Most people know of three options for body armor: steel, fiber (e.g. Kevlar), and ceramic. However, if you’re into military news, you may also have heard that more U.S. troops may soon be replacing their Kevlar-based equipment with a fourth option: lightweight plastic armor.

More specifically, the type of plastic is UHMWPE (Ultra High Molecular Weight Polyethylene), which is more resistant to impact than any other plastic. You’ve almost definitely encountered UHMWPE before: it’s been taking the place of steel skid plates for off-road vehicles, hull reinforcements for boats, and other consumer products designed to take a serious beating. Your fishing line or compound bowstring might be made out of it. It’s also a popular choice for joint replacements.

Naturally, a lot of R&D has been dedicated to the ballistic applications of this plastic.

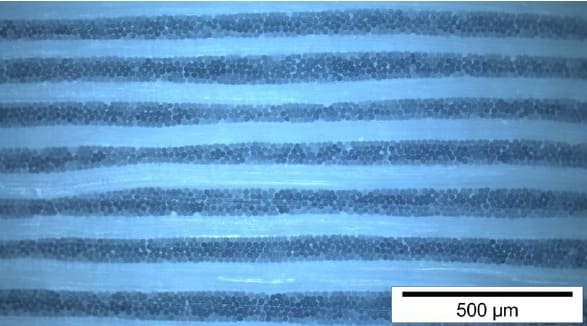

To produce a body armor plate, many thin sheets of UHMWPE are heat-laminated together under high pressure until they bond into one striated composite piece. The layered structure compounds the individual layer’s impact resistance, resulting in greater strength.

The result looks pretty cool under a microscope:

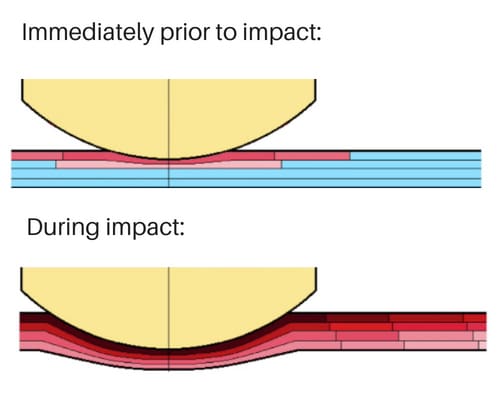

Upon impact, the resin bonds between the individual layers are broken, which disperses the force, allowing the bullet to be embedded in the material without penetrating. This is a very efficient way to stop bullets. In fact, you’d need a steel plate twice its weight to stop a round traveling at the same velocity.

The plastic plates themselves are so light they actually float, turning a 15-pound set of armor (two steel plates) into an almost equally effective set weighing in at just under 7 pounds.

Now you know how plastic armor works technically. How does it perform in practice?

After being tested by the NIJ, the AR500 Armor’s plastic plates earned the same rating as their steel plates: Level III, which means it will stop 7.62×51 M80 Ball at 2800 FPS, 5.56×45 M193 at 3150 FPS, and 7.62×39 AK 47 at 2380 FPS. This rating applies to the plastic plates as standalone armor, whereas the steel plates require separate trauma pads to earn the same rating. (That said, you will be significantly more miserable during and after impact if you don’t wear trauma pads or IIIA soft plates behind your plastic plates).

Although the plates have been professionally tested, Twang n Bang performed a DIY stress test, using a few 150gr .308 rounds. Impressively, the armor produced a completely survivable result. There were fragments embedded in the armor, but none in the plate carrier, which means the bullets were fully contained with zero penetration.

Here’s what that looks like:

When split apart, you can see how the impact was effectively distributed through those heat-laminated layers:

And here, you can see how the force was distributed on the other side:

Although it shouldn’t surprise you that the NIJ’s evaluation was correct, it’s amazing to see this lightweight plastic in action, offering comparable protection to steel.

So, besides soldiers, who is this for? Obviously, there are many professionals who might opt to wear body armor. However, if you do a lot of running and gunning practice with friends, it’s not a bad idea to protect your vital organs. It’s up to you to decide whether this is something that makes sense for you.

You can get more details and prices on these plastic plates here. Here’s where you can also find current discounts and promotions from AR500 armor.

I sure as heck don’t want to get shot.

Bruising is better then dying Id think.

If it can help save lives Im all for it.

Get it out there to the troops ASAP.

Less weight more comfort greater survivability. What more can you ask of it??

Unfortunately, there is currently no way to mass-manufacture Level IV body armor with the current technology if you use polyethylene. It’s a shame, because that is one of the only things stopping it. Inability to stop armor-piercers is an instant dealbreaker.

Considering all the weight that our military men and women have to carry in to battle. I think that weight difference 7lb vs 15lb is a great choice. Who would have thought plastic could stop lead.

“I think that weight difference 7lb vs 15lb is a great choice.”

Sounds like a win for the infantry, but does it simply mean “the system” will just add seven pounds more gear, retaining the impediment to swift action the soldiers already endure?

Of course it does… Hopefully, that extra 7 pounds of gear would actually be useful. (Unlikely, I know.)

Every time I see footage of the Normandy Invasion, US troops, wet clothes and boots, hundred pounds of gear (when dry) on their backs, trying to “run” across wet sand, I ask, “What the hell were the feather merchants thinking?” No one needed all that non-combat stuff if they couldn’t even get to cover. Doesn’t seem like much has changed since.

WHICH “noncombat” stuff The inadequate life belt? We overloaded them in 1944 and load them WORSE today. Today grunts are just better fed and better conditioned in better boots. Still vastly overloaded with combat equipment. From “must” have to “might be needed”. All the nifty “high-tech” stuff adds to the load. AND THE BATTERIES. Body armor is just crazy/moronic for a grunt. Turtle on it’s shell.

“WHICH “noncombat” stuff”

Anything that can’t immediately be used to protect the soldier, or kill the enemy. Like extra underwear and sox, tent halves and pegs, (shovels can be used to kill), etc. (I don’t have a list of the loadout for 1944 infantry). Just a wild guess (I only had three weeks of “ranger” training), but probably half of the gear was useless as defense or assault.

So, your idea is to dump everything but your rifle, bayonet, ammo, and canteen by the barriers at Normandy, and make your sprint through the killing zone without your tent and clothes? And if you die on the beach, you don’t need a tent to sleep in. If you take out the Germans, you can go back for your tent at your leisure or move into their pillbox.

The idea is to better understand the environment, and aid the infantry in mobility to survive. If you die on the beach (or any open ground), none of your gear matters. If you are pushed off the beach, none of the non-combat gear matters, either. On open ground, it would seem the faster you can get to cover, the less likely you are to be shot. Soldiers can endure without a change of clothes for days at a time. Even go without food for the same period.

My observation is the US infantry units (Army and Marine) equip their troops as pack animals, each individual designed to be a self-contained platoon. Just from film footage, it seems infantry would rather have more ammo and explosives than tents and blankets.

The modern US infantry soldier now carries FAR more in terms of weight, than any other US soldier of any previous era, infact, they carry more than ANY soldier throughout ALL of human history. Yes, even more than the soldiers of the Middle Ages.

at about a pound a mag I’d gladly take a “free” extra 200 rounds of 5.56 ammo.

1.3 inches seems kind of thick, but the weight savings looks good. (I must note that I know nothing about armor.)

Cutting 8 pounds from my 30 pound vest would be a game changer. Especially with temps hitting 110+ now.

More than likely they’ll find another 8 pounds of kit for you carry.

Why is there no weight comparison with Kevlar or Dyneema armor? Steel has not been used for body armor in a long time. It seems that motorcycle helmets would be a good application for this technology.

Kevlar plates aren’t generally level III. (There might be one or two out there, but I haven’t seen them.) A medium SAPI plate set (which is a little smaller) comes in at about a pound more, so still an improvement for roughly the same protection. The military won’t swap E-SAPI for these as standard issue any time soon though, (the E-SAPI set is about 4lbs more) since being able to stop AP rounds is an issue .mil has to deal with.

Steel or ceramic plates are still the go-to if you need to stop anything beyond a pistol round. I don’t think I’ve heard of a kevlar-only vest that could handle a .308 hit.

The most critical component of a motorcycle helmet is the shock absorbing lining. It has to absorb the impact to the head, and allow rapid deceleration as it crushes. The ABS plastic shell protects the lining and your head. Like a modern car, the helmet is sacrificial and absorbs impact with its destruction. I don’t know if the armor plastic would offer any advantages.

wow. pretty slick.

That’s a lot of back face deformation… You’re definitely getting at least bruised ribs from that. Honestly, I’d probably want a lvl IIIA full wrap vest to go with these to provide extra padding behind the plate.

I lost confidence in AR-500 when they marketed “carbon nano-tube” panels and delivered panels that in no way stopped bullets with carbon nano-tubes. What they actually delivered appeared to be Dyneema and aramid (just like what Citizen Armor delivered). Yes, I do realize that they did meet IIIa standards. I know they fooled Leghorn, but commenters here noted that the price didn’t match up to the price of carbon nano-tubes nor had the technology actually progressed that far to produce long enough strands in quantities large enough to make armor. The idea that a small not very technical company like AR500 (or Citizen Armor) would be the first to make such a momentous breakthrough in material science with no papers published or patents filed is ludicrous. I don’t know whether AR-500 was suckered or was the suckerer, but that incident cast much doubt on how reliable their word was. I am in no way saying or implying that their products don’t provided the protection they say they do, rather just that they were wrong or fibbed about how those “carbon nano” panels were composed and worked. Please correct me if you think I am wrong about this incident, I welcome having my notions corrected.

You’re not wrong. Carbon nanotube armor is bullshit at the moment. Eventually, it has the potential to produce amazing results, but we’re decades away from being able to make said armor.

That being said, UHMWPE is not a new idea, these sorts of plates have been around for years. The fact that AR500 managed to get production of these plates rolling, however, is a good sign.

For me it is that I consider admitting ones errors, when confronted with them, as an important component of honor. To my knowledge, AR500 just pulled the product and acted as if it never happened. I try not to do business or otherwise associate with anyone who exhibits such behavior.

Again, I may have missed the memo with their apology. I would be happy to find it had been made.

Oh, and as you say, this not new tech or a unique offering of AR500. Most armor manufacturers that I am aware of offer similar plates. I am surprised that most commenters here don’t seem to realize that.

Frankly, processed/treated wood is far more likely to be effectively deployed before carbon nanotubes…

https://www.scientificamerican.com/article/stronger-than-steel-able-to-stop-a-speeding-bullet-mdash-it-rsquo-s-super-wood/

I do hope they execute the manufacture with some accuracy.

“Eventually, it has the potential to produce amazing results, but we’re decades away from being able to make said armor.”

From something I read recently, the current problem in making carbon nanotubes is that each tube has to be ‘grown’ individually, one atom at a time. Meaning, a truly ‘glacial’ growth rate.

The second deal-killer is that the nanotube has to be *perfect*, not one atom out of place, or the tensile strength drops to near zero.

So, it looks like we are a *long* way off from making trillions of error-free nanotubes 60,000 miles long one carefully-placed atom at a time to build that space elevator.

We’ll see that nanotube armor plate much sooner, but still quite a ways off…

Actually, just in the past couple of years, it became doable. But we’re talking expensive enough to make The Donald look for a cheaper executive protection option.

At 3.5lbs, I could see this really hitting it big. I ended up getting ceramics because its the only thing I really knew and steel was always touted as being heavy. In hind sight, I would have got steel because they are re-usable.

If I get the money, I want some of these plastic plates, I wonder if a ceramic coating on the front or a think steel trauma sheet on the back would benefit it any?

See above. A soft trauma pad or a full-wrap vest would help quite a bit, but adding steel behind this sort of defeats the purpose.

On a side note, if you’re getting shot enough to care that your plates are or are not multi-hit rated, you can officially complain about having a bad day.

Spartan armor makes a ceramic/poly plate.

Weighs 5lbs per plate.

I use poly plates, worth every penny.

Your back and knees will thank you.

I wonder how it holds up to heat. I’ve worked with uhmwpe some and it degrades in to hdpe at around 180F. If the armor is improperly stored it could be bad.

I heard 170F.

You will likely see this stuff deployed to USCG and DEA types working off shore in drug interdiction. Those guys don’t dare use steel since one slip and you have an express elevator to visit old Davey Jones.

That’s what quick release carriers are for. I’d be much more concerned about the inevitable coat of rust building up on the plate. But in any case, that’s hardly an issue. .gov hasn’t used steel plates in decades. It’s much easier to just procure the exact same E-SAPI plates that .mil uses.

Waiting for wearable reactive armor …

Wear your mags on your plate carrier.

There is a video showing full mags stopping a round.

There are also plates that are a compromise. Mine are ceramic, .55″ thick and weigh about 1lb more each.

They’re only rated for 7.72x39API but then I don’t really need full on .308/7.62×51 for my uses. YMMV.

Overloaded for training purposes I’m at about 25lbs. Dropping to an actual “battle loadout” would cut the weight down to about 19.8lbs.

It seems to me that 1) Body armor is becoming both lighter and cheaper which means that more and more countries will be using it. 2) Military rounds are going to have to become larger and faster to penetrate said armor. So why still keep inadequate rounds like the 5.56 and 7.62 NATO? Should we design new combat rounds or try to use existing rounds like the .30-06 Armor Piercing? The pentagon needs to looking into this problem before we have to start issuing the Barrett .50 to every infantryman and woman.

M995 has been a thing for a while…

ESAPI ceases to be effective after a few hits of 7.62*51. In the game of offensive vs defensive systems the offensive always has the advantage. We might be closer to the knight in armor swing of the pendulum but it only takes a few advancements and all that armor is useless.

At $640 a set plus the cost of trauma plates that are needed I’m gonna have to pass on my budget

Why not just “back” the UHMWPE plates with a thin layer of aluminum to deal with the back face distortion?

My question is, how do these hold up in temperature extremes (110°+/-20°), how well do they work in those extremes, and what’s the degradation rate at those extremes.

On a side note, steel is heavier, completely multi-hit capable, and doesn’t have a shelf life. When they get these polymer things to a point where my $600 doesn’t have to be spent every 4-5 years, I think it’s a fantastic product. For guys who aren’t spending their own money to buy, maintain, and replace, hell yeah, I’m on board.

5 years is a CYA thing. I have steel plates with the same shelf life. You store and take care of your plates they’ll last longer than 5 years.

“How Does Plastic Body Armor Work?”

By stopping bullets? I’m just spitballing here.

Do they make bulletproof backpacks 🎒 for school kids with this material?

I have heard there are backpacks with a plate carrier pouch in there to use whatever plate you want in them…

Is there a clear version for school backpacks?

” It’s also popular for joint replacements.” Nope I don’t care how fancy a name you give it, I will never smoke plastic.

I’d like to save up to get some for my nephew, who’s a cop.

That sounds like a fair trade.

Dyneema, DSM’s polyethene used for armor, has been around longer than kevlar. Poly as both hard and soft armor is far from new. There were pure poly plates in the 90s. It’s even in ESAPI and SAPI plates and a significant portion of current ceramic plates. The “best of breed” poly plates like the Hesco 3800 weigh 2.2 lbs for a SAPI medium. The significant downside of polyethene armor is how it performs against rounds with steel penetrator and cores. Frictive breaking is not particularly effective at stopping steel. In the proposed NIJ 101.07 a pure poly plate would meet the RF1 standard.

I have shot .357 rounds into 1/4″ lexan sheet, just saying, with no penetration! I use two plates w/tape between them, works great. Make a couple test plates and work a simple formula up. . Cheaper than $500.00!! Now I know, I know I don’t have seal of approval and etc. I heat the sheets up and drape it over a wood mold and trim with saw. I haven’t weighed them, I guess I should. I also haven’t shot myself to prove it works, but then it works on my test piece.. This is not a recommendation, but it might be worth looking at. when SHTF…

Is the degradation of protection significantly increased with plastic as a opposed to other traditional armor materials? I’ve been told that plate becomes less effective with each hit.

Comments are closed.