Grow or die. Go big or go home. Lead, follow or get out of the way. You’ve heard all the clichés. So, apparently, has MasterPiece Arms. They’re adding manufacturing capacity and expertise with the acquisition of Spencer Rifle Barrels which they say will let them expand their product line. And more is better, right?

COMER, GA (June 2013) – MasterPiece Arms, manufacturers of the MPA MAC Line of pistols, carbines, suppressors and MPAR Rifles, is proud to announce their new acquisition of Spencer Rifle Barrels, Inc. of Scottsville, Virginia. The recent purchase will expand MasterPiece Arm’s capabilities and product line to include precision built and quality crafted rifle barrels and rifles. As a result of the new acquisition, future MasterPiece Arms products will incorporate high quality precision produced barrels using Clay Spencer’s methods and practices into their full line of products. MasterPiece Arms will also announce new products specifically built utilizing Spencer Rifle Barrels.

Spencer Rifle Barrels, Inc. in business since 1979 has a nationwide reputation as one of the foremost and award winning custom barrel and rifle builders. Spencer Rifle Barrels produces target, sporting, benchrest, 1000-yrd, light varmint, hunting, tactical barrels and rifles and silhouette and benchrest pistols; all featuring their precision stainless steel, match-grade target barrels.

“Bringing Spencer Rifle Barrels under MasterPiece Arms will greatly enhance our capabilities,” Phil Cashin, CEO of MasterPiece Arms commented. “Our business focus at MPA has always been driven by offering customers the highest quality USA-made products. Spencer Rifle Barrels is well known within the industry and by customers that demand the highest level of performance whether for competition, hunting or for high-risk vocations.”

For more information on MasterPiece Arms and their product line of pistols, rifles, carbine and suppressors, visit www.masterpiecearms.com. For information on Spenser Rifle Barrels, visit www.spencerriflebarrels.com

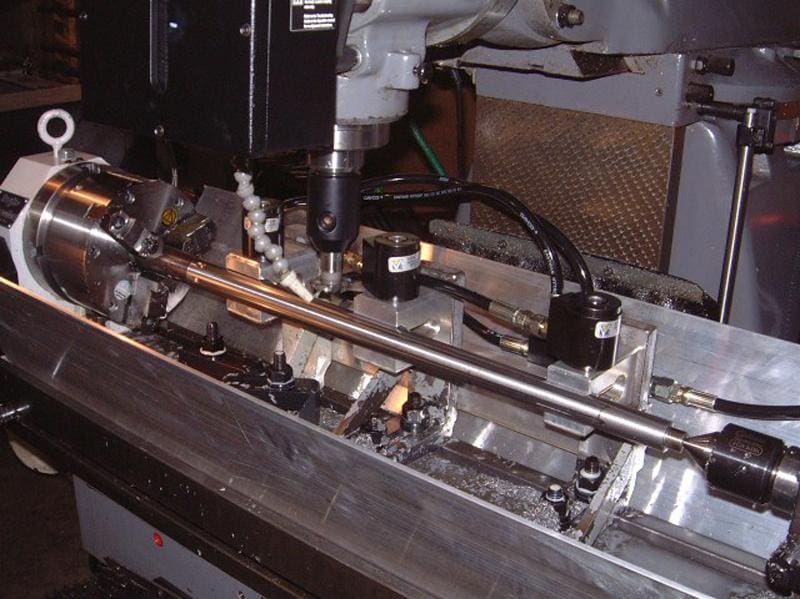

Regarding the picture: looks like a custom-built CNC lathe mounted to the table of a CNC-retrofitted Bridgeport mill. Pretty ingenious, but it’s the sort of solution you improvise when you can’t move up to a CNC turning center with live tooling.

I know its more practical but I fell out of tool and dye making because of CNC. It didnt interest me and Im the type of person who takes pride in my work. I would much rather physicaly draw my blue prints and manually operate the machines. Sometimes I miss the work but I dont think I would be as satisfied proffesionaly as I was when I was a student. Besides, making new brackets for the chairs in the hairdressing shop was quite rewarding 😉

I guess if I kept up with it I could be working for Barrett by now. I already turned down a QA position for an injection molding company contracted with S&W

Boasting .00005″ run-out and .0003″ concentric set threading, fluting, and chambering for 24″+ barrels… do you really think they need/want a 5 axis center with live tooling?

The best shops have -and always will- use purpose built equipment, and do 80% of their work by hand. Clay’s shop is a sight to behold, and his knowledge and skill are renowned in the small-bore, long distance shooting world. CNC equipment and mass automation are simultaneously the best and worst things to happen to the firearms industry in the last fifty years…

That machine, by the way, is not an all-purpose turning center. If I recall correctly, it is specifically for rebating and fluting thin-profile barrels, which generally flex enough under load to ruin that .0003″ concentricity previously mentioned. The two centers to the right of the post are ball-nose servos run off runout gauges positioned opposite the tool.

No offense intended, as I’m sure you know — that’s an amazingly cool setup, and I love the purpose-built fixtures. My point was more that this is a stepping-stone to a similar precision fixture set in a CNC turning center if they need to scale up the business, which seemed to me to be a likely result of the acquisition by MPA.

It makes me question the quality of their barrels. I’ve worked on a few converted mills and lathes and none of them had the precision of a good Haas or Okuma. How successful is their company if they can’t afford the equipment even a low-end job-shop has on hand?

“How successful is their company if they can’t afford the equipment even a low-end job-shop has on hand?” I find it odd that you would question a nationally known company after seeing a single picture of a single machine. During my years as a machinist I learned that some specific tasks need to be done on a machine with specific capabilities. Sometimes the industry doesn’t produce the exact machine you need and custom is the only way to go.

Hopefully they use the acquisition to make some really good barrels for their MPAR 556’s that they are coming out with.

MasterPiece arms deserves respect simply by manufacturing such politically incorrect guns in the USA.

I hope they manage to grow.

Clay Spencer was Homer Culver’s protege and he learned his lessons well. Looking at the name tags on the works in progress in his shop you would see national champions and noted gun writers, some of whom were asking Clay to “fix” guns built by supposedly good smiths. I have several live varmint and game guns he built for me, all are super accurate, several will group well under a half inch at 300 yards.

Comments are closed.