Blaser Jagdwaffen GmbH is a German firearms manufacturer primarily known for manufacturing high-end shotguns and multi-caliber hunting rifles in the European tradition, including the well-regarded straight-pull R-8. In 1997, when SIG purchased Blaser, Blaser released a police-sniper version of its now-discontinued R-93 action under the euphemistically benign name of “Long Range Sporter” (LRS).

Blaser is a manufacturing firm located in Isny im Allgäu, a town in the state of Badden Wurttemberg, Germany. Blaser shares its factory space with Mauser and J.P. Sauer. For those of you that are not familiar with them, check out their 250-page catalog here. Perhaps more than anything, Blaser is known for its tight machining tolerances. Everything about a Blaser screams precision. This, combined with their nitrided hammer-forged barrels, is the secret as to why they consistently shoot so well out of the box.

Between 1997 and 2014, Blaser produced and marketed one of the most unique and well-designed tactical marksman rifles to hit U.S. shores. And yet it’s still relatively obscure. That’s surprising, since the LRS 2 (and/or a modified and updated version known as the “Tactical-2”) had been adopted by special-operations forces in Germany, Australia, Iceland, Malaysia, the Netherlands, Bulgaria, Slovenia, and Ukraine, among others.

Truth be told, manufacturing a police sniper rifle was somewhat out of character for Blaser, whose roots run deep in the European hunting tradition. So despite this success of the LRS 2 and Tac 2, it appears that Blaser is now moving away from the military/police market, which perhaps reflects the new Germany political thinking towards pacifism.

Overview

There are three unique aspects to the Blaser LRS 2. The most obvious is its straight-pull action based on the R-93. Straight-pull bolts are faster to operate than a conventional bolt action, although training on a conventional rifle can narrow the speed gap. Even so, the R-93 can be made to operate even faster if a left-handed bolt is purchased, and the operator then cycles the action with his or her support hand.

Second, the Blaser LRS 2 doesn’t have a traditional receiver like a conventional bolt-action rifle. Instead, the aluminum receiver block is located underneath the barrel and bolt-assembly group. The receiver block cradles and beds the barrel, and contains internal rails that host the bolt-assembly group.

The receiver block also houses the trigger assembly. As a result, the radial bolt locks directly into the barrel shank, not the receiver. This allows the Blaser to be about four inches shorter than a conventional bolt-action design. Because the aluminum receiver is not subjected to recoil stresses, the Blaser is lighter than a conventional bolt gun.

Third, the Blaser LRS 2 is the ultimate modular multi-caliber platform; barrel changes can be accomplished in about a minute, depending on your degree of proficiency. One minute you have a .223 Remington; the next you have a .300 Winchester Magnum. Scopes will mount directly on the barrel, so there is no need to re-zero the rifle when you change barrels /calibers. This is an optimal set-up for a takedown rifle as well, since the LRS 2 can be stored and transported in a disassembled condition.

Bolt Assembly

The Blaser’s bolt isn’t a standard bolt-action design that requires the traditional 60- to 90-degrees of upward movement to unlock the action. Blaser’s straight-pull bolt has some outward passing similarity to a Schmidt Rubin K-31 or a Steyr M95. However, the Blaser is unique insomuch as it uses radial locking lugs instead of the rotary lugs found on the K-31 or M95.

Unlike the older European designs, the Blaser’s radial locking lugs collapse (unlock) and expand (locked) into a radial recess in the inside wall of the barrel’s shank. Once expanded into this barrel recess, the bolt is locked in place.

Besides providing a solid lock up, the radial lugs also pull the bolt head into perfect alignment with case head and bore axis. The bolt head is free-floating, so it self-trues into a concentric position in the bore. This design largely accounts Blaser’s phenomenal accuracy: the radial lockup distributes stress through a full 360 degrees of contact, resulting in greater system strength and durability.

Whereas a traditional bolt action unlocks by rotating the bolt up in a counterclockwise motion, the Blaser’s bolt handle rotates back approximately 45 degrees aft to unlock the bolt. Once unlocked, the bolt handle carries the entire bolt assembly to the rear to extract and eject the spent casing. Pushing the bolt forward will chamber the next round from the box magazine.

One word of caution about what I consider to be one of only two design flaws with the LRS 2: You can experience a misfire if the bolt isn’t pushed forward completely to its locked position. If you push the bolt lightly forward, it may appear to be locked when in fact it is not. When in this condition, the firing pin will drop when you pull the trigger, but if the bolt is not locked, the firing pin will not reach the primer, and all you here is a “click.”

To correct this, you need to be sure to push forward on the all the way and then pull the trigger a second time. I don’t mean to overstate the point, as it has only happened to me a few times in 12-plus years, but it’s a training issue.

The Manual Safety

The safety system on the Blaser LRS 2 is used to cock and release the firing spring. The safety catch is mounted on the rear of the bolt and reveals a large red dot when pushed forward. When the safety is released, it locks the bolt so that it is not accidentally opened during transit.

I mostly shoot this rifle on a range, so I confess that I rarely use the Blaser’s safety. Instead, I open the bolt. When on the few occasions I have used the LRS 2 to shoot coyotes at long ranges, I have used the safety. It’s a bit less intuitive than a conventional cross-bolt or lever safety, but again, once you get the hang of it, it’s easy to disengage and reengage.

Barrel, Scope Mount and Muzzle Brake

Simply stated, Blaser hammer-forged barrels are superlative. The barrel’s chamber, rifling, and internal locking recesses are all created as part of a single hammer-forging process. As a result, there’s no need to hand-lap, deburr, or break-in a Blaser barrel.

Once finished, Blaser barrels are subjected to a gas plasma nitride process, which makes them much harder than a typical precision-rifle barrel. In fact, gunsmiths have told me that Blaser barrels are more of a PITA to thread because they are so hard.

Many gunsmiths have found out the hard way that the Blaser barrels will ruin carbide tips. Blaser USA has also experienced barrels getting destroyed by gunsmiths who are not familiar with working on this type of hardened steel. At some point in the production run, Blaser started making capped threads a standard feature, so this is not a concern. Thread pitch is metric: 18×1.

The Blaser LRS 2 barrels are equipped with notches which are designed to accept Blaser’s excellent “Quick-Detach” (QD) saddle scope mounts. The saddle mount allows scopes to be mounted low to the bow axis. These return-to-zero mounts work as advertised: The operator can detach and reattach a scope without losing zero. Of course, there is little need to do this, since the scope is attached to the barrel and not the receiver.

Most Blaser users will permanently mate up a scope with each barrel, so that caliber changes can be accomplished without re-zeroing. A Picatinny rail mount (with 20 MOA of cant) is also available.

The barrel also includes two screw studs which are what holds the barrel to the receiver. Unlike many rifles, the Blaser is not very sensitive to variations in screw tightness: No specific torque setting is required for the barrel’s cap screws. The operator need only hand tighten the barrel screws with the supplied T-handled Allen-head wrench.

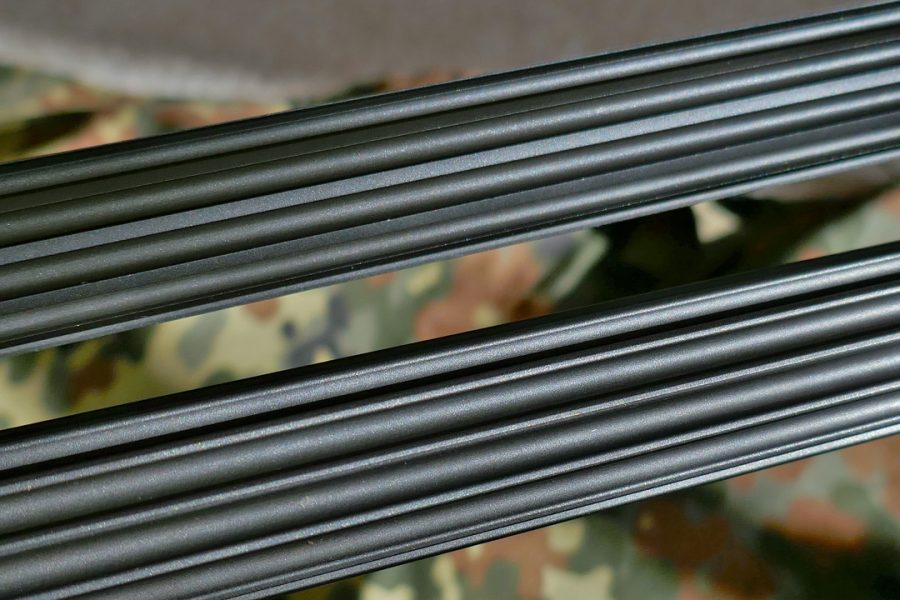

The barrels are also fluted in Blaser’s signature style, which is a cut above anything else I have ever seen. Note that the fluting has changed over the years: The top barrel in the photo above is circa-2010 production, whereas the bottom barrel is an older design (circa 2000) with more complex machining.

The flat-bottom, four-chambered muzzle brake is one of the most aggressive brakes on the market. While very effective it is extremely loud. It does a great job of reducing dust signature. Also visible in the photo above is the screw stud which acts as the front post for the mirage band.

The Blaser brake is thread-on design. When attaching it to the barrel, it the requires manual timing with an Allen wrench, which is a three-handed operation that requires two bubble levels. Older LRS 2s used a variety of different brakes, including the Sako TRG brake. Mine initially came with this unique brake design:

There is a downside to the Blaser barrels: they are very expensive at $2,200. But Blaser does not pretend to be a value play. Rather, Blaser produces high-end gear for discriminating customers. These barrels will last much longer than a typical precision-rifle barrel. Blaser reps have told me that they do not even know what a typical barrel life is because they have seen .308’s shooting sub-MOA with 35,000+ rounds down the barrel. My original Blaser LRS 2 has roughly 10K rounds downrange with no appreciable firecracking in the throat.

Chassis

Aside from the straight pull action, the LRS 2 polymer chassis may be the second-best reason to acquire this rifle. It is both extremely lightweight and highly adjustable, while maintaining extreme rigidity. It is also thermally stable over extreme temperature variations.

The chassis features a vertical handgrip, which is preferred by European shooters but often derided by American shooters for reasons I do not understand. The vertical pistol grip is much more ergonomic than a typical fudd gun stock when shooting prone and from a bench. The large target-style endcap can be used in conjunction with a shooting bag. In terms of adjustments, the chassis offers the following:

- Length of pull can be adjusted from 13.75 inches to 11.75 inches via the use of four .5-inch removable spacers;

- Buttplate is adjustable vertically, and locks with a thumb wheel.

- Comb height can also be adjusted vertically over a one-inch, and is locked into place via a star-head thumbscrew.

The chassis also contained four integral QD cup mounts — two on each side of the rifle. The chassis fore-end contains an integral UIT (Anshutz) rail for a bipod or other accessories, which is tapered into a wedge shape. When combined with the flat bottom, it is easy for the operator to make elevation corrections by simply sliding the fore-end forward or back on a rest or backpack.

Box Magazine

The Blaser LRS 2 is fed via a detachable five-round single-stack box magazine. It’s held in the rifle by two releases located on either side of the magazine. The magazine is one of the more controversial aspects of the LRS 2. It’s a complex design which costs $210 a pop. Moreover, the five-round capacity is somewhat limited for competition use. To my knowledge, no higher capacity mags are produced. Beyond that, however, the feed lips are also unique insomuch as they move up and down within the magazine to assist the bolt assembly in stripping off each round.

The main problem here is that you really have to be gentle when you seat the magazine into the rifle, because the top round or two will spill out of the rifle if you smack the magazine into place with too much force. You can avoid this problem by loading the magazine on a closed bolt. Nonetheless, this is a commonly cited complaint with the LRS 2, and from my experience, it’s a legitimate issue.

Trigger

The LRS 2 adjustable single-stage trigger is — to be succinct — simply magnificent. No creep or overtravel; it’s a proverbial glass rod. It is set at the factory at 1200 grams (2 lbs, 10 oz). The pull weight can be adjusted up or down, but I have never bothered to do so. Even better, you can adjust the trigger position forward or backward so that it indexes perfectly with your finger pad. You can also adjust the trigger for overtravel. If you prefer a two-stage trigger, the factory can accommodate this request.

Mirage Band

European police marksman rifles are usually equipped with a mirage band, and the Blaser LRS 2 is no exception. These accessories are probably are not mission essential in the vast majority of applications, but they do look really cool at the range (for whatever that’s worth!)

Buttspike

It seems that the general consensus in the long-range shooting community is that monopods are lame. However, I have always found the Blaser buttspike to be a very useful feature. You adjust the gross travel with a large knob located on the right side of the stock. Fine elevation adjustments are then made by manipulating the screw located at the bottom of the spike. I’ve had great results using this system, especially when compared to other monopod designs. There is no wobble, and it is easy to fine tune the elevation adjustment very precisely.

Accuracy

The LRS 2 is known for its outstanding accuracy, and is one of the most consistently accurate factory precision rifles when using factory production ammo. In fact, the Blaser LRS 2 was specifically designed to be exceptional accuracy using factory ammo such as Federal Gold Medal Match.

In my personal experience, the Blaser will consistently shoot ¼ to ½ MOA groups at 100 yards using factory ammo, and will maintain MOA accuracy or better out to 1000 yards. Of course, that is not to say that I can consistently shoot 10-inch groups at 1000 yards with my Blaser. At that distance, a lot of other variables come into play, and, as a result, it is clear that the rifle shoots better than me at such extended distances. YMMV.

Having said that, the photo above shows a nice six-shot group that I shot prone under field conditions at 900 yards using Hornady Precision Hunter Ammunition (178-grain ELD). You can see five shots clustered within around six inches, with some lateral dispersion which I assume was due to the wind. I was holding ¾ MIL for wind, and I dialed 9.2 MILs of elevation. One shot dropped a bit low compared to the rest of the group.

Here is what I would consider a typical three-shot, 1 inch (+/-) group at 300 yards with factory Hornady 168-grain BTHP match ammo:

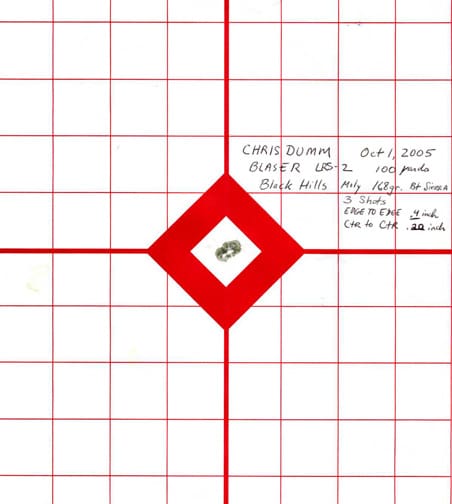

My buddy Chris Dumm (former TTAG writer) shot the LRS 2 for the first time in 2005, and he managed to turn in this three-shot group with his first three rounds at 100 yards:

Now, I can’t always match that group with the factory ammo I use (Black Hills, Hornady Match, Federal GMM etc.). Having said that, the vast majority of my 100-yard three-shot groups in that ¼- to ½-inch range. Over the years, I have turned in a few “one-hole” groups like this one with Hornady 168-grain BTHP Match ammo:

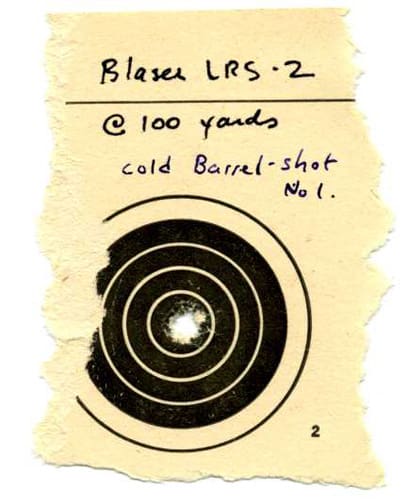

Needless to say, this gun will shoot better that most everyone who gets behind it — myself included. One thing I really appreciate is that it shoots cold-bore shots to the same POI as the rest of the groups.

Reliability

In the 12 years that I have owned this rifle, I have never had a reliability problem of any sort. Earlier this year, I did find out that Nightforce 34mm rings were not compatible with the Blaser Picatinny rail, because the spent shells would hit the bottom of the Nightforce rings and bounce back into the action. I switched to the Spuhr mount and no longer had issues.

There have been a few well-published incidents where Blaser R93 LRS2 actions have had “kabooms,” resulting in serious injury to the shooter. While the internet commandos are all over the map on the facts of these cases, everybody seems to concede that all of these incidents involved reloading ammunition or other user-error issues like shooting the wrong caliber ammo through the rifle. Like anything, you can certainly screw up any rifle brand design if you try hard enough. Nonetheless, every Blaser is proof-tested by one of the German government proof houses.

Conclusion

The Blaser LRS 2 isn’t perfect, but it’s pretty close in so many ways. On one forum one Blaser rifle owner sarcastically stated: “The only thing I don’t like about them is they shoot so well you don’t get to tinker with them. What’s fun about a gun you don’t have to glass bed, have a trigger job done yada, yada.” True that.

The Blaser LRS 2’s combination of James Bond cool looks, superb accuracy, and modular flexibility make it one of the most interesting and collectable police marksman rifles available in the United States.

There’s one other aspect that recommends the Blaser: resale value. Souping up a Remington 700 is a bit like turning a Honda Civic into a boy-racer: Why not just buy the Porsche and be done with it? A Blaser retains its value much better, and, now that the R-93s are no longer in production, one should expect the price of these rifles to gradually rise in the coming years as collectors start gobbling up examples in NRA 95 percent or better.

Specifications – Blaser LRS 2:

Caliber: .308 Win. (7.62x51mm NATO) [as tested]. Also in .223 Rem., 6mm Norma, 6.5 x 55 Swede, .300 Win Mag. etc.

Action: Straight Pull bolt action, Radial Locking Bolt

Overall Length: 45 inches

Weight: 10 lbs, 9 oz. (unloaded with empty mag, no scope)

Barrel: Chrome-Molybdeum-Nickel-Steel, thermally distressed, fluted barrel. 1:11.25 RH twist\6 grooves

Barrel length: 24¼ inches.

Magazine Capacity: 5 rounds

Price: Seen on the web for $5000-$7500

RATINGS (out of five stars):

Accuracy: * * * * *

The Blaser LRS 2 ranks amongst the most accurate factory-production precision rifles. They’ll go toe-to-toe with Accuracy International, Sako TRGs, Steyrs, as well as high-end custom rifles.

Ergonomics: * * * * *

The highly adjustable stock makes it possible to get the Blaser LRS 2 to perfectly fit most shooters. The stock spacers require a bit of time to swap out, but the design criteria placed a preference on weight reduction over quick adjustability.

Reliability: * * * *

One star off for the possibility of not fully lock the bolt and mag dumps if seated too aggressively into the mag well. Both can be overcome with a bit of training.

Durability: * * * * *

I have owned and shot this rifle for more than 10 years with no issues.

Customization: * *

This is no Remington 700: Aftermarket support for the platform is limited.

Collector Interest: * * * * *

Because of their relative rarity, Blaser LRS 2 and Tac II rifles (both variants are based on the Blaser R93 design) hold their value much better than many comparable precision rifles.

Overall: * * * *

The Blaser LRS 2 will turn heads at the range and has the accuracy to match its good looks.

More from The Truth About Guns:

[VIDEO] Blaser’s New R8 Ultimate Rifle With Tool-less Adjustable Stock at the Dallas Safari Club

Jeez Joe, that was a bit to digest in the morning but thanks again for the usual diligence. Although I have only handled them vicariously through folks like you I have come to appreciate the Blaser straight pulls. Maybe one day when my ship comes in…:-)

Awesome review!!! Loved it 🙂

An excellent article that makes me want one. And I didn’t even know this rifle existed before I reading your piece.

BTW – it’s ticky tack I know, but the text “While the internet commandos are all of the map”, the word “of” should be changed to “over.”

I’ll make the edit. Thanks.

I’ve had the pleasure of shooting That particular boom stick.

It’s almost boring in its accuracy. Then you realize you’ve got a sh!t eating grin going because you are hitting everything you aim at.

My compliments on the very high quality photos. The Columbia Gorge makes a great backdrop for anything, in my opinion!

Any piece of metal that has been nitrided/nitrocarburized/Tennifered/insert brand name here, can (and usually will) destroy carbide insert tooling or even solid carbide tooling when attempting to machine it. It used to be that we gunsmiths only had to worry about chrome plated bores, which would destroy a high speed steel (HSS) reamer or other tooling. We’d usually we’d run into chrome when chambering a barrel or setting a used barrel forward a turn to take out the wear. A carbide reamer would then be obtained and we could handle the chrome, no problem.

But that ain’t gonna hack it with nitrocarburized finishes.

I’ve had several customers come to me with rifles (and one pistol) they wanted threaded for cans, and I’ve turned down their work because they had a nitrided barrel. All of them were disappointed and couldn’t fathom how this could be. I even had one come to me after another gunsmith discovered how hard nitrocarburizing can be, seeking for me to set things right after a job was started on his muzzle that destroyed the other gunsmith’s tooling – and left a mess on the outside of this person’s barrel. Well, sadly there’s nothing I can do about it either, because I’m not about to invest the big bucks in diamond tooling to deal with this stuff.

If you want a barrel nitrocarburized (and getting it done can extend bore life, according to studies made of the issue by benchrest shooters), get it done after you’ve had all the machining you’ll ever want done on the barrel completed.

I bought this rifle after firing it at SIGARMS Academy 5 years ago in 308WIN. The only ammo I’ve put down the barrel is Federal Gold Match BTHP 168gr Sierra bullet. Put a NF scope on it and had the opportunity to shoot it on the NRA’s Whittington Center silhouette range to 1,000 yards. Accuracy is unbelievable with this system; a truly great rifle!

Technically, the factory is located in Baden-Württemberg, not Bavaria, but very close.

I briefly considered a Blaser LRS before going with the Accuracy International AXMC. The AXMC may be several thousand more initially, but it’s actually possible to get a 6.5 Creedmoor barrel for it and 338 Lapua is a bit of a barrel burner so at about $800-900 per barrel, it’s actually more palatable than the Blaser.

But the biggest reason was the magazine issue… AI mags are legendary and they offer 10 round capacity! 5 rounds in a Blaser would be perfectly fine for range or even hunting use… but would really limit you in PRS competitions.

An absolute gem of a firearm, other than the obnoxiously loud muzzle brake. I completely agree that the gun has better resale value than all of the Remington 700 mods. Unfortunately Rem 700 upgrades are a lot cheaper and easier to deal with. If I had a spare $6-7K for a gun and $6-7K for a sweet S&B scope, I’d get one.

In my experience these are more accurate than the Sako TRG.

This is a very good thorough article. If anyone is interested I do have a .308 for sale… with a left hand bolt and right side ejector. As Joe mentioned these are getting difficult to find since they are no longer made. If you search backpage.com for “LRS2” in the Phoenix area you can find the ad and get a hold of me.

Very thorough and honest review. Not a rifle I’ll ever own, but quite technologically innovative and interesting, As always, first-class writing and superlative photographs from Joe Grine. Thanks for sharing your expertise.

While evidently not the exact same rifle, the Blaser Tactical 2 can be had for $4500. The accuracy of the above rifle is beyond reproach but I don’t see them or the Tac 2 at PRS or F-Class matches.

i have the LRS (I guess it’s like the WW) until there was two there wasn’t a designation.

I absolutely love this rifle, when first announced I was on the prowl for it.

It’s serial number I believe is 47 it might have been originally intended as a trial in the US, I really don’t know. I especially like that it is a 10 round magazine and I’m I bought a couple I suspect another is impossible at this point.

Gear up as your favorite Delsin Rowe Vest. Slim Fit Leather Jackets brings this iconic jacket from animation to reality, especially for all the fans of this video game. Delsin Rowe is the main protagonist and playable character, a young Native-American man who later realizes he’s a Conduit with special powers.

Truth be told, manufacturing a 24 hour fitness cost

police sniper rifle was somewhat out of character for Blaser, whose roots run deep in the European hunting.

This is truly a good gun for hunting

Chick-fil-A has a new menu on their website. It’s really good! They have yummy sandwiches and tasty nuggets. The website is easy to use. Look at it and you’ll want Chick-fil-A all the time.

https://chickfilamenu.org/

Comments are closed.