The body armor market has been an explosion of innovation in the last 30 years. There is such a wide variety of new materials, from Kevlar and Aramid fiber soft vest designs to new Ultra High Molecular Weight Polyethylene (UHMWPE) plates, that there is always something new to experiment with. With the recent AR500 craze in reusable steel targets, many shooters immediately made the obvious logical leap to using ultra-hard steel as body armor (although the idea of using metal plates as body armor isn’t exactly new). The main problem with that is that steel, unlike Polyethylene or ceramic compounds, is extremely heavy, which makes the already uncomfortable task of wearing body armor even more taxing. But AR500 Armor has developed some new lightweight plates which deliver excellent protection in a slim profile, and I shot the crap out of them to see how they stack up . . .

AR500 Armor, an Arizona-based manufacturer of hard and soft body armor, recently debuted their new lightweight line of Level III+ hard armor plates, which sport a Special Threat rating that defeats a wide array of common (and uncommon) threats. It’s important to note that despite the company’s name, these plates are not made of AR500 steel. There’s simply no way that 3/16″ AR500 could stand up to six shots of .308 Winchester at 25 yards without significant cratering and deformation (and possibly failure). During a phone call with the manufacturer after field testing, a product specialist confirmed that these plates are a proprietary super-hard steel alloy with no metallurgical similarities to AR500.

Even though the steel core making up the heart of these plates is only 3/16″, the plates themselves are closer to 1/2″ thick, which is still slim for a hard armor plate of this threat rating.

The Paxcon anti-spalling buildup covering the plates is a rubbery, hard material. It’s applied over the entire plate, but these particular units had an extra “buildup” coating applied to the front, which I’ll discuss in depth later on. For those interested, Paxcon shares its heritage with Line-X spray-on truck bed liners.

Before moving on, I’d like to address the lack of stickers in the review photos. Although the plates came with front and back stickers indicating the strike face and other information like date of manufacture, NIJ threat rating, and shelf life, the early production run plates I received had stickers which were not up to par with AR500 Armor’s quality standards. As a result, they failed to adhere to the plates in 103F gusty Nevada weather. To prevent the stickers from littering the desert, they were removed for the duration of testing. AR500 Armor has assured me that none of the stickers on consumer plates have these issues.

Testing

Unlike other gun-related products like ammo and even guns themselves, there are very strict performance standards body armor manufacturers have to meet in order to legally brand their product with a National Institute of Justice (NIJ) threat rating. An ammo manufacturer can claim their product is “match” quality, but nothing happens to them besides attracting bad publicity when customers find that it’s actually a minute-of-barn performer. Conversely, if the NIJ discovers that a certain type of body armor isn’t meeting performance criteria, they will decertify the armor and issue a recall. Just ask the makers of Zylon armor how it went when their products failed in the field.

Our testing fell into two categories: subjective and objective performance. While the plates stopped certain rounds and succeeded at containing spalling in some cases, body armor selection involves more than just ballistic performance testing. Whether you can wear a plate all day, how many hits it will withstand, shelf life, and weight are all important considerations which can make a body armor that looks good on paper fail in the field.

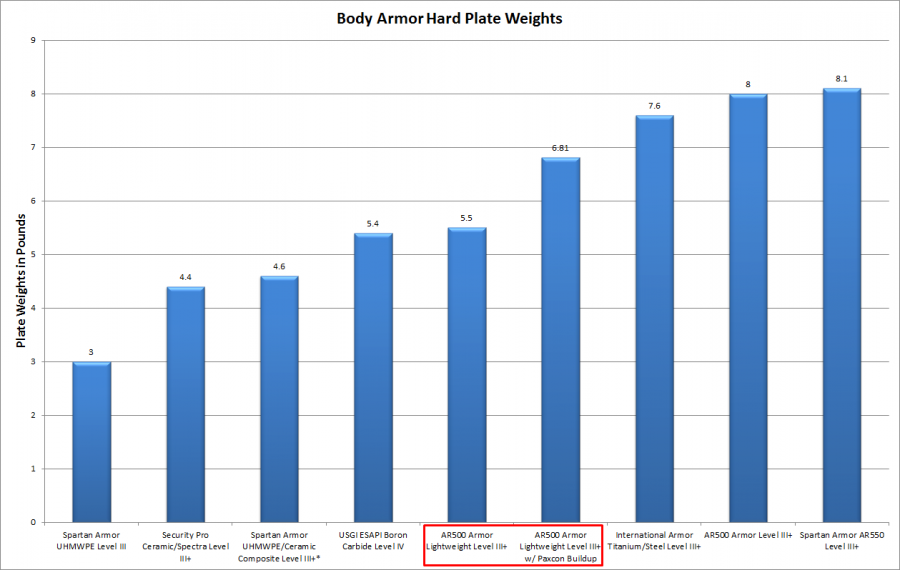

Weight

Aside from verifying the manufacturer’s weight claims, weight can provide insight into the consistency of the Paxcon buildup layer, since a heavier plate will have more than a lighter one. The manufacturer claims a +/-5% weight tolerance due to variances in the Paxcon coating.

Plate 1: 6.81 lbs

Plate 2: 6.78 lbs

The plates I received weighed almost exactly the same. That’s good because it means the Paxcon buildup layers are consistently applied. This also means that a potential wearer wouldn’t experience any additional fatigue from having one plate noticeably heavier than another in a front/back plate carrier setup.

For subjective testing on whether the combined weight of two plates was tolerable, I loaded the plates up in my PIG Plate Carrier and walked 5k in desert heat (~103F on the day in question). I found that the weight wasn’t unreasonable and didn’t add any undue fatigue, although having a well-padded plate carrier undoubtedly helped in this regard. I know the former infantry guys reading this are laughing at the idea of only carrying ~13.6 lbs, but I had to start somewhere.

Despite being tolerable on a 5k walk on flat terrain (which is pretty light work compared to any professional usage scenario), the weight has to be taken in context with other plates on the market to mean anything.

I compared the weight of these plates to several others and then graphed the data for an easy visual comparison. The comparative weights below were taken from manufacturer advertised data. The AR500 Armor Lightweight weights were my actual data.

When the weights are graphed, it’s striking how much weight the Paxcon buildup layer adds, increasing the weight of the plate almost 20%. That’s a significant addition just for the purpose of containing spalling. The buildup layer is actually so thick that it more than doubles the width of the plate, going from ~0.22″ (including the thin back Paxcon layer) to 0.53″ with the buildup. The Paxcon buildup layer is actually thicker than the plate itself, coming in at about 0.31″; for comparison, the Paxcon coating on the back of the plate only measures a paltry 0.005″.

Coverage

These plates are lightweight in part due to their reduced footprint. Compared to a normal SAPI cut, which is a fairly universal shape for hard armor, these plates have more material removed from the corners. This forms what AR500 Armor calls their “Advanced Lightweight Shooters Cut,” or ALSC, which incorporates a single curve along the plates’ vertical centerline to better-fit the wearer’s body. This shape is advertised as allowing for greater freedom of movement compared to SAPI cut plates.

After doing the math to figure out both plates’ surface areas, I came up with the following:

SAPI Cut: ~95 in2

ALSC Cut: ~86 in2

Compared to regular SAPI plates, the ALSC cut covers about 9% less surface area. For those wearing some of the more modern plate carriers which rely solely on the front and back plates for protection, this reduction in coverage may or may not be acceptable considering the weight trade-off. I’ve never experienced any mobility issues wearing a modern plate carrier with SAPI plates, but I also don’t work on a two way range for a living. Those who do likely have their own opinions regarding weight/mobility/coverage.

Shooting

This is the part everybody came here for, right? Besides penetration, a significant concern when dealing with hard armor plates is spalling, which occurs when a bullet impacts the much harder steel or ceramic plate and then breaks into many high velocity pieces going in all directions, including toward the shooter’s face.

Steel armor manufacturers have turned to several different techniques to combat spalling, but the most popular is applying a thick, rubber-like coating to soak up as much as possible and prevent it from injuring the wearer.

Unlike soft armor, which requires a backing to evenly distribute energy and prevent bullets from punching through the fibers, hard armor remains viable without any backing or support whatsoever. The only exception to this is plates labeled “in conjunction with,” which require a Level II or III supporting vest to deliver their stated level of protection. Notably, H.P. White performed their certification of these plates without any backing.

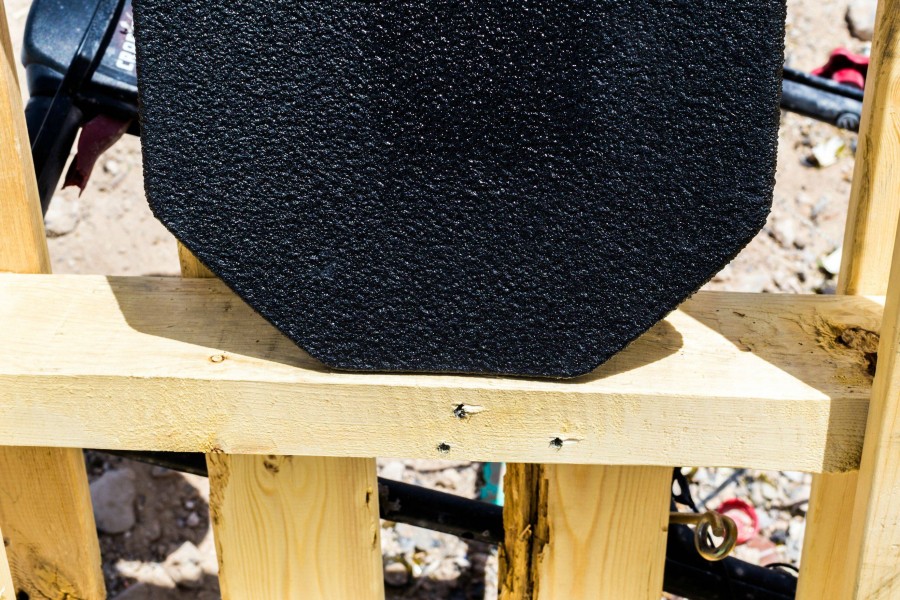

These plates are rated as standalone Level III+, so there isn’t any additional vest to worry about. In true KISS fashion I used an old pallet as a test stand. This provided points of contact on the bottom and two sides, allowing for a fair amount of support.

5.56x45mm M855 Mild Steel Core

One of the main selling points of this armor is its “Special Threat” rating, which specifically defeats 5.56x45mm M855 mild steel core ammo. AR500-based armor usually has difficulty defeating this round at close range, so I was eager to see how the plates would stand up.

Note: These tests were performed at close range and used several methods to prevent ricochet-related injuries. NEVER shoot steel targets or body armor at these ranges. Serious injury or death may result.

The test shots were fired from a bone stock S&W M&P-15 sporting a 16″ barrel from a distance of 25 yards. I’d never tested the Paxcon lining before and didn’t know how effectively it would contain the steel core fragments, so with other precautions in place (such as barriers and a little Kevlar), this seemed like a good starting distance.

The individual who was gracious enough to lend me their rifle hadn’t zeroed it, and this became evident in my struggle to get on target. Despite a bit of embarrassing shooting, I eventually made contact with the bottom edge of the plate. The entry hole is a tiny, almost imperceptible blemish in the Paxcon lining about half an inch below the large exit hole where the steel core ricocheted off the plate and through the anti-spall lining.

The exit hole is another story. While the majority of the fragmentation and spalling was contained, some portion of it exited the Paxcon coating. Depending on the velocity when it exited, this may have been contained by a plate carrier, especially if it was a supporting vest with its own threat rating. During a phone call to AR500 Armor after testing, they indicated that although the coating doesn’t contain all spalling, it does significantly reduce the amount and speed of fragments that make it through, which makes them much less dangerous to the wearer.

The impact caused the edge of the Paxcon coating to split slightly. The top portion is the solid buildup coat, with the bottom being the much thinner base coat surrounding the steel core. This became a trend for whenever the plate was subjected to high energy or difficult rounds like the M855 mild steel core, but is much better performance than what you might expect from thinner coatings.

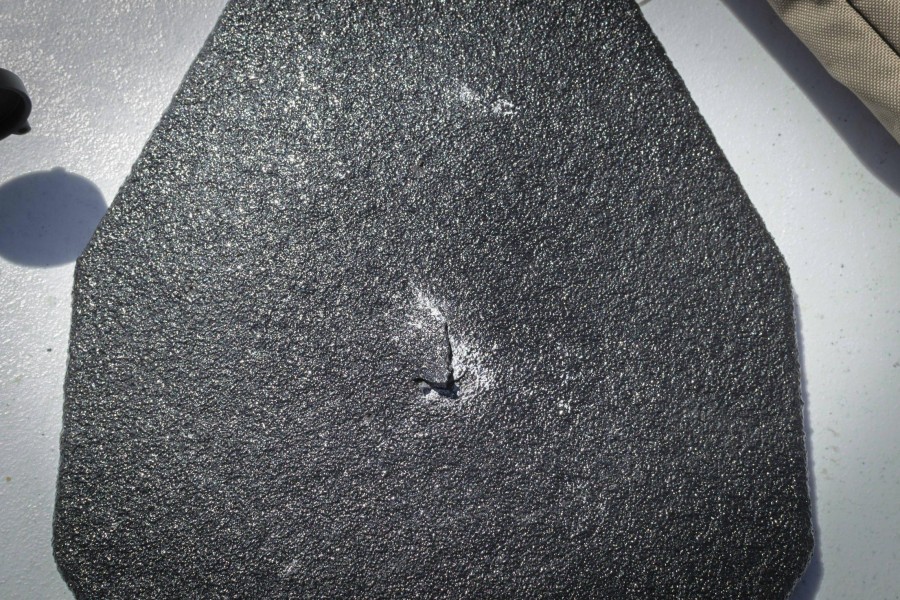

I was eager to see how the plate itself fared under such abuse, so I turned it over to inspect the damage.

I was promptly impressed.

Not only did the plate defeat the round at close range, but it didn’t deform in the slightest. The pictures make seeing plate deformation difficult, but after running my fingers over the back of the plate where the round impacted, I couldn’t feel even the slightest backface deformation. This is very good performance for a plate that is only 3/16″ thick!

Not wanting to stop there, I fired two more rounds at the top portion of the plate on the right and left sides.

These shots impacted a full inch directly below their prominent exit holes, leaving similarly-sized pinhole entry points to the first round.

A closeup of the right side impact clearly shows the tiny entry hole and the gaping exit hole where spalling wasn’t quite contained by the Paxcon coating. After seeing this performance three times in a row I was somewhat disappointed that the Paxcon coating wouldn’t completely contain the fragmentation, but that is a tall order when dealing with M855 at 25 yards.

Turning the plate over was just as uneventful as the first time: no penetration, and zero backface deformation.

Federal Flite Control OO Buckshot

I used my self defense load of choice: Federal Flite Control 00 Buckshot. Although I prefer their #1 Buck load of the same variety, finding it in recent years has been all but impossible. I was particularly curious to see how the hardened, copper-coated lead pellets would do against the anti-spall coating, since they would be more resistant to deforming and splattering on the plate than normal buckshot. Federal’s Flite Control wad also does a great job of keeping pellet spread to a minimum even in cylinder bores, which presents even more of a challenge for both the armor and the Paxcon coating.

Test shots were fired from my Mossberg JM Pro 930 with an improved cylinder choke installed. These shots were taken at a distance of 7′.

The first shot impacted between the two M855 impacts, with all pellets grouping fairly closely together. Although the pellets bored straight into the Paxcon layer, they completely deformed and splattered on the hardened steel core with no ricochets or spalling.

The shot, despite not impacting close to the edge, imparted enough energy into the plate to cause a split in the Paxcon lining between the buildup layer and the steel core. You can see here for the first time how thin the Paxcon layer on the rear of the plate is as opposed to the massive coating on the front. The coating appears to split consistently in this thin area (only ~0.005″) when too much stress is applied to the plate. Even though the anti-spall coating was beginning to fall apart, the hardened steel was performing admirably. Once again, there was no detectable backface deformation.

A second shot was taken at 7′ at the bottom center of the plate.

This shot performed more in line with what I was expecting from the Federal Flite Control wad. At 7′, all of the pellets grouped very tightly together (with the exception of one flier to the left). Even in this case, the buckshot was too soft to ricochet, and simply splattered against the steel plate without much incident.

At this point I wasn’t sure I was ever going to even dent this plate, let alone destroy it, so I fired 5 rounds of Perfecta 9mm from a CZ 75B and 2 rounds of .308 Winchester handloads (155 gr AMAX bullets at 2619 fps) out of my VEPR .308 at 7′.

Finally, even though the ballistic core had held up, the Paxcon lining threw in the towel. Although it’s not apparent from head on, the lining was almost completely separated from the steel, and it was deemed unsafe to continue close range testing. Rather than destroy the plate, the steel and lining portions were separated the rest of the way to inspect the damage.

The steel plate had taken significant abuse during testing. Here’s a quick summary of what it endured before the anti-spall lining separated:

- 3 rounds 5.56x45mm M855 mild steel core (25 yards)

- 2 rounds 00 Buckshot (7′)

- 5 rounds 9mm (7′)

- 2 rounds .308 Winchester (7′)

The plate, although covered in lead and bits of copper jacket, survived. The two dents are from the .308 Winchester handloads, which were absolutely screaming out of the VEPR’s 14.5″ barrel, generating 2360 ft/lbs of force on impact. These were the first rounds which even managed to phase the plate, and despite ever-so-slightly denting it, didn’t manage to penetrate. None of the other rounds fired managed to detectably damage the plate. I suspect I could have fired M855 at this plate all day long and it would have been fine.

The Paxcon layer previously adorning the front of the plate told a dramatically different story.

Although the steel core looked fine after all the abuse I put it through, the Paxcon buildup layer looked like a scarred moonscape. Each of the impacts can be clearly seen, with the .308 shots carving deep, long tracks as the pieces of bullet core and jacket radiated outwards from the impact point, with no exit holes at any point. If the coating thickness was increased around the edges of the plate, I the coating would have stayed attached to the front of the plate longer, increasing its usable life. Even thought it separated from the plate, it still had plenty of life left, especially for less powerful threats like 9mm or 00 Buck.

However, AR500 Armor were kind enough to send two plates so I could explore other threat combinations.

Second Plate

For this plate, I decided to go full power from the start.

PMC Bronze .308 Winchester (147 gr)

I wanted to see what would happen if I shot the plate repeatedly with .308 Winchester from 10′, which is the same distance used in NIJ certifications. PMC Bronze was selected, and was chronographed at an average muzzle velocity of 2415 fps from a 14.5″ barrel. This was significantly slower than the handloads I used on the other plate, but was more in line with what one might expect from off-the-shelf ammunition.

When dealing with all lead bullets, even at close range, the anti-spall coating shined. That is a full power, nearly point blank impact on the plate with no exit and no backface deformation. I actually had trouble finding the impact points and was suspecting I had only hit the pallet because the entry holes were so small. The next few rounds were also uneventful, with the third bullet creating a slight crack in the anti-spall coating but not failing to create a full-blown exit hole.

Finally, with a center shot, I was able to get the same effect as the M855 on the previous plate.

The bullet entered the plate about an inch low and to the left of its large exit hole, where it lifted up a flap of the Paxcon coating and left lead powder on the surface. Despite this damage, the back of the plate exhibited no deformation of any kind, which wasn’t entirely surprising given the lower power of these loads compared to the handloads used on the previous plate.

After five shots, the anti-spall coating began to separate on the left side of the plate. Although it wasn’t as bad as the separation on the first plate, I decided it was a good stopping point to change gears.

I’d shot at these plates a fair amount without succeeding in really damaging them, which made sense. All the rounds used were covered by the Level III+ Special Threat rating. At this point, I wanted to know what would happen if the plate encountered a threat it couldn’t handle. The big guns were brought out.

When somebody uses the term “elephant gun,” they’re probably referring to a rifle chambered in .458 Win Mag. This is .458 Lott: a round developed because Jack Lott thought that at 5300 ft/lbs, .458 Win Mag wasn’t powerful enough. We clocked these .458 Lott loads out of a Ruger No. 1 at 2315 fps with a 500 gr solid brass bullet, generating a whopping 5949 ft/lbs at the muzzle.

The plate was set up at 25 yards on the pallet. We said our goodbyes.

I never found all of the pieces, but I did manage to collect most of them. In character with super-hard steel, the plate fractured and broke apart like a ceramic rather than deforming and allowing the bullet to punch straight through. Elephants looking for body armor should consider investing in something thicker than 3/16″.

Although I wasn’t even remotely expecting the plate to stop a bullet hitting at nearly 6000 ft/lbs (for scale, .338 Lapua is only about 5000 ft/lbs), the final test was more about satisfying my curiosity about what failure mode the plate would take. It also broke the plate apart from the front Paxcon layer so I could see the damage caused by the 5 rounds of PMC Bronze that had already hit the plate.

The underside of the coating revealed scars similar to those left on the first plate, although these were slightly different in size, shape, and depth than the first plate’s .308 impacts (probably due to a different bullet construction and lower muzzle energy). Regardless, the coating impressively contained the vast majority of the spalling, which is exactly what it was designed to do. I don’t think it would have done well keeping anything above .308 muzzle energy contained, but I think you’re going to have bigger problems than spalling if you’re getting shot with 30-06 or higher at point blank.

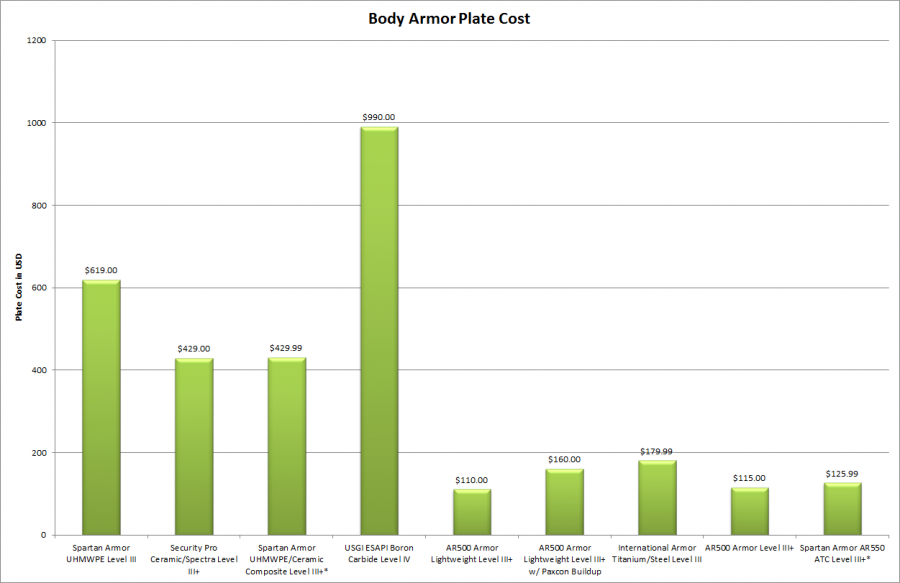

Cost

Steel armor has gained traction in the marketplace largely because of its price. Compared to UHMWPE or ceramic plates, steel is sometimes less than half the price, allowing the budget-minded user to purchase a full set of armor (front, back, sides) and a nice plate carrier to bear it all for the price of one plate of a competing material.

*Note: Items marked with an asterisk are sold as a set. Individual plate prices were calculated by dividing the set price by two.

I plotted the prices of the plates from the weight comparison chart in the same order. As configured in this review, the AR500 Armor plates come in at only $160/each, which is an excellent price point considering the protection level, curve, and Paxcon buildup layer you get for the extra coin (the “normal” ALSC plates come in at $110/ea). Although plates from other manufacturers may be cheaper, I didn’t see any which included coatings as thick as the Paxcon buildup layer on the front of the AR500 Armor ALSC plates, which performed admirably during testing.

Shelf Life and Material Benefits

One of the most attractive features of steel armor compared to other materials is its long shelf life and durability. AR500 Armor certifies their Level III+ plates for 20 years of sitting in storage, which is much longer than what you’ll get out of other plates. Steel is also resistant to environmental conditions which would compromise other plates before they’re even worn: leaving UHMWPE plates in a hot car repeatedly can turn an $800 setup into a lost investment at best and a false sense of security at worst. The Paxcon coating on the AR500 Armor plates is the most sensitive part to environmental conditions, and it’s rated by the manufacturer to withstand heat up to 200°F. The steel itself can withstand much hotter, but at that point you’re dealing with other issues like your burnt-to-a-crisp plate carrier.

Ceramic plates are less environmentally sensitive and lighter, but if dropped they run the risk of shattering (and not always detectably). While this may be an acceptable compromise for government agencies who can write off a plate and issue a new one, the average citizen can’t rationalize spending $5-900 every time gear gets thrown around too roughly – and that’s for just one plate.

I suspect the steel plates can last longer than 20 years if stored in ideal conditions, but the manufacturer would have to warranty them for just as long. I can’t imagine an armor manufacturer wanting to deal with the nightmare of supporting products sold 50 years ago and stored in unknown conditions, so the 20 year shelf life makes sense.

Specifications:

- Threat Rating: Level III+ Special Threat

- Weight (as configured for this review): 6.81 lbs/ea

- Size: 10×12 Advanced Lightweight Shooter’s Cut (medium)

- Thickness (as configured for this review): 0.21″ ballistic steel core, 0.53″ overall

- Shelf Life: 20 years

- Multi-Hit Capable: Up to 6 rounds .308 Winchester @ 10′

- Price (as configured for this review): $160/ea

Ratings (out of five stars):

Ergonomics * * * *

Although the ALSC cut is where a significant portion of these plates’ weight savings originates, the lightweight steel core making its debut here is phenomenal. We’re not quite into ceramic and UHMWPE territory, but we’re pretty close. The single curve isn’t as comfortable as the progressively-curved ceramic SAPI plates they were compared to, but once they’re in a plate carrier the difference is much less noticeable. The thin profile is a plus, but is less of a benefit once inside a plate carrier.

Protection * * * * *

Ultra hard steel plates can take a beating and keep going. These plates are only rated for 6 shots of .308 Winchester, but the steel core can take much, much more abuse (even after the Paxcon lining has called it quits). These plates cover just about every threat you’re likely to encounter, and can even survive edge hits where ceramic plates would fail.

Price * * * * *

For $160 you get a lightweight plate that can defeat most threats under the sun and do so for a very long time. There are slightly better deals out there, but they don’t have the thick Paxcon buildup coating on the front to contain spalling. For legitimate NIJ certified body armor, I don’t think you can do much better.

Overall * * * *

I’m knocking down a star only because I think the anti-spall coating should have been thicker on the sides to prevent the thick front coating from separating from the rest of the plate. In all other categories, the plates shined. I would not hesitate to purchase a pair of these myself if I needed low cost, competent body armor that may not get used day-to-day, but will be ready when I need it. I’m looking forward to what else AR500 Armor, and the steel body armor industry in general, can come up with.

Nice review. I run a set of plates I bought from AR500 in a “home defense” plate carrier (Grey Ghost Gear Minimalist) and they’re great. The company is hassle-free to deal with, and I’ve never any problems ordering from them.

Excellent write up, I would love to see an armor shootout to compare performance on these items beyond nij ratings, also would like to see how this compares to Soviet surplus armor that was all over the market a couple years ago

I want to see how it holds up against XM193. I’ve seen videos of plates that will stop XM855 get bored through by the 193.

That was accomplished with a 22″ bolt rifle using XM193 @ under 15 yards. I doubt even a 24″ AR-15 could replicate that at the same distance due to the lost of velocity from the gas system. Yea, it can happen, but what are the odds of someone shooting you with a 22″ bolt action rifle chambered in 5.56mm from less than 15 yards? That vid from the wound channel was an anomaly and didn’t discourage me from wearing AR500 one bit.

Oh wow, dat Lott.

Dat Lott will put a hurt on dat azz of yours…

I bet Tom would have loved to play with a Ruger chambered in Lott on his next vacation…

I’m going classic.

.470 NE in a double rifle.

Great write up on the plates.

when you shot the plate with 458 lott and it fractured, do you know if it stopped the bullet? did it function like a ceramic plate where the fracturing is designed to absorb the bullet energy to allow the soft vest to still catch the bullet? could you shoot a part of the plate still intact with some ballistic gel, clay, or water behind? maybe a regular soft vest behind to see if the plate absorbed enough of the energy to make the bullet less dangerous?

great review! thanks!

Current high end ceramic plates do not use or need a kevlar backing.

But some feature a composite backing. I’d be curious to know what that is in many cases. I know AR500 Level IV is ceramic with a “composite backing”.

Side note for anyone who sees this: Also what is the difference between the strike face and the body side on an AR500 steel plate? Except for of course the level of coating and the contour curve when applicable. Would having the plate “the wrong way” still provide protection to all rated threats?

I love my AR500 plates. Great stuff and since I’m not hiking through iraq I don’t care about the weight.

These plates look great, but, with my luck, I could be wearing two of them, and I would run into a shooter that would put one between my eyes, and two more in my nuts, when I hit the deck.

Well, don’t tell your wife your wearing plates, and maybe she won’t try to shoot around them. ; )

Actually, it’s easier to just take the firing pin out of her gun!

Stopping spalling, although a plus to help prevent eye damage and skin rash, is not the worry. The problem with steel armor plates is when projectiles deflect at impact angles of 45 degrees off perpendicular and steeper. I’ve tested them, and they defect, every time. Just set up some cardboard perpendicular to the outside plate edges to view the ugly results. Note that none of the steel plate manufacturers mention this fact beyond “bullets can deflect off any surface”. Yeah, no kidding.

At times, especially when in a combat stance shouldering a long-gun, there is a lot of your body sticking out in front of this plate subject to capturing deflected rounds, including: major arteries inside the biceps, your head (under your chin), and when running your inner thighs (with more arteries). At times in certain body positions your groin (ouch) is vunerable. Doesn’t take a lot of geometry knowledge to envision angled incoming rounds, and where they would deflect when hitting these steel armored plates at medium to steep impact angles. We found the deflected rounds travel close to the surface of the armor, they don’t bounce off like playing pool.

I’ll continue to wear ceramics. The splash may be greater during impact, but at least the round is destroyed and unlikely to injure or kill you in unprotected bodily areas.

I would not list ESAPI plates in your chart as “Level IV” plates. They do not undergo the formal testing required to give them a level IV rating; furthermore, there exists both ICW and standalone ESAPI plates.

GOOD REVIEW

I believe body armor is a good idea. Think people should buy it, if anything, just to grandfather themselves in before some idiot thinks of a solution and goes looking for a problem and tries to ban them.

Excellent writeup but it should be noted that these “lvl3+” plates are not directly covered by the nij cert and performance will vary between brands. Secondarily, their release by ar500armor took place after it became apparent that their lvl3 plates which have been advertised on their youtube channel as being able to stop mx193 from and 18in ar at 15yrds are in fact turned to swiss cheese by such a test. Upon pointing out this fact to them, I was told to purchase their new plates that actually work. I was also told that xm193 is an inconsistant load so I cannot faut them for their claims. I smell some bs and after spending thousands of dollars with them based on claims they knew to be false cant help but be a little upset.

It’s very well known in the armor industry that unlike lightweight plastic polyethylene composite armor, steel plates can readily defeat M-855, yet be eaten up by M-193 ammo. What keeps the guys selling steel plates sleeping soundly at night is the fact that following complete penetration of a steel plate by M-193 any respectable soft armor handgun rated vest will handily capture the lead remnants of the round – leaving a small bruise on the vest wearer.

For all you people wearing or contemplating using rifle capable steel armor without a soft vest behind it …. watch out! There are some rounds that will penetrate the steel, but stop in the soft armor behind it. Unless you’re not wearing soft armor behind it…..

>> What keeps the guys selling steel plates sleeping soundly at night is the fact that following complete penetration of a steel plate by M-193 any respectable soft armor handgun rated vest will handily capture the lead remnants of the round – leaving a small bruise on the vest wearer.

You’d think so, but apparently that is not actually the case:

https://www.youtube.com/watch?v=vsZ53ber3YE

I said “respectable” soft armor backing. The “prototype” alleged IIIA soft armor used in the video appears to be constructed with soft polyethylene (as noted by the telltale white strands of fiber hanging out of the penetration hole). Polyethylene plastic material has a low melt point and hot lead exiting the steel plate likely melted the polyethylene aiding its trip into the gel block.

In our evaluation of armor plates (steel & ceramic) we used good old American U.S Armor Corp (NIJ certified threat level IIIA) tactical vests made with Kevlar (yellow color) which doesn’t melt and IMO is the far superior soft ballistic material to be used behind any hard armor rifle capable plate.

As mentioned earlier, ceramic plates (well made) are a better material to wear as a rifle plate because they disintegrate rounds, including those from 45 degree or greater impact angles, preventing deflections of the entire round into non-protected body parts adjacent to the protective plates (which may include other good guys off to the side).

Very interesting, Rick. That would be a great test to make a video of.

Speaking of ceramic, while it’s obviously a better material from the protection perspective, I’ve heard that it’s high-maintenance in a sense that you must proactively check for micro-cracks that may cause the structure to destabilize – and that those can be formed from activities that would be routine for someone actually wearing such armor in combat, such as diving down to the ground. On that basis, I’ve seen people recommend steel because (with the appropriate coatings) it won’t rust, and there are no other points of concern, so it can be stored indefinitely and abused in the field. Does that make any sense?

AR500 III+ with their IIIA soft armor can stop a .30-06 M2AP round. Pretty impressive.

I’m torn on whether I want to go with regular AR500 Level III to be worn in conjunction with my AR500 IIIA soft insert or just go big with the III+ ALSC plate. Funds are not high right now so I am working on this slowly. I figure I could go Level III AR500 in front with soft armor underneath for additional protection and as a trauma pad and then grab a III+ plate in the future for the back of my plate carrier, that or a AR500 ceramic Level IV for the back of my plate carrier. I’m trying to keep the weight balanced since my spine doesn’t need any more damage! I know ceramic would be lighter but I really like the AR500 steel stuff. What do you guys think?

Note that ar500.com III+ armor also has this catch with 5.56:

“5.56×45 M193 and 5.56×45 M855 SS109 at a velocity of up to 3,000 feet per second”

M193 velocity out of a 20″ barrel is 3200 ft/s; out of 16″ barrel, 3100 ft/s. M855 is 3150 ft/s out of 20″, and around 3000 out of 16″. All at the muzzle, obviously, but as you can see M193 has quite a margin. So basically they don’t claim any protection against the most common rifle ammo fired from a most common gun that shoots it…

int19h, Yeah I guess I will be wearing soft armor underneath any AR500 stuff for sure then, which I don’t mind, it makes a great trauma pad and soft armor has always been comfy for me, even during hot days where the PC is on more or less constantly. I’m gonna have to look at some ballistics charts to see how fast velocity bleeds off at say 20 feet, 50 feet, etc. Obviously XM193 at muzzle will go through Level III but at 100 yards it might be a different story…either way I’ve been opening up my horizons to other companies….RMA armament has a IIIA+ plate that is 2lbs, by its self it will stop all IIIA threats plus ball ammo from 7.62×39 and 5.56, with soft armor backing it can handle .30-06….I figure with soft armor I have already weight 1lbs with the RMA IIIA+ SRT plate I can get great protection at 3lbs…they offered early bird pricing too but sometimes tried and true is best.

>> RMA armament has a IIIA+ plate that is 2lbs, by its self it will stop all IIIA threats plus ball ammo from 7.62×39 and 5.56

If you mean this:

http://www.rmadefense.com/SRT-Armor.asp

then I would not get too excited. It is so light because it is polyethylene, and that means that it won’t handle M855 (and indeed, if you pay attention to their threat profile table, it only lists M193 – that’s exactly why).

To properly handle all rounds at any distance, you really need a ceramic plate, or ceramic/polyethylene combo. There’s no tech yet that can pack this level of armor into 2 pounds per plate. We might get there in foreseeable future with carbon nanotubes – this is a very active research area, and the products are already trickling out into the market, but so far it’s all been soft armor. Give it another decade or so.

Good review, but two things- Highcom security plates, along with (I believe this is the name) Midwest Armor, are quite affordable, and superior to steel. Also, a tear came to my eye when I saw steel with such a beautiful PIG carrier- :).

Excellent review. Thanks.

>> One of the main selling points of this armor is its “Special Threat” rating, which specifically defeats 5.56x45mm M855 mild steel core ammo. AR500-based armor usually has difficulty defeating this round at close range, so I was eager to see how the plates would stand up.

Actually, AR500 armor usually does NOT have difficulty defeating M855. It does, however, have difficulty defeating M193 at close ranges, esp. from longer barrels:

https://www.youtube.com/watch?v=w1K3wCRjcdM

https://www.youtube.com/watch?v=xyEA3Nf–O4

https://www.youtube.com/watch?v=EpPVhbzPg2w

https://www.youtube.com/watch?v=vsZ53ber3YE

This is mainly because for steel plates, the key to defeating them is velocity, and M193 has more of it. Neither M193 nor M855 are hard enough otherwise, and that mild steel core insert doesn’t really make much of a difference.

OTOH, in polyurethane (UHMWPE) plates, it’s the reverse – they can stop M193, but M855 zips right through…

I’ve heard some steel plate manufacturers claim that their plates can actually stop M193, but I haven’t seen a video demonstration of it. If you can test these particular plates with a 20″ rifle at 25 yards, as in the videos above, it would be very interesting. Or maybe just ask the manufacturer first and see what they say!

It’s scary to watch the 5.56 results, in the above video. I know http://www.armoradvantage.com/index.php runs a video on their website that shows armor defeating 5.56 ?

It’s one thing to go against Haj/Muj with a 7.62-39, but what if your government sanctions blue on red white and blue violence?

Then there is a whole ‘lot more to worry about than body armor! But seriously in the case I would start using IIIA soft armor for backing, going for the III+ plates from AR500 or getting crazy and start stacking multiple plates.

Should have tested XM193. Speed is what kills body armor.

“Speed is what kills body armor.”

Ya, but sweat tortures it, and “whatever doesn’t kill ya. . .makes you beg for death.”

I would like to see some body armor comparisons with respect to weight and plate carriers with respect to buddy drag-ability (the ‘new’ stuff is a lot of webbing and seems more flimsy), and un-ass-ability when it comes to getting out of it in the water (where most of us have those terrible fires and seem to have an inordinate amount of un-claimed [insurance-wise] losses of our prized firearms).

Thanks. I really appreciated this review. If I learned one thing in my time in the infantry it was that I didn’t like carrying stuff around very much. UHMWPE is probably still at the top of my list, but I can certainly see how this may be better choice for people less work averse than I.

>>Speaking of ceramic, while it’s obviously a better material from the protection perspective, I’ve heard that it’s high-maintenance in a sense that you must proactively check for micro-cracks that may cause the structure to destabilize – and that those can be formed from activities that would be routine for someone actually wearing such armor in combat, such as diving down to the ground. On that basis, I’ve seen people recommend steel because (with the appropriate coatings) it won’t rust, and there are no other points of concern, so it can be stored indefinitely and abused in the field. Does that make any sense?<<

Sure it makes sense, but in the real world it is a very minor concern and not a danger. Micro cracks are not what allows deeper penetrations into the armor backing. In earlier generations of ceramics, square tiles were used (abutted up against each other) rather than today's monolithic one-piece ceramic designs. Testing was conducted onto the 3-way and 4-tile intersections, where the inherent cracks present by design were tested with laser aimed test barrels – level IV stand-alone plates still stopped 30/06 steel-cored penetrator rounds at accelerated velocities upon these cracks which were way larger than "micro".

The real issue with ceramics is loss of adhesion, or defects in manufacturing developing between the back face surfaces of the ceramic and the surface of the backing material. Impacts upon the strike face surface of the ceramic, whether from rough use or being shot, can cause severe damage to the ceramic because of loss of structural strength if air pockets exist underneath the point of impact.

If you take a rubber tipped tool and thunk back and forth across the surface of the ceramic, any change in tone may be an area where a void exists (like finding a stud on a sheet rock wall).

Only wear modern monolithic ceramic plates manufactured by companies that have recently (within the last 2 years to be safe) held supply contracts with the U.S. Military. Don't consider imports, or off-brands. And don't worry about diving onto a rock – if the ceramic is damaged to the point of potentially not-stopping common bad guy weaponry, you'll know it by a visual inspection, shaking it, and giving it the "thunk" test.

Fast forward to 9 minutes into this video and notice the angled round hitting the AR500 plate – which only occurred (by chance) due to the fact the first round of a two shot sequence tilted the top of the plate back, allowing the second round to hit at what appears to be a 30 to 40 degree impact angle off perpendicular.

https://youtu.be/b39MQxIi0mc

Note the big hole in the cardboard box that the shooter mistakenly (or intentionally) claims is due to spalling. Nope – it’s the entire round that tore through the cardboard box. That round would have entered under the chin and ended the gun battle quite badly for the plate wearer.

Hard to believe with all the video of steel armor plates being shot out there on YouTube, nobody EVER hits them at an angle with any rounds with a simple cardboard witness plate set up perpendicular to the plates perimeter. I’ll keep my ceramics, thank you.

Hi Rick, ive read through this debate going on and having just purchased III+ plates from AR500 am curious about your thoughts on their IV composite plates? Or any composite plates for that matter. Ricochets are quite serious, and would appreciate your advice. Thank you!

“That round would have entered under the chin and ended the gun battle quite badly for the plate wearer.”

good call being shot through the chest is a way better option…

these arguments are pointless and foolish you are arguing against the armor because of luck.

even if you are unlucky and get a deflected round. the SAME level of UNluck could have made the round go just over or just under the plate. or you stumble and it goes through the top of your head..

did you think there is a debate about if bullet proof metal will make bullets bounce off? because there wasnt one..

everyone who wears ANY Kind plate is or should be aware it isnt perfect.. and ALL can be defeated by UNluck

thats why we all know Mr Murphy’s name.

You ought to take part in a contest for one of the finest blogs on the

web. I’m going to recommend this website!

Dear Sir!

There for we need some product for our client, So give me your email address than i will send you the whole detaile of the product.

Thank you

—

Regards

Engr. Ishfaq Riaz

Sales & Marketing Manager

NSETS Pvt. Ltd

Office # 17, Ground Floor, Rehmat Center,

I -8 Markaz, Islamabad,Pakistan

Ph # +92-51-4938370

Cell: +923465006609

http://www.nsets.com.pk

[email protected]

Dear Sir!

There for we need some product for our client, So give me your email address than i will send you the whole detaile of the product.

Thank you

Tried to exchange my new AR500 Armor plates for a simple issue immediately after purchase. I was advised that due to “nature” of item there is no exchange or any customer support offered whatsoever. I suspect this is a one or two man operation that has no physical inventory on hand and doesn’t want to risk getting stuck with their own product collecting dust on a shelf (or maybe they’re tetoring on the brink of insolvency?). Either way; I’d avoid buyinging AR500 Armor products. You’d get better customer service from a gypsy home improvement contractor.

These plates are not NIJ certified and the company has a question history. I personally would not purchase from a company who has to recall their plates.

Many companies have had to recall plates over the years so that alone is not a deal breaker. The overselling of their lv 3 but likely not RF1 (if we ever pass the new revision) capabilities is concerning.

nike flyknit,nike air max,

ADIDAS OUTDOOR TERREX TRAIMAKER http://www.omjxy.com/

adidas nmd,adidas nmd cs2,

Nike Zoom http://www.aykqo.com/

Excellent review. I purchased a pair of these plates with only the base coating and I am fully confident in their protective abilities. I always figured that if I wanted to upgrade to a thicker coating I could just go buy some spray on rhino liner as it’s pretty much the same thing. I think your review effectively shuts down all the crap talkers who will say their Gucci ceramic and polyethylene plates are the only way.

Hope that works out for you and may you never encounter m193 from a 16″+ barrel.

It’s amazing to read through this and see how reduced velocity testing is being held up as something to be proud of. The Lott was near and all but the lack of 7.62 at 2780 fps is a bit lacking in what it should be rated for. As numerous commenters pointed out basic lead core fmj at 3000+fps tends to penetrate steel and the thickness of kevlar or equivalent backing needed to catch the bullet (and resulting steel plug from the plate) will likely exceed a level 3a vest. Most standalone ceramic plates have about half an inch of ballistic backing up the ceramic strike face. With that said there are actual certified armor steels from companies that do not tend to advertise incessantly and still manage to produce plates rated for a bit over 3200fps 5.56 m193 (high on has/had at least one such option). Neat finding this one years later and seeing years of the discussion and learning curve condensed in one progression of comments.

*highcom for company with relevant plate also highly recommend reviewing VPAM standards and how they compare to NIJ for a more complete picture on threats and what armor should be capable of at given ratings https://en.m.wikipedia.org/wiki/List_of_body_armor_performance_standards

Comments are closed.