When I replaced the horrible “Massachusetts trigger” on my Smith & Wesson M&P 40c with an Apex Duty/Carry Kit, the world changed. Okay, the world didn’t change, but that kit did turn a boat anchor into a precision shooting implement. Naturally, I thought it would be great to upgrade the trigger of my S&W M642 with a kit from the same manufacturer. I checked out the Apex Tactical Specialty website and it seemed like their J-Frame Duty/Carry Kit would make the trigger a lot easier to use. I also checked out the Apex YouTube video showing how to disassemble the revolver, and another viddy showing how to install the kit and put the revolver back together. I figured the process would be piece of cake. After all, if the armorer demonstrating the upgrade didn’t have any problems, why would I? Where do I begin?

The price of the kit was only $25 and the web site promised that the kit would reduce the trigger pull from over 12 pounds to a more finger-friendly 9 pounds. I figured that $8.33 bucks a pound was cheaper than linament, so I went for it. I ordered the kit from Apex, and it arrived in my mailbox within a week. Then the bad times began.

There’s not a lot to this kit. There are three replacement springs – a main spring, a rebound spring and a firing pin spring — and a new firing pin. Anybody can swap out three springs, thought I. I set up my workspace with a small flat screwdriver for the side plate screws, a rubber mallet, a Smith & Wesson “pickle-fork” tool for the rebound spring, sets of needle-nose pliers and tweezers for grasping tiny parts, a set of jeweler’s screwdrivers for tiny parts, a magnifying glass on a stand so I could see the tiny parts, assorted picks to push the tiny parts from here to there, a canvas mat to capture the tiny parts when they fell, safety glasses to protect my eyeballs in the event of a negligent spring discharge and a beer. The beer was the only tool I’d really need, but I didn’t know that.

Taking off the side plate is supposed to be a 30-second job, tops. It was not. No matter how hard I cranked, the hernia-inducing screws refused to budge. I tried PB Blaster, heat, cold, cursing and physical violence. Nothing worked. The damned screws were frustratingly over-torqued. That’s where the beer came into play. What? No, I didn’t pour it on the gun. Are you nuts? Sometimes I worry about you guys. No, I drank the beer and it made me feel better.

I admitted defeat the next day and headed off to the range with the unloaded 642 in my pocket. I expected that the armorers had some kind of miracle tool that would twist the screws right out. They produced – ta dah! — a screwdriver that was an exact match to the one I had been using so unprofitably.

If you ever struggled for fifteen minutes to open a pickle jar and then your spouse gave the jar a little twist and it opened – pssst – just like that, you know what I was afraid of. Well, it didn’t happen. The screws would not budge. Which actually made me happy, because nobody wants to be that guy with the pickle jar. And then it struck me: if I didn’t want to be the pickle jar guy, why did I take the gun to the damn range in the first place?

I should have gone directly to my gunsmith, because everyone knows that gunsmiths have magic powers and thus there’s no worries about being the pickle jar guy. Dave Santurri’s shop eerily resembles the lair of a medieval alchemist. Through a miasma of CLR, gun oil and powder residue, I explained the problem. Dave clamped the gun in his vise, put screwdriver to screw and after huffing and puffing for a few seconds, said, “They’re very tight.”

He’s sooooooo fortunate that good gunsmiths are hard to find.

I don’t know how Dave got those screws out. Maybe it actually was magic, or maybe, after inadvertently huffing all that gun cleaner, he has superhuman strength. However he did the job, in ten minutes I was out the door with a partially disassembled 642 and a tremendous Hoppe’s buzz.

Back at my home work bench, I removed the three sideplate screws, placing them in their own little Petrie dish so they wouldn’t get lost. If you watched the instructional video, you know that the next step is to remove the main spring, and to do that you must pull the trigger just enough to expose a little stopper hole in the stirrup, without making the hammer strike.

I pulled the trigger just a bit too far and the hammer struck. Since I had carefully unloaded the gun prior to working on it, I was surprised to see a small black object shoot across the room at around 300 fps. It took me a minute to locate that little bit. Who knew they could do that?

In the photo below, the tip of the arrow points at my flyaway part. It’s the bit that’s shaped kinda like an anteater’s head. What you might be able to see between that tail and the hammer (midway between the top two circular marks on the tail) is the subminiature sear spring. Don’t feel bad if you can’t see it. It’s impossible to see even if you spend an hour on your hands and knees with a flashlight and a magnifying glass. Don’t ask me how I know this.

Without the sear spring, I was in the crapper but decided to press on. When I removed the rebound spring, I discovered that the pickle tool does not work on a 642-2, but that proved to be no problem. A small flat screwdriver allowed me to depress the spring enough to remove it without mishap so I could replace it with the Apex spring. I also took the time to remove the internal lock. There’s a viddy for that on Youtube, too. The video takes ten minutes and features the most vapid music this side of an elevator. Removing the lock takes ten seconds and does not leave the gun with a hole in its frame. Here’s what the lock looks like once it’s out of the gun.

Okay, I removed the lock and swapped out the three springs and the firing pin with ease. As for the missing sear spring, I called Smith & Wesson customer service and ordered a replacement spring. The price listed in the parts catalog was 51¢, but S&W agreed to send me two without charge. The springs were delivered by my letter carrier in just a few days. Bravo, S&W. Your screws might be tighter than Dick’s hatband, but your customer service is more delightful than a summer’s day.

There’s a small space between the tail and the hammer where the missing spring is supposed to live. A little hole in the tail secures one end of the spring, while a shallow détente in the hammer captures the other end. After wonking around with my new sear spring, using every tool, clever ploy and workaround in my arsenal, I couldn’t get the damn thing to fit. After an hour I began to get a sneaking suspicion that I’d ordered the wrong effing springs.

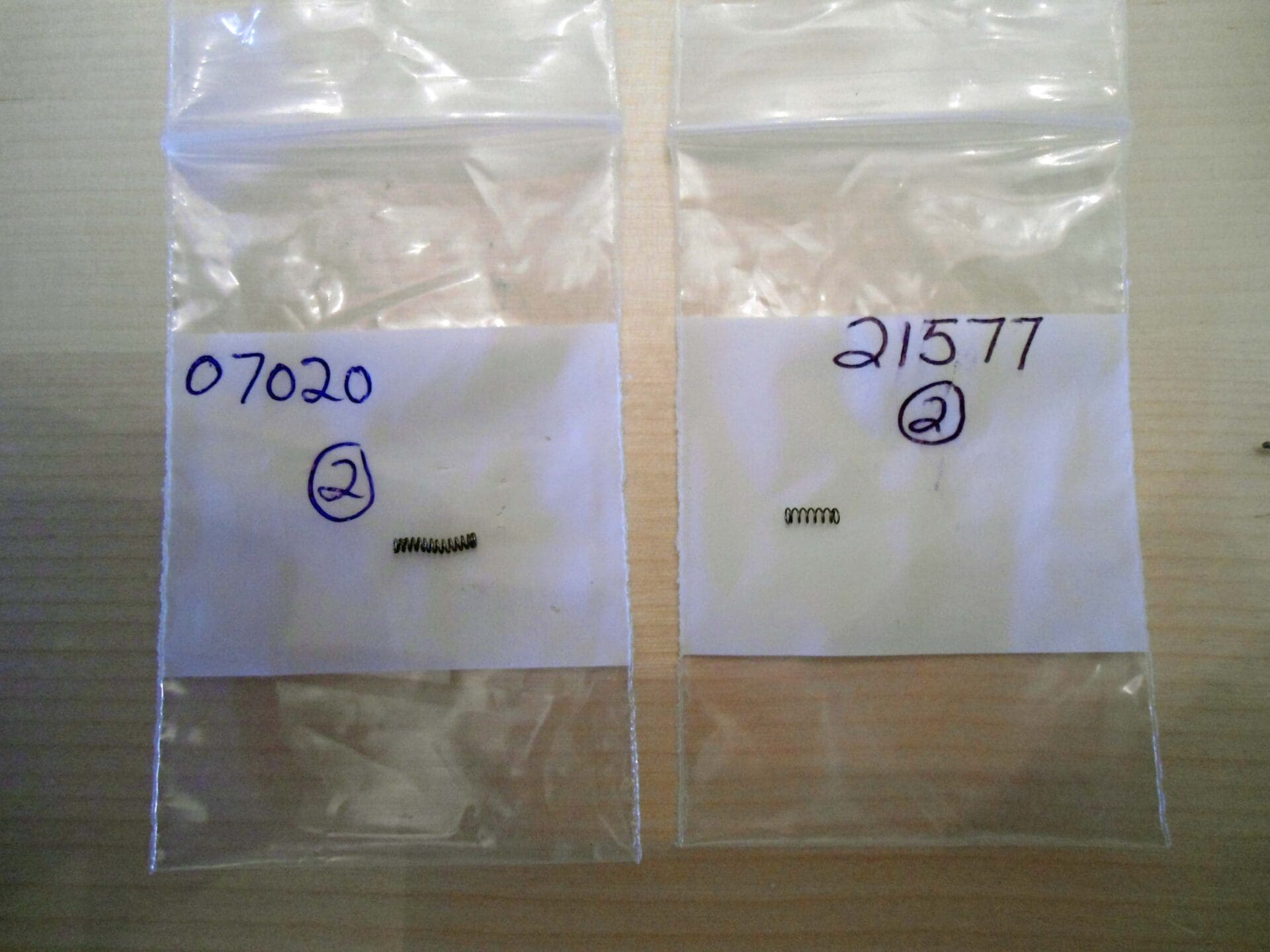

I called S&W customer service the next day, hoping that I wouldn’t end up talking to the same CSR from my previous call because, as we’ve already established, nobody wants to be the pickle jar guy. I got hold of a different CSR. I was going to mention that I’d heretofore ordered the wrong springs, but it slipped my mind. My new best friend agreed to ship me two correct sear springs right away. In just a few days, I was the proud possessor of two springs that actually fit. In seconds. With no expletives.

The part numbers are on the little nickel bags. The correct spring for a 642-2 is on the right. The one on the left, which didn’t fit, took a beating at my hands – for which I remain unapologetic. I’m keeping the twisted bastard around to serve as a warning to any future springs that may want to give me a hard time.

It took me two and a half weeks to do a ten minute install of the Apex kit. My trigger is now smoother, lighter and more refreshing than the old, heavy trigger, and I’m rid of that detestable internal lock. The kit works exactly as described, and it’s well worth the $25 cost.

Once I get over my PTSD, I’m going to polish the internals of my 642 with some really fine wet-dry and make the trigger perfect. I’ll let y’all know how it turns out.

Pray for me.

SUMMARY

It’s cheap, easy to install and lightens the trigger weight by 25% with 100% reliable ignition.

OVERALL RATING (out of five stars) * * * *

It’s a duty/carry kit, so the trigger is still heavy. Well, it’s a revolver, so what do you expect? Buy the kit and install it. I did, I went through torture and I’m happy anyway. So will you. Be happy, I mean. The torture is entirely optional.

Ralph, I so look forward to your reviews. Just the right mix of information and humor. Well done.

I’m a fan too. Best tip I can offer are magnets; trays, probes and huge powerful ones. Usually after I’ve spent 10+ minutes looking for the errant part I fetch the magnet to sweep the room and crevices, fabric folds etc. but strangely enough when I walk in with the magnet my eyes spot the part and the task resumes.

I have the same brand of magic magnet. And sure enough when I begin searching for the part that took flight I spot it across the room. Usually though a good shake of the Lazy Boy will drop a stray part on the floor..

The APEX spring kit for the 442/642 J frames makes the Performance Center’s action jobs as smooth as butter.

Ha ha. Pickles and beer go good together.

OK, here’s a tip for all of you who look at a gun and think “Hey, it has standard slotted screws, how hard could this be?”

Screwdrivers, for a gunsmith, are precision instruments. If I don’t have a screwdriver that fits the screw *exactly*, I will make one out of drill rod that is slightly oversize, then I will heat/quench/temper the tip of the screwdriver back about, oh, 1/2″, then I’ll finish-fit the blade to the screw under “discussion.” Fitting a screwdriver to a screw involves both the width of the blade in the slot, as well as the side-to-side “diameter” of the blade to insure you don’t bugger up the hole into which the screw goes.

When I’m done making a screwdriver, it gets labelled with the application and hung over the bench.

If you’re about to take a Sears Craftsman (or other typical) auto-shop/home-repair screwdriver to screws on a gun, please, in the Name of All That Does Not Suck, please, stop. Just stop it.

You would not believe how many guns I see where some kitchen-table hack has buggered up the screws on a fine gun with screwdrivers they use on their lawnmower. It should be a criminal offense.

Yup, I miss the days when mechanisms were designed such that the end user could work on them, too.

From what I see in the pictures, there’s nothing inside that J-frame significantly different than most other S&W revolvers.

Revolvers, since their invention in the mid-19th century, have always appeared “simple enough” for inexperienced or untrained people to work on them. When you look inside a Smith or Colt SA/DA revolver, you say “There’s just not that much there… how difficult can this be?”

If you open a Colt SAA or clones, you would really say “How easy! Look at how few parts there are!”

And you’d be wrong. Oh, so terribly wrong.

The complexity of revolvers is subtle and not obvious to the inexperienced. The angles of mating parts, the timing dependencies between parts, etc… that’s where the complexity snares the neophyte in revolver smithing and it’s been this way since the first revolvers hit the market…

Where do you buy good ones? I can’t imagine the cheapo chinese ones that CTD or CDNN sell are any good.

Midway

Brownells

cabelas (probably)

Anything made in China of steel is a piece of crap.

Good gunsmithing screwdrivers can be had from Brownell’s or MidwayUSA. I have sets made by Forster and Wheeler for general use, but once you start dealing with older guns, or obscure guns, or very fine guns… these sets are wholly insufficient.

The drawing on this page of the difference between gunsmithing screwdrivers and common automotive/household screwdrivers explains the differences:

http://www.forsterproducts.com/store.asp?pid=24836

In the URL below, people can see what happens when an amateur hack gets a common screwdriver onto a fine double gun:

http://www.finegunmaking.com/page16/page16.html

The discussion of considerations in making screwdrivers is also useful.

I’m sure people here will say “That’s a whole lot of work just for a screwdriver.”

Well, yes, and that’s the mark of a professional gunsmith: You can’t tell that he’s been into your gun, because the screws still look virgin and new when he’s done, and on a fine gun, they’re timed correctly.

I, too, am a member of the Lost Sear Spring Club. Took a month to get the replacement (bought two just in case).

We are a brotherhood of lost

soulssprings.I want a beer. I’m at work, which is terrible news. But I want a beer

I have a work keg (pale ale) out back, maybe I’ll have one for you.

I’ve got ~10 acres of grass to cut today. I’ll have several for you

I launched my M&P 9 Sear Plunger into low earth orbit trying to get it seated onto the microscopic spring. Apex sent me a free replacement with the spring already mounted in just a few days. I bet Apex gets at least a few of these sad stories each week. Your story sounded all-to-familiar and made me chuckle.

This may be a silly question, but do all 642s have 12 lb triggers or is it an MA thing? I have a 642 pro series and without having measured I’ve perhaps incorrectly assumed from just feeling it that it was around 9 lbs stock?

-D

I was looking at Wolff for some J-frame springs and they implied that they were all 12lb from the factory.

As far as I know, there’s no special MA trigger on the J-frames. While there will always be some variation among triggers, they’re mostly around 12 lbs.

I’m going to have to A) measure my 642 pro and perhaps B) recalibrate my trigger weight estimation ability.

-D

The Pro series may have a lighter trigger pull. They do have some factory upgrades from the stock pieces; like bossed mainsprings.

The from-the-factory DA trigger weight for most S&W revolvers is around 12 lbs.

Well ill be damned. Just measured a 642, two 36s, and my 642 pro, and they are all around 12.3-12.5 lbs. I totally underestimated that. I think i am going to give this kit a whirl on the pro.

-D

Here’s an easy way to deal with ‘tight’ screws. Go to your local pharmacy and ask for oil of wintergreen (also known as horse liniment) put a drop or two on the stubborn screws and wait anywhere from 30 minutes to overnight. Unless it’s all but welded in there with corrosion etc. the stubborn screw backs right out. Plus you get this nice minty fresh smell in your shop and on your gun. 🙂

Awesome story. Enjoyed the read.

Nice read, glad to see you worked it all out. For my money, I think I’m just going to have a professional do the stoning and spring install all at once. Alot more expensive, but that seemed like a huge headache. Does anybody have any experience with S&Ws performance trigger job for the J-frame?

Quite the adventure! Makes me glad I got my wife an LCR to go with her 686+ instead of a J-frame.

The LCR… On the grounds of “traditionalist” I wanted to hate it, I tried to hate it… but it absolutely has the sweetest trigger in its class.

-D

Ralph,

Thank you for reinforcing my mantra to young persons: go to school, work hard, get a good job, work hard, spend wisely, save a lot. Then: pay the proper professional to do the trigger work on your 642, while you enjoy a beer (in moderation). (I’m betting the all-in calculation of your direct costs and opportunity costs was way in excess of what a competent gunsmith would have charged—without all of the “pickle peril!”)

Save your talents for the installation of the Crimson Trace laser grip, which even I had the requisite tools, skills and patience to do.

I’m also with the group that favors the LCR trigger stroke. Ruger is on to something there.

My mantra to young persons: go to school, work hard, get a good job, spend wisely, save a lot and marry money. This system worked well for my ex-wives.

Yes, but how many of your ex-wives can do a trigger job on a 642?

Neither, but they can hire someone to do it for them.

Ralph,

Loved the article. I can only imagine how wry your legal briefs have to be.

I saw this product for the J-frame at Apex as well. There is nothing wonderful about my Model 638’s trigger and any improvement would be welcome. I considered buying the kit and in the short time I contemplated it a tableau of misery miraculously expanded before me, composed of launched springs, cussing, manipulations of tiny objects with my giant mitts and afternoons wasted until I could pass the mess over to my mechanically-gifted brother who fixed it in two minutes less than Apex’s recommended 10 minutes. My adventure with the J-frame spring kit died aborning. I congratulate you for having the fortitude to progress beyond the optimism stage that you knew was probably too good to last. Thanks for confirming all my worst fears. 🙂 I appreciate your effort.

Still haven’t bought the kit. My Glock 26 has a far better trigger and 160% of the capacity of my J-frame, plus it reloads in a fraction of the time. Problem solved.

When I took appart my J frame (442. Same gun, but black.), I had simmilar problems. Good screw drivers help, a lot.

http://www.midwayusa.com/product/439523/wheeler-engineering-89-piece-professional-plus-gunsmithing-screwdriver-set

Best $70 bucks i’ve ever spent. Brownells Magnatip bit sets are really nice, too, but they’re a bit more spendy.

Congratulations on your successful trigger job. Since you took the gun to the smith anyway, why didn’t you just bring all the parts and let him have the pleasure of changing them out, thus saving yourself the aggravation?

Santurri didn’t have the time to do the install for me.

I don’t own a “J” frame S&W, don’t really have much interest in ever owning one, but your review was still an interesting read. And I am also part of the brotherhood of lost springs. I am always amazed how a spring that is only 1/4″ long can travel 40 feet and go around corners to hide behind a bench leg (best case scenerio) or launch into the air and swirl in mid flight into another dimension, never to be seen on this earth again (what usually happens to me).

It gives a whole new meaning to “spring is in the air.”

A gunsmith friend of mine once told me that the most common sound while working on a revolver was “SPROING! ping – ping – ping …. Oh Sh*t!”

I once took the side plate off a Smith & Wesson revolver. Looked at the internals with all of the tiny springs and other tiny doodads. And then VERY carefully, making sure not to disturb the internal harmony of the machine or the universe, I put the sideplate back on the revolver. Hey, I do blacksmithing – if I can’t adjust it with a 3-pound straight-peen hammer, it’s too delicate.

Here’s a tip for amateur gunsmiths: If you have taken your firearm apart and wound up with a plastic bag full of small parts and the frame of the firearm, do NOT take it to your gunsmith in that condition. Put the plastic bag into a nice cigar box, and then take it (with the frame) to your gunsmith. A “cigar box gun” has a lot more class than a “plastic baggie gun”. Another tip: do not leave the cigar box at the gunsmith’s. Gunsmiths are human, and many will fall prey to the temptation of saying “gee, can’t remember where that nice [handy, convenient for storage of small parts] cigar box went, but here’s your gun back in tip-top condition!”

Heck, am I the only one who managed to install the Apex kit in my (438) J-frame in under a half hour?

If you are working with springs, put a gallon-sized ziploc over the gun while you work.

Also, if you lose a spring, the best thing to do is duct tape a sock or pantyhose inside a vacuum cleaner as a filter and vacuum the whole room. Take the “filter” out and sort through the contents to find your missing spring or part.

I use one of those magnetic pickup tools, the ones roofers use to pick up nails.

My first (and probably last) adventure in revolver smithing involved an el cheapo Taurus. I’d never take a chance on screwing up my Smith 642. Ralph’s experience with the sear spring is awfully familiar, except that Taurus won’t sell you a new one, the Smith sear springs I tried didn’t fit, and shipping the gun back to Miami costs almost more than it’s worth. A mutilated ball point pen spring now serves.

Here’s the best and easiest way to fix the trigger pull on your 642: Dry fire a Taurus. Then dry fire the 642. You’ll notice that the 642’s trigger is absolutely wonderful just as it is.

Got a special spring tool from midway and job went perfect. Videos were perfect. I’ll do all my J frames using this site.

Just bought one if these and followed the you tube video changed out everything and installed hogue grips in less than 30 minutes… On the toilet… I’ve also built 2 AR’s on the can… Gotta love IBS. I think your gun was the dud, not the kit 🙂

The manufacturers ram those screws in with a constant velocity screw gun with a clutch on the driver tip. It really jams them in super tight, and everyone from automakers, to gunmakers, to electronics instrumentation device manufacturers do it now. My really old 9 volt Makita drill driver comes to the rescue, again, and I use a Brownells tip that perfectly matches the screw heads. Set the torque on the old drill for medium or low low so the old drill ratchets & rattles and it will work somewhat like an impact wrench, & rattle them out. You think messing up a $445 S&W J frame is bad, try butchering a $13,000 Japanese flow sensor in use on a working $120,000,000 manufacturing line. The Japanese sensors all took a JIS cross point tips, and the grounds were all rammed into a cast housing with an amount of excessive force even Godzilla would envy. I am none too crazy about those constant velocity clutch actuated manufacturing line screw driver guns. That is how those screws wind up just jammed in so tight it is almost beyond belief. It is the high momentum of the driver that just rams the screws in super tight before the torque limiter even reads the torque let alone hits the set break point & the ball detent pawl slips. My old Makita 9.6 volt stick battery drill does many nifty tricks it was never intended for. Backing out stuck roll pin punches is another neat trick using that torque setting that ratchets, slips and has a very user friendly light hammer action. Make sure you check the rotation by holding the chuck & restricting it from rotating at full speed. Hold it completely stopped to back out punches, while the drill ratchets & rattles the punch back out. It works like a charm! A pattern maker’s/ gun smith’s vise is also a must.

i just finished installing the Apex Tactical J-Frame duty carry trigger kit for my 38 S&W Airweight. After reading all the great reviews regarding the huge change in how the trigger pull makes the gun so much better I found myself very disappointed.

I was able to do the total install in less then an hour by watching Nutnfasy YouTube video on installing the new springs. It all went fairly easy and I was happy that I got the gun back together but when I fired the 38 Airweight I felt that the trigger wasn’t changed by the new parts. To be honest I felt it had a slightly harder trigger pull.

I feel terrible after reading all the reviews on the Apex spring kit. If I only needed a replacement set of springs the Apex is great and works fine but I didn’t feel anything different when pulling the trigger.

I now have gone ahead and order form another company a set of springs that can be customize. I’m hoping that’s make the changes in trigger weight I’m trying to achieve.

My friend I feel your aggression and the whole intensity of searching for the #21577 sear spring which I’m going to call and see if I can snag one for my self. It’s funny cuz it was the first dam thing that went flying into the abyss of the carpet monster. I even tried the hardware store then snipping a couple rings and squeezing the dam thing to fit into the hole 🤬. No go! Thanks for the post!! I’m ordering it now!!

interesting info on the spring kit. I am looking at a pair of s&w 38spec airweight 642s. one regular and one w/ C. trace in the grips. I was originally concerned about the trigger untill the seller said he had put a spring kit in both.

getting both for 750. is that a good price? one speed loader.

Comments are closed.