I don’t know how it is in your area, but here in California, most gun shops either don’t install sights, charge an arm and a leg for the installation, or wont install them unless you buy them from them at inflated prices. This led me to begin searching for a more economical way to install sights on a bunch of my guns, some friends’ guns, and to change sights for reviews and testing. In my search I found that there are more than a few options, everything from DIY style contraptions to specific branded installers for specific sight and gun models. I wanted something that would last, work with multiple firearms, and not damage and slides, sights, or anything else for that matter. The only “real” option that I found was the MGW Sight Pro tool . . .

I say real because for my use I wanted something that was good but didn’t run me $600 and would work with a bunch of different models (rather than having 10 different tools). The Sight Pro can be picked up from places like Midway USA or Brownells for around $329.99.

Overall Construction

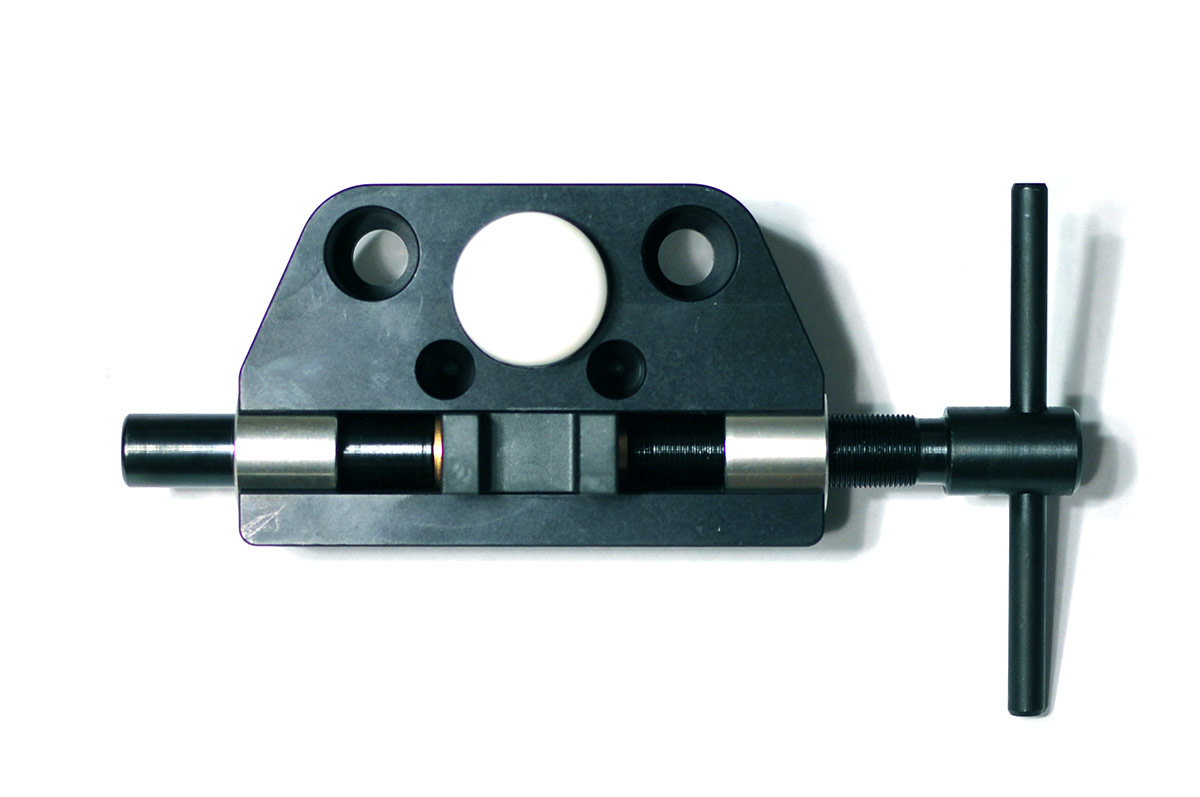

First and foremost, this is an armorer/gunsmith quality tool, designed for a lot of use. Because of this, it’s durable, well made and should last a long time.

The first thing I noticed when un-boxing the Sight Pro was its weight. I figured it would be pretty light, but I was definitely wrong. This thing, without any “shoes” attached (shoes are used for holding different slides in place) weighs in at 4 lb 11.5 oz. This thing is heavy duty.

All of the parts are precision machined; they fit together and move very smooth. All of the screws and adjustments used for clamping the slides in place and the main pusher for moving the sights all turn very easily and feel perfect. Everything feels precision; not a burr or cross thread or anything. It feels like a work of perfection.

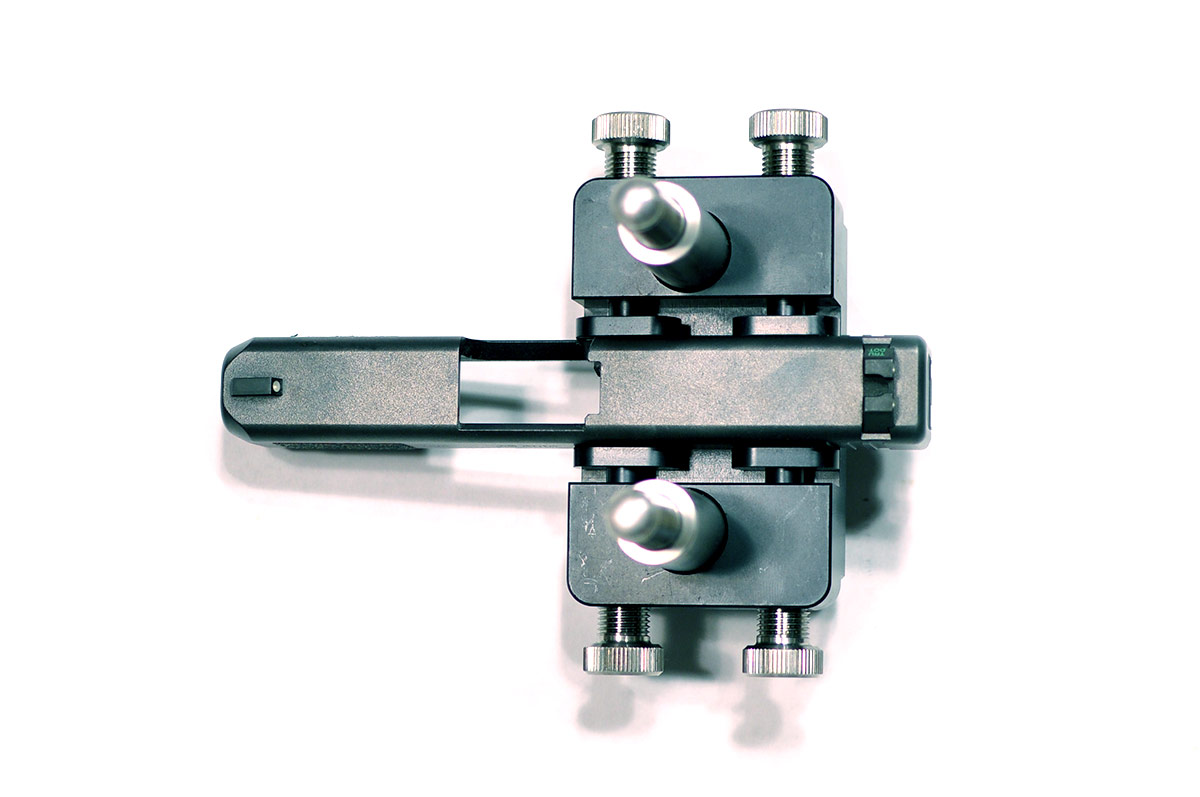

Slide Shoe Clamps

The tool its self doesn’t come with any “shoes”. You have to purchase them for the specific models of guns you wish to work on. The nice thing about this is that you get a secure hold of the firearms you plan to work on. The downside is that you have to purchase a variety of shoes at $17-$20 a piece.

The Shoes are what clamp the slide of the firearm to the tool. The slide, slides over the shoe like it slides over the frame of the pistol. So it’s more or less the same concept there.

The shoes are also made of a low carbon steel, this is designed to be generally softer than the slides, so when you are removing sights you wont cause any damage to the slide.

MGW offers shoes for the following firearms:

- Sig P220, P225, P226, P228, P229, P239

- Beretta 92/96

- Beretta Cougar, PX4

- Bersa BP9, BP40

- Browning Hi-Power, Tokarev

- Colt 1911

- Colt Mustang

- CZ-75

- FN

- FN .45 CAL

- Glock (all models)

- Glock 42

- HK USP, P2000, P30, P45

- Ruger LC380, LC9

- Ruger P Series

- Ruger SR9, SR9C, SR40, SR40C, SR45

- Sig P220, P225, P226, P228, P229, P239

- Sig P238

- Sig P938

- Sig PRO

- Springfield XD

- Springfield XD-S

- Steyer M40/MPS

- S&W Bodyguard 380

- S&W 3rd Gen 9mm

- S&W 3rd Gen 45 ACP

- S&W M&P

- S&W M&P Shield

- S&W Sigma

You may notice that there are multiple shoes for specific models, this is because some gun models have different width slides. For example, Glock slides are all the same, with the exception of the Glock 42, so if you want to be able to work on all models that Glock makes, you would have to purchase 2 shoes, one for the Glock 42 then one for all of the other Glock models.

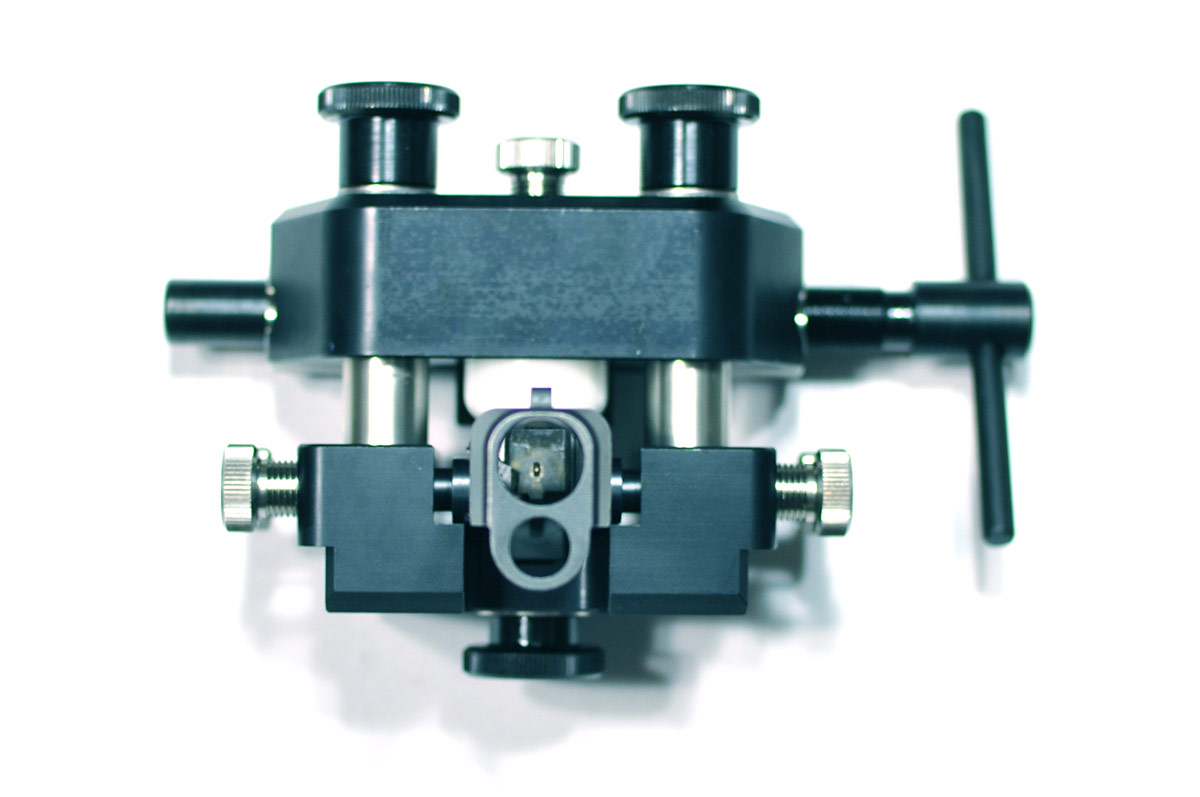

Usage

The general usage of the tool is pretty simple, in theory… you simply clamp the slide in, use the pusher to remove the current sights then do the reverse to put the new sights in. In reality, it can be a little tougher to get stuck sights out, or align things perfectly. But other than that, the usage is as you would expect.

There are some nice integrated features to help keep you from scratching or damaging a slide… There is a teflon (or some other material) stop that will keep the pusher at least 0.015″ off of the slide. So you don’t risk hitting the slide with the pusher. Also, there are 4 side supports that clamp down on the sides of the slide to keep the slide from being able to turn or roll when pushing the sights. This will keep slide rails from cracking or otherwise getting damaged in the removal or installation process.

The tool comes with a pusher for straight sided sights, while this will work on angled sights, they say it could scratch them. So they also offer a 30° angled pusher. For example of angled sights, they are the ones on most Glock pistols. I’m using the straight sided pusher for angled Glock sights, and it seems to work just fine. I did put a little “padding” on the sight just to make sure it didn’t scratch them. But other than that, it worked just fine.

You can watch the training DVD below for an up close and personal demonstration of how everything works.

Front Sight Removal

This tool will also work for the removal of dovetail style front sights. This is done with the same process as rear sights. The tool also has a notch cut out on the front side to assist with firearms that have a longer recoil spring cover, for example, 1911 style pistols. Other than that, the process works the same as rear sights.

Other Tools

There are a lot of tools out there for this. Some of them are listed below so you can take a look at some of the other designs out there. Personally, I like this design, It’s simple and has pretty much everything I can think of accounted for.

- Maryland Gun Works Rear Sight Tool Glock

- Glock 17 Or 19 Tool Set

- Ameriglo Rear Sight Tool For Glock GTOOL1

- Universal Handgun Sight Tool

- B&J Machine P500 Pro Universal Front and Rear Sight Tool

Ratings (out of 5 stars):

Fit, Finish and Quality: * * * * *

This tool is built tough and designed to last. It’s armorer/gunsmith grade and should last a lifetime.

Ease of Use: * * * * ½

Overall the Sight Pro is quite easy to use, but there are a lot of moving parts. So you’ll have to watch the instructions to really get how to use each component. Once you have it down, though, it’s very simple and easy to use. The design also makes it easy to quickly work on rear and front sights, etc.

Value: * * * ½

The MGW Sight Pro is a great tool, especially if you have multiple firearms, have a shop, or have a group of people who want to change sights on their pistols. If you have one pistol and just want the sights changed, you’ll be better off paying someone to do it for you. But if you have a number of firearms to work on, this is the tool for you.

Overall: * * * *

This is a great tool. It’s modular, works with most pistols (with the correct shoes) and is built to last. If you’re a gunsmith or just have a lot of pistols to work on, this tool is worth the money.

What ? 329 US Dollars ? Any good redneck could do quite a bit with some duck tape and a welders torch !

“…most gun shops either don’t install sights, charge an arm and a leg for the installation, or…”

And at $330 for the tool and $17-20 for each sight shoe, you can see why. Gunsmithing is like any other skilled technical profession. You are paying for the professional’s knowledge, experience, tools, and skills, not for the actual time it takes him to employ all of those and complete your sight installation.

I knew a blacksmith who could take the end of a 3/4″ steel rod and turn it into a completely realistic-looking grizzly bear head. It looked pretty simple, so I asked him how long it took.

His reply: “20 minutes and 20 years.” You are paying for the 20 years it took to get to the point where he can do the work quickly and correctly.

I am not a gunsmith, so this is a purely unsolicited testimonial. My major experience with home gunsmithing was taking the sideplate off a S&W revolver, looking at all of the little springs and levers and widgets inside that gun, and VERY VERY carefully re-installing the sideplate, praying that nothing would go “spring!” before I had it back together. I am proud of the fact that I used a correctly fitting screwdriver. and had the gun secured on the bench, so I did not bugger up the screwheads.

Gunsmith at a gun shop, LOL. Most gun shop “gunsmiths” are best described as armorers, they know how to fit parts that require at most minor fitting. They might have a few 1-2 day armorer classes under their belt. They will typically will have a universal sight pusher or a handful of the gun specific MGW tools.

Gunsmiths are like the blacksmith you knew, they can cut dovetails, checker grips, and a dozen other tasks either taught in a longish term school setting, or gained from years of working on guns. They are very rare at your typical gunshop these days. In Dallas there are dozens of gunshops, and there are probably less than a half dozen gunsmiths among them (just counting general purpose gunshops not independent smiths).

There’s a retired marine around here that operates a Class III/NFA FFL (Not sure what/how to call it), and does legit gunsmithing.

His machine shop is about the size of three garage stalls at a car dealership (Height and width).

He is so busy, even with an *APPRENTICE*, it took him six weeks to drill/tap a threaded hole for my 10/22 so I could put a Tech Sight on the front of my threaded barrel. ( This guy: http://www.tech-sights.com/replacement%20marlin.htm )

I was pissed at the wait time, but there’s no one else in the area that I could trust to do it right the first time, and sight everything up. I’m sure any other machinist could have drilled and threaded a hole, but I guess firearms are “special” in the way I viewed it.

Gunsmiths are like lawyers – there’s nothing in the world that’s more expensive than a cheap one.

Firearms are somewhat special in many aspects that will confound and piss off a machinist. I say “somewhat” because while making a new gun would be straightforward job for a machinist, the issues in existing guns require a lot of knowledge beyond machining.

eg, Machinists don’t see much in the way of case-hardened objects for drilling/tapping. Gunsmiths do – in certain guns. Your job as a gunsmith is to know which ones before you break off a tap in the hole.

Or, another example: you want to re-blue a Winchester 94. OK, what vintage is it? If you’re just going to polish off the scratches and dings on the outer layer on some vintages of Win94’s, you’ll find that the receiver is actually made of stainless steel, and it was plated with steel to allow it to blue. Polish it a bit too hard and… whoops! Now it’s hell on wheels to get it to re-blue.

Machinists and gunsmiths have quite a bit of overlapping skills, but if you ask a machinist to smith guns, he’d probably make a hash of some of the more subtle jobs, whereas a gunsmith would likely starve as a machinist, taking far too long to get things done that a machinist gets done quickly and profitably. Machinists look at the way we gunsmiths do many jobs with hand tools (eg, files, polishing stones) and wonder “Why don’t you get a CNC machine and just get it done?” and then we have to explain “OK, how are you going to set this job up? And who is going to pay for you to make all the special fixtures? And when are you going to get those made?”

Then there’s the issues of knowing the value of guns. Take a highly valuable pre-WWII 1911 to a machinist and ask for a modern dovetail for the front sight. This is a very straightforward job for a machinist. A gunsmith (at least a smart and ethical gunsmith) will know enough about 1911’s to ask “Hey, this is pretty valuable in original configuration – you sure you want me to decrease the value of this piece by $1K+ just to mount new sights on it?”

The problems a gunsmith solves are often way beyond what the customer sees. That’s the shortest way I can summarize the issue.

I know and pal around with real blacksmiths (ie, men who make their living from swinging a hammer on hot iron) in my area. We have a great time together, swapping skills and perspectives on metal. The skills of blacksmiths are something to behold – and I’ve learned a LOT from hanging around with blacksmiths. I teach them how to drive a file, and they teach me how to swing a hammer. It’s a symbiotic relationship.

And don’t forget the first two rules of blacksmithing:

“Just because it’s black, doesn’t mean it’s cold.” (Referring to the fact that iron goes from red to black at around 600 degrees F.)

“Don’t force it – get a bigger hammer.”

I would just use a brass punch and a hammer.

Have done in the past. Works great.

That vido shows the beauty in the work of a skilled designer and precision machinist.

If I find $300 laying the ground I’d likely order one for no other reason.

Ive heard Glock sights are pretty easy to get off and do yourself fairly easily. On the other hand, XD sight posts are anchored in with the power of Odin or something and my LGS/the interwebs confirmed a few horror stories of people having to dremel out their entire front sight and other fun activities.

Id like to have night sights/ XS Big dot on everything I own, sadly this is not the case yet.

I’ve used their XD-specific tool to install sights on XDm pistols (of course). The XDs are notorious for having a front sight that is damn near installed by the hammer of Thor at the factory. A few drops of penetrating oil and an un-Godly amount of force later, my MGW tool removed the sights without damage and installed the new ones the same way.

The near-ridiculous amount of force needed for the removal is a testimonial to strength of the tool – had the tool broken, I’d have put a substantial amount of blame on the sight rather than the tool (but not held it blameless as it’s sold as an XD tool).

The pistol specific models are probably more practical for individual owners and cheaper (only $124 versus $329 at Midway).

All I can say is it worked both out and in on what is widely held to be an especially tough to remove sight. I felt it was worth the $124 to be able to do it myself.

Since I was installing Tritium sights, I felt a pusher was mandatory and brass punches might end up breaking the glass vials so depending on your situation, you might think differently. Given the force needed to remove the front sight on an XD, just figuring out how to restrain a slide without damage for that sort of a beating might justify the purchase of the tool.

Which tool is best depends on how many different guns you own.

Until this tool came out I managed to collect three different MGW tools, and I still had to use a hammer and vice on some guns. I sold all three and bought the Sight Pro, angled sight thingy, and a half dozen slide plates. For me the ability to fit new guns for less than $20, and the fact that they will be making many more slide plates than individual sight tools was a killer feature. I got a new FNS recently, $18 for the plate. I will buying another Shield that is another $18 for a plate. Neither of these guns would warrant spending $100+ on a new tool.

Also yes there are cheaper universal tools, but I’ve used many examples of the universal tools, typically they are overly complicated to use, and many don’t hold the slide worth a damn for stubborn sights like Sigs.

Yeah.. good luck with the brass punch and hammer on a Springfield XD front sight.

This tool makes short work of Springfield Armory and other sights installed by Thor.

I could swear when the XD came out I saw video of more than one guy losing their front sight? Maybe they started really bolting them down because of those early incidents?

I had read all the horror stories about the XDs sights and how they were all-but-impossible to remove without an expensive tool and/or dynamite as well as knowing the secret, magical, words of power.

Despite these grave and forboding signs and warnings of impending doom I took a small ball peen hammer and some homemade hardwood drift tools and proceeded to remove the factory front and rears and replace them with Truglo TFO sights.

Yes, you really have to smack the factory sights to get them out but using a very fine stone on the TFOs made installation no different than, say, a 1911.

Are they tighter than most other sights?

Maybe. I changed the sights on my Colt Rail Gun using the same method and can’t really say there was much difference in the effort needed to remove the factory sights.

Bummer of a company name. They ought to relocate to Montana or Mississippi.

we actually moved out of that state 20 plus years ago!!! lol…we are in Georgia now but didnt want to change the name since cwe have a long history in the field.,

George

I THOUGHT SO! But the irony isn’t lost on me. And the Resistance is still alive.

Is it true the MGW tool wont work on 5″ Kimber Slides? I see there is a slide tool for the Ultra Carry II. I have a Custom II with standard factory sights, white dot. I’d like to put target or tactical Kimber night sights on it. The sight for the Ultra Kimbers on the web sight seems to be the same one for the 5″ models. Is is because the recoil spring lug is too long on the 5″ models?

What about the Colt tool for MGW, would that work for the Kimber? I was told Kimber 1911 have Novack dovetails cut in the slide? What say you?

$330 plus more for the adaptors for various sights?

Jeez. I’m in the wrong business. Instead of charging about one-sixth that price to drift/drive a set of sights out/in on a gun, I oughta be making and hawking tools for people with 12 thumbs.

You aren’t looking at it the right way.

Lets say you are a normal gun shooting consumer. I don’t have a vice at the range, but I also want to make sure that it is completely zeroed.

Right now I have three guns that need sights.

1 FNS

2 M&Ps

That right there is $150 plus waiting for you to do it. Soonish I will have a Glock 17 Gen 4, and a M&P Shield, that right there is another $100.

Though for me it is about doing it right. I wouldn’t trust my competition M&Ps and the oversized Warren Tactical sights to some lame brained gunshop “smith” because 90% of the time, they wouldn’t know that using a file is a normal part of installing sights.

Using a hand file is a normal part of actual gunsmithing. If you don’t know how to drive a file, you’re not an actual gunsmith.

I have over 150 hand files, rifflers, die files, etc in my collection now, and when I need a specialized file, I’ll chop up and modify an existing file. I have specialized files what will allow me to fit both 60 and 65 degree dovetails.

People will see me buy obscure files/rasps/rifflers/etc at auctions/estate sales/etc. They’ll always ask “You have more files than any guy I know – why do you need more?”

“You never know…” is my standard response.

Great review, I’ve been looking for a good universal tool for front sights. Now I just have to save some money.

I have a B&J Machine P500 and it seems to work on all guns without any extra shoes etc. When you purchase the tool there is an additional kit for about $30 that I recommend. It is heavy duty and very well made. It is a universal tool. It worked on my XDm and those have sights that are HARD to move. It is around $300 plus the kit but you don’t have to buy anything else. B&J is a small shop and the people there are great if you have any questions.

I used that tool several times, and the only gun it worked well on was the Glock. For everything else it just doesn’t hold the slide all that securely.

Also you have to spend a ton of time adjusting the tool to get it just right with your sights. With the Sight Pro, with exception of a few guns (that I don’t own I’ve only seen it on the video or else I wouldn’t have known about the need or feature) it automatically adjusts itself to the slide.

Good review and responses. I’ve used my Sight+Pro on a M&P, my new Glock 42, and several other full size Glocks. I shoot competitively in USPSA and 3gun. Its always in the truck with me and I’ve had to use it a couple times for other people at the range. I found a tool box at Lowes that the tool and shoes fit in nicely. I take it everywhere, just incase somebody needs help with their sights.

Just for those who care this will not work on a 1911 long slide for the front sight. Otherwise it is a great tool.

Dang, I was afraid of that. I have a Kimber that I’d like to put tritium night sights on. I see there is a add on tool for the Kimber Ultra Carry II with 3″ barrel. What is different from that and the 5″ Custom II? They look the same to me?

If you read these posts George at MGW can you answer this question?

Not so. I just spoke with the technician at MGW and he said the SP105 slide clamp shoe that will do Colt 1911, and SIG 1911, will work on a full size Kimber 1911 slide. It is also listed to work on a Kimber Ultra Carry II with a 3″ slide. The channels the clamp shoe goes into on the slide are Mil-Spec and for all practical purposes the same for the clamp shoe. It doesn’t matter if Kimber uses a Novak dove tail or not. The tool will work just the same.

You’re an extremely helpful site; could not make it without ya!

Comments are closed.