Defense Distributed‘s Ghost Gunner desktop CNC machine has been turning 80% AR-15 lowers into functional receivers for years. Now, it’s ready to sink its teeth into 80% pistol frames — 1911s, GLOCKs, specifically, with more to come. TTAG stopped by DD’s Austin HQ to get the lowdown from Cody Wilson, who pioneered open source software and hardware for making your own firearms at home.

https://youtu.be/KmpP-nXChZo

In the video above, Robert and Cody chat about pistol lowers, Defense Distributed’s mission, their struggles with The Man, and more. Then we hit the range with the first two Ghost Gunner pistols ever made for a quick function check. Spoiler alert: they ran flawlessly.

A quick Cliff’s Notes on 80% receivers: a receiver is the part of a firearm considered by the government to be the actual, regulated “firearm” part; usually the frame or the component in which the trigger parts go. But an 80% receiver is no more than 80% complete. Because of its unfinished state, it is not considered a firearm and is no more regulated than a figureless lump of metal.

https://youtu.be/Q5cwP1HmEGo

This unregulated lump of metal can ship straight to you, of course. As personal firearms manufacturing has never been illegal in the U.S. and has few if any restrictions in nearly all states — no serialization or registration is needed except in, naturally, California — you can turn that 80% lump into a functional receiver. Then assemble it into a functional gun. An off-the-books, untraceable “Ghost Gun,” that is.

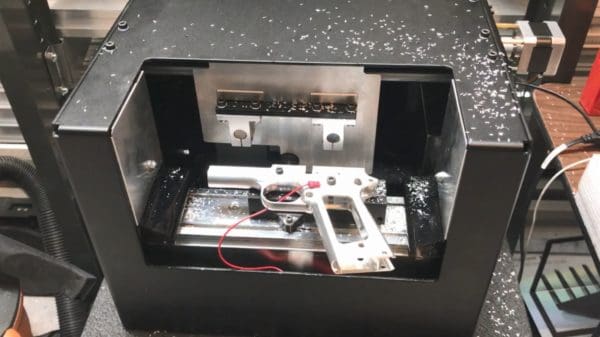

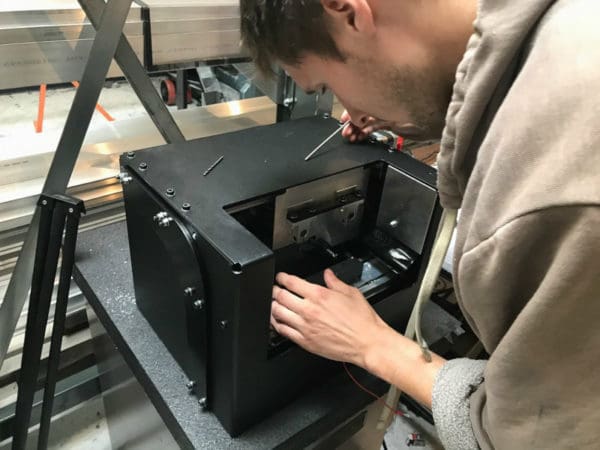

Lots of people people finish 80% receivers now using hand tools or drill presses. Results vary based on their skill, patience, and equipment. If attacking a would-be rifle or pistol frame with a drill isn’t your speed, Defense Distributed’s Ghost Gunner, a tabletop CNC mill, will do the job with professional-level precision.

Once your 80% frame is machined into a 100%-complete receiver, you can hit up a shop like Brownells for every other part needed to assemble it into a functional firearm. All of those parts can be ordered online and will ship straight to your door.

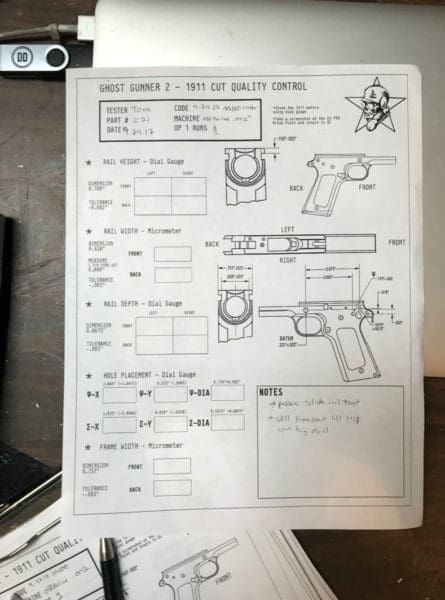

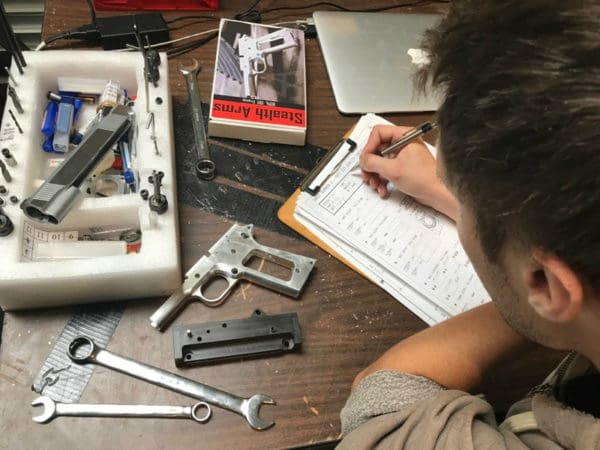

This is the first completed 1911 frame — it began life as a Stealth Arms 80% receiver — to come from a Ghost Gunner. We fired 58 rounds of mixed ammo — including steel-cased ammo — through it at the range and it ran perfectly. In fact, it was smoothly fitted and felt extremely well-sorted.

Some slide-to-frame fitting work is expected. We asked Cody if they were cutting the frame rails slimmer than usual so just about any slide would plop right on the frame and run fine, but, no, Defense Distributed doesn’t make maracas. Apparently the rails are cut so a gun will function without hand fitting but will be a bit snug. That means it will probably function best with some lapping compound to perfect the slide-to-frame clearances.

On the not-a-GLOCK side of the house, just drop the parts into the completed frame and hit the range…no fitting work needed. The factory GLOCK 19 slide on this factory parts-filled Polymer 80 frame ran like a champ. I even shot the thing suppressed with a Lone Wolf barrel, and it never hiccuped.

The ergonomics and feel of the Polymer 80 frame put GLOCK to shame, frankly. From the texturing to the shape to the severely undercut trigger guard and the high beavertail, it simply feels awesome.

That’s what we call a Texas glamour shot.

Does it matter if the 80% frame is aluminum or steel or stainless?

No. Spoke to Cody yesterday at the SAF Gun Rights Policy Conference – it will only cut aluminum or polymer.

The lack of a liquid cooling system pretty much rules out steel for all of the desktop CNC mills.

Wouldn’t be hard to rig a spray though, just grab a tile saw set up from Home Depot. Whether you could make that work with this mill is another question.

The frame of these desktop cnc mills is really incapable of standing up to cutting steel. You’d have to make such shallow passes that it would take ages to finish the slide cuts on a steel 1911 frame, you’d end up with a dull bit halfway through. I’ve seen “cheap” desktop mills that flex so badly cutting brass that the piece was ruined in short order.

Actually, I’ve recently learned that a supply of compressed air to the tip of the cutting tool/work interface is all that is needed to keep the tool cool, and that oil is simply not needed because it mainly reduces heat-induced friction. This keeps the workspace a lot easier to keep clean, and a vacuum attachment to the head will suck up most of the shavings.

I wish they would make 80% suppressors too.

yeah, if you own a oil filter and the right size threaded nut, within the same state, the mean ole ATF will drop a ton of bricks on ya. just saying….

or one of those stock things that fit in a glock pistol, even if you have it on a airsoft pistol, yup, ATF again.

Those party poopers and they constructive intent laws.

Are your congressmen and senators co-sponsors of the SHARE act? Once that goes through you’ll find 80% suppressors everywhere.

The only thing sh!ttier than a 1911?…an unfinished 80% 1911. Who is this type of article target to?

You misspelled GLOCK… twice.

LOL… I noticed that too. Since when is Glock spelled with numbers?

The poor SOB’s in CA (-ca land).

“If ye love wealth better than liberty,

the tranquility of servitude better than the animating contest of freedom,

go home from us in peace.

We ask not your counsels or your [CA COMPLIANT 80%] arms.

Crouch down and lick the hands which feed you.

May your chains set lightly upon you,

and may posterity forget that you were our countrymen.” – Samuel Adams (the dude not the lager)

When can I expect it to do P320s?

Not falling for it.

Why don’t you want to fall for it?

Are you holding a p320?

$1800 to mill 80%s for “personal” use? That’s a lot of crack someone is smoking.

Well, if it’ll do both an AR lower, and a 1911 frame, and a GLOCK frame . . . ya, just to get something that pisses off the ATF and California (wait, that might actually be worth it).

Can they do a nice little FEG 9 x 18 frame? P-64 Makarov? Or a Tokarev frame with a little more angular rake to the pistol’s grip? Or make a Lebedev frame for a GLOCK and machine an angle on the ass-end of the slide. Or a Polish Radom Vis Model 35 9Mm Pistol frame? Or a U.S. made / equivalent of the GSh-18 Pistol?

You could build yourself up an FEG or Tokarev for pretty cheap, and make yourself more nice concealable weapons.

Once they make their way up to cutting steel you could combine the slide / uppers with MAC-9/-10 parts kits.

I think Cody mentioned how they are working on frames for guns that don’t exist yet . . . straight to cnc machine. The sky is limit for this thing. The early entry price is indeed steep but like home computers and ever other technology the price will come down.

Is there an 80% GP 100 in the works?

The headline suggests that ghost gunner is making 80% pistol frames, but then the article talks about ghost gunner selling $1,800 CNC machines that finsish the 80% frames.

Does ghost gunner make and sell the 80% frames PLUS the $1,800 CNC machines that finish the frames?

If yes, how much does an entry-level 80% aluminum 1911 frame cost?

Headline says completing 80% frames, not making them. In the first paragraph, “1911s” is a hot link to 80% 1911 frames and “GLOCKs” to 80% Glock frames. Defense Distributed does sell 80% frames as well, but they do not manufacture their own brand of them. Their Ghost Gunner mill is ready out of the box to finish existing 80% frames. It’s a desktop CNC mill that’s capable of machining all sorts of stuff, not just gun stuff or 80% receiver gun stuff. If you can write your own CNC programs or find existing ones that are compatible, this machine is large enough, I believe, to create receivers from actual square/rectangular blocks of aluminum or polymer.

Forget the 80% frames, time for the machine to do red dot slide cuts!!! Bigger market for that.

This was discussed above, the machine will not cut steel which limits its options.

“Defense Distributed doesn’t make maracas.”

Had to lol on this. Great! that DD uses CNC to its full potential.

REALLY like the look of that GLOCK frame ! and I am not a Gaston zombie.

+ on the Easy Rider “Texas glamour shot”.

TTAG could do a whole post on people’s similar “glamour shots” from around the country.

lol 🙂

Woooooooooooohhffff ! ! !

The DD video with the lume rounds flying.

Oy.

Posts not posting

I used to own one of these and the biggest problem is that there is a LOT of runout doing AR lowers. The FCG holes and the thumb safety holes end up being just a tad too large. I’d recommend using some cutting fluid which will make a mess but the end result is much better. Lower was still functional but it was sloppy.

Ghost Gunner is a big waste of money, One its not Mill Spec accurate. two the Selector hole is way to big and the trigger pin holes on one side of the upper are larger then the drill bit leading me to believe that the bit reamed the hole as it drilled the holes in the opposite side of the lower. So not only was it a waste to buy the CNC machine but it ruined 2 lowers.

so let me get this straight they sell you a machine that can make the 80% lower from a block of whatever you want with extremely low margin of error as a kit to finish off a 80% lower of course it will finish it off perfectly but this is the sort of thing this type of machine does

Great, the lathe is controlled by a modern CNC system, I advise you to read more about it here. Modern equipment and qualified employees are always a guarantee of the best result

Yes, these machines can complete complex parts and create your product prototype almost 100%. Now companies like this can provide you with their technology for your ideas and prototyping.

Comments are closed.