By Joel Thompson

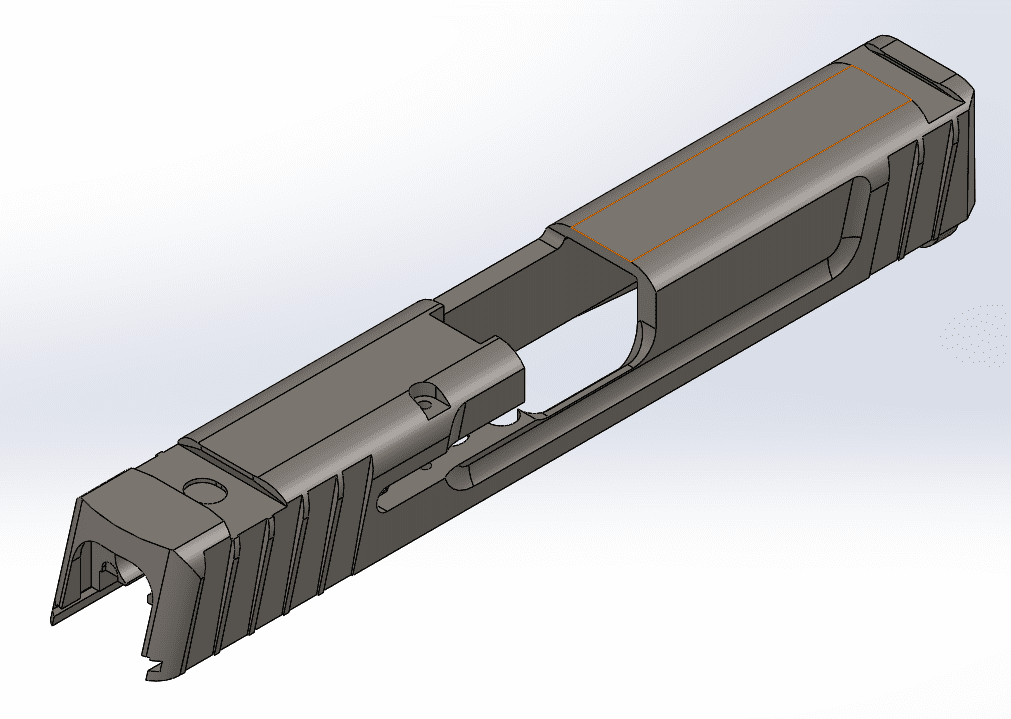

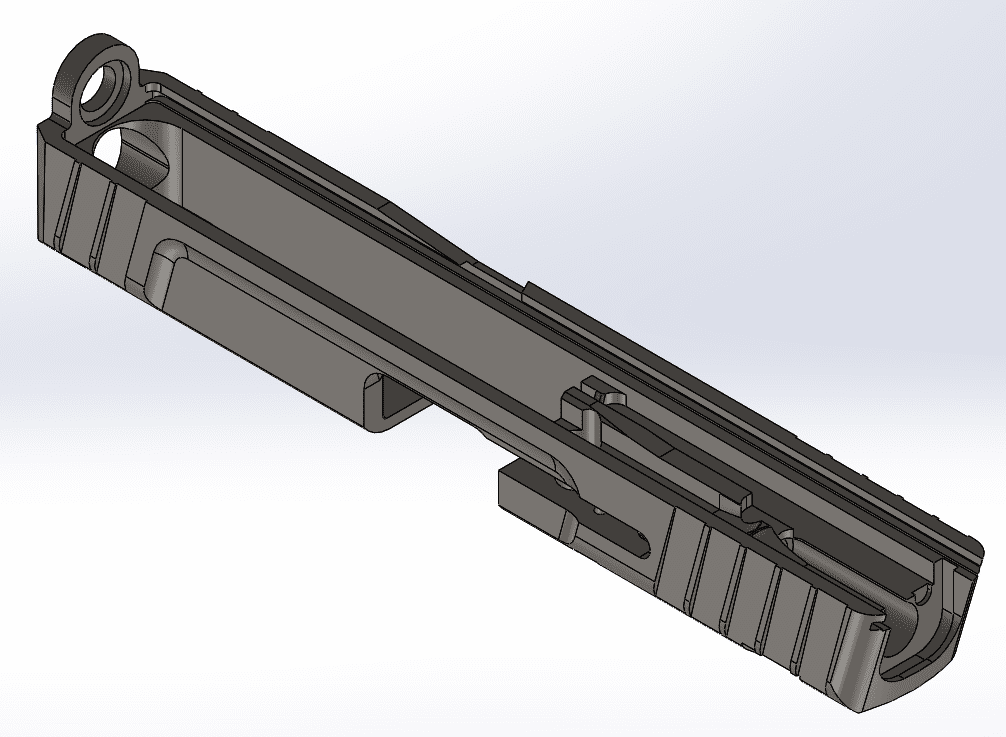

As a mechanical engineering student, I have a serious interest in firearms design, and I’ve been wanting to develop my CAD-modeling skills for a while now. So, I thought I’d kill two birds with one stone. I took one of my handguns (not my carry handgun), disassembled the slide and started measuring it with a $10 pair of Harbor Freight calipers and a basic set of fillet gauges, taking careful consideration into how the part may have been machined, and why each feature existed. I then started modeling the slide in SolidWorks, the same CAD software used by Smith & Wesson (I believe). I pecked at the model a little bit at a time until a couple days ago I created a “finished” model of the slide . . .

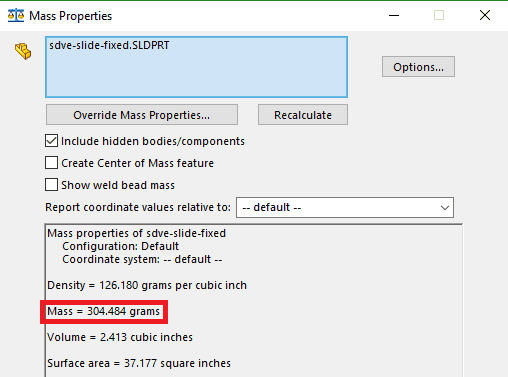

One way to know how accurate the model is compared to the real part is to measure its weight. SolidWorks allows you to define what material the part is made from. It then uses this information to calculate its mass properties. According to SolidWorks, my model would weigh approximately 304.5 grams in the real world.

I then took the real part and weighed it on a $10 Harbor Freight scale: 303.4 grams.

That works out to a 0.4% difference, or 99.6% the same! Now this method can really only tell you if your model is in the ballpark of being close to the real thing. I may have the right combination of features, however, if they are in the wrong place then the slide won’t work. So, how close is my model to being accurate? There’s one way to know… make it.

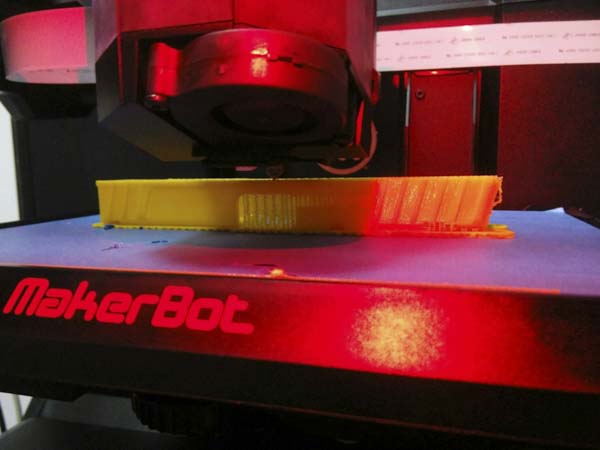

Yesterday, I fired up my 3D printer and let it run. Three hours and twenty-five minutes later I had a finished part.

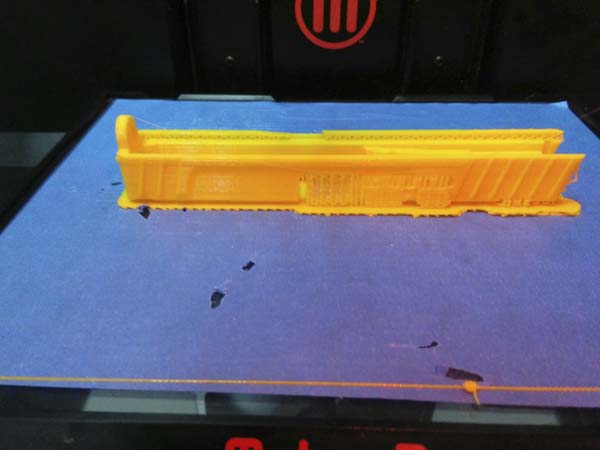

I popped off the raft, cleaned out the supports, and attempted to assemble it. Well…it worked! Sorta… The fit was very tight, this is to be expected with 3D printers. The 3D printer is great at making parts, but it doesn’t handle tight tolerances very well.

Here’s a reminder of why gun manufacturers don’t make slides out of plastic, and why you shouldn’t either.

No, I didn’t test fire it. In order to have the 3D printer to finished in a timely fashion, I reduced the infill of the model to 2%. In other words, the plastic slide is 98% hollow inside. After playing with it for a while, the barrel slammed into the breech face hard enough to cause the devastation you see.

I also wasn’t able to clean the supports out of the striker housing or the extractor cut well enough to attempt assembling a full assembly. However, after widening a few of the spaces with my knife, I was able to insert my barrel, guide rod/spring, back plate, rack the slide, and lock it back. Everything about its function seemed to be correct, including the trigger reset.

One of the great things about being able to prototype parts with a 3D printer is that you’re able to notice minor details you didn’t notice before. For example, the slide was about forty-thousandths of an inch short (0.040-in). This was because my cheapo calipers weren’t long enough to measure overall length, and I had to rely on an old ruler. I also discovered that the barrel hole cut had an approximately 3º cant to it that I didn’t notice initially.

Without it, the barrel couldn’t move freely in the slide. A quick cut with the knife, and the barrel was in motion. All-in-all, I had somewhere around 25 hours invested in modeling the slide, most of that spent measuring, re-measuring and wondering, “how on earth am I going to model that?” Nevertheless, I successfully completed the model unaided.

While my model has yet to reach 100%, I’m satisfied with the end result. I’ve learned more about the handgun in those twenty plus hours studying it than I have in the last few years of owning it. More than that, I’m satisfied with my rapidly improving modeling skills.

This was easily the most complex model that I’ve ever created with close to 100 individual features (that number could probably come down if I had to start over again). Less than a year ago, I could barely model the simplest of parts. I’d call that a success.

Nice work. A recommendation from a mechanical engineer that’s been there? A GREAT way to build up modeling skills is to solid model a set of 1911 prints.

http://www.m1911.org/technic.htm

http://www.sightm1911.com/blueprint/m1911a1_blue.pdf

Thank you, and it’s on the list! 😉

This kind of person is on their way to becoming a firearms EXPERT: Mechanical Engineering student, performs detailed dimensional analysis, design intent analysis, creates prototypes and use failure mode analysis to learn even more.

Someone who reads gun magazines and hangs out on blogs is a gun ENTHUSIAST. For the future of our industry, people have GOT to start learning the difference.

Just because you LIKE guns, doesn’t mean you really UNDERSTAND guns. It is important for comment section ‘experts’ to temper their dogma with this context.

I love the POTG, and we have an impressive communal knowledge and an even more impressive moral compass – but in terms of real firearms design, our collective ignorance is profound. That’s why I love TTAG, Forgotten Weapons and other places that try to really get into the meat of firearms function and design, rather than regurgitating “common knowledge” as a substitute for real factual analysis.

Keep the powder dry.

I really want to build my own firearm from the ground up including the magazine. There are certain things that would be “cheated” (notably the barrel being rifled, for legality reasons) but I want to do say 90% of the work my self including my own spring for the mag. I would actually like to do 25 or 32 auto in a delayed blow back but in reality will likely end up with 9mm because the brass is so common where as 25 ACP or 32 ACP are kind of rare.

“I really want to build my own firearm from the ground up…”

TTAG’s ‘Dyspeptic Gunsmith’ has indicated he is working on a book to do just that very thing.

I, for one, (along with welcoming our new insect overlords, er, I mean, our new likely female Democrat president) eagerly await all of DS’s future writings…

*reptillian overlords.

There, I fixed it for you.

Pick up some lost wax filament for your printer and print a wax model of your slide.

Use that to cast an aluminum slide for it.

(I do *not* recommend test-firing it)…

If he has access to a CNC machine, which any MechE department should, he could build an aluminum or steel slide from an ingot. That’d be way stronger than a cast one.

The aluminum would be okay for lower pressure rounds, like a .380. But the steel would be a safer choice for the 9mm and bang-ier.

Then just load it into a ransom rest, get a long string, maybe a lexan shield, and see if it works.

True, but wax is *fast* to cast…

I would selectively defeature the model to cast it. That way all of the features that require precision can be milled. Get a used Sherline milling machine, buy a Chinese CNC conversion, and you’re in business. It would take all day for my heavily modded Sherline 2000 to cut a slide, but it could easily do an aluminum model. Check out the work done at cncguns for inspiration.

My friends and I have been contemplating this very thing, though not at school, we have access to another machine shop. However, I don’t see much of a point in casting a slide for an SDVE. Maybe when I have other models I’ll try it.

Wish I had a license for SolidWorks. My MicroStation does the job but SolidWorks is meant for that. Great work!

Arrr P)

Would you not be able to get a similar model out of FreeCAD?

Also, does FreeCAD handle 3D printing?

Not that I want to try this sort of thing or anything…

Personally I’ve had horrible luck with every free 3D CAD package I’ve ever tried, mostly due to the interface. They may be capable, but I’ll be damned if I can figure them out.

You might try SketchUp Make by Trimble. It is free and easy learn as there is lots of help on-line.

http://www.sketchup.com/products/sketchup-make

I haven’t tried it yet, but a friend of mine swears by AutoDesk Fusion 360. It’s free for start-up businesses and hobbyists, as long as they make under $100K a year, I believe. You have to renew the subscription every year, but as long as your status doesn’t change, you can continue to use it. It has a full CAD, Simulation (including FEA analysis) and built in CAM package, that according to my friend that uses it at work, is top notch. I plan on learning how to use it this summer.

After you save in the native CAD platform file type, always save in a neutral file format that all CAD platforms can interpret, like .STEP or .IGES, so that you can continue to have access to your models if, for some reason you lose access to that particular CAD platform. It may or may not save any of the features, so plan on it being a dumb solid, but you will still have a usable file for years to come.

I used Inventor for a couple years. If Fusion 360 is anything like it Id sooner dust off my drafting board.

After using Pro-Engineer (pre Creo), Inventor, and SolidWorks professionally I’ll take SolidWorks 99% of the time. The only time I’d prefer Pro-Engineer is in the rare event I had to work with surfaces.

I think Autodesk is resting on their laurels, big time.

I’ve tried Creo/Pro-E and SolidWorks, I love SolidWorks. Even so, I want to have as much experience with as many platforms as I can. My friend tells me Inventor and Fusion are different. Inventor and Fusion are better at different things. I’m afraid I can’t offer anything more specific than that until I get to try them both.

I recently started dabbling with Fusion 360 at home, even though I have a Solidworks home use license and my work laptop. I have found it to be more similar to Inventor, which I used at my previous job, but it’s hard to make up for the “free” bit and all of the CAM support.

The “free use” thing is why I say I think they’re resting on their laurels. AutoCAD was THE standard for a long time, then the solid modeling offerings left them in the dust. I liken them to Microsoft: when some companies get that big a market share they stop caring about what their customers want.

The first place I was with used Inventor by default, because it was cheap. If you already had AutoCAD they’d tack on a full seat of Inventor for like $200.

The most recent version of Solidworks is horrible. Grab an assembly while viewing and rotate the view… and the machine locks up for 30 seconds while it is doing … who knows what? Then there are the issues and bugs.

Great program, great ideas, poor execution on an even more poorly executed platform. I wish we’d go back to CAD/CAM software on a Unix workstation. Every time I have to tangle with Windows, I want to strangle someone.

Linux is a kinda ‘flavor’ of unix, one thing that might help you is find a linux geek at your comm. college to set up a dual-boot system with a bare-bones streamlined linux install running WINE for your CAD needs. Maxing out your RAM will help as well…

@DG

We are running 2015 SP3 at work and I have yet to hear a complaint like that except from the one person who was running on 8gb of memory and we have some pretty large assemblies. Solidworks says 8gb is minimum but in reality it should be 16gb. That’d be where I start.

If you don’t/can’t have the board memory, an SSD is a good band-aid (depends on bus speeds and all that, but still better than platters).

I’ve got a couple of pretty fast XP boxes, with only 3gb on the board, just because of the SSD.

Very good! How hard would making “grease guns” be? If stone age condition Khyber Pass gunsmiths can cobble together revolvers and AK’s with nothing…

https://eatgrueldog.files.wordpress.com/2013/01/9mmpistol.pdf

I imagine it could be done. Just a few months ago I believe TTAG did some reporting on homeless men in LA, that were making Sten submachine guns, and selling them for cash.

WW, if you have a little space, keep a lookout for an inexpensive China drill press at a yard sale, and a stout vise on a sturdy workbench and you’re most of the way there…

Ha! Not terribly mechanical. In fact my wife fixes most stuff that goes wrong. I am OCD on cleaning my rifles,shotguns and pistols I’ve had but beyond barrels and simple stuff I’m not going. I’m more of a woodworker/refinisher with the antique business we’ve had…when yer 60something you know yer limitations…

IMPORTANT: Make sure if you want to make a homemade firearm, everything you do follows all state and federal laws concerning making your own firearms. It’s not worth losing your gun rights and a trip to prison. Also, be safe. If you don’t know what you’re doing, then don’t. It’s not worth having a homemade contraption blowing up in your hand, and losing life and limb.

If you are wanting to design and plan out a firearm made of common household hardware and generic parts, like the grease gun, I would start on mcmaster.com. McMaster-Carr has a 3D CAD model for almost all of their products that you can download for free. It’s on the “Item detail” page, next to the drawing of the part. Download the parts you think you’ll need, and then use a CAD program to modify the parts in ways that you can replicate with the tools you have… Example, drill a hole here, cut-off here, grind off there, etc.

Then test the parts in an assembly to see how everything theoretically fits… After you’re finished designing it, you can create detailed drawings, and instructions for yourself if you wanted actually make one.

To answer your question directly, I don’t think it would be that hard, as long as you understand how you want the operating mechanisms to work.

That actually sounds like a fun project… I’m adding it to the list of projects I want to try this summer, designing one anyway. 😉

Ditto on McMaster. Except threaded fasteners, model your own with cosmetic threads. The model the full thread profile which absolutely chews up resources when you drop them in an assembly.

OK, as in what, it takes forever to render the drawing when you open it, or massively ups the file size?

Rendering the assembly model, mostly. Each thread has at least 4 complex, curved surfaces. When you get up to a dozen or more fasteners in a model it has to render every surface on every fastener. Everything slows down – adding new parts, exploding the model, even just spinning the view.

You can set the model to wire frame and a couple other tricks, but it’s crazy simple to just model a cylinder and insert a cosmetic thread. It pops into a detail drawing with the right call outs and you save a ton of aggravation waiting for the software to catch up to you.

Or he could have made a homebrew FARO Arm and CMM’d it.

Regardless, good to see kids taking up the actual tech.

I actually have access to one of those, or one like it, and before I my modelling skills got up to par, I was toying with the idea of taking one of my slides and using it to gather a cloud of 3D-points, and importing that into SolidWorks as a solid model. In other words, scanning it to make an exact copy.

However, that was not the point of this particular exercise. The point was to get insight into the design process. Every feature on this slide was very likely 100% machined. Therefore, every design decision they made about this part was based on what they could machine. The vast majority of the features were likely machined using common endmill sizes and avoiding as much custom tooling as possible to keep costs down. In order to keep costs down, they would have used as few of tools possible, in the quickest combination possible, with the fewest number of set-ups possible.

I basically used two tools:

1) A caliper, because its one of the most useful measuring tools and a standard equipment for any engineer,

2) a fillet gauge, because it gives me instant feedback on what that radius of a fillet or contour is supposed to be. By knowing the exact fillet size, It gives me a good idea of not only the size of the endmill, used, but what type of endmill was used. Example: Was this feature cut by a normal endmill or ball endmill? If the radius gauge tells me that the internal fillet is 3/16″, then they likely used a 3/16″ endmill. Also, I can confirm that Smith & Wesson designs in English units. 😉 :captain obvious:

I didn’t include a lot of the more technical information I gleened in this write-up, because I don’t know how much information is “too much” and I don’t want to catch Smith & Wesson’s ire for reverse engineering one of their products. For that reason, you also won’t my model hosted anywhere online for others to download it. It was purely a learning exercise for my benefit.

If I get a chance to do this again, I’m hoping I can find something in the public domain that would be interesting to talk about. Though, winning that REX Zero 1 would give me something new to model too. 😉

Keep up the good learning!

(But please, buy at least a Mitutoyo caliper for anything but the roughest of measurements. You can find a used Mitu, B&S, or even Starrett on CL for around a c-note. I have some HF stuff too, for doing that which just has to be “close enough”, but when it has to be right, use the tool not made to the lowest cost possible. Just sayin’.)

CFD and FEA are hopefully your next points of interest. Then SLS, cryo, and coatings.

The gun industry is a sad and primitive beast, with very little in it that didn’t exist 50 years ago. I understand why, but there needs to be new blood to force the change. Guns could be so much better.

Best of luck to you!

I would love to get a Mitutoyo and Starett metrology equipment, however, until I can afford better, I’m trying to make due with what I’ve got. My boss has a a metrology lab, and I love it!

I am planning to run FEA on the slide, and testing how changes in the geometry strengthen or weaken the slide.

As far as the industry not innovating, I have a feeling that’s about to change. A little while back I saw a job listing for a senior engineer, project director. Among the list of desired skills was someone who had experience in selective laser sintering, metal printing.

If they merely wanted to prototype, it would be much cheaper to prototype with much cheaper 3D printers, or have a rapid prototype service providers leverage their tools.

I don’t think metal printers have become economically feasible or good enough to make a commercial firearm, however, I think they are experimenting with it to see what is possible.

With 3D printers, all the old rules of design have been thrown out of the window. It’s a whole new frontier. Who knows what they will come up with.

Think about building a slide using SLS. Clue: they don’t have to be solid, think about the hex-cells in composites.

I wish you luck, and hope you actually learn something about manufacturing, not just what the ‘accepted practice’ is. Because the ‘industry standard’ for guns is about 70 years behind the ‘industry standard’ for cars.

Pro tip: just cause it’s harbor freight doesn’t mean it’s automatically junk. I’ve checked my hf torque wrenches and calipers against calibrated torque gauges and gauge blocks, and they work great.

Also, a little dose of engineering reality: anything you measure with calipers IS “close enough”.

Detroiter, My HF stuff has all been fine calibrated on my standards too. But it’s Chinese, the people who sell poison toothpaste, scrape cooking oil out of ditches, fake pharmaceuticals, not to mention have an army hacking our computers every day and are growing increasingly aggressive in the South China Sea.

The Chinese can build anything you want, and since what HF specs is something cheap, that’s what you get.

It is automatically junk. Very often serviceable junk, will serve your needs a few times, but garbage just the same. It doesn’t last, have the same ergonomics, materials, the fit and finish of something not designed to be cheap as it can be. 30 years from now no one is going to be praising the longetivity of a HF compressor or a Chinese motor.

Great article.

Get yourself an SLA printer. The tolerance/shrinkage on plastic extruding FDM printers is horrendous.

Haha, thanks. I will when I’m out of school and have a job. Loans come first, then a fully-stocked backyard machine shop. 🙂

Sounds like heaven. Best of luck.

One of the quirks and vagaries that drives civilian firearm design here in the US is legal requirements. Barrel length, magazine disconnects, semi-auto versus full-auto, that sort of thing.

If the Left has their way with laws and so forth, you’ll see a robust underground market of homemade firearms. They might not be pretty, but they’ll be quiet, efficient, compact, and have select-fire capability. Because if you’re making guns at home in violation of a (hypothetical) law against doing so, you’re gonna add all the fun features in anyways since if you get caught, it probably won’t matter if you’re making a bolt-action rifle or a machine gun in terms of penalties.

AGREED. Think about it this way, anything with a short barrel has to be rifled, you have to add complexity to your trigger packs because they’re disconnector mandatory if making an auto loader. See the article that TTAG did a while back about the “Carlo.”

I’ll just leave this here…

https://www.youtube.com/watch?v=gPKA2tG1JBI

Don’t forget that Glock frames are mostly Nylon 6. In a few years I image you’ll see someone using the MakerArm or a device like it to churn out good quality polymer frames. If we can get to that point it’ll be pretty much all over but the cryin’.

Thanks. You just made me cry a little tear of shear joy.

“I’ll just leave this here…”

Holy, crap, now *that* is cool!

I’m geeking on the thought of using the dremel bit to carve out traces on blank G-10 board then pic-n-place the SMD components that grow tinier and tinier every damn year.

Only thing to make that perfect will be a box with a striker bar, some metal powder, and a CO2 laser head….

This was really neat. Keep up the interest and experiments!

Wow — there are signs of intelligent life in the American university system! It figures that the author would be an engineering student and not a liberal farts major. Good job, young man.

At my university, it’s in abundance. I have over a dozen friends that sit around in the engineering department hallways and talk about guns. Outside the engineering department, there is a student marksmanship group that has a huge number of people. Most aren’t actively competing, but hang out and go to training sessions all the same. Every semester we have a free CHL/LTC class on campus, and this last one had close to 1000 people expressing interest in attending. Over 400 people said “they want to go” and we only had 150 seats. We had people from all demographics and walks of life in attendance. Including a teacher from McKinney that contacted us saying she was referred to us by McKinney PD.

Our Campus Carry restrictions are really relaxed compared to most schools, and I genuinely believe the taskforce leader was pro-campus carry.

You must be attending the University of Heaven.

I’m sure we have a liberal student/professor majority, however, I think all the noisy ones went to the larger, more prestigious schools. I look at places like UT Austin, and I count my lucky stars…

Joel,

Write up a report and send it to S&W. You should get an internship.

Best wishes,

Lol, well, I would absolutely LOVE to. However, I am afraid I’d be more likely to get a cease and desist notice. So far, the only worthy skill I’ve demonstrated is ability to model something adequately, which probably isn’t that impressive.

However, I’m not done with the model. I’m hoping to run it under some simulations, like Finite Element Analysis, to test the default stresses and fatigue, and then make the usual slide cuts people often do for red-dots, porting, and skeletionizing, that people typically do, and learn how those cuts affect the slide. I’d like to learn what cuts are acceptable, which ones aren’t, etc. When I know more about how slide design affects the slide performance, maybe then I might be worthy, maybe.

Thanks for the encouragement! 🙂

Table top CNC mill.

Shiny!

What I find most amazing about this post is that someone out there still has a functional Makerbot.

Good job.

If you really want to learn how to “think about guns” as an engineer does, you need to take apart (and re-assemble) lots of guns. Every gun you disassemble, lay the parts out on the bench in front of you, and think about how the whole thing hangs together, and how the parts interact.

Every gun has to do four things:

1. Load a round into the chamber.

2. Cock the lockwork.

3. Trigger the lockwork (firing the cartridge).

4. Extract & eject the cartridge casing, then go back to #1 above.

These steps are true on single shots through belt-fed/crew-served weapons. On a revolver, #1 and #4 are handled by rotation of the “magazine,” which also contains the chambers for each round in the magazine.

Once you start thinking in terms of “every gun HAS to do these X things, in Y order,” you start to see patterns appear before your eyes, and all manner of fiddly little parts in a gun become obvious in their function – because every gun has to do these four things. You start to see that most all parts have at least one function in these four steps. Elegant designs vary in their approach for various reasons – eg, Browning’s designs have a “lot” of parts compared to more modern designs, but JMB did this on purpose to spread the wear and forces inside his guns across several parts to slow down wear.

More modern guns with more modern steels and heat treating processes can go with fewer parts that will still wear well with few parts and higher forces than older designs. You’ll study materials and steels in the BS course level for a MechE, and you’ll need to go well beyond what they teach you to really understand the practical consequences of steel choices in guns. eg: Which is more corrosion resistant, 300 or 400 series stainless steel? 300 series steels are. So why do guns use 400 series steels? Because you can machine 410, 416 and 420 so much more easily than 304. My materials course (I was a EE, but we were forced to take materials and the MechE’s in my school were forced to take Electrical Science) never touched on things like machinability and issues of wear and heat treatment for steels. There are some parts in guns where you just have to have the correct steel with the correct heat treatment (eg, springs, firing pins, sears, hammers, etc), or you’re not going to make a quality gun.

Once I started thinking about guns per the above four steps, I could take apart guns I’d never seen before, diagnose their problems, fix problems, then re-assemble them without a schematic or diagram. Think about what the gun has to do, and how does the part in front of you fit into the gun to do one of the four things the gun must do. If you think of guns as a 3D jigsaw puzzle (as so many people do), you’re much less successful in fixing or diagnosing issues.

I appreciate the complement and advice, I’ll keep it in mind!

Dyspeptic, I used to read TTAG far more before I decided to go back to college for an engineering degree 2 years ago. I still pop by a lot, but not with the frequency I did before. Your name sounded familiar, but I couldn’t place it initially. After reading some of your comments, I ran a search through TTAG’s history and found some of the articles that you wrote. You sound like a tremendous resource!

I only got into firearms about 3 years ago. Before that, I grew up in a home without firearms, and my parents made it clear that we’d never own any. There’s a whole story about what got me firearms, but the point is that everything I’ve learned, I’ve had to learn on my own in that time. I didn’t have any resources other than what would be returned in a Google search, Youtube video, the clerk at the big box gunstore (often times I knew more than they did), and sites like TTAG. I’m the type of person that loves quantifiable data on X is done and not Y. However, most information out there is based on anecdotal evidence and “well, the way I heard it…” stories in forum posts.

Nevertheless, learning about firearms has inadvertently become a full time hobby. I find them interesting from both an engineering perspective and from historical perspective (I’m hooked by History Channels old documentary series: Tales of the Gun). I’ve only managed to acquire four firearms to my name, but I’ve been tearing them apart to learn about them all the time. A fellow engineering friend and I have been sitting down to study the design of the AR15 in great detail with the intent of designing our own modular platform. Not with any business aim in mind, but just as an educational exercise. I tend to learn more when I try to work towards an objective, like modeling an accurate slide. I’m currently trying to model a systems control and dynamics transfer function to describe the AR15’s operating mechanisms.

As much as I’ve learned over the last 3 years, there’s still so much I don’t know. I don’t really have a solid resource that I can rely upon for accurate knowledge about firearm design and function. On top of that, it sounds like you’ve got quite a bit of experience with SolidWorks, my preferred modeling medium. I saw your animation video on the Maxim machine gun, and it was quite impressive. Would you mind if I asked RF for your email, so I can bug you with a question every once in awhile?

I like this and want more of this!

Just curious… Is there a way to have a computer laser scan an object and render it dimensionally into CAD?

Comments are closed.