By AT3 Tactical

The AR-15 upper receiver (often simply referred to as an “upper”) holds and protects many of the most important components on your AR-15.

There are many types of uppers on the market, and it’s vital to understand the differences between uppers when building or buying an AR-15.

Different Types of AR-15 Uppers

Your receiver will be either a “flat top” or a “carry handle” upper.

The flat top has a Picatinny rail on the top of the upper, while . . .

Carry handle uppers feature a fixed carry handle on the top of the upper. (Note: the carry handle doubles as a rear sight assembly, so you probably shouldn’t use it to carry your weapon).

You’ll often hear of receivers referred to as being A1, A2, A3, or A4 receivers. We have a great article that explains this in detail, but generally the big difference is flat top vs carry handle.

The other big consideration is the forward assist button. Some uppers have them, some don’t. It’s debatable whether this button is really necessary for most shooters, but just remember all military M16 and M4 rifles have them for a reason – a tap on the forward assist will assure that the bolt is fully forward and seated in battery.

So which upper is right for you? We recommend a flat-top upper with a forward assist for most AR-15 builds – the Picatinny rail provides versatility (you can always add a carry handle to a flat top if that’s your thing), and it’s the most popular style of upper, which means that they’re cheap and plentiful.

Upper Receiver Construction: Forged, Billet or Cast

Upper receivers can be made from various metals, but aluminum is by far the most common. Beyond the material being used, the construction of the upper is determined by the manufacturing methods used.

Forged Upper Receivers

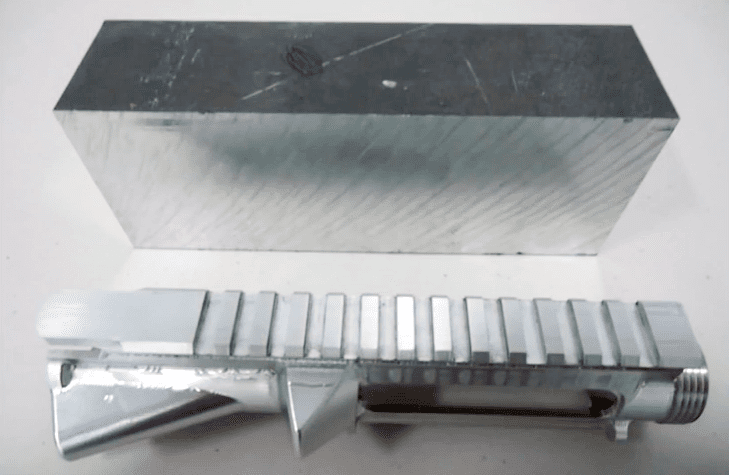

Forged metal uppers provide the ideal grain structure or orientation that produces the best mix of mechanical properties like hardness, fatigue limit, specific weight and others, but they’re denser and heavier. A forged upper is created by “forging” (hammering) the upper into the proper shape and then typically it’s finished on a CNC machine.

Billet Upper Receivers

The billet receiver is made by milling a solid hunk of metal with a CNC machine until it’s the proper shape. Billet metal has similar mechanical properties to forged, but they’re generally less dense and lighter at the expense of a little strength in the material.

Cast Upper Receivers

Cast metal is the lightweight of the group, but it also offers the least amount of relative strength. But since it’s usually the lightest upper, sometimes cast is more than “good enough.” Cast uppers are made by pouring molten metal into a form (also known as “die casting”). Typically some finish work is then done with a CNC.

Stripped vs Complete Uppers

A stripped upper consists of only the upper receiver itself, basically a shell that needs to be completed.

A completed upper will come with the ejection port door and the forward assist button installed.

You will also see “complete upper assemblies,” which include the completed upper along with the charging handle, barrel, handguard, and possibly the bolt carrier group.

So basically, the stripped upper is a single part – the upper receiver. A “complete upper” will include a few more parts. And a complete upper assembly is a full upper-half of an AR-15 rifle. Just attach it to a lower receiver and it’s ready to fire.

One Last Tip

If there’s anyone that knows the AR-15 platform, it’s the US military. As a special offer for our readers, you can get the Official US Army Manual for AR-15/M4/M16 right now – for free. Click here to snag a copy.

This article was originally published in AT3 Tactical AR Academy and is reprinted here with permission.

“the stripped lower is a single part – the upper receiver.”

The lower is the upper? Really? 🙂

Joking aside you really should fix this. It could cause a lot of confusion for newbies…

You forgot the magnesium “break into pieces when you least expect it” receivers.

If I made an AR type rifle, I make it exactly like an m16, then I’d throw it in the river cause they ain’t worth a —-

Let me guess…. the ideal rifle is the M14, you carry a 1911, and you drive a Ford or Chevy?

Keep in mind he could be an AK loving commie!

Which is based

Hey …wait a minute! I carry a 1911 …but I love my Daniel Defense DDM4! LOL

He must drive a yugo & with a title like that , must be a COMMIE.

Likely just living in 1983 some forment NCO sold him on the “made by Mattel/Tonka/lowest bidder.

In an article like this it’d be smart to mention feed ramp compatibility in the upper receiver with the feed ramps in the barrel extensions.

Doesn’t matter to them. This is an advertisement for AT3. They only sell flattop M4 receivers.

The only thing a forward assist is good for is making a feed problem into an unclearable jam and a worthless club.

“typically it’s finished on a CNC lathe.”

I think you meant CNC mill.

Well, it would certainly be “finished”.

LOL!

That was good Mr. Taylor!

I’d be willing to bet the threads are done on a lathe.

Casting imperfections could be ground off.

So you could do it without a mill if the casting is good.

And as a comparison what type of upper is used on a Colt or FN AR15/M16?

I also refer to the early models without the forward assist as ” slick-side” upper receivers.

Unfenced lower receivers are known as “slab-side” lowers. There were also “partial fence” and “full fenced” powers to describe the fencing around the magazine eject button.

Now they have “NFA” (No Forward Assist) uppers with the picatinny rail and case deflector only. We live in interesting times.

*Aero and a couple other companies make them.

I’ve used them on a couple of lightweight “toy” builds as well as a dedicated .22 LR upper.

I like them. That forward assist is solid steel and weighs a surprising amount.

Colt uses whatever stock they have on hand to make their civilian AND military guns, and there are certain model numbers that seem redundant. The original Colt AR15 SP1 introduced to the American civilian market in like 1964(?) had a slick-side upper and slab-side lower. In the early 80s when they introduced the AR15A2 it had a partial-fence lower and an A1E1 upper, with A1 sights but a case deflector like the A2 (same as the one used on the Canadian C7 rifle and various M16A2 Carbines and M16A2 Commandos used by special operations forces). Later AR15A2s had the complete M16A2 upper and full-fence lower, but it was still kind of a mixed bag. Then the AR15A3 came out in the 90s and all of those either had M16A2 uppers or M4 flattop uppers. After they started on the XM4 project in the early 80s they started cutting the extended M4 feed ramps in all of their carbine models. MT- and CR-series 20″ rifles had flattop M16A4/A3 uppers without extended M4 feed ramps, but the MT and CR carbines had M4 feed ramps. Then, about 5 years ago, after many years of other companies making 20″ barrels with M4 feed ramp extensions, Colt introduced the AR15A4 with a 20″ barrel with M4 feed ramp extensions and flattop upper to match with those feed ramps. Now Colt has pretty much switched all production to M4 uppers (plus their proprietary stuff like the ACC-M/LE6940), but if someone did order M16A4s again it would be a simple matter of just not cutting the feed ramps before anodizing, or delivering them with AR15A4 uppers.

There is NO reason to buy a carry handle upper. Even if you are cloning a period correct M16, you are still wrong.

What about a service rifle match?

Flat top with carry handle is allowed in service rifle.

Also, since they allow optics in service rifle matches, a flat top is needed if you want to use an optic.

So like Lowell says. there is NO REASON to buy a carry handle upper anymore.

And there is NO REASON you telling me there is NO REASON. I happen to like the convenience of a carry handle. So put that in your pipe and smoke it.

they’re hella sexy. that’s the only reason i need

This unnecessarily complicates things.

First lets eliminate most of many choices.

No cast uppers. Period. The upper is where it all happens on an AR. Cheap out on the lower if you want. But spend the extra $10 for forged.

Second, no carry handle uppers. Flat top only. If you like the look of a carry handle, buy one and put it on your flat top.

That leaves us with only 2 choices. Forged or billet. Very simple.

In most cases billet is just bling. So if you want to spend extra money for a rifle that looks cooler. Go for it.

There. Done. Buy a forged flat top upper.

Don

So who are you, the reincarnation of Eugene Stoner?

What’s with the ads for AT3 lately? Is their stuff any good, because their articles are just meh…

I carried the M-16 throughout my tour in Vietnam, and for the rest of my 21 year + career in the military.

I happen to like the carry handle. Never did it cause any problem with the sights. The rear sight is actually protected by the carry handle, and is recessed with a spring loaded pin to keep it from shifting. The front sight is treated the same way. On top of the carry handle, we mounted a scope or a NOD (Night Observation Device aka Starlight Scope) on top of the carry handle.

I have an AR-15 with a removable carry handle, as well as a number of additional flat top uppers in various calibers for a variety of uses, each with it’s own optics/sights.

Some years ago, a hot-shot gun writer wanted to be clever and gain some reader attention, so he sneaked in the word “billet” when he was describing an article that was made from aluminum alloy “bar stock”. Ever since then, it’s been billet, billet, billet, ad nauseam. Well, the fact is you can’t buy a billet of an aluminum alloy from your favorite metal supplier, because they don’t stock it. Yes, there is such a thing as an aluminum alloy billet, but it is an intermediate form used in the mill when turning an ingot casting into salable products (e.g. sheet, plate, bar stock, forgings, pipe, etc.), but it doesn’t leave the mill. PLEASE, NO MORE BILLET!

Comments are closed.