Lone Wolf has been the #1 name in aftermarket GLOCK accessories, at least based on sales volume, for many years. While they’ve earned a solid reputation for decent quality at extremely competitive prices, they’re now looking to capture another segment of the market; buyers wanting even higher quality parts that are made in the United States. First up in what will be a growing roster of made-in-the-US products is the Alpha Wolf barrel series available in stock length, threaded, and conversion caliber flavors.

One of GLOCK’s MOS pistols would seem to be an obvious candidate for hosting a suppressor, but GLOCK doesn’t make threaded barrels available a la carte. And the few factory pistols that came with a threaded barrel used metric thread patterns that we don’t see much of in the US. If you want to suppress your GLOCK — and why wouldn’t you? — you’ll have to turn to the aftermarket. For me, this meant an Alpha Wolf M/19 for my G19 MOS.

These new barrels come in new, retail-friendly packaging. While I don’t care about the ability to hang one up on a peg like a gun shop would, it’s still cool to get it in a box with the stand-out features listed on the back rather than in a plain plastic tool tube (like a carbide bit is usually packaged) as LW’s previous barrels were shipped. In case that’s hard to read in the photo, the Alpha Wolf barrels — threaded or not — bring the following to the table:

- machined from 416 stainless steel (certified, stress-relieved no less)

- salt bath nitride finish

- fluted for heat dissipation and debris clearance

- fits all GLOCK generations

- exacting tolerances allow drop in installation

- threaded versions come with thread protector and U.S.-standard thread sizes

- button rifled, three stage honed bore

That last point — traditional rifling — allows the use of lead ammo (as in non-plated, non-jacketed, bare lead projectiles) without fear of kaboom-inducing lead buildup as can happy in the factory, polygonal rifled barrels. This is the primary reason I purchased a 6.6″ Lone Wolf barrel for my GLOCK 20SF; I wanted to run Underwood’s 220 grain hard cast lead ammo as my “woods load.”

Logo and model number live on the left side of the barrel hood, meaning they’re hidden when the barrel is installed.

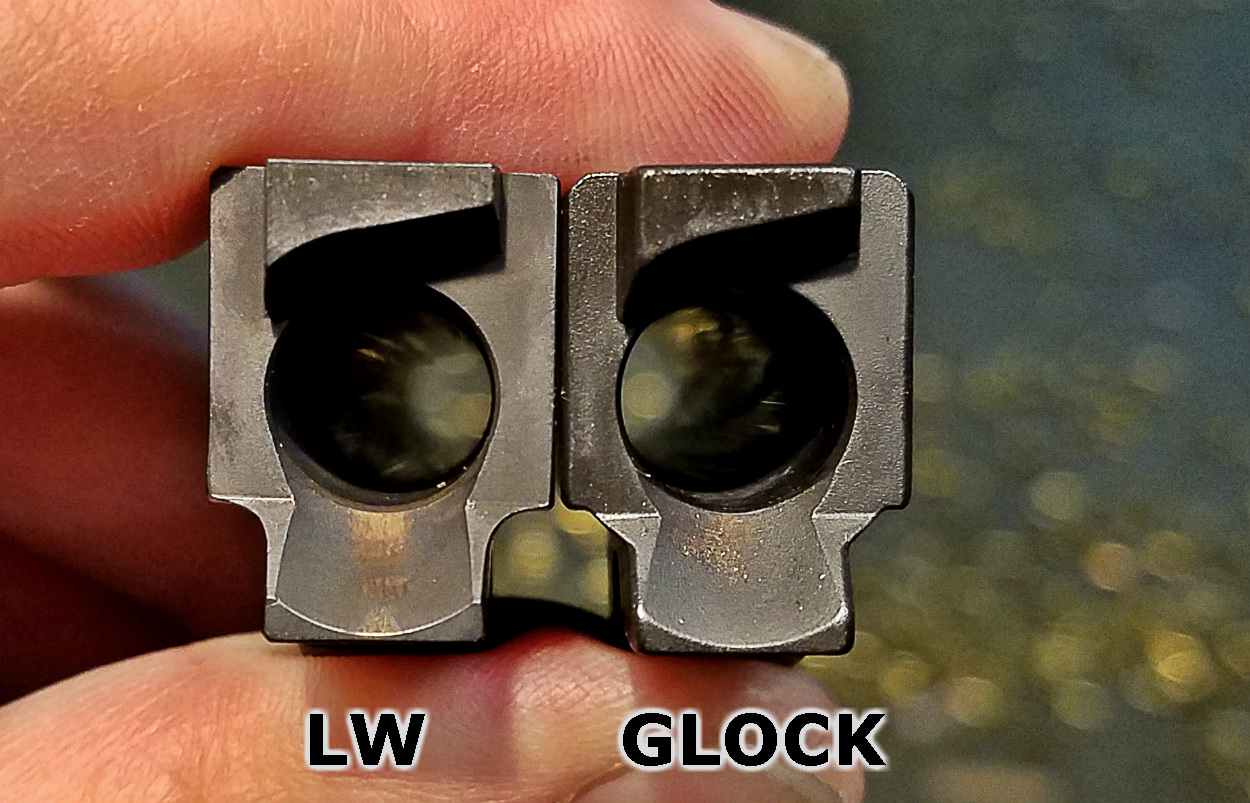

There are no real standout differences in barrel hood, feed ramp, or chamber as compared to the factory barrel. Corners and edges are sharper/crisper, finish is smoother, and the chamber is ever so slightly tighter. It’s still a self-defense sort of chamber rather than a match-tight chamber, but it’s a skosh tighter. So is the barrel’s fit in the slide. It’s smooth and doesn’t hang up, but it’s tighter and leaves less wiggle room.

The threading job is clean and precise and the barrel shoulder is generous and, as near as I can measure, totally square. The photo above shows a tiny divot on one of the thread edges, and at this point I have no idea if it came like that or happened during the last seven months that I’ve been using this barrel.

On The Range

First, it works.

With or without my Liberty Mystic X on the end, it has run reliably. I’ve shot eight brands of ammo through it at this point, including 115 and 147 grain reloads, and haven’t had a stoppage.

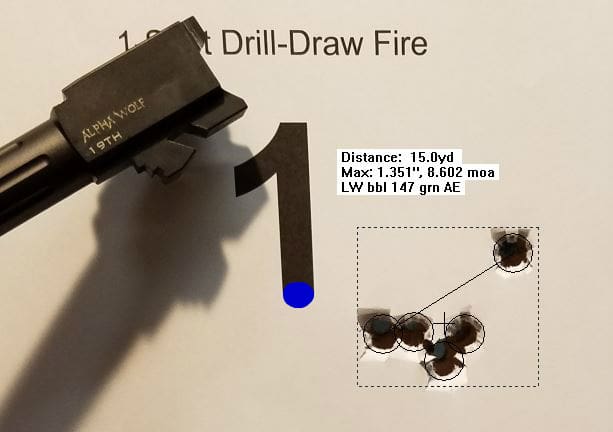

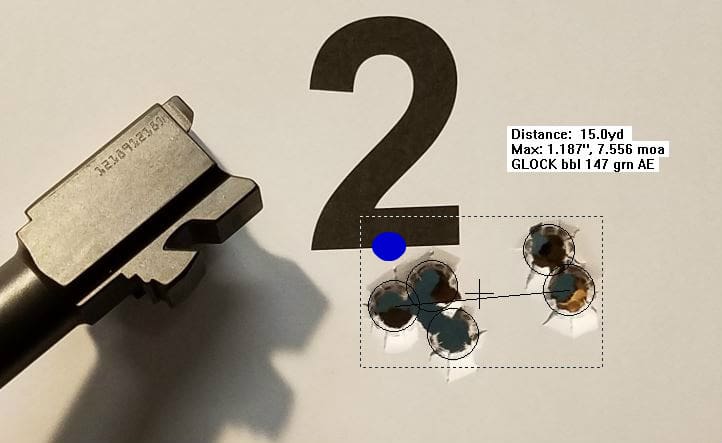

All of the ammo — from lightweight +P fodder to the particularly slow, 147 grain reloads — grouped approximately the same. Which is to say…

From a rest, about the same accuracy as I can squeeze out of a factory GLOCK barrel:

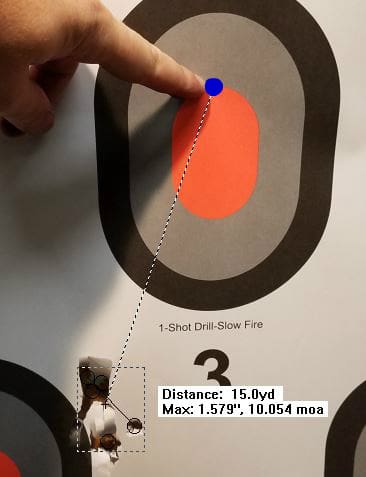

I marked the point of aim (the JPoint red dot is zeroed for the factory barrel at 25 yards with 147 grain standard pressure Federal HST) with a blue dot on all of those photos, because…

It shifted down about 7″ as well as a few inches left with the suppressor attached. This will certainly vary based on suppressor choice, ammo, and shooting distance. The Mystic X may be one of the quietest 9mm suppressors on the market and overbuilt to handle 5.56 and other calibers, but it’s no lightweight.

Unlike on a rifle, I don’t believe this POI shift is due to the barrel flexing. In this case, I think it’s due to the nature of a drop-in pistol barrel that must necessarily leave a certain amount of clearance so it fits in every factory G19 slide. While it’s a slightly tighter fit than the factory barrel, it still doesn’t lock up at the muzzle or barrel hood like a hand-fitted barrel would, and I think the weight of my Mystic maxes out its wiggle room.

Conclusions

At an MSRP of $159.95, the threaded Alpha Wolf barrels run about $70 less than most of the competition, but are $55 more than LW’s overseas-made offerings. I’ve had good success with those as well, but appreciate the nicer aesthetics, upgraded finish, and US-made aspects of the Alpha Wolf line and am willing to pay a few extra bucks for that.

Price aside, the barrel has been working flawlessly for me. It fits perfectly, shoots straight, locks my suppressor in place nicely with its square shoulder, and after seven months, the finish still looks great. Although the Alpha Wolf barrel series is relatively new, they’re already available for most GLOCK models and possible caliber conversions, both threaded and not. There’s even a 9×18 Makarov conversion barrel for the G42.

Specifications: Lone Wolf Alpha Wolf Threaded Barrel for GLOCK 19

Barrel Length: 4.60″

Thread Size: 1/2-28

Finish: salt bath nitride black

Material: 416 stainless steel

Warranty: Lifetime

MSRP: $159.95

Ratings (out of five stars):

Fit, Finish, Build Quality * * * *

It’s as perfect as a “combat reliable” barrel could hope to be, but I’m giving it four stars because there are shops out there making match-grade GLOCK barrels that are works of art. There are no flaws on the LW piece, but they keep it simple as well as functional with drop-in, self-defense-reliable clearances.

Value * * * * *

I think the only way to get a new, threaded barrel for a GLOCK for less is to go with Lone Wolf’s foreign-made models or with something that’s both foreign-made and noticeably inferior in quality. The Alpha Wolf is well made, it works, and it’s priced more than competitively.

Accuracy * * * *

So far it’s about the same as a factory barrel for me, but I’m adding an extra star because it shoots cast lead ammo accurately, too. Even if the barrel is manufactured more precisely than a factory one — which I believe it to be — it’s still going in a GLOCK and it has to leave large enough clearances to work within GLOCK’s tolerances as a straight drop-in affair.

Overall * * * *

There’s no shortage of options for aftermarket GLOCK threaded barrels, but most of that market has seized on the opportunity to aggressively gussy up the aesthetics of Gaston’s finest while charging a premium for the fancy machining and finishes. If your concern is more of the functional variety, Lone Wolf’s Alpha Wolf barrels will treat you right. They’re well made (in America), they shoot straight, they’re backed by a solid warranty. They’re also available in any color and finish you want as long as it’s salt bath nitrided black.

I was wondering what the knurled knob on the bottom was for (what could you possibly want to adjust on this?) and how on earth it would even fit in the Glock…

Then I realized it was the thread cover, and you were just using it to prop up the barrel to photograph.

If you shop around Silencerco barrels are at that price point. $155.82 for a G19 barrel. Not sure if they are lead friendly or not.

Yeah, but that’s street price or on-sale price or whatever. MSRP on those is like $230 I believe. You can get LW under MSRP as well through retailers like Brownell’s and such. Gotta either compare lowest available price for both or MSRP for both, but you can’t compare full MSRP of one thing to closeout sale price on another 😉

Lead-friendly is indeed a plus, AFAIAC…

One more reason to love Gaston’s creation. And before some one says it, I am aware this is an aftermarket barrel. I have owned 20 + Glocks since I turned 21 a nd I have never had a single failure of any kind in the thousands of rounds I have put out of them. I know a lot of people hate Glock, but they have always been great for me.

As near as I can tell, the Glock haters hate them for a couple of reasons. 1) They’re ugly/ungainly/uncomfortable/point badly. Those are all factors that depend on your personal dimension and/or taste, and really aren’t a reason to condemn a gun that thoroughly (unless you can show the gun doesn’t work for people in general, rather than just you and some others). It’s fundamentally unjust to just revile something as worthless because of personal factors.

2) It makes my fancy multi-thousand-dollar custom whatsis look bad, because it works more reliably. But that’s hating something for its unambiguous virtue, instead of MAYBE reassessing your multi-thousand-dollar custom whatsis (or even the cheaper models, which if anything are often even worse). If it’s fundamentally unjust to revile something for personal factors, it’s surely worse to revile it because it’s better than yours.

Looks like keyholes on paper with the can attached. Perhaps some bullet instability.

Any info on the barrel twist rate? Glock barrels are 1/9.84″

It was just a loose/puffed paper target over a cardboard backing that was torn to shreds from a full day of range use. The target was getting ripped, I think mostly by the wind from the bullet pulling it into the jagged cardboard. The cardboard was more solid up where the higher groups were, but it still happened some.

Thanks for the review! My LWD barrels have been working out very well, and I’m also having good results with American Eagle (and HST).

I bought the 9mm conversion Barrel from this company. NIce looking barrel. However, the chamber is so tight that it doesn’t meet SAAMI specs. My reloads that measure less than SAAMI spec wouldn’t even come close to chambering even though they work fine in my H&K, Sig Sauer, and S&W. Contacted the company and they were extremely rude. Customer service was horrible. I felt lucky to get my money back (minus shipping of course). Don’t buy this barrel unless you only want to shoot factory loads on the low side of SAAMI spec. I definitely won’t be buying from this company again.

For a POU of self defense, the most important criteria is reliability IMO. One of a Glock’s glories is its “looseness.” That’s a major reason they are so tolerant of dirt and crap ammo.

Never malfing even with crap ammo is important for training course and IDPA-style match costs (when the weather is better than Arctic-level here in SW Montana, I’ll run 1k rounds per month). More importantly, a daily packer being happy with Wolf/Tula/et al predicts a bigger margin for error when using the dollar-per-round SD gun food.

So, I’m always looking for chamber dimensions and feed ramp subtleties in an SD pistol barrel review.

AFAIC the only reasons to purchase an AM Glock barrel is to get one longer, threaded, ported, or unique caliber option. Within these parameters the primary thing I’m looking at with a 10mm barrel is chamber support, then everything else. Several years back I bought an LWD 5.15″ tactical 10mm barrel for my G20 and when it arrived I noticed it had just as much unsupported area oover the feed ramp as did the OEM barrel! The difference was the LWD ramp cut was slightly deeper and narrower. The OEM cchamer is more generous which lead me to an interesting theory about chambers and pressures.

On the LWD barrel, shooting Underwood 155 grain 10mm I observed a distinct bulge in the case over the feed ramp that left a nice crease and made me wonder what I’d paid the money for. Using the OEM barrel with the same ammo, I had no such distinct bulge though the overall case expansion was greater. I then realized that the “looser” chamber in the OEM barrel causes the entire case to expand before “point pressure” focuses on the ramp cut out…basically the greater total case expansion reduces the amount of pressure that can be exerted on the unsupported case web. With the tighter chamber, yet just as much unsupported chamber LWD barrel, since the case can’t expand as much, total pressures peak sooner and focus more over the area where the case is free to expand. This is the only explanation I can find for why the OEM chamber seems to show less pressure spike over the ramp cut.

My next LWD barrel was my .460 Rowland 6.61″ that arrived with a FULLY supported chamber! I mean the entire circumference of the case is surrounded by the steel of the chamber! Naturally I wonder why LWD’s QC would allow such variance in chamber attention, but this seems born out by what others report.

When I bought my G29 and examined the chamber and ramp I noted there to be very little unsupported case area over the ramp…on the OEM barrel – very much like the earlier G20 barrel, which made me question the purchase of any future LWD 10mm barrels simply to get a more supported chamber.

With my G30 the factory barrel ramp is quite deeply cut into the chamber with a great amount of unsupported area which I suspect is because the .45 ACP is meant to operate at a much lower pressure, but I wonder why I haven’t been reading about “kabooms” using OEM G30 barrels with hugely unsupported chambers, firing +P and .45 Super power ammo.

I want to buy a replacement barrel for the G30 but am hesitant due to the uncertainty of whether I’ll get a great chamber, or one no better than factory!

What I would like to see is an aftermarket barrel maker post high-quality, close-up photos showing chambers and “guarantee” that specifically.

I see no reason a Glock cannot have a fully supported chamber. My CZ75B .40 S&W has one…FULLY supported. My SIG SP2022 has one…FULLY supported. Even my 30 year old Firestar .45 ACP has a FULLY supported chamber!

Clearly LWD has proven they CAN build a chamber will full support, now they just need to commit to that level of quality control.

Having viewed the SBS comparison of the Alphawolf barrel and OEM barrel I see ZERO difference between ramp cuts…maybe the AW cut looks a bit broader, so why would I spend even more money to obtain one? Sure, if I’m committed to a caliber change, extended or threaded barrel I’m pretty much forced into the LWD “crap-shoot-of-quality,” but AISI, gone are the days of automatically installing an LWD barrel…they just aren’t delivering the confidence they used to.

Jeremy,

Did you have any trouble installing the alpha wolf into your Glock? I just got mine, but it’s way too tight for a drop-in. Did you have to dremel yours to make it work?

I purchased the alpha wolf threaded barrel for the Glock 40MOS. Befor my 40 arrived I ran it in a G20 with no problem. When I went to install it in the G40 it didn’t fit. Because it was a backorder product I filed on the top where it was obviously to big but it still didn’t fit. I called customer support and told her I had tried filing to fit it. She said no problem, send it in. I later got an email explaining that warranty was void because of the filing I did and I was told that Glocks inconsistancy was the reason it wouldn’t fit in the slide. They did offer to coustom fit a new one to my slide for $70 in addition to what I paid for the original barrel. I have had no issues with the other 4 lone and Alpha wolf barrels.

I have a LW /Dosan Glock 27 threaded barrel that FTF 3-4 times or more per mag when my DeadAir Ghost 45 is attached. It fails to feed less often without the can. My other pistols with factory threaded barrels do not encounter any problems with this can. FTF occurs with used and new mags and I fired 250 rounds with various brass rounds, no reloads or Russian steel cased ammo, only WWB, S&B, Federal and Armscor of various grains of recent production. Any suggestions? I am reluctant to buy a LW for my Glock 21 or 26.

Actually the stock glock barrel is perfect for heavy hard cast lead NOT for regular lead though, so you’d have been happy as a clam shooting buffalo bore hhc lead through polygonal stock barrels fyi.

I have found lone Wolf barrels to be the most accurate in the years of testing I have done the customer services beyond excellent and if a customer has a problem they work very closely and are very concerned. I highly recommend them

I couild not refrain from commenting. Exceptionally well written!

Comments are closed.