By Mike Morrison

I’m still fairly new to firearms and like many over the last few years, decided the best course of action would be to start reloading to cut costs and shoot more. After lots of research, reading forums, blogs, and watching YouTube videos, I realized reloading might not achieve either of those ends, but it still looked worthwhile. To that end my generous in-laws gave me a Lyman Crusher Master Reloading Kit with the Crusher II single stage press (yeah I’ve got great in-laws, but that’s another blog post) . . .

To my lovely wife’s great disappointment, the Lyman set doesn’t come with everything you’d need to get started. Of course you’ll need a workbench (I opted for this prefabricated Home Depot one) but you’ll also need dies for each caliber you want to reload, a case trimmer and gauge, a primer turner tray, and a set of calipers, not to mention the powder, primers, bullets, and brass. All in for the tools, I put up another $50 or so beyond the Lyman Kit.

I can still purchase more tools (a hand primer, higher quality processing station/cutter, tumbler for brass, bullet puller). If you can find in-laws who encourage your shooting addiction habits and give awesome Christmas presents, that’s a huge help.

Gear assembled, it was then time to start reading. I dove into the Lyman 49th Edition manual and read it, multiple times. Most of the manual is suggested loads for various calibers, but the first six chapters are crucially important general information about reloading. It’s a must read. You’ll find just about every single caliber, round type, and powder you can imagine within this manual.

Once I thoroughly digested the info, I started bolting things to the bench. In retrospect I would have given myself a bit more room to the right of the press. It’s enough space, but it’s tight.

After cleaning and drying the brass, I lubed the cases (with the included lube kit) before depriming with my Lee 223 dies. The depriming process is simple and cathartic, though removing lube is annoying. Be sure the brass is going into the depriming die straight to avoid crushing your brass. The Lyman primer catcher mostly catches the primers, but occasionally a few can get wedged between the press and the wall of the catcher. Flexing the wall of the catcher usually released the spent primers, but occasionally spills one or two on the floor.

Once deprimed, the cases needed to be trimmed, deburred, and have the primer crimp removed. Using calipers, I measured every piece of brass, sorting those needing a trim and those ready to shoot. While sorting, I examined all the brass for dangerous imperfections. Attaching the case trimmer to my cordless drill, I was able to fairly easily trim each case. The case trimmer and gauge I used can ID an uneven trim, if you don’t seat the casing correctly.

Deburring with the included Lyman case prep tool was simple and not too tiring. It conveniently functions as storage for the smaller bits too. Unfortunately, the primer pocket de-crimpers leave much to be desired. The designated small primer bit quickly grew dull and caused issues for me as I tried to seat primers. Eventually, I took the cordless drill and chucked the chamfering tool. Throwing a zip tie around the trigger of the drill sped the process up even more.

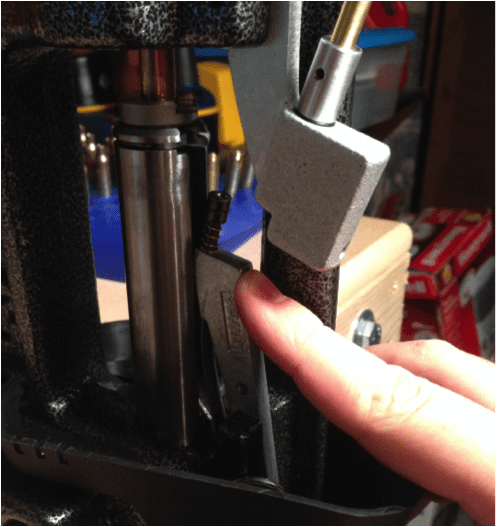

The Lyman kit includes a Universal Primer Arm. Using the included small and large primer tubes, pick up the primers and place it into the arm. Load a deprimed case, pull the handle, press the arm forward, and drop the handle to prime a round. You can pretty easily feel when a primer seats correctly. When the arm is released a spring pushes it back into the frame of the press and releases another primer. The spring s holding back primers may need to be adjusted, which is easy to do with the included tool. I don’t mind priming at the press, but others like to use a hand tool so they can prime while watching TV on the couch.

Finally, it was time to charge the rounds and seat the bullet. The Lyman kit includes a single tray, electronic scale, powder measure, and funnel, so you have all you need to charge the rounds. I mounted the powder measure to a shelf above my bench. You can screw it into an extra reloading arm or use the plate and screw to tighten and secure it on a shelf or something. I adjusted the barrel to correctly drop the right amount of powder. This though, was mostly through trial and error.

The markings on the barrel that are supposed to show you how many grains of powder are dispensed don’t seem to correspond with reality. Perhaps I don’t understand the indicators, but regardless, I ignored them. I dropped powder and measured each charge until it consistently gave me the 21 grains of IMR 3031 I was looking for.

NOTE: When you setup the scale for the first time, it’s output is in grams, not grains. If you don’t change the mode, you’re going to have a bad time.

Being inexperienced and quite fond of all my fingers, I decided to measure each and every bit of powder before charging a round. Rather than charge all 85 rounds at once, I only did 5 rounds at a time then went over to the press to press the 55gr bullet into place. Soon I had 85 rounds ready to go.

As a Northern Virginia resident, I’ve got a few options for close indoor ranges, but I usually trek out to Clark’s Brothers in Warrenton to use their 100 yard range. There’s no range fee, but you’ve have to shoot ammo purchased from their shop. I grabbed more powder and primers for the next batch of bullets, which easily covers my next few visits.

I have to admit; pulling the trigger on the first round was simultaneously terrifying and exciting. But thankfully it went bang and not boom. On top of that, I was able to put some pretty nice groups together even with a 16” PTAC HBAR barrel, all right around 4 inch groups. I’m not the best shooter by any stretch of the imagination, so I was quite proud of myself.

Using this spreadsheet I am tracking every single bit of powder, each case, and every primer not to mention my shooting results. This first batch was a bit expensive, around 40 cents per round, as I didn’t quite know what I was doing.

Ratings (out of five stars):

Fit and Finish: * * * * *

This of course is a tool, but the blueish finish of the press looks very nice and there are zero blemishes, quality issues, or other problems with the press or other tools.

Function: * * *

For my purposes, this ranking is probably higher. Single stage presses are slower, though good for my purposes. Those who plan to reload higher quantities of ammo should look toward turret or progressive presses.

Overall: * * * *

Descriptions of this kit suggest you can begin reloading with just the included contents and the dies for each caliber. Though technically you could, I suggest you don’t. Measuring the length of the round for proper seating and case trimming is important to make your loads consistent. The kit has very nearly everything you need though.

Nice review. For rifle cases, I really like depriming as a separate step from sizing, because I like to deprime and clean my cases prior to lubing and sizing. Lee makes a universal depriming die just for that purpose thats pretty cheap. It’s a really rewarding way to expand the firearms hobby especially when you start to break even on your startup cost and saving money on ammo. Pistol ammo is a lot simpler ( I skip the cleaning) and even cheaper.

I always suggest the Lee depriming die. $10 or so and totally worth it to be able to clean the primer pockets while tumbling or sonic cleaning.

Dillon Super Swager. About $100. Don’t make the mistake I did and ream out a couple thousand 5.56 primer pockets the same way you’re doing it before discovering such an amazing invention exists.

I actually almost cried at the ease of use. Also, chamfering the primer pocket like that supposedly shortens brass life… But who knows.

RCBS also makes a primer pocket swager that you mount on your bench like the dillon. I’ve been using it for a few years re-sizing 5.556 for reloading and it works great.

They also make a swagger die kit, but I have no experience with that.

I’ve been using the Swagger die, just like Marky Mark Wahlberg in his role as ol’ Bob Lee.

Good article. This makes the learning curve and equipment investment seem a lot less intimidating. Really just comes down to willingness to spend the time. Well, that and money. Even the lowest of startup costs is a problem. I have more time than money, but all that tells you is how little money I really have (which is yet another reason to bite the bullet, since reloading ought to save me money in the long run).

It depends on what you’re reloading. Loading pistol with a single stage you’re not going to see the benefit right away. Premium hunting rounds is where it’s at. I can mimic a $2 Hornady round for about $.35 for my .243. That’s how I paid for my initial equipment. Check out the Smart Reloader series that Natchez sells:

http://www.natchezss.com/Category.cfm?contentID=productDetail&brand=UY&prodID=UYVBSR00831&prodTitle=Smart%20Reloader%20Omega%20800%20Pro%20Kit

$130 for an entire kit including a tumbler is pretty good. I don’t know anything about the quality but that’s an easy way to start.

Ing- never get into reloading to save money. It will NEVER happen. NEVER. If you are looking at it from that stand point you have to consider the type of ammo that you are buying. If you are buying the cheapest stuff you can find then it will take some time to recoup your startup cost. Even when you do recoup the cost then you won’t save money but you may be able to shoot more, instead of 100 rounds you maybe able to shoot 120 rounds.

Now as far as reloading far superior rounds that can be done very easily. If you are looking for supreme accuracy then reloading is the way to go. And you can roll premium ammo at a much cheaper price. It is really nice to be able to find a grain that your gun really likes and then play with the charge, neck tension, COAL until the gun really sings. So by all means get into reloading. But don’t try to kid yourself about what you will get out of it.

I started with a single stage, then exploded from there over the years. Progressive, electric case trimmers, case holders, shell plates, auto dispensers, tumblers, ultrasonics, full length dies, neck only dies. Every tool has a job and so i keep everything around. So trust me saving money is not the purpose of reloading, but I wouldn’t trade it

I can’t agree with your generalizations. The economics of reloading involve several factors. I can reload 9mm for less money than the cheapest, steel cased factory crap ammo available. But you need to consider some things:

1) Brass availability – The case is the most expensive part of the cartridge. But if your chosen caliber is readily available on the ground at your local range, you can cut your cost per round in half, easily.

2) Buying primers or powder online involves hefty hazmat fees to get it shipped, but the fee is the same regardless of weight or quantity. Buying larger quantities at a time will lower the cost per round significantly. On the other hand, buying such things locally will usually mean higher prices and sales tax. Put a pencil to it before you buy.

3) What is your time worth? Reloading will put you in the red if you pay yourself minimum wage. However, if it’s a winter time activity when you’re normally house-bound and bored, it could be a productive use of your time.

Every year, I keep looking at getting a progressive press. And every year, I keep looking at how much they cost and denying myself the idea of a progressive.

I buy single-stage presses at garage sales, estate sales, etc. I set them up in a row on my bench, and down the line of presses the cases go. Gets me nearly the throughput of a progressive, but without the expense.

My best buy on a single-stage press? Two were just given to me by a widow cleaning out her garage. “Here, I think they had something to do with Bob’s gun hobby, but I have no idea what!”

“Can I give you $25 for each of them?”

“NO, just get them out of here!”

“Yes, Ma’am!”

There’s tons of reloading equipment out there on the cheap. There’s literally nothing to go wrong with a single stage press unless the casting has been cracked. Stick with one manufacture (so you can share shellplates) and you’ll be loading lots of brass for much less money than you’d think.

I started with the Lee Anniversary Kit around $125. You have to add dies for each caliber you load about $40 each if you stick with Lee. There are also some additional accessories you will need, as discussed in the article. Especially the calipers and case trimming tools. A lot of people look down on the Lee stuff, particularly the powder measure and scale, but they do a good job especially for what you pay for them. I’ll upgrade the powder measure and scale eventually but for now I’m satisfied with the results I’m getting. My rounds perform better than the factory stuff I was using before.

I cannot stress enough though, get a good manual and take the time to read it. It will save you from making a lot of mistakes. You can even find a pdf of the Lee Manual online. I have that one and the Lyman 49th.

Good review. I wish TTAG would do more reloading based articles for those of us who have little to no knowledge of the subject.

Maybe a Reloading 101 article?

A thorough run-down of the various case cleaning methods available would be a good article by itself.

You can lower your cost per round significantly by reloading. That doesn’t mean you’ll spend less, it means you can shoot more.

In the several years that I have been reloading I have come to the conclusion that talking about reloading is much like talking about sex. Everyone has their own opinion. There are thousands of way to do it with all of them being viable options. Sure there is a couple wrong ways to do it but in large most will get the job done. It all depends what you are wanting the end result to be.

I would whole heartedly be in favor of TTAG doing more articles on reloading including product reviews. I understand why they haven’t done many thus darn because the comment section would be full of what they did wrong but I for one would love to see more.

Only if its written by the Dyspeptic Gunsmith.

Which unfortunately will never happen, because he’s too busy running his business.

And being involved in the community (volunteer FD, EMT training, etc). It all eats up time.

I started with a lee kit. A couple years later and a lot of rounds fired I’ve replaced a lot of cheap tools for better ones.

One thing about hand loading, you end up with a ton of gear.

True of a lot of hobbies, actually.

As for the the markings on the barrel of the powder measure – Different powders have significantly different densities, so I wouldn’t put much stock in that. The same setting on the powder measure could give quite different weights with two different powders. You gotta use a scale.

Just for comparison, RCBS sell a kit that goes for about $330.

http://www.midwayusa.com/product/937051/rcbs-rock-chucker-supreme-master-single-stage-press-kit?cm_vc=ProductFinding

The RCBS kit comes with a hand primer, and a balance beam scale instead of an electronic scale. Other than that, I think they’re pretty similar.

I think Lyman and RCBS both make quality tools, generally speaking.

Correct. The markings are primarily there for setup purposes. Once you get the powder measure adjusted for a particular load, you can jot that down in your notebook and return to it after you’ve reset the measure a few times for reloading other cartridge types. You’ll still need to adjust the load using your scale, but it doesn’t take nearly as long as reinventing the wheel each time.

The author probably thought that the markings were correlated to the grains that would be dispensed instead of a volume measurement requiring some math to correctly set. Regardless it’s still trial and error once you get in the ballpark.

The primer tube looks similar to that on my RCII press….. which means the end is generally right at the proper level to poke your eye out…… took me 20 years with this press before I figured out a hand primer was $30 and a lot faster and didn’t snag my glasses off and toss them.

Fantastic article. I also recently started reloading, and even purchased the same bench. I’ve held off on buying all my gear at once, though… I’m spacing out the purchases so that I buy what I need when I need it, in theory having more cash to buy the better stuff from waiting.

Speaking of the bench: I STRONGLY recommend putting another 3/4″ board on top to reinforce it. I also think bolting it to the wall is a generally solid idea, albeit I have not done so yet… I’ll probably source a couple L-shaped brackets on the next Home Depot trip.

The “Strong-Tie” bracket system sold at Home Despot is very good for knocking together very solid workbenches in a hurry.

http://www.strongtie.com

For the ultimate in benchtops, look at the butcher block countertops – Grizzly.com has some in various sizes.

Some of my benches have a 1/2″ steel plate for a top (eg, my welding bench). When I finish the swaging press to make my own jacketed bullets, it’ll go on a bench (yet to be built) that will have a steel plate top and square box tubing for legs.

Great post.

I’ve been reloading for a good many years. It’s very satisfying. And, not really too difficult.

I think one of the biggest benefits to reloading is being able to tune a round for a particular rifle. If you’re very careful and exact you can create groups that will be tighter than any factory ammo could ever be. Factory ammo is loaded to work in a wide range of firearms, whereas you can tune a round to your rifle. You can also neck only size (bolt actions only) to increase accuracy. It’s very rewarding when you dial in the right charge and see those clover groups. Especially if it’s a gun that you never thought would be accurate because it didn’t shoot any factory ammo well.

One of the things that I would disagree with the author on is measuring each round. Bullets, especially polymer tipped ones, can have small differences in the shape of the tips. The key, for accuracy anyways, is to set the bullet seating die once and use it for all of them. The die will seat the bullet by the shoulder and will have a greater consistency in case volume. This is more important for safety and accuracy than the actual overall length.

Otherwise, a good intro to reloading and a beginner’s perspective.

I think you get out of it what you put into it. I started out by wanting to put a ton of rounds out. I was able to do this but realized that the rounds I were putting out seemed to be more accurate than cheap store bought. That’s when I slowed down on the amount and focused more on consistency and really got hooked from there. So I don’t disagree with you at all about using reloading to increase accuracy but if someone just wants to put out a lot of rounds then that can be done too. Of course with a progressive.

I’d pick it back up again, if I could find powder. Used to reload .223 for prairie dog shoots a while back. Started out with a RCBS kit, and moved on to a Dillon progressive. When you have to load 2500-3000 rounds in a week, a progressive press is the bee’s knees.

Hey, next time, could you throw in a few more amazon affiliate links?

Honestly, after the first product list, I just skipped the rest of this post. I have a great interest in reloading, but the opening was too much of a hard sell pretending not to be. Maybe next time, you could give the review, then like, link everything later..

That was part of my point. I didn’t really expect that is need to buy more items on top of the kit. I linked to what I bought seeing as how I was reviewing things that I actually have.

Oh, I do appreciate the effort you went through, and I will end up reading the whole article. I honestly still haven’t. I just wanted to let you know what turned me off of it. I hate it when I get generic feedback of my writing, or worse, no feedback at all.

I appreciate it. Hope you enjoy the rest of the piece.

Mike,

After reading the whole thing, and getting past my initial irritation, I will say that you did well. Your flow from topic to topic was pretty good, and you gave enough information (for me) without going off into wall of text lecture mode.

Keep writing, and I’ll keep reading.

The spreadsheet link leads to a YouTube video. Anyone have a link to an actual spreadsheet they like?

Thanks!

The link to the excel sheet is in the description of the YouTube video.

Save your reloads for range and hunting use. DO NOT use reloaded ammo for home defense. It’s one more thing a prosecutor can use to hit you with a murder charge. “He makes his own custom killer ammunition! Clearly he was itching for an excuse to gun down poor innocent Daquan!”

Maybe if you get your lawyer off a billboard….

Another internet myth with no proof to back it up.

Use factory loaded defense rounds for defense. For that extra little measure of reliability, not for the imagined reason Jim mentions.

I’ve found that some of my initial practice loads for my carry gun don’t always fire on the first strike. Probably due to how well the primer is seated. Since I carry a revolver I just run the cylinder around a second time and they fire. They are great for practice but I use factory loaded for self defense.

I’m cleaning out the primer pockets now so I’m expecting that to help reliability.

+1 on Slick’s idea for a Reloading 101 article.

I’m buying a reloading set when I get my tax return. I’ve put it off long enough. I like having something to tinker with when I get home from work and reloading would be perfect.

Reloading to me is a great hobby, and yes, you will buy tools along the way to increase your speed or for the utility of the particular tool. The kits made up by the various tool companies can be pretty good (RCBS, etc.) or Lee which is pretty basic and I think each has its place.

Rolling your own is not for everyone, and while I have helped a few friends get into it, there has been a couple that just couldn’t grasp the hang of it and stopped. I believe that’s where the less expensive kits come into play. If you aren’t sure whether this is for you, at least you are not out a lot of money.

I recommend a good single stage press such as a Rockchucker or similar, especially if you are going to reload the taller case rifles such as 30-06 which most of the progressives wont handle. Single stage presses are always good for loading rounds you are trying to develop in either rifle or pistol with graduated charge weights, etc.

Progressive presses are great for hi volume shooters in both pistol and small rifle, but learn the basics-it will save you a lot of grief in the long run.

From my experience, where reloading makes the most economic sense:

1. Hunting loads with specialized bullets. You can buy so much more premium-bullet factory ammo than you could when I was younger. Back in the 70’s and even the 80’s, you were lucky to find pre-loaded ammo with even a Nosler Partition (the original premium hunting bullet) on it.

Today, you can find a huge array of hunting ammo with premium hunting bullets. But ow! The price.

Save your brass from premium hunting ammo and load your own. Just saving the brass for larger magnum calibers can save you $0.50/round right there.

2. Where you want to run a “hot” load and you know why and what you’re doing. eg, you own a Ruger single-action revolver in .45 Colt. You know what this gun is capable of, which is a hell of a lot more than an old SAA would have been. The reloading manuals will have sections for the .45 Colt (eg) that show the nominal load, then a load for Ruger handguns, then one for older rifles, then one for newer rifles, then one for a Thompson Contender/Encore, etc.

3. Where you’d like to increase the accuracy of a rifle by playing with the leade of the bullet (the jump between the bullet and engaging the lands). By playing with this dimension (which you will control with your OAL and bullet seating depth), you can sometimes get rifles that won’t group well with factory ammo to tighten up a fair bit.

On this issue, get a Lyman reloading book. NB in there they will have not only starting loads & max loads, they will often call out an accuracy load. This is a great starting point for your own work. NB2 that the accuracy load in the Lyman book is almost never the maximum load, nor is it usually anywhere close to maximum.

4. You don’t need digital calipers. A set of dial calipers will do just fine. Learn to make the pressure with which you close the calipers on an object to be measured as uniform as possible. Calipers might read to 0.001″, but I can show you on any set of calipers how you can get +/- 0.002″ on ANY reading just by changing the pressure on your thumb.

5. Buy used. Things like dies have very little to go wrong with them. In straight-walled pistol dies, buy carbide dies and dispense with lubing your cases.

That’s all I can spout off the top of my head just now. Reloading can be done more cheaply than buying everything new. My shotgun press (a progressive MEC) was something like $50 at a garage sale. I’m really serious to look around at garage and estate sales. Most widows know what guns are. Some widows are stupid enough to take the guns into a “cop buy-back.” Most aren’t. Sadly, tho, even the most well-intentioned bride often has no idea what reloading stuff is, how it is used or now much it should cost. I’ve stumbled into some huge deals on reloading gear this way – and at times, I’ve offered more money for the items because I don’t want to go to sleep that night knowing I’ve ripped off a sweet old widow.

They same deal applies in reverse, guys. If your wife is big into weaving/sewing/knitting etc, you should ask her what some of those items are worth. Recently, I’ve run into my very first $8K home sewing machine. Yes, you read that right. $8,000+ for a sewing machine. It doesn’t look like much, but trust me – that’s the price it commands, and there are more than a couple of women who buy these things.

Lee Classic Turret press. Economical to buy, faster than a singlestage, easy to.learn, and precise when needed Super fast and easy to change calibers. Just have a turret for each. I started with straight walled pistol rounds to learn the ins and outs. It’s a good feeling to shoot rounds you rolled.

And as the author said, its a good.idea to take your time early .My first batch of 9mm included one without powder. Luckily the case stovepiped and I found the bullet halfway down the barrel.

I’ve been researching reloading for years before I jumped in and since I reload mostly for pistol plinking I went with Hornady LNL progressive press. It’s not as hard to start right on progressive (rather then single stage press) as some people claim. There is more going on at the same time to keep an eye on, but not overwhelmingly so. And after a while, when you get feel of the process and the rythm down, you can really crank them cartridges out.

Hornady has great “no questions asked” warranty as I found out when I managed to break the only plastic bracket on the press. Otherwise that thing is built like a tank. After very short phone call the part arrived in two days.

DG – I lube my cases lightly with Hornady spray lube before sizing even with carbide dies. It makes it easier.

Frankford Arsenal makes some useful and inexpensive gear I use like vibrating tumbler, digital scales, bullet puller, primer tube filler etc.

Comments are closed.