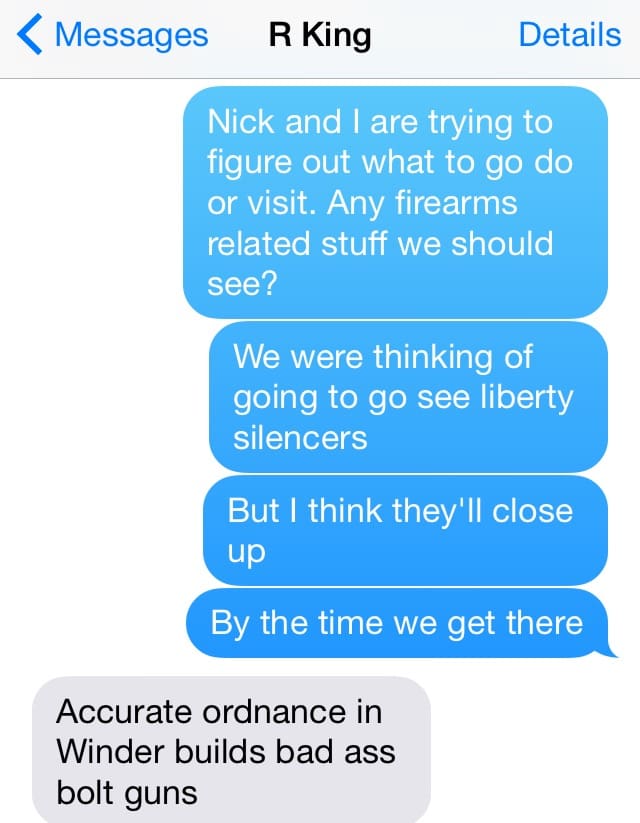

Recently, Nick and I went to northern Georgia to hang out with a mutual friend for the weekend. Said friend had some guns to show us and Nick and I rarely need much of an excuse to go shoot stuff. But our buddy got waylaid by delayed flights and various other engagements, so we found ourselves with a few hours to burn in the Atlanta area. After visiting Gladys Knight’s Chicken and Waffles, we texted our buddy Richard King for some advice on gun stuff we should see while we waited around . . .

Nick and I both shrugged our shoulders and pointed our rental towards Winder, Georgia. Richard called to make sure the AO guys were going to be there, and texted us the info. A short hour later, we were in a very nondescript industrial park in Winder. The offroad vehicles adorned with gun sticker told us that we were in the right place.

Upon entering AO’s small office we were greeted by Mark Kuczka and Rick Thompson. Mark and Rick are the operations and sales part of the trio that owns AO. They were wrapping up a customer delivery when we arrived, so after a short wait they gave us a warm welcome and showed us around.

First up was the showroom which featured a few spec builds they’d put together to show off to customers to give them an idea of what they could accomplish. These spec builds are absolutely for sale and the guys commented that on more than one occasion, they’d had a guy come in the door with a laundry list of things he wanted only to walk out a few hours later the proud new owner of a gun that used to hang on the wall.

The wall also serves as a great “Why don’t you try that out first?” sales tool. The guys commented that many times, a customer will come in hell bent on a M24/M40 style rifle for hunting, but will quickly switch directions when they pick one up and realize how much of a pain in the ass it would be to lug around over miles of trails. They also keep a healthy selection of barrel contours so that they can put the actual contour of the barrel they’re talking about in the customer’s hands.

It was becoming apparent to both Nick and me that AO was concerned with building functional rifles that would make their customers very happy. And given that they build several hundred custom rifles a year, they’ve got some experience in what works and what doesn’t.

Moving back into the work area, we got to meet the third leg of the tripod, machinist Jason Nixon. Jason was busy threading a barrel when we stopped by, and we made sure to stay out of his way while he let the chips and oil fly. As our tour guide, Mark spent some time talking us through Jason’s steadfast attention to detail. There are a couple things that Mark feels make Jason’s work different.

First, Jason insists on measuring tolerances down to 50 millionths of an inch (.00005), though Mark and Rick both mentioned that he’d prefer smaller than that. Second, Jason has taken a different approach to the way they cut chambers. Specifically, they use a much higher volume and pressure of oil to flood the chamber and tool-cutting surface. This keeps chips from scoring the inside of the chamber and allows them to keep temperatures in the cutting area much lower.

Mark mentioned that one of his customers burns through 6.5 Creedmoor barrels each season, and wants AO to cut an exact replica of the chamber and barrel that he had previously. The process they uses helps them deliver on the demanding requests of their customers by extending their tool life and giving them smooth, consistent chambers.

Next, we moved over to the paint booth and stock prep area where the AO guys bed actions and custom paint customer guns. Check out their Instagram or Facebook pages to see more examples of their paint work. While you’re there, you surely can’t miss the pictures of targets sent from their customers showing the ludicrously small group sizes that AO rifles are capable of. Which is ultimately what this whole custom rifle thing is about. AO guarantees 3/8 MOA at 100 yards for all their rifles with high quality factory ammo. Rick mentioned that customers rolling their own regularly report group sizes in the teens.

As you might expect, Nick bulled his way into the interview dispensing with all pretenses of finesse. “Why would someone buy a gun from you instead of someone else?” Mark and Rick smiled and said that tons of shops sell a quality products. In fact, they fully admit that from a product side, they aren’t doing anything that other custom rifle builders aren’t currently providing. Mark told us that there are two things that differentiate them. The more minor of the two is that they stock a ton of inventory on the shelf, so instead of the typical 9-month build times you see from a lot of custom builders, they can often knock out work in weeks or just a few months.

But the more major differentiator according to Mark that separates AO from other custom shops is their high degree of attention to customer service and an ethos of doing what is best for the customer first and always. Both of us nodded and then asked for examples.

Mark was happy to chime in. He gave us several (Mark’s a self-admitted talker), but the one that stuck out to me was a customer from a couple years ago who had them build a custom rifle as a retirement gift for himself. The customer was headed off for a trophy hunt to celebrate. A true, once-in-a-lifetime trip. They’d happily obliged, but when it came time to put the optic on, the guys found themselves in a pickle. The customer had been more than willing to spend the money on the gun, but had cheaped out on the optic. They mentioned it to the customer as delicately as they could, but he held firm. So they installed the glass and several months later, wished the customer bon voyage.

A few days later, they got a panicked phone call that their worst fears had materialized. His optic had fogged up on the first day, threatening the hunt. He’d also only brought along enough rounds to bring down an animal, not enough to sight in a gun, and take that once-in-a-lifetime shot. Mark and Rick didn’t delay. They overnighted him a brand new Nightforce optic they’d just gotten in along with another couple boxes of ammo. A few weeks later, they got a note from the customer that included a check for the scope, the ammo, and the shipping. And a few months after that, they got the first of many referrals from friends of their customer.

Overnighting a scope to a guy who by all rights deserved his fate is a bold move for a six-man shop. That’s a lot of money and trust to send out the door, but the AO guys feel that doing the right thing has never hurt them, so they keep plugging away building several hundred guns a year. This also includes facility tours for TTAG writers who just happened to be in the area with five minutes notice.

You can buy standard AO models from $3495 to $4395 and custom rifles that are ready to go from $3,485 to $4,675, but truly custom builds are their bread and butter and can go way up to and past $6,000. The only limit is your imagination. And your wallet.

They just built an awesome 338LM for me!

Hmmm, the 6.5 creedmore keeps calling me.

They build a lot of them. Mark told me that its the most popular caliber they build for. And they shoot that Hornady factory ammo too. Less time reloading, more time shooting.

This sounds like a good company and fun to deal with. If I had the money, it would be fun to take a cross country road trip out there and spend an afternoon speccing out some awesome tack driver. Being near sighted would make it even more pointless than usual, but still …. it would be fun to have something that could shoot so well.

I used to drive tacks with my .177 pellet gun.

Aren’t these rifles more for spikes?

I’ve got an Accurate Ordnance 6.5 Creedmoor that is an absolute hammer. They’ve done many other projects for me and no matter how big or small, the attention to detail and customer service experience is world class. The whole crew at the shop is outstanding to deal with.

I have a 6.5 Creedmoor TMR built by Mark and the gang at Accurate Ordnance. Rifle is a pleasure to shoot… With sub 1/10th MOA groups with 140 AMAX… It’s stupid accurate…

Hmmmm, not so sure about that.

That’s incredible. You should take that on the benchrest circuit if that is true. That’s a record holder level gun.

Wow – that looks like a Haas TL-3 lathe. That’s a *very* fancy lathe for a gunsmith.

TL-1- it’s the perfect rifle lathe!

Beautiful machine. If you don’t mind my asking – how much time do you work in manual mode vs. running CNC programs?

About 99.9% CNC using manual programming. I use the handles to touch off two specific tools in a specific way, so I can’t do without them. Since most manual work relies on power-feed anyway, the handles don’t see much cut-time.

Thanks again Jason, appreciate the info.

Have two rifles from AO. First rate outfit. Professional – Patient – Quality.

Highly recommended!

Hmmm. I’ve been thinking about building an R700 on an AI-XR but in 260 rem. Then all of this talk about 6.5 Creedmor. I drive near that area on the regular might need to check out the store. Maybe its time to go custom.

I am no expert on the precision scoped rifle competition scene but have had some professional PSR training so take it FWIW but whenever people start talking about a better than 1/2 MOA in practical shooting I get very skeptical. I don’t doubt the equipment but I do doubt the people.

Give ’em a call. They’ve built a lot of 6.5 guns in both creedmoor and Rem and have thoughts on both. Or call ’em and show up.

I think the 3/8 MOA guarantee is based on “mechanical accuracy” and not necessarily practical accuracy. The guns are capable of fantastic accuracy is my understanding. We’ve dropped some heavy hints that we’d like to test one out to make sure. We’ll see what comes of that.

I have a 6.5×47 that they built and its capable of less than 1/4 MOA.

Love my 6.5 cm from these guys, can’t say enough good things about these guys

Comments are closed.