Before I get into the meat of the article, let me start with the disclaimers. This is not a full test, for reasons which will be explained below. It is more an account of my meeting with Colorado gunmakers Karl Lippard and Charles Henderson, and my “first impressions” of their much-ballyhooed M1911 variants, the A2 “Combat NCO” and the CQB.

Second disclaimer: No, we did not get a 400-yard test. That one is in the works, but may have to wait for Spring to arrive in the rockies and melt the snow on our long range shooting facilities (we’re enjoying a bit of “false spring” today but we know better than to expect it to last.)

The wife and I traveled down to Colorado Springs last Saturday, were we met Charles who then took us to the Lippard estate. Karl led us in through his garage/workshop where many of his guns were laid out for final inspection and assembly.

The first thing I learned about Mr. Lippard was that M1911 pistols were not his first foray into gunmaking, in fact, they had become something of a sideline to his main business, which is the crafting of gorgeous, museum-quality shotguns and rifles. (Click here for his website.)

Now personally, I’ve never been “into” these handcrafted sidelock shotguns and double rifles. Sure, I can admire the craftsmanship that goes into them, but when it comes to guns, I’m more of a “function” guy. My workable Mossberg 500 has always been shotgun enough for me. One of Lippard’s $50,000 shotguns would be as out of place in my gun safe as a horse in church. But I have to admit, his shotguns are stone-cold gorgeous, with a fit and finish that has to be seen to be believed.

More amazing, to me, is the fact that the barrels and chambers of his double shotguns are rifles are created out of a single, solid block of forged steel. In fact, he had a couple of drilled “blanks” sitting on a rack waiting to be finished. Sitting on the coffee table in front of us: a half-finished shotgun, with one barrel completed and the other still a block of steel with a hole in it. Impressive, to say the least.

Also impressive: the passion and enthusiasm that both Lippard and Henderson bring to their work. So much so that it’s sometimes difficult to digest all the information they’re putting out. However, after reviewing my notes, it seems that there are approximately four major differences between the A2 “Combat NCO” pistol and the run-of-the-mill M1911A1 clone (Charles was kind enough to bring his old M1911A1 Series 70 to serve as a baseline). The differences are:

1. The construction, which is a proprietary steel that is much more resistant to bending, warping or deforming than the kind used in most steel pistols

2. The “Bellau Wood” modification to the grip safety, lessening the likelihood of a malfunction that can render the weapon unable to fire in critical situations.

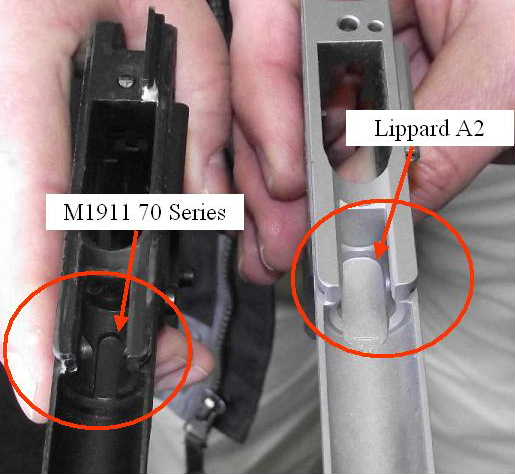

3. The improved barrel link that prevents side-to-side motion of the barrel, enhancing accuracy, and

The frame’s interior is slightly modified to allow for the fatter barrel link:

4. The improved ambidextrous thumb safety.

There are also a number of smaller upgrades. They’re the subject of a series of patents, and a little too technical for a non-gunsmith like me to really understand. Not that Karl and Charles didn’t try. They spent several hours explaining the development of the A2/NCO and the CQB pistols. I won’t reiterate the info here; it’s on his web site in any case.

Of course TTAG readers want to get down to the nitty gritty: How do Karl’ 1911s look and feel, and shoot?

The fit and finish is nothing less than remarkable. Although we weren’t able to do the “400 yard” shooting test, Karl performed the “bucket test” (i.e., throw the parts in a bucket and see if you can assemble a workable gun). Karl sjopwed me how easy it was to interchange slides, barrels, and frames between guns.

No matter he how mixed up the frames, slides and barrels, the guns went together perfectly, without any need for additional fitting. Karl further displayed the fit and finish by showing doing the exact same thing with his fine shotguns, He could pick up a side plate from one gun and it fit flawlessly onto a different gun, with no visible gap and no side-to-side movement of the part.

The A2/Combat NCO models had a gorgeous deep blue finish that reminded me of an old Smith and Wesson revolver. Back in the days before black painted guns were the norm, a nice bluing was the mark of a quality gun. The high and deeply stepped sight (which is how you get those supposed 400 yard shots) looked a bit odd at first, but no more difficult to use than any other target sight.

The guys took apart the ambidextrous safety and explained it in loving detail. Comparing the Lippard piece to Charles Henderson’s 70-series with an off-the-shelf “ambi safety,” the Lippard piece proved superior. It boasted a tight, movement-free fit as compared to the mass-market safety’s sloppy fit and mushy feel.

The fat barrel link was also an eye opener, and allowed the barrel to move smoothly in and out of battery without so much as a hint of side-to-side motion or twisting. The final major item that was A2 specific. The “nose piece” was, like the rest of the gun, machined from a solid piece of proprietary steel and as tight as the rest of the gun.

Shooting Impressions:

Because of time constraints, we weren’t able to do a full-on review. I’ve been in contact with Karl and Charles. They’ve promised two sample guns for full, independent and unsupervised review.

We brought one example each of the Combat NCO and the CQB pistols to the range for a short test. While the guns felt solid and shot well overall, we didn’t shoot them off a rest. Worse, we had some trigger issues with the Combat NCO model. I attribute this to the fact that Lippard simply picked up a couple of partially assembled guns off the bench and put them into his box – the guns were unlubricated and untested.

As such, they weren’t really representative of the types of guns that will be for sale, and so another test is being arranged as we speak.

Final Notes:

When talking about a gun like this premium .45 M1911, the million dollar question is really the $2750.00 question ($2750 being the difference between a run-of-the-mill .45 at a median price of $750 and the $3500 that Lippard is asking for his A2 models.). Is it worth it?

The answer to that, alas, is subjective. Even if the A2 proves to be as accurate and dependable as Lippard states, $2750 is a lot of coin. Many shooters will reach the point of diminishing returns long before then (this writer included.)

On the upside, Lippard’s 1911 designs aren’t all-or-nothing. If you don’t have $3500 to spend, you can upgrade just about any 1911 to receive a significant number of the A2’s benefits. The wide barrel link and ambi safety alone cold be attractive to a few serious 1911 shooters (particularly southpaws). My guess: while the A2/NCO might be the “halo” vehicle for Lippard, he’ll sell a lot more components to shooters who want to upgrade their standard-issue 1911’s than he will complete guns.

A more complete write-up will follow when we have time to test the gun more thoroughly, including the four football field test. Stay tuned…

So, what do we know so far?

– The fat barrel link is interesting.

– The proprietary alloy claim is likely BS. Lippard doesn’t have the resources to be doing his own metallurgy; he is likely buying an exotic, but production, steel. No mention of forging or casting… how are those frames made?

– The grip safety is interesting, but little is known about it.

– The ambi safety is interesting, but little is known.

– He didn’t pass the “bucket test.” Making slides, frames and barrels work together while you fingerbang them is easy. To truly perform this test, you need to FULLY detail strip the weapons, randomize the parts, re-assemble and test fire. Swapping frames, barrels and slides proves nothing about his ability to solve the fine fitting requirements of a 1911.

– He appears not to have touched on what Vickers thinks is one of the major 1911 design flaws; the plunger tube. That tiny tube crushes or gets fouled up, the weapon is Non-Op. The Lippard plunger tube looks like a standard part; it isn’t integrated into the frame or ride in a slot in the frame.

The best part is… the weapon didn’t work. Lippard is watching this forum, seeing people’s reaction, knows that someone from TTAG is coming over to give him a chance to back his claims up… and the weapon he chooses FAILS.

Really, what more needs to be said beyond that?

Ha! That was my thought too. Thats some circle-talk if you ask me. They drag out the explanation process for “Hours” and then low and behold there is not sufficient time for a decent shooting test. Oh, and that gun doesn’t work cause we didn’t have 45 seconds to lube it, and its not actually done being built…And no, there are no working examples to be had. Not even a demo or prototype. Hey they don’t have to answer to a bunch of light-weight yuppies.

To answer at least one of your questions, the guns are made from forged steel. Lippard has contracts with CNC machiners in several locations around the country where the frames and slides are machined, and then sent back to Colorado for final assembly.

Since you last visited Mr. Karl Lippard, have you had a chance to fully test both the NCO and CQB 1911’s. I’m currently considering a Wilson Combat, Springfield Proffessional or Mr. Lippards. I’ve never fired any of these pistols, but would like some input in making my decision.

uhh, he did say solid-block forged steel!! What do you expect from a review that was CLEARLY stated to be unfinished!? A proper test takes weeks to months to perform. I agree that it seems that the Lippard crew were not prepared to amaze the masses, but if you guys think its a crappy upgrade GREAT!! I’m gonna drop the A2 Upgrade into my Armscor Medallion and be completely amazed!!

I wrote to KARL LIPPARD from ebay in regards to his barrel link,cam/sear, tool steel hammers and his response was curt,crass and abrasive at best. He told me 1911s were obsolete and he doesnt build 1911s….he builds “1911-A2s” like they were some futuristic carbon fiber,titanium,scandium revolutionary pistol. So here i am doing research before i buy the parts for my next build andi read this review. While i think the the SEAR with the hammer “lift CAM” is interesting and larger PACHMAYR style wider link ($7.50 PACHMAYR) that he didnt invent,still look nice and the hammer with recessed area maybe well made i would never pay the amount of almost a full custom S.V.I. since INFINITYs are proven to work in competiton and even the cheaper S.T.I.s. i dont understand guys like BOB MUNDEN (read sports illustrated “vault artcle” on his lies), LIPPARD and rude owners like ED BROWN, still have a clientele. I can see a KORTH and a JANZ revolvers quality and exclusivity possibly be worth the price tag. However to have a 1911 FAIL when your supposed to have a 600yard claim is inept at best. It makes me laugh when i read the new 1911TC when tested in SHOOTING TIMES had the sight fall off. Why do these companies give 1911s for tests with faulty mags and no quality inspection prior to testing? Im tired of hearing the 1911 besides (faulty follower/mag,personal defense cartridges,wad cutter,slide stop etc etc) it ran great and then the author recommends it. There are crappy M.I.M. Ridden SAM/ARMSCOR made 1911s that can make it through a few mags and if a $3000 1911 cant it should be boycotted. Then again people love to have a name brand even if the Q.C. Is now shit. I build custom 1911s using nighthawk or BAER frames/slides with SVI internals and never had any issues. The only custom builders ive seen that has made consistant 1911s are: SVI,CLARK,HARRISON,YOST,CHRISTENSEN,Ive since WILSONs,BROWNs and others with terrible fit and finish and have failures more than ive seen perfect runners. Moral of the story,go compete borrow a friends custom and ask ol’timers what customs they have had issues with and why. Then you wont be kicking your ass for spending thousands on a 1911 that needs to be sent back for repairs! GOOGLE/YOUTUBE :ED BROWN customer service/quality contol,WILSON quality control issues. I used to think $2-3k 1911s had to all be equal but they are not. Price doesnt equate quality.

Sorry for the rant.

He claims an AMBI safety like no other, a total DROP-IN?

This is my personal favorite quoted from LIPPARD’s website :”Lippard A3 Ambidextrous Safety is designed to drop in and function in all 1911 pistols.”………

Hmmmm next sentence……. ” No filing is needed to fit the Sear in most 1911 pistols. It is easy to install”…….

So it fits ALL and MOST 1911s,..a bit contradicting if you ask me. Nothing worth its salt is a true drop in except GRIPS on a 1911 in my opinion..

I don’t know if the Lippard 1911 is the “right gun,” but I do know that Martin Albright is the right gun reviewer. Keep it coming, Martin, because we really want to know the truth about this gun.

Thanks for the honesty Martin. I’m still intrigued, but becoming a bit more skeptical about these weapons.

“simply picked up a couple of partially assembled guns off the bench and put them into his box – the guns were unlubricated and untested”… Tell me Martin, did you just “pop” in at Karl’s place one afternoon? How long did this guy know we were coming? For a physics and ballistics expert, Karl apparently doesn’t understand the space-time concept too well. Perhaps through all his incessant and somewhat incoherent chatter, he forgot to realize that we actually wanted to shoot a gun, not just be dazzled by his immensely large cranium, and innate ability to convey intellectual thoughts. FWIW, I ran my Springfield Loaded unlubricated and untested the day I bought it. She still ran through a whole 150-round Steel Match without a single hiccup.

I agree 110%, no excuses for failures especially on a sear that is pulled off the hammer ledge by his proprietary CAM.

I would like to know precisely what LIPPARD said the failures were attributed to. Why doesnt the 1911 community call this guy out about his obvious 400yard range 1911s? The hold over at that distance is what 15feet+ . Its like lobbing morters rather than precision long distance shooting.

I want to see a 25-50-100yards test V.S. LES BAER out of the box. Recorded on something other than an IPHONE and have a camera fixed down range on tripod to see the hits in real time,that would make me a believer if he had 1″ -2″ groups at 100yards,heck evennput them in the 6-7 ring.

In addition to the comments noted ahead of me, 400 yards? With a self-described high-end defensive weapon, a 45acp/1911? For what purpose? Give me a break.

uhhhh its OFFENSIVE..not DEFENSIVE.

People must have forgotten how to read lately. On Lippards website it clearly states that the NCO & CQB A2’s are meant for offensive long-range actions. Everything from marksman to suppressive-firing. This whole ‘Upgrade’ was to allow the 1911 to adopt more roles than it is currently used for.

The only thing “offensive” about a 45 acp handgun at 400 yards is the mere thought that it could be.

A $3000 UBER pistol that the manufacture can’t be bothered to properly fit the beavertail??? PASS

Comments are closed.