TTAG’s readership is a well-informed crowd. So I’ll spare you an explanation of the purpose(s) of an eighty percent lower. I will say, however, that if you’re not making at least a portion of your (where legally permitted) DIY firearms each year you should strongly consider doing so.

At the very least, it’s a great way to further your continued learning about the mechanics and maintenance of firearms. The better you know your tools — both those on the workbench and “on your hip” — the easier it is to deploy, employ and repair them, if needed.

When it comes to eighty percent lowers, polymer is a popular choice. The finishing process is less-intense than aluminum (think hot knife cutting through ice cream versus cutting though an ice cube). Polymer lowers tend to be lighter and less expensive than aluminum. However, there have been more than a few instances where polymer frames have failed due to poor material choice or design.

The folks at James Madison Tactical (JMT) have decades of experience in aerospace engineering and manufacturing. They have a range of skills and knowledge easily transferable to the firearms industry, as we’ve witnessed through their Saber Drop-in Trigger.

JMT ‘s AR-15 80% Polymer Lower (Gen2) is a prime example of intelligent humans thinking critically to produce a solid product. Gen2 utilizes the same special composite/polymer blend as Gen1, lending itself to increased durability while remaining easy to mill.

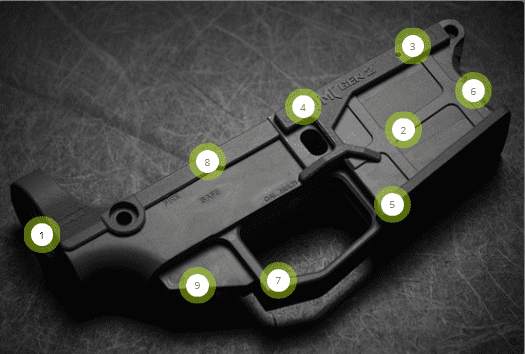

On its product webpage, JMT calls out nine features of the Gen2 lower receiver:

1) Enhanced buffer tube mount

2) Grated magazine well matched for PMAGS

3) Textured areas on lower receiver

4) JMT markings

5) Flanged magazine well

6) Grated front finger hold

7) Oversize trigger area

8) Boxed longerons on left and right side of fire control pocket

9) Threaded brass [grip screw] insert

While the many of the Gen2 upgrades are cosmetic refinements, there are also several design changes that increase compatibility and strength: extended upper fire control box sections, upper left magazine well box section and extended bolt release roll pin posts.

It’s worth noting that JMT’s manufacturing process calls for the buffer tube mount to be molded around buffer tube threads. So instead of threading the buffer tube mount post-molding, they simply unscrew the buffer tube thread portion of the mold once it cools. Aligning the buffer tube thread mold to the overall mold helps to ensure more precise placement of the threads.

The JMT Gen2 lower comes with a polymer machining jig. The jig’s designed for one-time use and fits the Gen2 lower perfectly. The polymer jig surely isn’t as forgiving as a steel jig, but it comes at no additional cost; if you prefer to use an alternative jig it’s no loss.

When using the included JMT polymer jig, I recommend using vice plates and paying close attention to any flex in the jig due to over-tightening, which could potentially lead to axis misalignment.

Using a drill press with manual X/Y axis controls, I got to work on the remaining “twenty-percent,” following a fairly standard process that begins with the trigger pin, hammer pin and selector holes.

As it was my first time using a polymer jig, I admit I was nervous. But each of the three presses of the appropriate bit perfectly hit their mark on the other side of the jig.

After flipping the jig ninety-degrees, ensuring the press was set to the appropriate RPMs, and triple-checking axis alignment, I began the laborious (and rewarding) process of hand-milling the fire control pocket, trigger pocket and trigger slot.

I quickly determined the limits of the material/bit/RPM combination. I worked the bit methodically within the confines of the jig. Pass by pass, I removed the unwanted material from the two main cut areas, then finally pushed through to create the trigger slot.

Working with JMT’s composite/polymer material was easy. No splintering, cracking or melting. The material cuts cleanly.

The detailed yet simple machining instructions provide the information needed to keep the user on-track. Due to its contrasting color, the jig is also a good platform for feedback.

If I saw light grey remnant at any time during the finishing process I knew I was cutting outside of specifications, or drilled completely through the lower. Compared to a steel jig, you don’t risk damaging your bit or kicking the jig out of place. A downside: you can easily cut through the jig, permanently removing critical material from the lower.

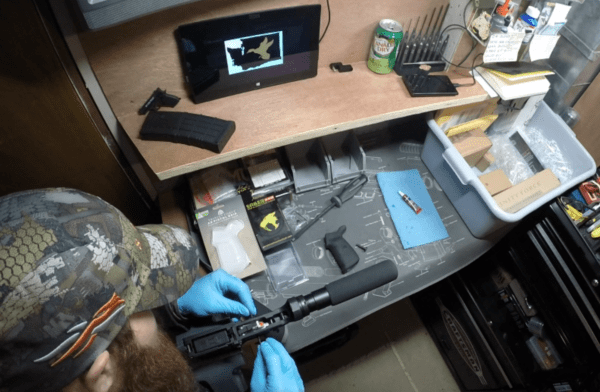

Once the milling was finalized to specifications, I took the new “firearm” over to the workbench to fit the hardware and mate the upper. Working my way through the orderly installation of components I encountered a variety of fit tolerances.

The molded buffer tube threads, pre-milled bolt catch and pivot troughs, and pre-drilled buffer detent, pivot/takedown pin detent, bolt catch plunger and mag catch spring holes all fit well with their appropriate components. The brass grip screw insert is a great touch; it provides added security for a wide range of grips that fit to the lower.

I encountered zero issues across a selection of drop-in triggers, anti-rotation pin sets, selectors, end plates (standard and QD) and buffer tubes (with and without ears).

There were a few surprises. The takedown and pivot pin holes are slightly oversized, allowing the pins to wobble more than I’d like when they’re in the “out” position (no issues when assembled).

The magazine release trough and magazine release button hole were under and over-sized, respectively. I removed material from the magazine release trough to allow a Mil-spec magazine catch to fit properly, then removed a little more to make an ambidextrous magazine catch fit perfectly.

Several ambidextrous magazine catches are not compatible with the JMT Gen2 lower, such as the Troy ambidextrous magazine release. All magazine release buttons I tried resulted in a sloppy fit. Angled buttons may require the removal of a small amount of material from the frame of the lower in order to function reliably.

Mating the lower to its 7.5″ Spinta Precision/Trinity Force/Cross Machine Tool .223 Wylde upper was rewarding. Finding no play at the pivot pin, I removed a minute amount of material from the sides of the CMT upper’s takedown pin hole post (mostly coating). The two complete halves locked-up well. Zero wiggle, nor waggle.

On the range, I dumped over five hundred rounds of CapArms .223 Rem 55-grain FMJ and 69-grain SMK through the platform, over an afternoon spent testing various buffer systems and tubes, gas systems, barrels, and BCGs.

The lower integrated well with each change. All mags fed consistently, bolts locked-back and tolerances remained. Altogether, the JMT Gen2 lower shows no signs of weakness.

Despite its angular profile, the Gen2’s oversized trigger guard is quite comfortable. The ribbing on the front of the magazine well and flared squared-edge magazine well lip provide lots of potential for positive contact and control.

James Madison Tactical’s Gen2 AR-15 Eighty-percent Composite/Polymer Lower is an excellent balance of technical, functional and aesthetic considerations.

The lower is simple to finish. It proved to be a reliable mix of material and solid engineering. Its design lends to compatibility with most AR-15 parts.

While there are a few areas are that could use another look and possibly some adjustment, the JMT Gen2 AR-15 Eighty-percent Lower is a great option for your next build.

Specifications: JMT AR-15 80% Polymer Lower (Gen2)

Price as reviewed (Gen2): $99.95 MSRP

Colors: Black, Wolf Grey, ODG, FDE

Ratings (out of five stars):

Design: * * * *

JMT’s Gen2 lower is simple to finish, feels great to shoot, and is visually pleasing, to boot. The magazine well is sculpted to match Magpul magazines, flows well with the other lines of the design, and will appeal strongly to PMAG fans. There are several areas that could be improved, but they are not function-critical.

Jig / Finishing Process: * * * * *

The included finishing jig is more than adequate for completing the “twenty-percent tasks.” While the jig can be flexed, I never found the jig to actually flex in the vice or create any issues. The finishing process itself is clearly outlined step-by-step with very nice diagrams. The composite / polymer material is forgiving and produces a smooth finish.

Durability: * * * * *

The composite / polymer material utilized in the Gen2 lower, combined with precision engineering, makes for an extremely durable product. The lower can take a beating from high-pressure uppers, holding-up better than most polymer alternatives. The material also seems to resist scratches quite well.

Compatibility: * * * *

While most aftermarket components I tried fit well with the Gen2 lower, I was disappointed that the design inhibited the use of several popular ambidextrous magazine catches.

Overall: * * * * 1/2

JMT’s Gen2 AR-15 Eighty-percent Lower is a rock-solid product that will appeal to experienced and novice builders alike. The included jig and nearly dummy-proof instructions allow completion of the lower in minimal time with basic tools. Gen2 has a few kinks to iron out, but that shouldn’t stop you from seriously considering this lower kit for your next eighty-percent build. The JMT Gen2 Eighty-percent Polymer Lower is an excellent option, available at a very fair price.

[h/t @dawgpoundtactical]

Good article. But I’ll still pass on the polymer lower. “Silicone parts are made for toys”

It isn’t made of silicone. And I’ll remind you that everyone said aluminum was made for toys when the AR-15 was new. In some respects, fiber reinforced polymer is stronger and more durable than aluminum.

InRange TV makes this same argument in their “What Would Stoner Do” series. Idea being how Stoner would build the AR if he had access to modern technology given what they know about his initial design and philosophy from back then.

Because yeah, steel and wood was how you made rifles. Stoner came along with forged aluminum and fiberglass (later plastic), which was considered stupid and wussy. It’s not unreasonable to assume that Stoner would have used polymers abound in his design today.

JP Enterprises makes over-sized pivot pins to eliminate waggle.

They also make under-sized ones, which was nice for my too-tight Daniel Defense upper.

Great review.

I’ll be interested if the buffer tube ring fails.

I was with you till the price. For that I can get a fancy engraved aluminum 80% (free pickup too thanks to being local)

Not sure I see the value in a $100 polymer lower when you can buy a complete finished forged aluminum lower with parts kit and Magpul furniture installed for $150. I understand the appeal of “building your own”, but if you’re doing all that labor, shouldn’t it be less expensive?

It’s all about the serial number and the ATF 4473, or the lack thereof.

Yeah, I suspect the dozens of 4473’s I’ve already filled out have tipped off the gubmint that I own guns. That horse left the barn a long time ago.

If I want an “off-the-books” rifle, I’d rather buy one in a private sale than overpay for a plastic lower receiver.

This statement sums it up for me too.

It certainly looks like a fun project but for $100 I could buy two cheap aluminum lowers that will probably out perform this.

Even as a Glock owner, I hesitate at the idea of plastic rifle.

I would like to see an article on TTAG that “rounds up” the more popular Aluminum 80% lower kits/jigs available and describes the tools and know-how needed to get the job done.

I would love to own a gun with no serial number (lawfully), if only to prove to the libtards just how stupid our gun laws are.

Sounds like the ‘surprises’ are the kind of thing I wouldn’t want to deal with, although someone eager to make their own might not be put off.

I might be interested except my arsenal of tools involves no jig or even drill press (I have a bunch of saws, will that help?)

> buy a laminate router and 80% Arms easy jig.

> make all the lowers you ever want out of whatever material you like

https://www.80percentarms.com/pages/easy-jig-information

So here’s the thing, devil’s advocate-wise…

Suppose where you are they actually get some balls and decide to start collecting up all the ARs in the neighborhood? Since the BATFE says that the lower receiver is in fact the firearm you could in theory dismantle your AR and hand over the lower, sans trigger, bolt carrier and other important pieces, and throw the rest of the stuff in a box. As soon as the goons leave the premises you can break out your 80% lower (without a serial number), go down to the basement, and in a few hours have a complete AR again named Casper.

In (unrealistic) theory, yes. And the same would apply to any gun, given that person had a block of acceptable material and the tools to machine it into a receiver, frame, and other parts.

Now, if a government entity forced a collection of all AR-style firearms, all AR parts would also be included in the ban. So by holding back parts, then making a non-serialized lower, and then assembling all parts into a working firearm, that person would be committing a litany of felonies (with a LOT of effort). And if you built it, your DNA is on it.

Also, law enforcement really only comes to homes to seize weapons if they have a warrant / probably cause. If there was a blanket forced seizure of firearms, folks would be required to bring the weapons to a (heavily guarded) collection point. Sending law enforcement into neighborhoods to round-up guns would most likely be a literal suicide mission.

Biden and the current administration is very capable of sending enforcement on a suicide mission to do just this; as the objective is to disarm society and establish totalitarian rule that would make Hitler seem like a nice guy.

I like your thinking. Approved comment.

$99 seems a bit steep for an 80% polymer lower. Recently another maker of 100% finished polymer lowers dropped their price from $80 to just $40. So unless you’re just looking to create a gun without a serial number that you can never legally sell, what’s the point?

The fiber-reinforced polymer used in this lower, combined with the design, provides a lightweight option that is much stronger than regular polymer “$40” lowers.

And plenty of people are looking to create a non-serialized firearm that they will never sell…enough to warrant an entire market of competitors, as you noted.

(assuming you are not an FFL of some sort)

you can legally sell finished 80% lowers.

you cannot finish an 80% lower with the intent of selling it.

there is a difference.

::edit::

you can legally sell a finished 80% lower that you built for personal use.

you cannot legally finish an 80% that you intend to sell.

there is a difference.

Can you explain the difference? My understanding was they were the same thing. I mean I get the ‘difference’ in intent, but how would the law differentiate?

I bought a JMT lower a couple of years back, no complaints whatsoever. you can sell one of these the same as you would a serialized lower. by going through an FFL dealer. the lower would become serialized at that point via engraving serial numbers on the lower itself.

To all you guys bitching about price.

Really? I’ve had a JMT Gen2 lower for 3 years now. Mated up with a DPMS Oracle in 5.56 NATO and using C Products steel mags. I’ve beat the ever living hell out of that thing and it still runs. Is the Gen2 perfect? No, not quite, as it took some minor tweaks for the trigger group parts to fit. Am I crying about it? Hell no. I’ve been on the phone with Dan (one of the brothers) from JMT, not to complain but just talk. He took the time to talk me. And that right there is enough to ensure a base of solid customer service and loyalty from me.

Price….? They have sales all the time. 20% off. Well under $100.

The point of the polymer lower (and this one is NOT like the cheap s*** such as cough cough, Polymer80) is that one can assemble a rifle, undocumented to the “gubment” and have damn good lower in the process. A lower that’s made of polymer but will actually HOLD UP to abuse and maintain tolerance. I’ve dumped mag after mag, thousands of rounds, on my lower and it’s honestly impressive. My brothers didn’t believe it and now they have them too from being impressed. The JMT is NOT some cheap plastic horse s***. It’s SOLID and I’d put it up against any forged or extruded aluminum lower any day of the week. Nevermind I have 19 years in the 101st AIRBORNE, and 10 years as a master control sergeant and second armorer with the NCDOC SORT. It really IS a solid piece. Sure the jig isn’t ideal but anyone with even a half bit of mechanical and milling skill can see and work it out. Instructions are clear, depths given presicely… if you can’t follow or read them or you don’t know how to use your tools, then don’t bother. However, if you’re not stupid, you can have a fantastic lower that will take beating.

SGT JC Davis

Tarheel Gun Rights

X2 Sgt Davis. A good piece.

I love this “but it’s PLASTIC” nonsense. So are Glock lowers and the lower/frame of every other modern handgun out there. So is the lower of the vaunted ACR. I got it, the ACR is basically vaporware, but the point is that it was a good design and it still used a polymer lower. I also don’t understand what’s going to cause this lower to fail. There are little to no gas pressures entering the lower receiver. Exactly what significant stress is the lower going to absorb besides just the normal stress of recoil? Polymer AR parts have survived recoil since forever.

I just want someone to come up with an actual example of a polymer lower failing, or anything solid besides the same old “A MAN’S GUN SHOULD BE METAL” bullcrap. As has already been stated above, they said the same thing with the AR-15 first came out, and look where we are now.

The funny thing is, I’m not even some polymer fanboy defending his baby. I do have a Tennessee Arms polymer 80 lower, but I haven’t milled it yet so it’s not like I’ve even fired it. But I’m sure it will be perfectly fine.

Plastic is everywhere, Glocks, AR-15 magazines, so this can be a good idea to.

Generally I don’t learn post on blogs, however I wish to say that

this write-up very compelled me to try and do so! Your writing taste has been surprised me.

Thanks, quite nice post.

“If I want an “off-the-books” rifle, I’d rather buy one in a private sale

than overpay for a plastic lower receiver.”

Unfortunately in places like Oregon and Washington state “Universal Gun Registration” makes even handing your AR to

a friend at a firing range a felony now. Gun grabbers have stopped trying to ban guns and now have

moved to just make sure you cannot exercise your 2nd Amendment rights. The State Police in Oregon make a

point to harrass gun owners at places

like Cabalas for the slightest issue so buying a 80%

Lower is now a necessary fact of life….

Which one worked?

I was disappointed that the design inhibited the use of several popular ambidextrous magazine catches.

Gear up as your favorite Delsin Rowe Vest. Slim Fit Leather Jackets brings this iconic jacket from animation to reality, especially for all the fans of this video game. Delsin Rowe is the main protagonist and playable character, a young Native-American man who later realizes he’s a Conduit with special powers.

Just as an update… after almost a decade of using the same Gen2 JMT lower… mating it with multiple different uppers from different owners just to prove a point from the crap-tastic PSA Freedom series, to high end makers such as Daniel Defense… and plopping many a round of 5.56 and .223 the JMT has… Gee guess what… STILL HOLDING UP JUST FINE AND DANDY. The guys at JMT did a great job with the design of their lower and they could use some support from us 2A people.

Comments are closed.