This isn’t the first TTAG item you’ll see referencing Texas Armoring. We’ve covered them before here and here. With almost 5 million views at the time of this writing, statistics say you’ve probably seen the viral video footage, above. If you haven’t check it out, cause it’s probably the only time where ignoring all of the Golden Rules of firearm handling results in a good time. Seeing as their factory is just down the road from where Nick and I spend our working hours, we decided to pop over and have a poke around.

My coworker Adam let it slip a few weeks ago that he’s good friends with the crew over at TAC, and went to work setting up a meeting. Thirty minutes and a flurry of emails later, Nick and I were set up with a tour of their manufacturing facility in San Antonio led by Executive VP, Jason Forston. Nick managed to keep a poker face during the whole thing in large part due to the experience he got during his multi-day tour of AAC last fall. I, on the other hand, giggled like a schoolgirl the whole time. This place is a gearhead/gun guy/machinist/nerd playground.

The first stop was to meet our tour guide for the day in his office, and Nick couldn’t pass up the opportunity to snap a picture of Ronald Reagan’s presidential photo framed on the wall. It pretty much summed up the opinions of the guys that work there.

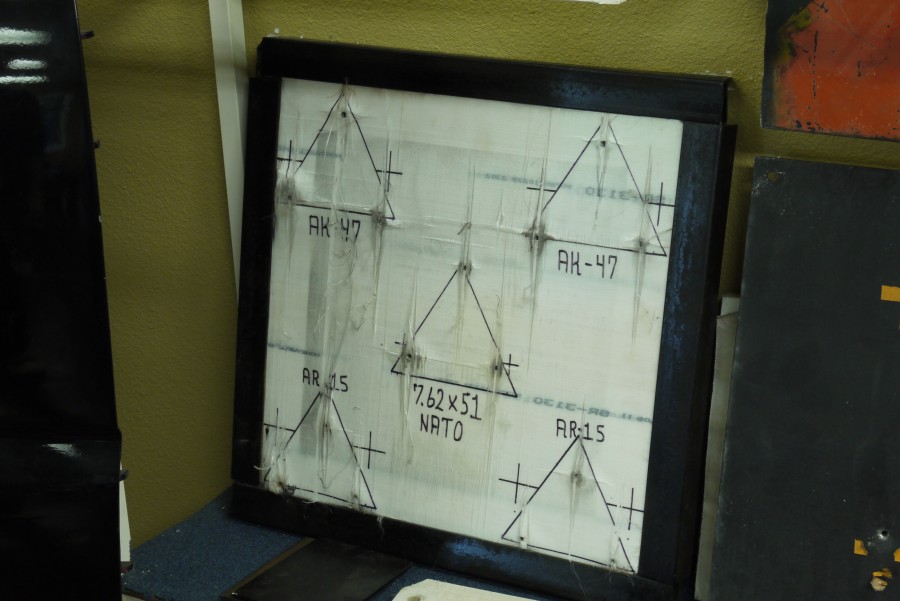

We started our tour with various bits of armoring that had been shot up with everything from 9mm to .50 BMG. Jason explained that they take a completely custom approach to every armoring build. Their whole goal is to provide safe products that still retain all of their original function. It starts to make sense — the car, truck, or SUV is going to spend 99.9% of its life not getting shot. It should spend that time being comfortable and inconspicuous.

If you want to show off the fact that you’re armored up, buy an APC. If you want to be just another black Escalade in the crowd, call TAC. Jason went on to show their various armor levels and the firepower they’ll stop. And yes Virginia, they can armor up to withstand the .50 BMG. They’ve tested it as close as 30 yards. Like most high end packages, TAC only does about two or three of those a year. Most of their clients choose armor to withstand 5.56 and various 7.62 flavors.

Who is their regular client, you ask? Turns out they don’t really have a “standard” profile, it’s just anyone concerned for their safety. In the shop they had vehicles being worked on for everything from Nigerian millionaires (apparently spam e-mail can be surprisingly profitable) to “high officials in the middle east” as he put it. The kind that wear the white robes. Anyone with enough money to spend on an armored car probably has good use for one, and their shop gets their orders on a regular basis.

How, exactly, do you get an armored car across the globe? According to our guide, the most popular way is via shipping container on a boat, as fully armored cars can be just a tad heavy. There have been a few more interesting delivery methods, like one customer who chartered a cargo 747 just to ship his car to a sandier environment. In other words, even after you pay for the thing to be built you still need to pay to get it to the destination.

Next up was the welding area. TAC has close to 50,000 square feet of manufacturing space But with business booming, space is at a premium and the frenzy of work is incredible. There are people hustling everywhere cutting, fitting, welding, and hammering. We got to see the blank canvas that TAC starts with. Say goodbye to your off-the-lot $80,000 Escalade. A crew of guys will have it ripped down to the chassis and frame in a few days and then the real work starts.

Since TAC’s whole focus is making the finished product not look like an armored car, they armor from the body skin back in. So instead of just welding steel plate inside the current body and gluing body panels, they replace all the factory mounting points with armor and create a totally “stock” look and feel. They also keep the weight down by using composite materials wherever possible. Whereas steel will deflect and make bullets shatter, composites act more like a catcher’s mit to absorb the rounds. Think of a built up bulletproof vest.

We then headed over to the finishing and interior build out area. Since everything they do is so customized and they need complete control over the build, TAC also has an in-house finishing department. They have no problem doing stretch limos, leather, suede, and stereo work. This is also where they’ll wire up all of the switches and controls for the defensive line of solutions. Eat your heart out 007, because the boys from TAC can have you dropping tacks and pumping out smoke like a pro.

Once your interior is done, your shiny, new armored car goes through an extensive quality assurance process. A fair number of TAC’s clients are international and the time to find a mistake is not when your product is on the ground 5000 miles from home. Jason has even personally driven a customer’s car for 3 weeks just to give the client peace of mind and stand behind their products.

As soon as the car is ready to be rolled out of the facility it’s virtually indistinguishable from a regular car. Unless you know what to look for, you won’t be able to tell the difference between a normal car and an armored car that these guys welded together. Don’t believe me? Spot the armored car in the picture above.

So what did we take away from this? The biggest thing I learned is that it takes a TON of money to bulletproof a car properly. Top Gear thinks they can do it with old bits of phone book, but unless you only drive between your house and the dump, that’s not really a viable solution. Unless you have a couple hundred grand lying around a true armored vehicle is out of reach for the normal American citizen.

Instead of bulletproof glass AS550 steel plates and composite materials we need to rely on our situational awareness to keep us out of trouble. Because no matter how much money we throw at keeping bullets away from our soft squishy flesh, the best method is to avoid them wherever possible. And that means being aware of what’s going on around us and avoiding stupid people doing stupid things. Pretty much what we’ve been preaching all along.

I was in the middle of saying “Holy s**t” at the video when the third guy stepped into frame and said it for me. Awesome.

And now I know what I want for Christmas.

Cool stuff!

I bet the armored car in the picture is the Mazda “Ranger” pickup. lol! Nice I bet that company makes a boat load of money.

I think they make a ton of top line money, but I don’t see it being a big profit margin type business. They have hundreds of man hours wrapped up in each project, not to mention hundreds of square feet of AR 550 steel and Spectra. It is an expensive business to be in for sure.

Either way, it was the coolest place shop I’ve seen in a very long time.

cool stuff. wonder if that glass would’ve held up to 30 rounds of ak…..?

http://youtu.be/cT6Hq95OQZ0?t=1m25s

check out this video

Comments are closed.