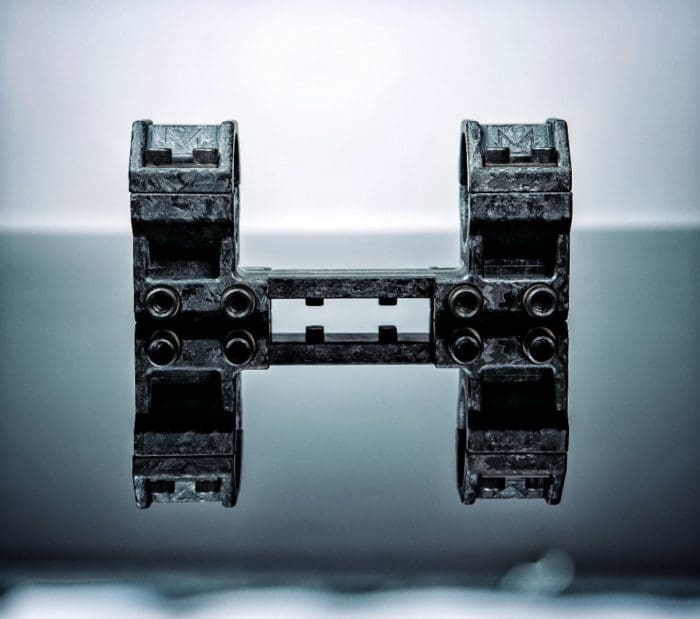

Two months ago Black Collar Arms (of which I’m a part owner, just to be clear) announced their new Forged Carbon Fiber One-Piece Scope Mounts. TTAG ran the press release here. More than just a new product from Black Collar, the entire forged carbon fiber process and the products made thereby are quite new to the world and new to the gun industry.

As such, folks have questions . . .

Most notably, just how strong is this stuff? Yes, it was developed specifically for structural applications and it’s known that Lamborghini uses it for suspension arms, spaceframes, and much more, Callaway Golf uses it for club heads, and it makes up structural components in everything from airliners to snowboard bindings. Yes yes, that’s all good and well, but what about scope mounts?

I’m glad you asked. Though from a materials science standpoint we know forged carbon fiber, done properly, is stronger than titanium despite being one-third the weight and we know it’s as stiff and as rigid as steel — three times stiffer than aluminum — but that doesn’t mean it’ll hold a scope properly.

Fair enough. Though approximately 18 months of testing by manufacturer McVick went into this particular mount before it saw the light of day (well, except, I suppose, for the accelerated UV testing they experienced during that time), Black Collar figured they’d put a mount through a little bit of a torture test, on camera, so we can all see just how strong their Forged Carbon Fiber Scope Mounts are.

First round of testing:

The obvious first step was to mount a scope on a typical firearm setup and beat the crap out of it. As a small company with a [very] small budget, we chose a decent, but budget-friendly scope that retails for $470. To be fair, we were more interested in an indicative aluminum tube here than the clarity of the glass and the precision of the internal turret tracking anyway.

The video above documents the abuse delivered with a 4-lb steel sledgehammer, but here’s the short version:

• After a sideways blow and a couple of vertical blows, the Picatinny rail (scope mount and scope still attached to it) ripped off of the Remington 700 receiver. All four of the steel screws that hold the aluminum rail to the steel receiver, thread locked and torqued to spec as they were, ripped out. Threads were sheared clean off and clean out.

• Next, a pair of 1-5/8″ deck screws were used to mount the Picatinny rail to a railroad tie. Blows to the top of the objective bell stripped the rear wood screw inside of the railroad tie, and a blow to the front of the scope sheared the front screw off — cut it clean right where Pic rail met railroad tie.

• Yours truly then went full ‘roid rage and mercilessly beat the scope against the lumber until the ocular bell physically bent away from the scope tube.

At the end of all of this, the Black Collar Arms Forged Carbon Fiber Scope Mount didn’t seem to care. In addition to the mount itself looking as good as new with zero indications it noticed anything was amiss, the scope had not slid or rotated within the rings. Not a fraction of a millimeter. And remember, I hit the scope directly on the front hard enough to shear a deck screw in half and dent the objective bell something fierce. Not to mention the rest of the abuse.

But the scope still looked far too much like a scope. I was hoping for more of a banana.

Yes, something like that. Much better.

Second round of testing:

It took two, 3.5-inch, high-grade deck screws and finding a rock hard knot in the railroad tie to secure the Picatinny rail sufficiently (sufficiently enough to banana the scope — the rail still came loose!). Here’s how it went down, all in wonderful slow-mo:

My biggest disappointment is that the hits don’t look nearly as hard on video as they felt (and were) in person. Perhaps the way the massive railroad tie jumps and debris bounces into the air is a good “tell.”

Or, sure, the scope banana is a solid indication of solid blows. It is not okay. None of it is okay.

You know what is okay, though? The scope mount. Forged carbon fiber is really strong stuff! It’ll break, yes, but it’s probably the strongest point in your optics mounting system.

So it’s strong. Check. Very strong. It also holds zero like the insanely rigid, grippy little monster it is. You see, prior to the testing seen above I had already internally broken the elevation turret in this scope . . .

As part of Black Collar’s testing before we started selling these mounts, we mounted the scope to spec and shot an accuracy group, beat on the scope with a smaller, softer rubber mallet in every possible direction, then shot another group. And repeated. And repeated.

Despite strong longitudinal smacks to simulate powerful recoil, the scope never slid in the rings. Despite strong smacks to the top of the parallax turret, the scope never rotated in the rings. Despite strong sideways smacks to the objective bell, the mount never shifted on the Picatinny rail. We never lost zero.

Well, until all of a sudden when a sloppy group appeared some seven-or-so inches high. Worried initially that the scope or mount shifted, we quickly found the elevation turret to be inoperable. It spun, but nothing happened internally.

At that point it was Black Collar Arms Forged Carbon Fiber Scope Mount 1, scope 0. Then the mount bested the Picatinny rail screws, then it bested a pair of wood screws, then it delivered the true death to that poor, poor banana scope.

All for science! And glory! And sales! Find your Forged Carbon Fiber One-Piece Scope Mount in 30mm and 34mm ring flavors here.

Wow.

Now you need to take some other rings and bases made from traditional materials like steel and aluminum and do the same testing.

^That. Right there.

The scope, screws, and rail have already proven weaker than the mounts, and are no longer pertinent. Scopes are expensive, and their optical functionality is irrelevant in a strength test.

I’d recommend mounting this and the competing set(s) of mounts to something that isn’t going anywhere (big, thick pieces of rail-profile steel) on opposite ends of scope-diameter barstock. Then move each side up and down, left and right, clockwise and counterclockwise, and axially apart – noting which breaks or lets go first in each instance.

@Jeremy

I guess that answers most of the questions the Conoscente frequenting the site posed when the original article was published.

Impressive!!

I have a set of these as well. For about a month now every day I have put them in the deep freeze at night and taken them out during the day. I can’t shoot anything heavy right now so today I’m dropping them and some .458SOCOM rounds off with a friend to mount on his gun just to put rounds out and shake it up.

We will test these mounts 6 ways to Sunday.

Should have dropped rifle and all out of an airplane like they do to travel luggage or ran over it with a Humvee like they do to the garden hose on TV or set it on fire like Hendrix did to his Strat. Carbon fiber is tough and I see no reason it should not be suitable for scope mounts. No convincing needed here.

Wow! Where can I get one of those hammers?

“Where can I get one of those hammers?”

Any standard Leftist skull will do… 🙂

I might have liked that video when I was 9 years old.

thats out of my price range and that much abuse dish out by me. But there was one time my 7 mag came off pack saddle down on a steep mountain pass, oh the good times. Maybe next year elk in Wyoming

If I had a rifle and optics that cost $10,000 or more, I’d probably spend the $400 plus tax for a set. Let me know when they get down to $50 or so.

Most expensive rings I ever owned were some Warne rings, possibly some Badger Ordinance MAX 50 rings @ $160, but damn they sure were some fine rings. I had to sell both of those sets to raise money. Now I use some cheap Chinese special super sniper rings that were probably made for air soft; they are holding up well on a .308 and shooting hogs. Not bad for $5, but I wouldn’t take them to war, buying a new set of badgers ASAP.

There needs to be a head to head test between this CF mount and a quality mount such as this…..

https://www.milehighshooting.com/spuhr-qdp-4046-cantilever-scope-mount-34mm-0-mil-0-moa-quick-detach/

If Black Collar wants to show everyone how tough their stuff is, let’s see it!

Measure flex too, that kills a quality scope.

Trump/Pence 2020

Yep. Need to show that the cost is worth it. Someone with FU money might buy them to show off but this just shows that their gear can take it. It does not show that they are superior to other products.

This simply isn’t that test. This is a demonstration for the folks concerned that a CF scope mount wouldn’t be strong enough or would be the weak point in your optics mounting system. Clearly this isn’t the case.

We may not do a heads-up destructive sort of test vs other mounts, as there are many great mounts on the market that are also stronger than your scope and stronger than the rail attachment system just like this one is, and getting into a strongest mount on the market contest isn’t of particular interest to us. We’d make a 4-lb hardened steel mount if so haha. What we have here is a mount that’s the strongest point in your optic mounting system, grips your scope securely AF, is likely the stiffest mount going, weighs only 5.2 ounces, and looks great. Maybe there’s a stronger mount out there…but if there is I can’t say that’s a concern to us as this mount is already significantly stronger than it needs to be. The focus of this mount was rigidity and scope retention without excess weight. Our next designs are going to focus more on weight savings as a driving design factor. I’m fairly sure they will not be the strongest of their type on the market, but they will still be much stronger than they need to be and they’ll be insanely, crazy light as well as rigid and, of course, sexy 😉

I have a bit of a problem with this carbon fiber technique being called ‘forged’. There’s no giant hammer or press pounding the material into shape.

Molded or maybe even poured carbon fiber would be more accurate.

And destroying a brand-new 400-dollar scope for an advertisement is pretty much the same as those YouTube channels who buy brand-new 1000-dollar iPhones and destroy them on camera…

Election update, 2PM – Philadelphia :

“Watch: GOP Poll Watcher Denied Entry In Philadelphia Days After State AG Says ‘Trump Will Lose’ ”

https://www.zerohedge.com/political/watch-gop-poll-watcher-denied-entry-philadelphia-days-after-state-ag-says-trump-will-lose

The Leftists are stealing Pennsylvania…

Yeah.

The Reps knew this was going to happen all along.

The demoKKKRats only move is to cheat and steal, it’s all they know!

Not accurate, G. There is a press. The way this is forged is very similar to compression forging of metal, like how an AR15 lower receiver is made. The difference is that, instead of screaming hot metal being placed between two halves of a mold and then pressed into shape under high heat and high pressure, it’s a blob of carbon fiber resin mixture. Being smashed between two halves of a mold is one reason forged carbon fiber is stronger than traditional methods of forming CF, why the carbon-to-resin content is higher, why it can form more precise shapes, etc.

OK , thanks for clearing that up…

I admit there’s some marketing there, but it isn’t a very big stretch 😉

The testing is all well and good, and for the record I like good things and am willing to pay for them. In light of the blows and beatings the mounts were subjected to, however, one would have to wonder what would be left of the rifle they were attached to… Makes for good articles but as far as real world applications I have to wonder.

People wondered if the CF mount would be the weak point in their optics mounting system. This testing was intended to resolve that question.

It would be more apparent that the Rings didn’t slip on the Tube: if “Slip Mark”(TM), also called Torque Seal was used to mark the Tube/ring connection. Its like a thick paint. If the two surfaces shift position the “mark” will crack or become misaligned. I’ve used it for decades so I know at a glance that none of the mounting fastners became loose or scope tube shifted in the rings.

We used dykem and scratch marks. Slip Mark sounds sweet! I’ll pick some up for future use.

Put it head to head against mounts made in the traditional manner, top dollar types, and match blow for blow, hit for hit testing. Running your own test on your product leaves a lot of doubt.

Clearly this is not a test of our mount vs other mounts. This is a demonstration that a CF mount isn’t the weak point in your optics mounting system. When we launched this product, some commenters expressed concern that it might not be strong enough for the application. I don’t think any question remains after it ripped out the rail mounting screws from the receiver, sheared off wood screws, and held up fine while the scope turned into a broken banana. It is NOT the weak part in the system — quite the opposite. This is the takeaway today 🙂

It’s good the mounts hold up when you destroy an expensive I guess. Be nice to have a scope the takes the same level of abuse.

A senseless act of violence

That’s for sure! Haha

Seems to me more like a mostly peaceful demonstration!

LOL

Looks like a waste of money as a mount unless the scope and rail is also carbon fibre.

Who cares the mount is stronger than the scope when your money is in the scope.

The selling features of the mount are extreme rigidity, fantastic clamping surface area and trueness (no scope slipping), no loosening hardware, no zero shifting due to temperature, very light weight, and good looks. Due to expressed concerns about carbon fiber’s strength and whether it’s strong enough for this application, we created these videos to put that to rest. But it’s the zero retention and rigidity at 1/3 the weight of similar (wide ring, thick one-piece base, etc) scope mounts that are the reasons we’re selling them.

Put it in the tube then and kill two birds with one stone. I think you missed the mark on this one.

A forged CF scope tube would be awesome. CF for scope tubes has been done before, most notably by Kruger Optical (see https://www.thetruthaboutguns.com/new-from-kruger-optical-kc8-1-8×24-carbon-fiber-scope/), but I think their main focus was aesthetics (and it’s clearly your typical laid up CF weave tubing, not forged CF). Generally speaking, the aluminum scope tube isn’t typically the weak point in a scope — it’s usually the internals. Most scopes will break internally or at least lose zero long before they become physically damaged externally (as was the case with the scope in this article — the elevation turret completely lost function internally without any damage ever being done to the scope externally, or even coming close to that), so I’m not sure there’s much to be gained from making a super strong tube.

Scopes have a lot going on inside, including lots of small parts, springs, levers, tubes, lenses, etc. Example photos and a cool article on Guns & Ammo:

https://www.rokslide.com/wp-content/uploads/2016/01/SWFA_X5_Rifle_Scope_cross_section_text-1024×731.jpg

https://www.rokslide.com/wp-content/uploads/2016/01/SWFA_X5_Rifle_Scope_cross_section-2_with_text-1024×832.jpg

https://www.gunsandammo.com/editorial/the-anatomy-of-a-scope/248420

Make me one that will mount on an AR10 with full length top rail that has a 20 moa can’t and will clear a 56mm objective and 34mm tube please 😀

Haters are always going to hate…

I say good on ya for doing what you’re doing. Pretty sure that it’s called “the American Spirit”, and what this country was built on. I hope some big outfit sees the bennies of your efforts and cashes you out for a big ol bucket full of green paper! Cool test as well.

Comments are closed.