

I recall also suggesting at one point that a cast acrylic barrel might be suitable for muzzle-loading black powder one-time shot, then discarded.

Nice to see some folks catching up.

Don’t hurt your arm patting yourself on the back.

Chromoly aircraft tubing, benchtop drill presses, and Dremels are everywhere, attract no attention, and produce more lasting results, but I guess they lack the cool factor.

Current edition of RECOIL magazine features an interesting article on building Sleazy, Creepy, Senile Ole Joey’s suggestion for a double barrel shotgun from hardware store pieces.

The “duty cycle” of the gun assembly is increased by swapping out barrel modules, not reduced.

I was talking about the cycle of the individual barrel assembly, not the gun itself.

Ahh, then you would be correct. My mistake and my apologies.

Hmm. If these single shot disposable pistols are good enough for criminal work I wonder if someone’s going to try and do it with disposable derringers. Or hell, maybe some like the old COP 4 shot .357 mag derringer. Although in a much weaker caliber, due to the weakness of plastic frames.

It’s kind of surprising that Australian criminals would bother with 3D printing. Gangs and organized crime have a history making real guns, modifying real guns. Before 3D printing there was already a long line of pistol and sub-machine gun seizures, even an entire machine shop at one time I recall reading about.

People come and go from the criminal world all the time. Some people go into it and leave before they end up in prison or dead. Others leave the hard way. When someone leaves, others replace them quickly.

Newcomers don’t have connections, so they’ll resort to stuff like this.

Where there is a demand for something…somebody will fill it…legally or not…

THANKS FOR INFOR LOTS TO THINK OVER BEFORE MAKE N ONE .

These are just the tool to get the real one.

“You can’t stop the signal, Mal.”

Yep. All a gun ban does is set criminals back 150 years, and we had very capable firearms 150 years ago.

The 1858 Remington had interchangeable cylinders that were often preloaded, and they were popular with cavalry for that reason.

It’s very easy to purchase an invitation printer that can print on cardstock and the Brother business color greeting card printers is a precise product that can get the job accomplished. Its connectivity is easy and the process is fast to obtain the 2400 600 x 2400 pixels resolution. Its top quality allows users to connect wireless devices to get speed of 33 pages in a minute.

HP printers are extremely reliable and reliable when it comes to providing good quality images using HP printer ink installations. This makes the printer extremely efficient in obtaining information from mobile devices or Google storage via Wi-Fi. Isn’t it great to have 17 papers in a minute at a high speed and precision?

Talking on behalf of my more than 5 years experience of using HP Laser 2487 color printer is best for saving your printer ink if your are printing color copies in bulk. It also depend on the type of printer you are using that which one is the master piece and which one is just a dude. Last week I read an article for best printers that utilizes less ink. I found it very informational you may also get benefit from the information they provided. For more details continue here

Comments are closed.