To master the shooting arts, you need two thing: training and practice. Beyond practicing my cowboy-style holstering twirls and Dirty Harry impersonations in front of the bathroom mirror, I try to work in as much actual “bang bangness” down at the range as possible. Two factors stop me from shooting as much as I’d like: time and greenbacks. As Steve Miller reminded us, time keeps on slipping, slipping. Range trips tend to be day-long events; placing the pleasure in direct competition with real life. Every once and again one has to work to pay the bills, pay the bills, say hello to people and perform other activities which gun enthusiasts classify as “not range time.” As for money . . .

Money’s too tight to mention. So anything that helps make my obsession more affordable has my full attention. Writing for this website, for example. In exchange for my time and meagre talent, RF blesses me with access to OPG (Other Peoples’ Guns) and a limited quantity of free ammo (courtesy Lucky Gunner). Otherwise, well . . .

What if there were a training aid that lets you reclaim some of that precious time and hang on to some of those slippery greenbacks? Speer Bullets has an answer. Plastic wadcutters powered only by large pistol primers.

I stumbled upon this product whilst plowing through the inventory at Midway USA, looking for bullets of various weights to try new powder-loads for my .45. Despite my natural aversion to infomercial-style innovations, curiosity got the best of me. My checkout cart was suddenly $8.50 more financially burdensome.

I stumbled upon this product whilst plowing through the inventory at Midway USA, looking for bullets of various weights to try new powder-loads for my .45. Despite my natural aversion to infomercial-style innovations, curiosity got the best of me. My checkout cart was suddenly $8.50 more financially burdensome.

The bullets themselves are nothing extra-special: cylindrical pieces of black-plastic not more than an inch long with a hollowed out end. I snagged a few spent casings off of my workbench, drilled out the flash holes per manufacturer’s recommendation, and set about priming them. I decided only to sacrifice 10 cases to the cause.

Prepping all 10 required less than five minutes of my time. The primer provides adequate energy to propel these from the barrel at 300 – 400 feet-per-second (FPS). No powder is used in loading. I repeat; no powder is used in loading.

I created a backstop / target out of some old shipping cardboard and unloaded my Springfield. I loaded five “training rounds” into the magazine, snugged her home, and moved to my make-shift training range.

In other words, I put the cardboard box at the other end of the garage ~25 feet away. The thought briefly crossed my mind: “Hey, this is a bad idea bucko.” But it was quickly repressed like my childhood fear of ranch dressing and Rock ‘Em-Sock ‘Em Robots. “Damn the Torpedoes!” I racked the slide. FTF (Failure to Fire). Wonderful.

The hard plastic edge of the training bullet snagged on the slide-stop inside the chamber of my 1911. Easy fix; drop the mag, clear the weapon, and try again.

A small fury face appears in the interior window of my garage as I rack the slide a second time. As the slide comes forward and grabs the round, the cat loses balance, plummets off of the laundry shelf and takes half of my laundry rack with her, dumping detergent across the room.

Why is this relevant? Frankly, it’s not. But it adds another dynamic to the “fail-arity” happening in the garage. The second round ALSO jammed. The second time, the bullet’s flat leading edge deflects off of the feed-ramp. The entire bullet wedges itself half-chambered in the pistol. Spectacular.

Not-so-easy fix this time, Mr. Bond. I dropped the mag and struggled like hell to clear the weapon. I finally resorted to resting the slide in a bench vice, using both hands and a significant amount of body weight to operate the slide.

Not-so-easy fix this time, Mr. Bond. I dropped the mag and struggled like hell to clear the weapon. I finally resorted to resting the slide in a bench vice, using both hands and a significant amount of body weight to operate the slide.

As the bullet leaves the gun, another thought pops into my head: I could have driven to the range by now. Time to think outside the mag. Let’s load the cartridge manually.

OHD! It works! I dropped the cartridge in, sling-shot the slide, and assumed the low ready. Safety on. In other words, I fumbled with the flat-nosed way-too-lightweight and out-of-balance cartridge, gently pushed the round into place and closed the slide to bring the pistol into battery.

Safety glasses? Check. Hearing protection? Hrmm . . . un-check. Clear field of fire? Check (aim past the car, above the oil cans, at the cardboard propped on the paper-towel rack). Gentle trigger-squeeze? Check.

*POP,* *SMACK,* *TING!*

The plastic bullet impacted squarely on target, over-penetrated, ricocheted off the drywall, and landed on the reloading bench behind me.

Oops! Seem I’d disregarded Speer’s advice of Speer. I didn’t coat the inside of my bullet-trap with carpet scraps. So, I took a short break for a quick inspection of the dent in the drywall and some target “adjustment.”

Since there is no powder in the plastic casing, the pistol will not cycle after each shot. After wiping carpet remnants off my person, I ejected the spent casing, manually loaded the next round and took aim again. Lather, rinse, repeat—for a total of five indoor discharges. The cat was back in the window, with an expression that says “scuuuuse me … WTF are you doin’?” Relax, cat; I’m discharging firearms in my garage!

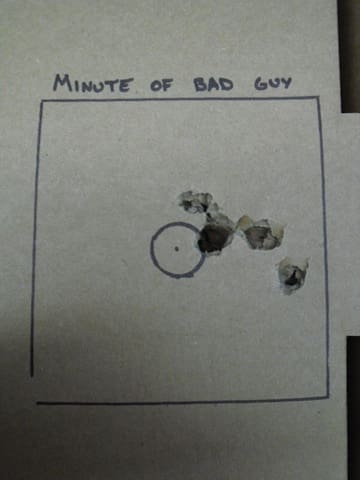

At 25ish feet the plastic bullets hit dead on point-of-aim, then still bounced around my garage like a blaster-bolt in the garbage compactor on the detention level. Quite fun, and reusable! As the target shows, my groupings were fairly consistent.

The novelty factor of the Speer Plastic Training Bullets wore off after about ten rounds. Don’t get me wrong; they’re a literal blast to shoot in a [well-ventilated] garage. But these not-so-bad boys are a giant pain in the rear to load into the pistol. I wonder if RF will reimburse me $10, plus shipping and handling.

Specifications: Speer Plastic Training Bullets

Caliber: Available in .38, .44, or .45

Price: ~$9 per box of 50

Ratings (out of five)

Ease of Use * 1/2

Drilling out the flash holes in the cases designated for use with these bullets takes time, but assembly / use is otherwise easy. Manually loading each cartridge into the chamber is a drag; like hanging with a Grateful Dead-loving friend, jamming is a major issue.

Fun Factor * *

Shooting in my garage was a riot . . . when I was actually shooting. The fumbling around trying to get the bullets to feed properly / having to manually load each one significantly detracts from the fun that could be had here.

Utility * * * *

I’ll give high marks here; practicing draw, aim, fire (which my local range prohibits) is a huge advantage to using these “training bullets.” Think of them as one step up from snap-caps or a laser bore sight in draw / fire drills.

What Could Possibly Go Wrong * * * * *

Truth be told, I was tempted to give the cat a 300fps smack on the butt (we have history). But I didn’t. Nor would I recommend any kind of animal cruelty to anyone at all ever so help me God. Meanwhile, I’d bet the farm that someone had the bright idea to “shoot” a friend with one of these. And yes Christmas Story fans, you can put your eye out.

Overall Rating * *

Fun, but not THAT fun. Accurate, but not THAT accurate. Delightfully useful, but not THAT useful. Home-made paraffin wax bullets seem a better bet.

Rather than a gear review, this seems more like it should be a “What Could Possibly Go Wrong” post.

It definitely ranks up there pretty high on my “Bad Idea O’meter.” It isn’t hard to imagine an event where playfully “tagging” someone with one of these leads to something horrible if there’s a mix-up.

I can see something awful happening even if there isn’t a mixup. You just KNOW some idiot will shoot their buddy, hit them in the eye by mistake and kill them.

To add to my compadre’s review (this incident happened after Ben’s article was written); Unless the plastic bullet is in 100% condition, it will not make it out of the barrel. The very first one I fired out of my 1911 in Ben’s garage this weekend was a squib load because the bullet had been slightly deformed after being fired and hitting the “backstop”. The slight deformity grabbed the rifling in the barrel, twisted it strangely and promptly got the “bullet” stuck halfway through the barrel very tightly. But on the plus side, I got to practice my amateur gunsmith skills.

Wooden dowel rods and a piece of leather or rubber to sit the barrel down on, and a hammer and knock it out back through the throat is how I do that I’ve had a couple cheap Russian steel cased rounds squib and put an fmj halfway through my 1911 I luckily had a wooden dowel the perfect size to slip in the barrel and I slid it in the muzzle end and popped it twice with a hammer and they came out the barrel throat. That was a cheap easy way to clear the barrel. I’ve also got one for my 30/30 because I lost a cleaning tip somewhere in the barrel and had to rush to walmart to get a 1/4″ dowel rod to Gerry that sob out…

Very nice article.

Just FYI, someone finally traded me for that WASR. I am the proud new owner of a stainless steel Springfield 1911-A1.

I think I would rather save my pennies and get a .22LR conversion kit for my CZ. Sure, it could be kind of fun, but for all the trouble why not just save up for an airsoft pistol; it would be about equivalent.

FWIW, the .38/.357 plastic bullets are much better sellers since they don’t need to feed or cycle.

Could the wadcutter shape be the issue with feeding? I’ve seen an XD jam up tight because of bullets with flat surfaces.

Rob,

I would wager heavily that the flat-nose, wadcutter design is in fact the culprit in the fail-to-feeds. If I find the motivation (or if it’s something that’s requested here!), I could see myself bevelling the edges of a few of these to test the theory..

Would be nice to see a round nose plastic bullet. I have an air soft target (paper plate) set up on the other side of my shop about 18′ I usually empty a couple mags every time I go out there.

Paul

I bought a full sized, metal, 1911 airsoft pistol, the same size and nearly the same weight as my Kimber. Make sure you get one that cycles when shot. I can draw from my carry holsters. I set up a “shoot house” in my basement. Use old towels, spray paint human form target on the towels and hang with “S” hooks from overhead piping. I can do all sorts of things that is prohibited at my local range. When I go to the range I have a .22 conversion for my Kimber. Then I always finish off with several magazines of .45 ball and one magazine of my .45 carry ammo.

This made my day:

Relax, cat; I’m discharging firearms in my garage!

Beat me to it! What a line!

These would be ideal for a revolver.

Great post.

These work great in a .38 special revolver, but then that’s what the wadcutter was made for. The 1911 platform is probably the most sensitive to bullet weight and shape.

That is true for the wadcutter design in the 1911. However, I know semi wadcutters feed very well in 1911’s I cast thousands of them for my target ammo and powdercoat them only time I get geeding issues with them is when I drop ones that are a bit out of round

I shot these out of my .357 Ruger maybe 10 years ago? In my basement. Until my wife made me stop. Still got a box or two up on the work bench. Could probably get away with it in the backyard. The ones I have actually came with plastic cartridge cases that were bright red. You’d put the primer in the plastic case, squeeze in the black plastic wadcutter by hand, and then load it up. The bright red plastic helped prevent mix-ups. I don’t think I’d want to put these in the same metal cases as my regular reloads.

Yes! My Dad had some of those in .38. Still have a few cluttering up my junk miscellaneous ammo bin.

“plastic cartridge cases that were bright red”

I first saw those a bunch of years ago. Got shot by one, as a matter of fact. Not pleasant, but not as bad as the 22. I got shot with when I was a kid.

Where can i get some? Not one of the gun shops I’ve been in has even heard of them.

Stay safe.

dan

I’ve been told that loading single rounds into the chamber is hard on the extractor because it has to jump over the rim rather than the rim sliding up under it during normal feeding. Could be problematic after a bit…

I’d be willing to bet that some fool will load one of these with powder and then someone’s going to have a really bad day.

Here’s another check in the “What Could Possibly Go Wrong” column: primers are made with lead styphnate. Yep, lead. It gets vaporized and blown all over your shooting area (probably your basement or garage) and then you get to breathe it in and filter it with your lungs. Unless your garage has a high-volume external ventilation system like an indoor shooting range, I’d suggest only using these outdoors.

Great on doggies..They leave and won’t come back and no injury.

I suspect a revolver owner would enjoy these more than the author did.

Don’t get me wrong, I had a blast with them. They’re plenty enjoyable. Since I’m so keen on .45ACP, maybe this will tip the scales and force me to buy that Smith and Wesson 625 I’ve been eyeing for some time now .. muaha..

I’m going to take a file to some of these and try to create a more rounded nose-cone profile and see if I can fix the feeding issues. If I could fire, rack the slide, fire, rack the slide etc. etc… I’d be having a heck of a lot more fun.

They work fine in my Charter Arms and do well in accuracy.

FUN, FUN, FUN!!!!

Anyone use these in a 9mm semi? I guess the .38 version would work? As someone mentioned if you could put 17 of these in a clip and shoot them back to back (rack/fire/rack) these would be pretty fun in the back yard etc.

Bought and used the 38’s in early 1970, just reloaded the plastic cartridge cases now while reading the posting. Short on the bullet parts, since I lost some chasing off woodland critters. Time to restock.

My Sig P220, an older one, “cycles” them fine.

It’s been a while but I seem to recall finding the sweet COL.

No! I remember. I loaded them “backwards” with the hole facing out.

I never did know it that was right or not.

It wasn’t until they got gouged up a bit that feed problems would begin.

I used a box with crumpled aluminum pans inside after the first exiting set of ricochets.

I’ll bet a slight bevel would be all it took for anything less picky that a 1911.

Just passing through looking for flash hole size for .38 so the wife can practice her new LCR without the kick. They should be pretty much on where the laser is set for.

PS. I always marked the casings, not so much that I thought I would be dumb enough to load a real round when using these but because I had to be sure never to load those cases with anything but the plastics. A sharpie, reapplied every so often does this well.

if you want to try this, just use 1/2 inch glue sticks (which fits well in the .45) cut them into 1 inch pieces, prime your brass, shove it in and pow…. instant garage bullet. i have bought a bag of glue sticks for $4 or look around your wifes stuff, she may have some.

Im glad you didn’t shoot your cat. I chronographed mine at average of 700 fps.

Those are supposed to be used in. 45 revolvers with the red plastic cases. The reason they didn’t work well is you didn’t know what you were using.

These are meant for REVOLVERS!

Use the black plastic bullet with a red plastic casing and a large pistol primer.

They won’t load into a semi auto, especially with expanded spent brass casings.

If you must use a semi auto, use unfired brass and taper the end of the bullet with an arrow tapering tool. Then you just need to rack the slide between shots.

OMG! I am SOLD !!! Now…..where did that d___ned squirrel get off to?

Got a batch of the plastic bullets speer brand marked on box .38 spl. 8510.

Advertised as .356 dia. could not get the plastic cases as they where out of stock from speer, no prob. I have tons of .38 spl. cases first off, sized cases normal for reloading, found that the plastic projectiles just fell into case.???

Measured a few projectiles and they are consistantly .345 dia. WTF I had to put a crimp on the the cases to hold the plastic in the case

Tested them with small pistol primers worked but inacutate 4.25 in. groups at 15 ft. also left keyholes consistently tested with small pistol magnum primers same results.

These may work better in a 9mm pistol but i don’t have one.

Comments are closed.