Martin,

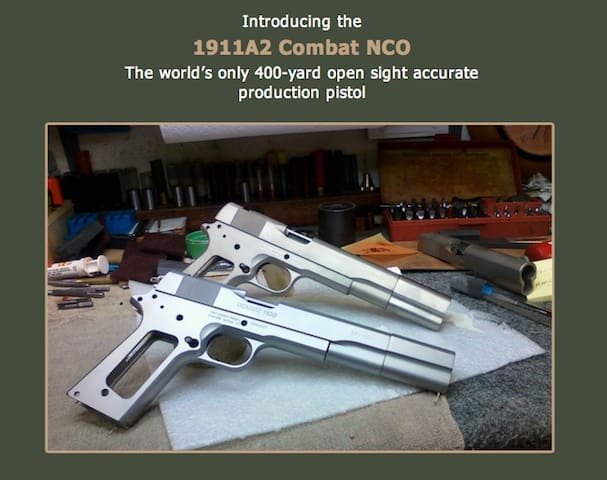

Karl has had two guns ready for you to evaluate now for more than a couple of weeks. Just waiting to hear from you so that we can put them in your hands. Primarily, you should be testing and evaluating the Combat NCO, but if you want to also do likewise with the Close Quarter Battle Pistol, then we have that available for you too. We are quite anxious for you to get this underway, as the last words on the street in The Truth About Guns produced quite a bit of negativity without evaluation. Granted, people like to throw rocks at things new. Therefore, we hope that you can take the gun or guns for however long you need and put them through all the paces. We hope you will compare with all other pistols you have fired, and see how the Lippard compares to them.

In another area that should be of interest to you and to Robert Farago at The Truth About Guns, we have made some quite disturbing discoveries that we want to share with you.

We began performing the first “Retrofits” of existing 1911 guns last week in North Carolina. The first step in the retrofitting program is to check the subject gun inside and outside, to be sure that all components are in acceptable working order, and can accept the retrofit A2 parts. One of these step-one processes is taking measurements of the receiver/frame and slide, and other components that will remain with the gun. We have discovered a disturbing, very high percentage of the guns fail to measure up to specifications. In other words, the gun maker manufactured the guns outside acceptable tolerances and specifications. Some guns are so bad that they require major milling work to bring them into acceptable specifications.

Specifications are the standard mil-spec measurements and plus/minus tolerances found in the standard drawings for these guns. These drawings are widely available and should reflect the military specifications prescribed by the US Government when the Government contracted for the guns that were manufactured for purchase for military use. A gun owner should be able to obtain a copy of the drawings for his or her 1911 pistol, and have it measured and inspected to be sure that it falls within the tolerances listed on the drawings.

Several of the guns that have come in to be retrofitted fall way outside those specifications, and that required additional cost in milling and gunsmith work just to bring them into the specifications envelope.

One brand new Colt Gold Cup pistol was not only far out of specification, but also had the interior of its frame cut off center. Yes, the interior of the frame was not even centered. It is amazing that this gun even operated. What Colt apparently did to the gun, in order to make it cycle, was to literally bend the barrel link mounts to one side. Not easy to do. But the gun did fire. Sort of. The lock up was never secure because the lugs were off to one side of the barrel. A terrible example of shoddy workmanship that was just pushed out the door. This particular gun was in for the basic upgrade, but required the frame to be fully milled out to come to center, and required a new barrel along with link and bushing.

The good news is that once the guns have been corrected and brought into standard 1911 specifications, then all Lippard A2 and A3 parts will drop in and fit perfectly. Therefore, this is an exercise that the gun owner will only have to endure once.

Bear in mind that Colt was only one example. Other brands failed to spec out as well.

I think that it is well worth the time of every owner of any brand of 1911 handgun to have them checked. If they wish to send them to Lippard for upgrade, the gun will be checked and measured out before any work is done. At that time the gun owner can decide what and how much he or she would like to spend on the work. In some cases, the A1 gun is simply not worth trying to bring into spec, and money would be better spent purchasing a new gun. We would, of course, recommend the Lippard Combat NCO.

Prices and parts lists are at the Karl Lippard Designs website— www.karllippard.com .

If you would like to obtain specific details and numbers from the people doing the retrofitting, and quote them on their exact findings, we will be most happy to put you in touch with the man in charge of the North Carolina operation, C. J. Quinlan, President, Tactical Applications Group. He has collected data on all retrofits and can give you down to the thousandths specifics.

I think it is important that gun consumers be informed that the work of these manufacturers is less than acceptable quality, and a large number of their guns fail to meet their own manufacturing specifications.

Meanwhile, let us know when you want to put the Lippard guns in your hands.

Semper Fidelis, Frater Infinitas

Charles W. “Bill” Henderson

I can’t wait for this to die its long overdue death.

Ye of little faith.

Perhaps he has enough faith to know that although the Golem moves, it ain’t really alive.

Quite the opposite… I have LOTS of faith

I’m always a little leery of someone claiming to find widespread and disturbing problems where no one else has. On one of the most prevalent pistols for high end modifications. That’s been in production for a century. You’d think Jim Wilson or Les Baer would have maybe noticed this problem at some point in the past 20 years? And said something?

I was willing to give them some benefit of the doubt, seeing as how I’ve shot revolvers at 100 yds with no problem hitting my targets. Providing cover fire at 400 should be possible, although sniper like accuracy is a stretch. Still, the more I hear from them the more I doubt.

Well I don’t see how Mssrs. Lippard and Henderson could be any more accommodating. Come and get two guns, take them for as long as you like and do anything to them you like. Then let us know what you think. For all the hyperbole and sometimes esoteric prose coming from these guys, it doesn’t get any more black and white than this.

I am hoping that, whatever happens, everyone involved turns out to be pleasantly surprised.

I can not afford to purchase one of Mr. Lippard’s hand crafted 1911’s but if I could, I would. If nothing else, the attention paid to the machining and fitting of the gun’s components would make it worthwhile to me.

It would not surprise me to find that most production 1911s are hacked together considering the overall spotty record of reliability of the out of the box models. My concerns are their outlandish claims

Exactly. 1911 out-of-the-box quality has always been excrement. It was when my grandfather was in WWI and it was when I was a kid in the early 70s. I heard gramps bitch about those POS 1911s more than I care to remember when talking ’bout life in the trench and his “killin’ those damn krauts”…

The 1911 is, at its core, a dogshit design. I’d never trust my life to one of those crapfests, no matter how ‘tuned’. I’ve seen seen (and owned) the custom units (Baer, AMT Powerballer, Wilson, ad nauseum) and they all fail in ways before 2K rounds that a stinkin’ Walther/Browning/Steyr never would until after 20K.

Duh, a Colt 1911 is even farther from ‘blueprint’ than a 350 Chevy. Water is wet, grass is green, my dog shits outside. If you didn’t know that the day you bought one, took it apart and mic’d it out, you have serious issues. Lemme help, the world is not flat, and revolves around the sun.

The standard 230 gr. 45 ACP cartridge drops 28 inches at 100 yards. I’m not sure of the drop at 400 yards, but from my experience, I would guesstimate it to be about 30 feet. Something like lobbing a mortar round. That’s why I use a 44 magnum!

28 inches @ 100 yards.

http://www.sightm1911.com/Care/45acp.htm

Wait, what? Shoddy workmanship in modern 1911 pistols? Alert the media.

The core problem with Mr Lippard is not a question about his ability to produce an excellent 1911, it is that his hyperbole utterly ignores the fact that there are newer pistols in the world that are NOT of the 1911 pattern that already solve the problems he is going to extraordinary lengths to rectify with the platform.

Again, the HK45 does this with aplomb (especially the Compact variant). Here is a weapon that also launches .45 bullets and does so with match grade accuracy. It does so with wood burning stove reliability that is now proven in combat with not one, but TWO tip of the spear units (the Combat Applications Group and Navel Special Warfare) in active duty combat. This weapon requires very little maintenance, high round-count part replacement (extractor and recoil springs) and features 100% drop in components that anyone can replace with a 6 hour armorer’s crash course.

And at government pricing, the Marines (read: taxpayers) can procure 6 of them for ever Lippard 1911.

HK doesn’t twirl your beanie? Than you can look at the FNP 45, M&P .45 or the SIG P220 Combat. All contemporary pistols, built using contemporary techniques that offer the sort of improvements in reliability and accuracy Mr Lippard is claiming to have “invented” for the 1911 platform.

Mr Lippard may well have seriously improved on the 1911. Doing so strikes me as an intellectual masturbatory exercise that is an interesting curiosity, but has little practical application. Even if every single one of Mr Lippard’s claims are true, the only thing I want to know from him is this: Why should the Marines select his $5000 artesian curio instead of a modern, inexpensive weapon (the HK45/HK45C) that has a *proven* combat track record of being more than accurate and reliable enough for soldiers/sailors who are actively in combat today?

It’s a simple question. The only reason he hasn’t answered it is that he’s got nothing…

HalleFallujah Brother!

amen!

!!!!! Damned right you are!!!!!!!!! He’s got a perty gun but, it costs way to much to be dropped in the dirt. Even if I had the 5gs to drop on one I’d spend it on several other’s first( the afore mentioned listed above) and still have money left for the bullets to fill them all.

100+ years ago a genius named John Moses Browning gave the US Army what it was asking for. A reliable combat pistol with one shot knock down power. In order to “pass the test” the pistol needed to fire 6,000 rounds continuously, only stopping to eject and insert magazines. It did just that flawlessly.

As far as the design being less than good…I might suggest that when any other combat pistol gets 100+ years of experience under its belt, then the design comparisons can be drawn.

Mr. Browning does have a couple of designs that seem to be classics. Take the MA-2 .50 cal. Heavy Machine gun. Is that a piece of shit design too? Or, his .30 Cal Light Machine Gun, which I believe still holds the sustained fire record of around 48 minutes at 600 rounds a minute. Nearly 29,000 bullets sent downrange. The only reason it stopped then, was it ran out of bullets in the pre-made bandoleer.

Are there better semi-auto pistols available in the marketplace today? Undoubtedly. However, I would posit that their designs are more complex, require more machining, and contain more components than JMB’s “classic” 1911.

Just my two-cents, and that’s what it’s worth.

Gaff

I know I’m late to the party, but I’ve owned a fair number of 1911s. Some of them did exhibit problems. There was a Springfield Milspec with a badly cast extractor, which comes immediately to mind.

None of them exhibited problems in the first 2000 rounds, though. Even that shitty cast extractor took longer than that to fail.

Maybe I’m doing something wrong. (“yeah, using an outdated design,” hurr hurr)

My current 1911 is a 2011 production Colt O1991, almost bone stock except for Hogue grips and a Colt arched mainspring housing swapped on, and an 18.5 pound recoil spring. I am willing to bet my life on its reliable function, and further believe that with a Chip McCormick 8 round “Power Mag” full of .45 ACP +P 230gr Ranger-T hollowpoints plus a ninth in the chamber, it will permit me to solve any tactical problem that is susceptible to solution with a handgun, and that if I fail to do so, it will be due to lack of skill, coolness, or resolve on my part, not any design shortcoming.

Comments are closed.