The 80% Arms GST-9 Pistol Built Kit I reviewed late last year was easily the best pistol lower build kit I’ve seen yet. It was window-licker simple and produced a great product.

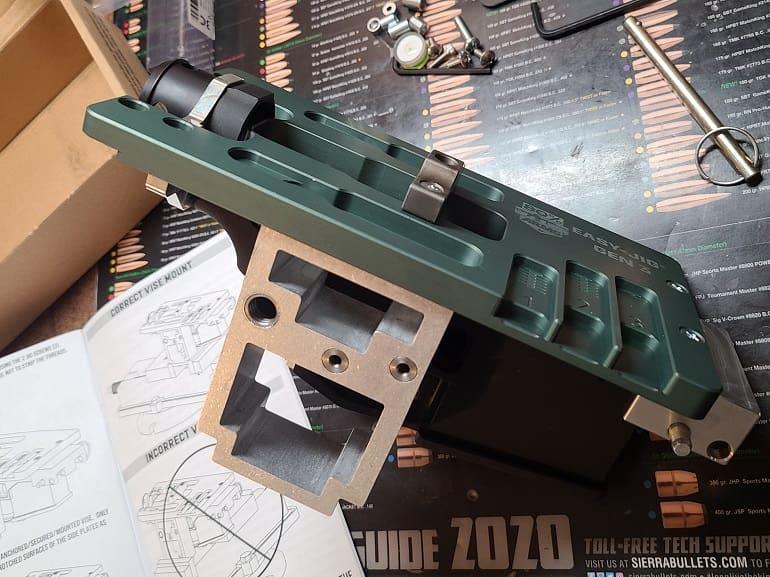

The 80% Arms Multi-Platform Easy Jig is even better.

The Easy Jig allows the user to turn AR-15, AR-10, and 9mm GLOCK compatible AR platform 80% lower receivers into finished lowers. It fits any “mil-spec” lower, and you can use it over and over again.

You’ll need a few tools to do the job, but just a few. Most important is your router. Something like a Dremel or rotary tool won’t work, you’ll need a bit more power than that. You don’t need anything special, though, and there is a router compatibility chart posted on the 80% arms website.

You’ll need a real drill, not a glorified screwdriver. You do not need a drill press. You’ll also need a vise, and the bigger and sturdier it is, the better. You’ll also need a single Phillips head screwdriver. A shop vacuum is also highly recommended. Beyond that, and some vegetable oil, everything else is provided.

If you’d like to watch videos of the entire process, you can do so on the 80% arms site. I did the project without ever looking at the videos. I just following the supplied instructions.

Even if you have zero mechanical aptitude, as long as you follow the very clearly laid out instructions, everything’s going to go fine. 80% arms has created a project that is essentially brain-damaged-old-redneck-proof (ask me how I know), and that’s saying something.

First, put everything together. That means installing the guide plate on your router and putting the jig together. This was the most challenging part of the entire process and it’s super easy.

The genius of the whole thing is that top plate on the jig. You can mount any of the receivers to it, depending on what holes align. This part is pretty much impossible to screw up.

After that, you’ll need to mount it on a sturdy vise. I decided to do all of it outside in an area where I wouldn’t care much about stray aluminum shavings, so I just screwed the board one of my vises was mounted on to a sawhorse and got to work.

Once the receiver is mounted into the vise and, again, the instructions are extremely clear here, you’ll need to drill your first pilot hole. The instructions tell you exactly what bit to use. But wait, you say you don’t know what bit is what size? The bits they sell have the size printed on each bit for you.

The instructions make it clear that you should be using a cutting oil. You could absolutely get away without using any cutting oil on this process. This is hardened steel bits vs. aluminum. But you will get more miles out of those bits, and probably a cleaner cut, if you go ahead and liberally apply some cutting oil.

I used simple vegetable oil, which works perfectly well. A spray bottle is nice, but just pouring it on the bit and receiver works just fine, too.

Once the pilot hole is drilled and the guide is removed, it’s time to start the work with the router. You’ll see the intelligent design of the jig here.

There are three sets of guide pillars of different height on the top of the router. These correspond to three different depths of section on the top of the jig. You’ll also find a handy little set of three hashed sections on the corner of the surface of the jig.

The shortest pillars go first, cutting the largest section. Put the router on top of the jig, with the router going into the guide hole. Use the hashes to go bit by bit, making pass after pass.

Follow the suggested pattern in the instructions. Between each pass, use a shop vac to remove shaving from the jig surface, receiver, and the router guide plate. After you’ve removed all you can, use the hashes as a guide to lower the router cutting bit a little more, and do it again.

Take your time, taking only one hash mark worth of metal off each time. When you’re done making the last pass on the last hash mark, you go to the next longest set of pillars, do it all again, then use the longest pillars and do it all a third time.

And you’re done. Spray it all off, clean and deburr it with a hand deburring tool. That’s it. You now have a “firearm.”

The first AR-15 lower receiver took me a total of 2½ hours to complete. That included a drive into town to buy some vegetable oil from the Dollar store and, while I was there, a dipped cone from DQ and a couple of chopped beef barbeque sandwiches (extra pickles, extra onions). The actual work time was closer to an hour.

The next two — a .308 and a 9mm lower — took me 90 minutes total for the both of them, including the deburring and cleanup. In a single afternoon of light work, I machined three firearms, had lunch and some ice cream. That was a very good day.

I’m still waiting on parts to finish the AR-10 and the AR-9, but I had enough laying around to build out the AR-15 lower and match it to a few other AR-15 platform uppers. I had some mostly milspec-ish parts laying around, and assembled the AR-15 lower using those.

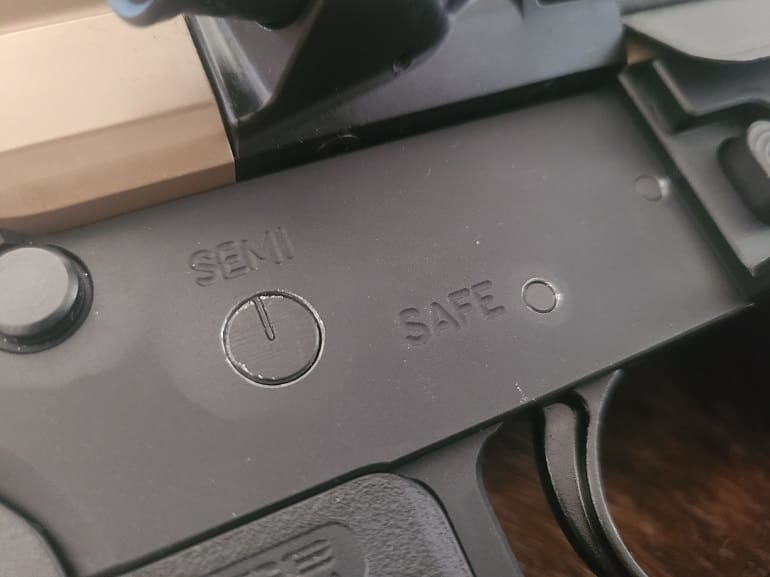

Everything fit great. When compared to actual MIL-STD specs, the trigger well came out 15 thousandths of an inch wide and the takedown lug pocket was 10 thousandths over spec as well. Everything else was dead on perfect.

I’ve seen lowers completed where the selector pin hole or takedown pins weren’t just right, but I had no such issues here. The disadvantage to the slightly oversized trigger well is that the trigger has a bit of wiggle room to move around. The advantage is that any trigger will easily drop in and fit.

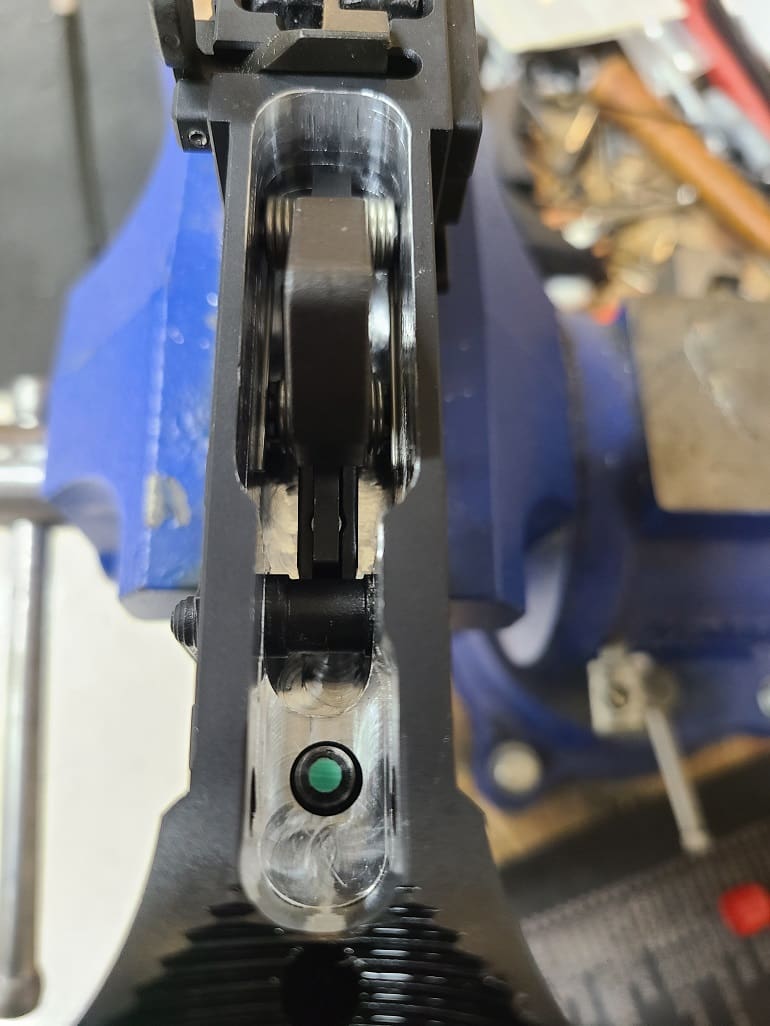

Note the little green button-looking thing near the buffer tube. That’s the screw that exists on some billet lowers that allows the user to insert it from the bottom, screw it up, and add pressure so that the upper and lower mate tightly. It’s a nice, but not always necessary addition.

So how does it run? Like a spotted ass ape.

Does a SIG MPX upper receiver, with its dual captured spring system work on the 80% arms lower? Yes it does, and perfectly.

Does a Daniel Defense 6.8 SPC upper fit and work? Yup.

Does an upper from a $10,0000 hand engraved one-off art AR from Underground Tactical fit and work? Yes, and the combination is a spectacular amount of ridiculousness.

I also ran a bone stock direct impingement Colt Competition upper on the 80% Arms lower and put it through its paces. It worked flawlessly. The takedown pins are a little tight, but that’s a heck of a lot better than loose. You’d have to look pretty close to suspect it was done at home on a router, and not a big brand commercial CNC machine.

I ran a cheap trigger and whatever mixed trash I had laying around to complete the lower, but if you wanted to fill it up with a better trigger and upgraded internals, they wouldn’t be out of place at all.

At the end of it all, the jig and the tools, including the drill bits from 80% Arms, are still in great shape, and ready to do more work. If I had a dozen lowers, I have no doubt I could make a dozen more good, very well performing lower receivers with this kit.

There is a current back-order on the 80% Arms Multi-Platform Jig, as well as all of the 80% lowers. 80% Arms notes on their website that they are currently shipping orders for these items that were placed in late November of 2020. Even if the current national political climate wasn’t hostile to firearms, I have no doubt these would still be selling out.

The 80% Arms Easy Jig Gen 3 Multi-Platform jig works. It’s an elegant piece of kit, able to solve several problems at once. It’s precise enough for the job, reusable, portable, and makes all of the major AR platform lower receivers.

So far, so very, very good. As soon as I finish the AR-10 and AR-9 uppers and get in some lower receiver parts, I’ll finish those and do an update on them as well. I have no doubt they’ll run just as well as the AR-15 receiver has.

Specifications:

Easy Jig Gen 3 Multi-Platform – AR-15, AR-9 and .308 80% Lower Jig

MSRP: $329.99

Easy Jig Tool Kit

MSRP: $59.99

Billet AR-15 80% Lower

MSRP: $99.99

Billet AR-10 80% Lower

MSRP: $129.99

Billet AR-9 80% Lower

MSRP: $159.99

Overall * * * * *

I think I spent more time standing in the kitchen trying to figure out why I came in there this week than I did building these lower receivers. 80% Arms continues to impress me with the clear instructions, ease of use, and overall great final products. This is kit that’s very much worth the wait.

Killer review. Seems like a nicely thought out product.

And when u click on the blue highlights it gets pinged to Homeland Security.

What does that mean?

Don’t worry it always has. They just finally said the quiet part out loud. It doesn’t take millions of gallons of water per day to cool servers in Utah that don’t spy on your every move.

Cash, no plastic. dont have plastic cant order online.

I like the way > I’ < can Google earth and see your house, if you know what I'm saying.

I have one and the routing aspect is genuinely idiot-proof. My issue is that the trigger pin holes aren’t located perfectly in one side, so a box trigger has fitment issues. A mil-spec trigger, or any trigger that isn’t one-piece works fine.

I grabbed several commercial stripped lowers, and installed them into the jig, and then fed the back of the trigger pin drill bit into the guide holes. They passed through the factory lower trigger pin holes one one side, but not the other.

If things calm down I may grab one for a 9mm. Maybe at end of this year. What router do you have? Mine is a huge two handle, I will look into buying a smaller one.

PORTER-CABLE Router, Compact, 1.25 HP (450)

Got it from Scamazon, but they appear to be OOS at the moment. Works very well.

Nice article. Thank you Mr. Taylor.

THANKS FOR INFOR , ALWAYS

I have a previous 80% Arms jig set that required a lot more drilling (8 holes instead of one). Since then, I purchased the 5D Tactical version of this very same jig set. It’s identical, and it does indeed do splendid work. I’ve completed nine lowers, two of them in 9mm. If you follow the instructions, they’re idiot proof. But I’d add that if you have the patience, it’s well worth the extra time and effort to go only 1/2 hash mark at a time — or even less. You’ll end up with a mirror finish even better than what was pictured in this article.

The jig sets from both 80% and 5D Tactical are more backlogged now than they were before, and I ordered mine last August and got it in October, knowing things were only going to get worse. I’m afraid that anyone who’s waited this long, may have waited too long, and it’s now too late. I’m afraid Joe & Cameltoe will slam the door on these companies any day now. This time next year, I could probably sell my jig set for a fortune. Just sayin’.

One went for over 2k in mid Jan and another for 1600 last week. So yeah. These are going to be worth their weight in gold one day. The prob is I bet the atf goes after every single person who bought one…….

Given the fact that HS is now cracking down on 3D, and companies have been raided and their customer lists stolen, yeah, I’m probably high on the list. Especially since I’m on the customer list of at least five different 80% sellers and a dozen gun parts vendors. It makes me wonder why so many people are wringing their hands over “potential registration legislation,” I think there’s enough info out there that they’ve already had a pretty damn good list for years now anyway. I’d been patting myself on the back for “stocking up” on 80% lowers the last two years, somebody’s gotta be scratching their heads and wondering why I’ve bought so many. I’ve got three kids, and ten grandkids, along with a half-dozen nephews and nieces, nearly all of who shoot, or will be learning in the not-too-distant future.

Dude, hey man how are u. I’m Kevin from Massachusetts I’m so lost with my mine I don’t want too get all thoughs tools for one thing can u help out what to do… (603)978-398-8443

IT LOOKS LIKE THIS IS AN (ALMOST) EXACT COPY OF 5D TACTICAL’S AR JIG. I HAVE HAD MINE FOR AWHILE AND IT’S FANTASTIC ! I HAVEN’T USED VEGETABLE OIL AS I USE THE MARVELOUS WD-40 BUT THE VEGETABLE OIL IS A GREAT IDEA & A LOT CHEAPER THAN WD. AS THE AUTHOR SAYS, IT’S EVEN, “brain-damaged-old-redneck-proof” !

Veggie oil makes decent gun oil too according to fireclean.

Never really understood the brouhaha around that (unless it was just the Fireclean people making asses of themselves, which they did). If it’s pure and the smoke point is high enough, there’s no reason why vegetable oil of some kind couldn’t be great gun oil.

As vegetable oil heats it gets sticky. Over time it gums up.

Reading an old army manual about the 1911, two drops of whale oil here, two drops there. Whale oil, how about that.

80% Arms, 5D, and Modulus appear to buy from the same suppliers. All of their stuff has only minor differences. I believe 80% was the first to develop a router jig.

I have ample evidence to suggest that 80% and 5D are in fact, the same company operating under two different names. I have ordered lowers from 80% Arms and received them from 5D.

Things that will make your life easier when using one these, never move the router until it up to full speed and wait until it is completely stopped prior to making adjustments, clear the chips after every pass, make each cut depth half of what is recommended and use lots of cutting fluid. If the end mill starts to chatter, make sure no aluminum has stuck to the bit, if so it will come right off using a exacto blade.

This is an absolute travesty! I cannot believe you would do such a thing! Pickles on a barbecue sandwich! SMH.

This class system is the better choice. I have used one like it on AL 80% lowers very successfully. Also used drill press techniques several times on polymers. Learned about the value of JP weld to fix errors. The best 80% polymer lower was the one with the white trigger pocket with the colored lower formed around it. You could hollow out the white with a toy drill press without any jig. Of course the ATF lied about the manufacturing process and banded them. These router jig systems are expensive but versatility helps amortize the investment.

PS the cooking oil may be better than WD-40. WD-40 has been known to use it penetrating capability to kill primers making for bad ammo. You can always clean the finished part with acetone.

I wish the PTB would leave home builders alone. I’ve built several 80% Glocks but would love to try my hand at a 9mm carbine AR platform, or better yet 10mm or 45. 3D printing is interesting, but alot of info is required before starting

(I do know lubricants; decades of professional experience.)

Vegetable oil eventually turns rancid and stinks…because large amounts of germey bacteria are breaking it down, and you’re smelling their…bodily wastes; toxins that also make you sick if they’re transferred from your fingers to your food. Also may attract vermin, flies, and ants. And it’s not nearly as strong or scorchproof as mineral oils, and synthetic oils are better still. That whale oil mentioned by one commenter is far beyond the capability of any petroleum-based oil (but not the synthetic lubricants that eventually replaced it) so you can see that experts have always specified far, far better oils than vegetable oil, especially when drilling stonger metals like iron, steel, and even tougher ones.

But you know what? I love your idea of using veg oil every once in a while. Sometimes you go into battle with the one you have, not the one you might wish to have, and you just apply yourself and make sure you win that way.

I’d have to agree with Mr. Taylor. These jigs are nearly idiot proof. I’ve had mine a couple of days now, and I’ve done two lowers. Three more to go in this round, and I may order a few AR10’s for some high power builds I want. The jig is unbelievably simple to use, as long as you’re patient and competent. My first lower took just over an hour and a half. Second one was right at an hour. I didn’t take as much material with each pass as I could have, but I don’t like hearing the bit chatter either. What really blows my mind was how quickly I received my order. I was expecting 4 to 6 weeks. I got my order in less than 3 weeks. Couldn’t be happier. I’ll be building several more in the future.

Whale oil has been banned by the tree huggers