Timney Triggers has been in the business of making replacement triggers for decades. Started in 1946, the company made its reputation by providing quality replacement triggers for rifles brought home form WWII. From Arisaka rifles to Remington 700s, Timney has made replacement triggers for every popular rifle on the market today. While the core values and work ethic at Timney is right out of the 1940’s, the machinery that makes those triggers definitely is not.

When John Vehr took over Timney Triggers, the equipment was a little dated. “We still had milling machines that had ‘Property of the War Department’ stamped on them. Not Department of Defense — War Department. That’s how old they were.” John invested heavily in the tools and machines the company uses, and the results are paying off. Precision and quality seem to be the goals with Timney, and as a result they use some really cool processes that may take longer but result in a better end product.

According to John, new triggers start their journey one of two ways.

The first step in getting a new trigger made John deciding that the gun is really cool. With the Tavor trigger, for example, John was given an early copy of the rifle to play with and immediately wanted to produce a trigger for it. The same thing is happening right now with the Beretta ARX-100 — John liked it and asked his engineer to make it happen.

The second way triggers get made is that customers ask for it. Timney prides itself on responding to customer feedback and being customer oriented, so when a critical mass of customers start asking for the same trigger John takes notice.

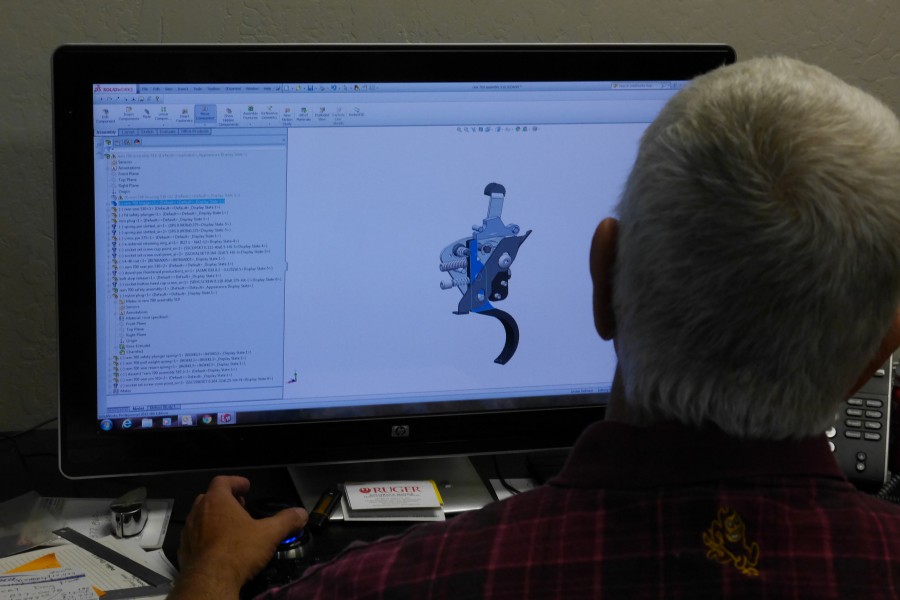

When the trigger green-lighted, the first stop is a silver haired engineer named Calvin. From his computer, he creates and constantly improves the trigger design until it’s ready for full production. As you can tell from looking at his desk, that process can sometimes take more than one prototype to finish the process.

Once Calvin is happy, trigger production starts.

Most machine shops rely heavily on CNC machines to knock out everything from their small parts to their huge chassis systems. CNC parts are good, but they weren’t accurate enough for John and Timney. Instead of simply milling the internal parts, they decided to cut out the internal components for their triggers using a wire EDM process. I had only seen that process used in one place before Timney — Advanced Armament. I knew it was an incredibly slow process, but the end results are hard to ignore. The lack of tool marks on the parts is part of what makes the Timney triggers so damned good, and it’s only really possible with this process.

While the internals get the EDM treatment, most of the trigger blades are made on more traditional CNC machines. The intricate cuts needed to make the trigger blade feel just right can’t be done with the EDM process, so instead Timney individually cuts each trigger from a solid block of metal.

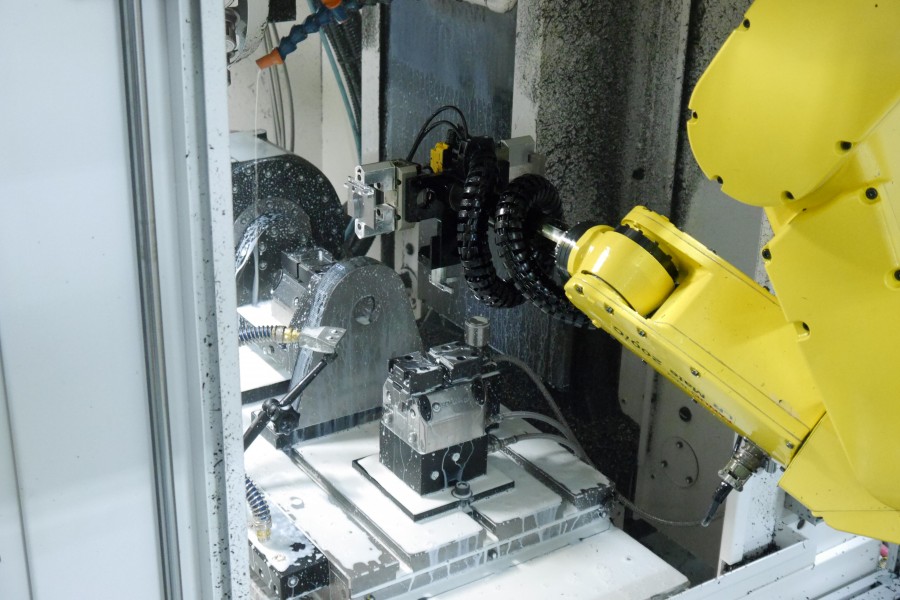

EDM cuts can be made at the same time on multiple stacked parts, but CNC work is done one at a time. It’s a much more time-consuming process, and as a result Timney has invested a ton of money into both new CNC machines and some interesting accessories.

While the new CNC machines are still on their way, John found a way to make the most out of the machines he has to fill orders. The machine shop itself might be a 9-to-5 operation, but the CNC machines run all night long. John takes particular pride in pointing out that the shop is truly a “lights out” manufacturing facility, meaning that there are no staff watching the machines while they whirr and buzz and make new triggers while everyone is sleeping. The machines are tended by sets of robotic arms, constantly feeding a steady stream of pre-cut metal blocks that arrive on a motorized conveyor belt ready to be milled. When the crew comes in the next morning, a bucket of triggers awaits them.

The housings are made the same way with CNC machines, just from bigger blocks.

The overall concept is that John wants as few instances along the manufacturing process where an actual human touches anything. Humans make mistakes, but computers and robots can perform he same monotonous task repeatedly (almost) forever without tiring or messing up. It’s a model that not only reduces cost and waste due to mistakes, but improves quality.

When the parts are finished, they make their way to a holding room and then are pulled out for assembly. A dedicated staff hand-assemble each and every trigger, and then immediately hand them off to the testing staff to set each trigger and test it by hand.

While mechanically setting the trigger to be “just right” is important, the human factor in testing the triggers is essential. “When I first started, John would come in and re-test every trigger I had set that day” one employee told me. “If I had done 100 triggers, he would re-check all 100 triggers. At first, only about 40 out of the 100 would pass. He’d hand it back and tell me ‘it doesn’t feel like a Timney.’ At first I didn’t understand, but then one day it just clicked. Now they all pass.” That relentless hands-on attention to detail is something that John Vehr seems very good at.

Once the triggers are assembled and tested, they head off to be packaged and stored before shipping. The big push at the factory right now is to get to the “red line” — a metric that means they have a certain number of triggers of each type available in the factory. Some triggers have low red lines (one old rifle design with less demand had a red line of 10), others are in the hundreds. When an order comes in to the factory it’s immediately processed and shipped out, but not before a small addition is included.

I asked John Vehr about the sweet inclusion to the standard shipment, especially since it was something I touched on in my very first review of their trigger back when I lived in Virginia. “I ordered something and it came with a Tootsie Roll in the box, and I thought that was pretty cool” John replied. “Some people think it means we’re calling them a sucker, but I just thought it was a nice idea.” The Tootsie Pop has been a staple of Timney packaging ever since.

For most products, that would be the end of the line. Once it’s made, they just keep cranking them out again and again. But for Timney, every trigger is constantly changing. Every time they run into an issue or find a better way to make their triggers, they roll that change out to all future versions of that trigger and keep on trucking. It’s not something they advertise, especially since their triggers don’t have version numbers associated with them. But if your old Timney trigger ever has a problem, Timney makes it a point to fix it no matter how old the trigger.

Just be aware that they might swap out your old Timney for a new one, and put the old one in their display case.

Nice article, but old machinery can still make good products. Savage’s factory in Mass uses WW2 or maybe pre-WW2 machinery as far as I know.

Old machinery wears down. It breaks more often, can’t be repaired as easily, etc. Of course, there is a point where it reaches that. A 20 year old CNC machine is not going to spit out bad products, but a much older one might have quality issues.

CNC machines are quite capable of spitting out bad results.

And the best barrels in the rifle business are turned out on machines from before WWI.

Why someone would think CNC couldn’t produce bad products is beyond me. CNC is a subset of software, and as such, has the potential to suck royally.

The main advantage of CNC is repeatability. The machine will do the same thing over and over. If those instructions end up producing a crap product, they’ll faithfully churn out that crap as long as you want.

TL;DR: GIGO

the residential garage where i received my back alley machining apprenticeship has a fadal cnc and some haas servo stuff. it loses zero from time to time.

the hob, vertical mill, horizontal mill, lathe and surface grinder are all from the ’30’s and ’40’s and have manufacturers like cincinatti or rockford or whatever. when cnc first hit this stuff got dumped and ol’ boy bought ’em right. as it was explained to me their load ratings were capable of being sustained around the clock: three eight hour shifts at full load every day for the war effort. for the drill press that means auto feed 3″ boring into cold rolled steel. nonstop forever. pretty tough to wear out.

I think the biggest issue is that old machinery has quirks that require the knowledge of old machinists 🙂 . The person who has been using that machine for years and years. Put a new person on an old machine and it may never output anything of quality…

I’ve heard– and this is just one of those internet rumors– that that’s what happened to Marlin.

The guys who knew right where to kick the presumably ancient machine got shitcanned when Freedom Group *spit* took over and the new folks didn’t know the quirks of the machines well enough th turn out quality.

So that fact combined with the pressure to turn out product even if it was inferior (f’ing WAY inferior). And here we all are. Damn shame,too.

Too rich for my blood.

I do wish these drop in trigger manufacturer’s would make a super cheap gritty drop in trigger for home builders. For those of us that are too cheap to buy a jig for our 80% lowers. A 30 or 40$ drop in trigger would be perfect. Nothing fancy – just functional.

That’s called a Mil-Spec trigger bud. It’s cheap, it gets the job done, and if you have the knowledge and tools, you can turn it into a pretty darn good feeling trigger.

Yea – but its not a drop in trigger like a said in my post. So – no appeal for me.

ALG Defense makes some slightly upgraded mil spec triggers for about 45.00 to 65.00 dollars.

I really like my ALG QMS trigger. Not a drop-in, but only 5 minutes of my precious time to install. No grittiness is *da bomb!* and less than $50.

(this comment not a paid advertisement)

folks sell the barely used mil-spec triggers that they replaced on their rifles all the time, sometimes they just give them away.

…for those interested about “wire EDM”:

http://www.youtube.com/watch?v=pBueWfzb7P0

I’ve not heard of this process before. Now I know, and knowing is half the battle!

EDM comes in two forms – wire and “ram” or “sinker” EDM.

You’d use ram/sinker EDM’ing for blind holes/cavities/recesses, and wire when you want to cut an internal/external profile.

The cavity need not be a simple hole or 2 dimensional. Can be as complicated as the electrode you machine and then plunge into your die. A art in it’s self.

My S&W i-Bolt came from the factory with a Timney trigger and it is an absolute joy to use.

Timney replacement in my AR made it a whole new gun. Just amazing.

I just received the new, fixed Tavor trigger in the mail from Timney and am looking forward to checking it out. I liked it a lot the first time around, but the failure to fire any ammo with stiff primers (mil-spec stuff, Russian steel stuff… 30% to 60% failure rates) was an obvious problem. Worked 100% with all brass cased .223 I tried, but there’s no way it was going to live in my Tavor if it wouldn’t reliably fire 5.56. Anyhoo… the upgraded (call it v2.0) one is here and I’ll test it out shortly. Still absolutely loving the ShootingSight trigger, though.

Edms are still cnc. Why does it seem like everyone makes a big deal out if it?

Old manual machines are great. If you keep them fixed they are better than new machines because the old ones were over built and are generally heavier. Also old iron castings are better than new cast iron. Its not just true for machines but also dutch ovens and skillets. Old machines arent going to be cnc. Alot of old machines are more mechanical controls. you generally set them up to do one thing and it will do that one thing the same way every time til the end of time. No they dont do lights out.

Im a cnc machinist and for cnc machines newer is better. I might sound like an old guy with the old machines are better but im not. Im only 27.

I had a Timney in the AR that I lost in a tragic boating accident. I’d like one for the Mosin if it wasn’t over half the price of the gun. Maybe after I fix the hole in boat…

$100 is not a bad price at all considering the quality, adjustabililty, and additional functionality. Actually, it’s a really great deal and Timney’s Mosin Nagant trigger is absolutely amazing! But yeah… it’s sort of weird because of how cheap the gun itself is. However, it completely transforms the thing. I put a Timney in my Mosin that I purchased for $75. Yeah, that’s awkward if you think about it too hard but it was totally worth it. Don’t overthink it 😉

All I want for Christmas is a Timney trigger for my Colt AR15.

while they whirr and buzz and make new triggers while everyone is sleeping.

And that one time there was a murderous robot capable of actual thought waiting for the day crew, poor bastards. Thing called itself Timney.

It’s still out there… somewhere. But it’s not really discussed.

Cool article! In the pic where the tech is measuring trigger pull, notice how the gauge rod is dragging on the web of his thumb. Can’t be a very accurate measurement that way, can it?

I thought exactly the same thing. But then again, with the direction the trigger gauge is pulled and the way he is holding it, it seems as though the measurement would read heavy. So the end result might be that the trigger falls into their specified range testing-wise, but in reality is even lighter. Or maybe I’m overthinking it.

i really dig the how its made series on sci channel. i would buy how its made: guns on dvd in a heartbeat.

canada, though…

Just got off the Timney website. They don’t seem to have a target trigger for my Savage model 10. They do have a trigger I think rated at 1 1/2 lbs. Too heavy for me! I can get a Rifle Basics at down to 3 oz. for 50 bucks more than the Timney.

I have used the Rifle Basics trigger on another rifle and find it quite adequate.

So… Your rifle discharges every time you even think of going to the range? I’m giving you shit but that kind of subliminal trigger pull would be awesome, truthfully. I doubt I’ll ever experience that sort of subliminalness, but I can hope.

I have shot “bench rest” and trigger pulls can be in the one to two oz range, and yes, my rifle discharges, but only at the range, and only when I “breathe” on the trigger.

I’m still patiently waiting for the timney Beretta arx100 to be released. Hopefully they release it before I die…I’m 35 LOL..

Comments are closed.