The M16 has a fascinating history in many ways. Its appearance is iconic, and has certainly become part of American culture. It is also a symbol, a microcosm, representing both American ingenuity, blunders…but also triumph.

The M16 design and development process itself was a brutal slog, resulting in a number of wrongheaded missteps, and ultimately in the tragic deaths of service members due to bureaucratic idiocy. Eventually, however, it became, in many ways, a superior rifle to the ones it replaced and led to the current service rifle of our armed forces, the M4 carbine.

It began with a comedy of errors, but ended in success. I’m going to skip a few details here and there to keep this a reasonable length. If someone wanted to commission me to do a book-length feature on this topic (if you’ve got the money, honey, I’ve got the time), get with me after this.

The M1 Carbine fared no better; while the greater capacity was in its favor, the rather limp 110-grain .30 caliber bullet (less powerful than a .30-30) didn’t have the necessary wallop.

Since most killing in combat took place at rather close range (within 150 yards) they also decided that there were too many weapons systems in service. Why bother issuing the M1 Garand, M1 Carbine, Thompson submachine gun AND the BAR when you could replace them with a single gun that fired the same cartridge?

The government wanted a .30 rifle caliber cartridge, since that’s what they were used to. Additionally, the new .308 Winchester round offered a lot compared to .30-06. With the shorter case length, slightly flatter trajectory and roughly equivalent power, the soldier loses no firepower, but more ammunition can be shipped in the same size of cargo container.

So, they started taking submissions for a new rifle.

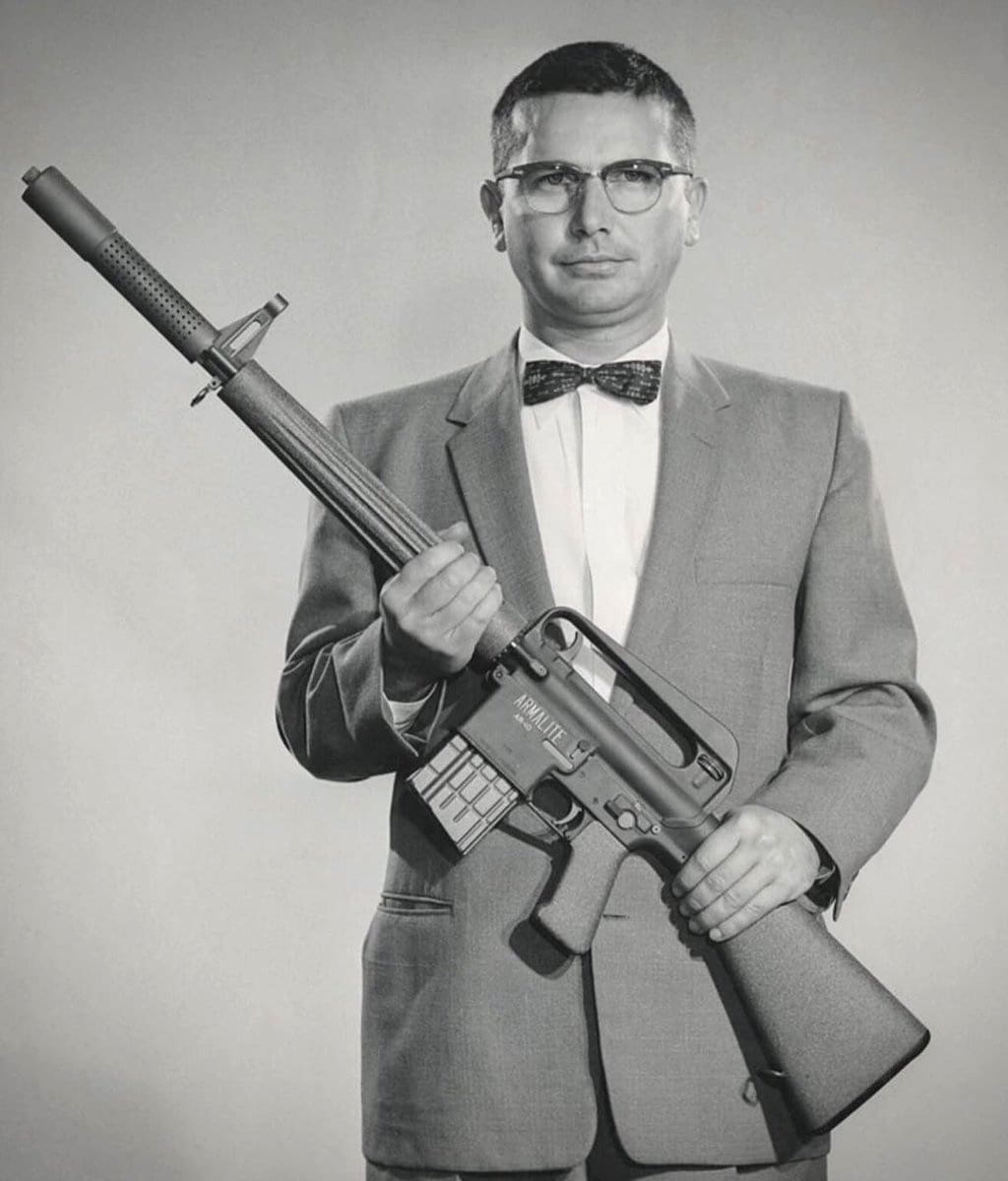

Armalite, a division of Fairchild, and their design wiz Eugene Stoner, created a semi-auto rifle that handled a .30 caliber cartridge (the then-new .308 Winchester) with a simpler semi-automatic design and lightweight construction. That rifle, the AR-10, used a direct gas impingement system to cycle the bolt.

The AR-10, was fitted with furniture made of Bakelite (a hardy, somewhat heat-resistant resinous plastic notable for being the first totally synthetic plastic) and an alloy receiver, weighed less than seven pounds unloaded.

It had most of the features you’re familiar with. There was a carrying handle, rear aperture sight and front blade sight, polymer stock, pistol grip and forend, the charging handle in the carrying handle rather than on the receiver, flash suppressor, an adjustable gas compensator and the hinged takedown design.

However, some folks in the armed forces felt almost right away that a smaller cartridge would solve several inherent problems. The .308/7.62mm round is effective, no doubt, but its recoil is rather stout when firing rapidly in semi-auto, and darn tough in full-auto. If a smaller cartridge could be created that had killing power out to, say, 500 yards, with lighter recoil, it would increase the effective lethality of the soldier wielding it.

That was exactly the thinking of General Willard Wyman, who put out a proposal in 1957 for a lightweight infantry rifle that chambered a .223-caliber bullet, effective to 500 yards and with more velocity than M1 Carbine ammunition. Since such a rifle would be easier to fire in close-quarters combat, it would replace the M1 Carbine, M1 Garand and Thompson as well.

The receiver, made of stamped alloy, was easy to make at scale since it didn’t require machining. The receiver and barrel, chrome-lined for durability, made it very reliable. The cyclic rate of 600 to 700 rounds per minute was very good and the rifle was quite controllable in full-auto firing. The barrel – with a fast 1:12 twist – made it quite accurate.

Now, by 1958, the M14 wasn’t Facebook official quite yet. Armalite, which was made into a going concern by Fairchild’s investment, had yet to sell any guns beyond the AR-7 (which was only sold in limited numbers to the Air Force) and was tired of having nothing to show for all its hard work. When General Maxwell Taylor ix-nayed the AR-15 in favor of the M14, Armalite decided it had had enough and sold the AR-15 and all rights to Colt.

Colt realized the potential of the AR-15 (and thus the M16) and decided to hang in there. Army trials demonstrated the easier operation but also the efficacy of the rifle, leading to General Curtis LeMay of the US Air Force ordering more than 8,000 of them and declaring it the standard service rifle of the Air Force in 1960.

Around that same time, the conflict in Vietnam was heating up. M14s in the hands of US “advisors” were already showing some weaknesses. Full-auto operation was all but untenable and semi-auto operation and the heavy rifle wasn’t much better when you’re confronted by a close-range ambush or mass charge. The M1 Carbine lacked stopping power, so that was clearly a non-starter.

As a field test, a few thousand AR-15s in their early configuration were put in the hands of South Vietnamese troops for testing under fire. The results were overwhelmingly positive, and reports of the M16’s performance continued to make their way back to Washington.

However, a series of tests conducted by the US Army continued to favor the M14 despite reports from the field indicating the opposite. Secretary of Defense Robert S. McNamara ordered Cyrus Vance – then-Secretary of the Army – to look into why that was happening, and he discovered that the Army was (purposefully) testing match-grade M14s against off-the-rack M16 rifles.

However, the old guard wasn’t done. They insisted on the installation of a forward assist in case of jams, which the M1 Garand and M14 had. Everyone who developed the rifle responded, “What are you doing forcing a round in that doesn’t want to go…just eject the thing!” but they would have none of it. The Air Force, however, went ahead; Air Force M16s lacked the forward assist. However, the Army version – the XM16E1 – were equipped with a forward assist. At that point, it was basically done.

By 1963, the M16 was adopted as the standard service rifle for the armed forces. Colt even started selling Colt Armalite Rifles and Colt Sporter Rifles to civilians, which were semi-auto versions for sport shooting. However, at this point, a few key revisions had been made to the M16 that severely compromised its use in the field.

The chrome lining of the receiver had been omitted, to save cost in manufacturing. And by 1964, DuPont informed the government that it couldn’t keep up with demand for propellant.

The .223 Remington cartridge was devised by seating a 55-grain .223-caliber bullet over IMR 4475, a stick powder. Olin came up with an alternative, WC 846, a ball powder. While WC 486 did the job of propelling a 55-grain projectile at 3,300 feet per second, it burned dirty and produced a lot more fouling. Colt also decided it was good idea to bill the rifle as “self-cleaning” and therefore, soldiers didn’t need a cleaning kit.

Early editions of the rifle, had a storage compartment in the stock which contained a cleaning kit. In the first few years of its service history in Vietnam, there was no cleaning kit in there, nor did many infantrymen receive one.

Prior to that, the rifle was known to function reliably. It was accurate at ranges up to 500 yards and lethal. It had few stoppages. Bureaucratic in-fighting and corner-cutting would end up costing many US Army soldiers and US Marines their lives.

By 1965, all troops in-country were issued M16 rifles. Reports started coming in of frequent stoppages, usually failures to eject caused by constant fouling; dead soldiers were found clutching a cleaning rod. Keeping the rifles in working order required constant cleaning, often more than was feasible.

Eventually, the US Government decided to do something about it and started making some fixes. The chamber and bore were chromed to reduce fouling, cleaning kits were issued more liberally, and new lubricants and propellants were developed to make the gun run cleaner and more reliably.

They also added a birdcage flash suppressor and – in limited batches – created a variant that fired three-round burst instead of full auto.

The fixes worked, and the new variant with said improvements – the M16A1, which first entered service in 1967 – was immediately noted as a drastic improvement over the original.

By 1969, the M14 had been officially knocked off its perch, and the M16A1 remained the standard service rifle until the M16A2 was introduced in the 1980s.

After the war, the new standard 5.56mm NATO round (and experience) required some updates, which the US Marines and the army started asking for by the end of the 70s. The Marines asked for a heavier end to the barrel, a flash suppressor with a closed bottom, and sights that could be adjusted for windage and elevation on the fly.

They also wanted a round handguard as opposed the triangular handguard that had been the standard for so long, and they wanted to be able to put a grenade launcher on it (because freedom). Additionally, the twist rate was to be changed to 1:7 to accommodate heavier NATO rounds, including 62-grain tracer ammunition.

The firing mechanism was also changed to three-shot bursts, as it was found the full-auto M16A1 lent itself to “spraying and praying” by inexperienced operators. Pretty much everyone agreed, and those changes were instituted by the mid-80s and the rifle re-designated the M16A2. This rifle served as the official rifle of the US armed forces from the 1980s through the first Gulf War.

A limited number of M16A3s, with full-auto capability instead of 3-round bursts, were made for Navy SEAL and other special operations groups. However, the M16A2 remained in service until…pretty much a few years ago when they were finally phased out of Marine Corps service.

Throughout the Vietnam war, a number of carbine-length versions of the M16 were created and used in various capacities, called the Colt Commando. It wasn’t much at long range but was well-liked for close-in work.

Colt set about tuning it up in the 1980s, eventually settling on a variant with a 14.5-inch barrel. This gave the rifle the optimum balance between accuracy and compact form, along with an adjustable stock which let it be compacted even more.

The US Marines also made some revisions in recent years to create the M16A4 variant. The M16A4 eliminated the round handguard in favor of a quad-rail handgaurd by Knight’s Armament. The carry handle and sights were eliminated in favor of a Picatinny rail running the entire length of the receiver to the end of the handguard, and combat optics (red dot sights) added in lieu of iron sights.

However, these improvements came a little late in the game. M16A4 rifles were issued in limited numbers starting in 2014 and 2015, which happened to coincide with the announcement that the Marine Corps was switching entirely to the M4 Carbine.

Some other changes occurred along the way. No longer entirely satisfied with Colt’s products, the Army and the Marines have both changed providers to FN. FN had already been making M16A4s for the USMC, but is now also producing M4s for the US Army and the Marines…though the Marine Corps is also in the process of phasing out the M4 in favor of the M27 IAR, an improved AR design by Heckler and Koch.

I know and have all the history I need with the m16. The m4 is just an m16 that’s been circumcised.

M stands for Mattel and 16 is how many shots you get before it jam’s

Eugene was a stoner.

The Army got them because the enemy was hiding in holes so they got a ground hog cartridge.

A few things you omitted: First, you say that field testing in the hands of South Vietnamese troop was “overwhelmingly positive.” It is true that Project AGILE reported decapitations and amputations of limbs, but the Army Ballistics Lab could never reproduce such results. Its report, however, was kept secret for several decades, while these “overwhelming positive” but false reports became a selling point with the military.

Second, there have been longstanding reports within the military that the 5.56 round is underpowered. Ballistics testing all the way back to the early 1900s has shown that the 6.8 round is the best suited for combat. The military recently adopted the 6.8 rifle as its standard combat rifle.

The original NATO round was going to be .280 or 7 mm based as you said on lots of practical testing and two world wars.

The new 6.8 round is basically the same ballistics with the round modified for AR platform.

The British army was looking at a smaller round in the 1930’s but lack of money and the short time between the world wars made it impractical to change their world wide supply chain.

The decision to not buy the FAL and to stay with .30 caliber was unsurprisingly made by ordinance officers who did not leave the USA in WW2 and had never seen combat. The double dealing, lack of standards and not buying the FAL are an article in themselves.

The British .280 cartridge and “mid-sized” FAL fit to it would have been much more effective against the AKs than the rehashed Garand M-14 or full-sized Fals. Might be a different world today.

That was because the prototypes deployed used a 1:14 pitch which barely stabilized the bullets.

“It is true that Project AGILE reported decapitations and amputations of limbs, but the Army Ballistics Lab could never reproduce such results.”

Yeah, there were no “decapitations and amputations of limbs”. Basically, the .223/5.56 round simply does not have the energy or mass needed for such damage which is why the Army Ballistics Lab could never reproduce such results.

I like the anti-gun fairy tale of this, its hilarious. Their fairy tale is the gun is so powerful that one .223/5.56 bullet fired from it can vaporize an entire body, no DNA or blood or even clothing left, so completely that no trace can be found as if the person never existed and that’s the reason, according to them, some of the victims bodies in mass shootings are unaccounted for. In fact one doctor actually made this claim again with the Highland Park shooting, when the number of victims claim was challenged he claimed the number of victims was correct but the reason some of the victims were not found was because the bullet vaporized the entire body.

There have been different variations of this “decapitations and amputations of limbs” myth over time, one being the ‘vaporize’ variation. For example, after the Uvlade shooting, a coroner spoke to NPR and “assured” them that AR-15 bullets travel with such velocity that they can decapitate an adult and leaves the body looking “like a grenade went off in there” and not to be outdone in the stupid Rep. Lucy McBath weighed in and added that exit wounds from an AR-15 can be a foot wide, and AR-15 rounds “cause skulls to explode on impact, and the reason you never see the bodies is that they’ve been vaporized — there’s nothing left to show.” … Then there was the stupid variation from Bill Pascrell, Jr., New Jersey’s Congressman representing the Ninth District. He said on X (formerly twitter) “A bullet from an AR-15 war weapon can travel nearly triple the speed of sound. It liquefies tissue and vaporizes bone.”

Anti-gun people don’t see to understand basic science or physics.

all anybody needs to know about the ar15:

it means

“americas rifle 15 ways better than an ak”

the main reason:

a $500 ar15 is better than a $1000 ak

and a $750 ar15 is better than a $1500 ak

and so on

I paid $250 for my AK and it came with a boomerang magazine.

Ar Arkansas Ak Alaska

Who’s bigger, uhh huh uhh huh

Kalashnikov built the AK especially for the fat lazy Americans who dont like to clean gunms.

The AK is so good Our president wont let the Russians or Chinese sale them to us.

Proof right there what’s better.

The AR’s ergonomics were ahead of their time. And still timely today.

The “Carrying Handle” is a dumb idea…..ever tote one around a range like a briefcase ? Probably be banned for life.

It’s a design holdover

Some of the prototype versions had the charging handle on top, the “carry handle” was to surround/protect it.

It wasn’t ever really meant as a handle.

A .308 has a flatter trajectory then a 30-06.

That’s because they are the same diameter and the 30-06 is 100-150 fps faster.

Yep adding speed decreases flat trajectories.

The little .30 carbine may be weaker than the others but the rifle is a natural for quick handling, etc. The AR-15 reminds me of a Flounder, once upright it handles nice, the M14/M1A shoulders fast. And now It’s Honey I Shrunk The AR-308, have not shot a shrunk one so it maybe good or maybe it’s a bigger kicker. Recently I watched a video on manufacturing the Split Window Vet…business minded people like the vet techs and Mr. Stoner dressed neatly back then. Hopefully the rifle Mr. Stoner is holding is in a collection.

A small nit pick, it wasn’t Stoner himself that scaled down the AR10 to the AR15, but instead Jim Sullivan as well as Robert Fremont that were hired for this work. Sullivan did the same for several firearms platforms.

what about the rapidly produced cleaning comic book————i also remember a family friend Marine that complained of the new round’s inability to make it thru the local vegetation to the intended target

True

One of my late friends was Australian army M113 commander in Vietnam.

One day they were waiting to move some US infantry and there was some discussion about their weapons. In the end they tried an M16 against some banana trees and none of the rounds went through. His F1 sub machine gun cut the tree down. His drivers FAL in 7.62 went through six trees and kept going.

I didn’t realize I needed a history full of rumors, wives’ tales, and .inaccurate asides. The Thompson submachine guns were already replaced before thr end of WWII by the much cheaper M3 “Grease gun.’ The early AR-15s (as the Colt Model 01 (601). was called) had 1:14 twist, which was later changed to 1:12 to stabilize the 55gr bullet.in cold conditions. AFAIK, no issued AR-15 or M16 ever had a chrome receiver, although various ones had chrome BCGs or bores. The cast, not stamped, alloy receivers needed less machining, but it wasn’t completely eliminated. Stamping involves the bending and cutting od sheet metal, which is often then welded. The early buttstocks did not have a door to store.a cleaning kit or lube — it was a single rubber pad. They didn’t newd grease pots or oilers stored.in their buttstocks, but I have never seen a reliable reference to a manufacturer or designer saying they didn’t need cleaning. By the time of the model 603, the M16 name had been chosen, the barrel twist changed to 1:12, brass deflector and forward assist added, a fence.put around.the magazine release, a trap door placed in the buttstock, green painted bakelite replaced with black plastic, Edgewater buffer replaced, captured pivot pins added, duckbill flash hider replaced by the 3-prong, and sundry other changes down to the knurling on the bolt hold open and magazine release.

1. Stoner didn’t scale the AR10 to the AR15. It was Jim Sullivan (initially that started the work on it) as well as Robert Fremont (who joined in after Sullivan had started), and together (more Sullivan, because by the time Fremont joined in it was already about 90% done by Sullivan) they both completed the scale down into an intended civilian version.

2. Armalite wanted a rifle for the civilian market. That’s why Sullivan and Fremont worked on the scale down, Armalite wanted to capture a growing market niche desire for rifles with military styling cosmetics so they selected the AR-10 for scale down to what was going to be the 15th rifle in the Armalite design series (thus the ‘AR-15’ – Armalite Rifle 15) to market a civilian semi-auto modern day (of the day) ‘sporting’ rifle. (thus the adoption of the term ‘Modern Sporting Rifle’, or MSR for short, is more correct for reflection of the original invented purpose and design of the rifle.)

3. The AR-15 origins were as a civilian rifle, it was originally designed and created intended for the civilian market and not the military. Stoner took the existing AR-15 civilian platform and changed some things to create a rifle to appeal to the military, he did not ‘invent’ the AR-15 rifle platform nor was it invented as a military weapon. Because of the way Armalite designated their designs series at the time Stoners changes were not a new design worthy of a different designation because they did not change the foundation of the rifle from its original civilian rifle design and intent, and as a result the AR-15 designation stuck with the Stoner changed version for the military. This is where the anti-gun say the AR-15 was originally invented/created as a military only ‘weapon of war’ – this has never been true, it was originally invented/created as a semi-auto civilian ‘sporting’ rifle. All Stoner did was make changes the military would want – that is what went to Colt when Armalite sold to them. After purchasing the patents Colt did a ‘redesign’ of (some of) the Stoner and rifle attributes and that is what became designated by the military as the M-16, and not the original AR-15 civilian design which was later ‘updated in some redesign’ by Colt and introduced to the civilian market by Colt like the AR-15 design was originally suppose to be for.

4. “As a field test, a few thousand AR-15s in their early configuration were put in the hands of South Vietnamese troops for testing under fire.” – no, not actually. Only 10 rifles were actually sent to South Vietnamese troops, a few thousand were ordered but only 10 actually made it to South Vietnamese troops. And it wasn’t an ‘early configuration’ of the AR-15, it was the Stoner changed configuration that went to Colt.

1. Always surprised when people bitch about the M1’s recoil. I never noticed it, but when I ran a round from the same can thru a Remington 700, I bled for an hour (too close to the sight). Difference was gas bleed off for chambering the next round.

2. Back in the early days of the Vietnam War, the army was touting the new M16. The claim was since the bullet tumbled it did more damage and a hit in the arm would shatter it causing massive damage. Apparently the nogun group took this bull to heart. This is the same critter some combat vets call “the Poodle Shooter”.

Its sometimes very strange how superior calibers and superior weapons often fail in the marketplace while inferior ones somehow manage to hang on for decades.

The .222 Remington Magnum, now all but forgotten, was a superior varmint cartridge in every way compared the .223 and the Stoner AR18 rifle was superior and cheaper to produce than the M16.

Since the M16 was adopted by the U.S. Military the lovers of this weapon make every excuse for its shortcomings even though it still is not reliable enough to be used as a military weapon.

One of the most infamous modern examples of total failure of this worthless weapon was the very well publicized massacure of a squad of U.S. Troops in the Desert Storm War which made Jessica Lynch a military Heroin although all she did was manage to get shot and somehow survive. The real hero of the fight was a guy that grabbed a mortar but ended up being killed (no one pays much attention to dead heroes) Every one of her squads M16’s failed to function in the desert environment while the insurgents who were using AK 47’s annihilated them and the insurgets have never been noted for taking care of their weapons. All this was glaring proof how worthless the M16 still is as its got countless hapless soldiers killed ever since its adoption. Anyone that has even the mechanical knowledge of an orangutan knows that when you have a gas system that sprays burnt powder all over the action that this is a system that should never have been adopted.

And yet she’s still done more than you ever will. Mommy’s basement gets smaller every year, doesn’t it dacian?

Jessica Lynch didn’t fight in Desert Storm, much less in Iraqi Freedom. I’ve never met any veteran with knowledge of that situation who would characterize her inaction as heroic in any way. She got scared, panicked, and couldn’t/wouldn’t operate her weapon effectively. But, whatever.

The only thing I need to know is the Stoner DI action is going away, not fast enough IMHO.

With the DI action going away, the top mounted charging handle needs to go away too. The side mounted ones are much better.

In whom’s lifetime?

After 45 years, why think direct impingement is “going away?” It’s been in service longer than any other. There is an issue with describing how it works, tho, a major error that has become folklore among the ignorati: it does not cycle gasses into the receiver to cycle the action. It cycles gasses into the bolt carrier, where they pressurize a gas cylinder sealed on the forward end with gas rings on the bolt, and with the bolt tail in close proximity to the interior of the carrier. Cleaning the bolt tail allows more gas to escape – it’s better, up to a point, to let it get residue build up on it to seal it and retain more pressure to operate, which it naturally does as you fire more ammo.

That pressurization counteracts the brass pushing on the bolt face taking stress off the lugs, which makes them easier to turn unlocking the action. Gas pressure on the case continues to propel the bolt carrier backwards, along with the mass of the carrier moving in it’s expanded state. A properly operating and timed action can even operate with no extractor, and its been done many times. An extractor is only needed to remove unfired ammo – consider that the next time extractors seem to be marking the rim of cases. What is really happening is the bolt is unlocking too soon, with the case expanded against the chamber wall – that is why extractors rip rims, bad timing. Gas port location controls that, it’s determined to be 5-6″ from the muzzle – not measured from the chamber.

Self loading actions with gas operation are a lot like cam timing in a internal combustion engine – the single cylinder of a M16 needs to cycle as the brass case is almost relaxed. And that gas pressure is relieved by passing gas out the two gas exhaust ports out the ejection port of the upper. It’s not released willy nilly in the upper uncontrolled, it’s piped and channeled every step of the way.

Where does the gas residue come from then? Same as blowback .22, or a roller lock action, from the chamber – the gas tube is small, the gas port in the barrel is only .069″, but the loose brass withdrawn from the chamber is much larger, a huge donut of open space pressurized by the charge in the barrel. It can’t vent fast enough at the muzzle, and pushes on the brass against the bolt face until the brass is loose enough to vent around it. Barrel volume is much larger than a venting gas port, and it’s the source of residue on the bolt and carrier.

Keep in mind that military powder is still low bid winner, in huge contracts, and not the premium powder capable of being made on the market. Its so cheap it’s moderate flash – forcing the use of a flash hider, rather than the more expensive and cleaner burning ones in high end ammo that have much less signature.

Anyone who’s owned and shot an HK91 will know this – fire up a bandolier of cheap Paki surplus, with NO gas action at all, it’s coming from the chamber. And it’s a mess. Almost all self loading actions do this, again, even a blow back .22. We don’t see it with bolt or lever guns, for good reason. We leave the brass in the chamber until the barrel is completely vented. A self loader uses pressure in the barrel to assist in the reloading action.

Once this is studied and understood, you will be equipped to instantly recognize when others comment on the M16 with their misinformation or even out right lies. Everyone likes to say “Stoner did this or that” but few actually have studied it, and fewer grasp the fundamentals.

I’ll never foget when I saw an AR-15 in Nha Trang, Vietnam in 1962. A Marine Captain had this strange rifle sitting on his gear. I said to him what the hell is that toy your carrying. He told me what it was an AR-15 and showed me he ammo. That was another shock to my brain. A varmit

cartridge. He also said he was field testing it for the Marines.

I will never forget that meeting..

Full of inaccuracies and outright lies.

Whatever you want to term the AR-10 and AR-15 gas system, it ain’t “direct impingement”. Were it that, there’d just be a little cup on the end of the bolt carrier, and that’d be all she wrote–It’d work just like the Ljungman or MAT-49/56.

Instead, that gas carrier key directs the gas into the interior of the bolt carrier, where the gas transmits energy to effectively “blow apart” the bolt and the carrier. This does two unique things, one it imparts much more energy to that bolt and it blows any dirt or other material out of the action.

Most people don’t bother to even try to understand how the damn weapon works, and it doesn’t help that people keep terming it a “direct impingement system”, when it manifestly is not. It’s its own unique thing, and should probably be called the “Stoner System” just to differentiate it all from the rest of the actual direct impingement systems out there.

If the gas goes inside the bolt carrier to force it to expand and have the bolt rotate, how is that not “direct impingement?” It’s directly acting by pressurizing the bolt carrier sealed by the bolt gas rings.

I think what confuses some folks is like it’s much the same as a radial aircraft engine that bolts the prop to the engine block – the block rotates, the crank is stationary. It’s backwards from the normal gas operation of piston guns, the cylinder is the moving part. The piston is the bolt itself, which remains stationary until the carrier unlocks it from the chamber.

My description of the operation was to explain something many confuse with operation, that gas is dumped into the receiver by the gas tube. Very little is transmitted by the tube since most of the initial gas is directed inside the bolt carrier, and vented by the carrier ports out the ejection port. The gun community often thinks that the M16 “poops were it eats” when the reality is most of the gas residue comes from the chamber, not the gas tube. The interior of the bolt carrier is no dirtier than any other gas cylinder, and the interior of the receiver is no dirtier than any other self loading action, why I mentioned the HK91. All of that discussion remains a fact.

That the engineer himself described it as direct impingement is his call, when a board of gun designers is commissioned to declare it otherwise to correct the record, we will then be informed of their decision. Until then, there will be a difference of opinion with Stoner, and after their decision, there will be a difference of opinion with them. In either case, we are still discussing gas pressure acting inside a gas cylinder to cycle an action. Some will disagree no matter who or their qualifications.

Stoners creativity certainly reduced a lot of the pars,t eliminating rods and separately located cylinders, simplifying things a great deal. The operator can gain access to the inside of the action in seconds, not the difficult and sometimes lengthy time it takes to clean the M1 – which often suffers damage from the operator attempting to take down it’s gas cylinder. Stoner was more than familiar with it, he had been trained to operate and clean it, too, as a Marine. He did us a big favor getting away from that obsolete design.

If the M16 has suffered issues, it was from people who directed changes from it’s original specification arbitrarily, not well versed in its design intent. It’s still not being fed cleaner, more modern powder, except for the 70+ grain ammo loaded for the SDM by Nosler.

your nomenclature is off, a rotary aircraft engine has revolving block and cylinders, stationary crankshaft. the later, radial design has rotating crankshaft.

Comments are closed.