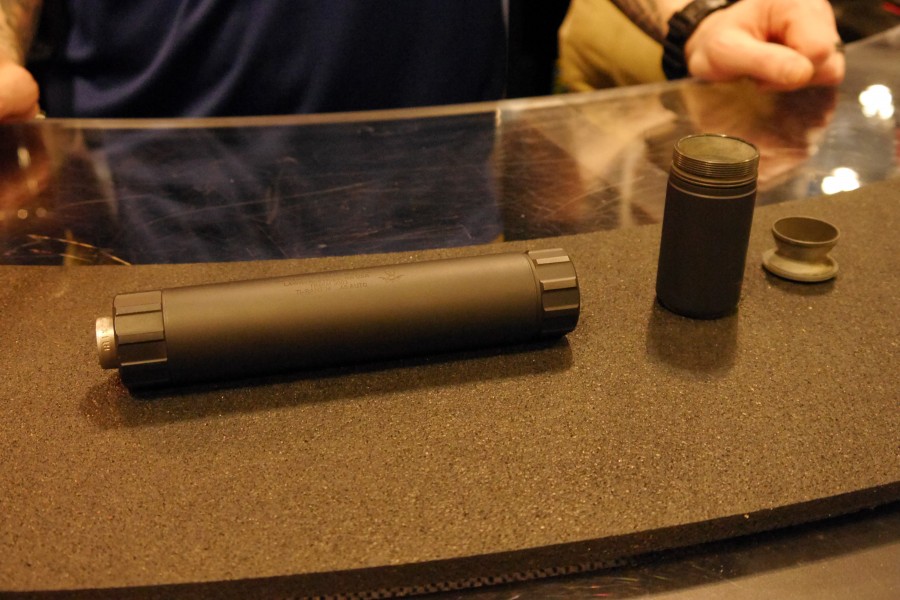

When I was over at the IWA show in Germany, something I noticed was that modular silencers were quite the thing. I thought we’d never see the likes in the USA due to the ATF and NFA getting in the way, but I may have spoken too soon. First the SilencerCo shotgun silencer sports removable sections to make your can as long or short as you need it that day, and now AAC has a modular .45 ACP pistol silencer that they are showing off with the same general idea. Instead of buying a long can and a short can to cover your various suppression needs, the Ti-Rant 45M can will cover all the bases.

The root concept is pretty nifty. You buy the can in its “long” form, and the silencer is segmented into two sections. There’s the rear section that houses the Nielsen device and the majority of the baffle stack, and a detachable front section with a few more baffles and the end cap. If you’re looking for maximum suppression, use the whole thing. If you just need a touch of “signature reduction” and value a shorter overall length over a quieter gun, leave the front section at home. In short, it basically replaces both the Ti-Rant 45 and 45S in AAC’s product line.

The baffle stack is basically the same as the original Ti-Rant line, with some minor engineering improvements (but visually identical). The pistons from the original Ti-Rant line will be 100% compatible with the Ti-Rant 45M, which means if you like your pistons you can keep your pistons. It also means that there’s no lag time for accessories to arrive — the replacement parts are already on the market.

One design change I really like is that the end cap has been re-designed to allow the shooter to disassemble the can using just their hands. The original Ti-Rant line of silencers required a special proprietary disassembly tool (of which I have lost a few over the years) that fits into the end cap and allows you to remove the baffle stack. Its a pain in the butt, and one less proprietary part to worry about is a good thing in my book.

It will be interesting to see how well this thing sells. As someone who keeps a silencer on their nightstand gun, I get that having the smallest package possible is a good thing. The ability to have a small silencer for home defense purposes and be able to add a few more baffles when I want to impress people on the range is good, and given that you only need one $200 tax stamp for the lot there’s some potential there. But the stacked individual baffles in my current Ti-Rant are the bane of my existence, and my personal preference is always for a monocore design for any silencer you can take apart. I’d love to see this concept with two monocore sections, despite the whole “first round pop” thing.

All this can be yours for an MSRP of $849.99. Which is exactly $0.01 cheaper than the Ti-Rant 45. But $54.99 more than the 9S. Comparable pistol cans on the market include SilencerCo’s Octane 45 ($892), Gemtech GM-45 ($595), and SIG SAUER’s SRD45 ($695). So the price point is within the range for the existing market if slightly on the high side, but none of the competitors offer the same modularity.

- Weight: 13 ounces

- Length: 8.74″ / 6.75″

- Sound Reduction: 30 dB / 18 dB dry

$849? The markup on these things is incredible. You’re looking at less than $100 in labor and parts. Probably, $75 or less realistically. So everybody loves suppressors but eats Firearm Concierge for lunch when he discusses getting a few extra points on his bottom line?

CNC shop time is roughly $50 – $75 per hour, in house. Between baffles and can I bet they spend at least two hours, maybe three, on it just machining it. Another $50 or so goes to inspection time. $100 between materials, packaging, shipping raw stock, finishing, burring. Minimum $250, but I’d guess closer to $350+ for manufacture. 100% markup is pretty normal, because some of that pays for indirect costs like ads, sales and management staff, etc.

These are baffle stacks: if you are machining them one by one, you are doing it wrong.

I think you’d be shocked–SHOCKED–to see the actual cost. The times you have and amounts are way off.

Well? Are you going to tell? Or have you been “silenced.”

Come on. CNC shop time etc. implies that these are being build on a custom basis, one at a time. I doubt that is the case. Mass production should drive the cost WAY down compared to custom work.

Slidefires were around $360 when they first came out. I now see them for $129. Did technology magically make them cheaper? Nope. Competition meant they had to stop gouging. Mass production is a marvel but let’s not fool ourselves as to what stuff really costs. I was in retail. If I had a product at $70, my cost was $30-$35. My supplier had a 40% markup making their cost $18-20. The factory had another markup making the actual cost $8-10. This was “high-end” stuff I was selling.

I work in a CNC low-run production shop. If you are machining these, which I assume they are, then you are running one or two baffles at a time per machine. It might have a bar puller and two spindles, and a button to button time of a few minutes, but it’s still coming off the machine one at a time. I assume something like ten baffles each? So 30-40 minutes per suppressor for the baffles. The tube is probably machined from tube stock which cuts time somewhat, but you have a few parts to make that will take longer than the baffles. Overall time is likely in the 1-2 hour range. Where you save on mass production is the cost of tooling, setup times (only done once per machine so spread out more), jigs, the like. We make handles for some Benchmade knives – the reason those cost $300+ is because of the machine time involved, and since we can make that out of flat stock we can run 40+ at once in a horizontal mill, which you can’t do with lathe work.

I work for a driveline manufacturer and had the unpleasant experience of buying my own parts from a dealer because we couldn’t get a sample from overseas fast enough for a prototype build. The markup against what we sell these to the customer (a large German car manufacturer) was around 600%.

My point is this: It is very hard to look at a price and walk it back to cost.

Yes because in iconel and some of the other proprietary alloys they make these things out of us as cheap as the aluminum bar stock you buy at your local Home Depot…. Right

Heck even a high quality stainless for something a simple as a car exhaust is going to set you back more than what you stated above. Then there is the R&D that goes into the thing. I would bet the markup on the cheaper Liberty and YHM cans is maybe… MAYBE 20%, probably a lot less.

As a NY resident, the closest I can get to a suppressor is watching Archer. So I’m a little behind on my suppressor terminology. Can anybody explain what “first round pop”is?

The “schwing” you get the first time you fire one ?

First round pop is when the first round fired through a ‘cold’ suppressor is noticeably louder than subsequent rounds. It is due to the presence of oxygen inside the silencer being consumed by the still-burning combustion gasses. After the first shot this oxygen is consumer and replaced with non-reactive combustion products, so following rounds will not exhibit this pop. If you were to let the silencer sit for some time, or purge it with outside air, the next round will again exhibit the “first round pop”. Certain designs/style of silencer are more prone to this.

What would happen if you put a little piece of dry ice in there? Would the melting CO2 purge the O2 and give you a silent first round?

It’d probably take a while for the dry ice subliming to actually replace all the oxygen with CO2 gas. I also can’t imagine supercooling and then rapidly heating the metal would be ideal for your suppressor.

In the future, please include length, weight, diameter, decibel figures if available for product announcements with this. If necessary, carry a scale and ruler with you.

I haven’t heard them or have reliable decibel level data to compare, but based on specs I consider the Ti-Rant 9S far less impressive than the Thompson Machine Poseidon 9mm (.45 version also available). Literally half the weight, less than half the price (not including NFA tax). An inch shorter and slightly smaller diameter. Much less tempting to take off of the pistol. No specifications given in this TTAG article, but the new Ti-Rant 45 in it’s “short” configuration still looks pretty long for defensive/offensive/stopping/killing applications. For pistol silencers the long ones—while they work for home defense—are generally regulated to range toy status, and I wish manufacturers put more of an emphasis on the compact pistol cans that are more useful for defensive use. No, I don’t expect really short sound suppressors to be anywhere near hearing safe anytime soon, but the purpose with them is more to “take the edge off” of damaging gunfire noise. I appreciate long pistol suppressors as well, but I want to have my guns suppressed as often as possible. If I only had a full-size 8″, 9oz can I’d be removing it and shooting without it all the time.

Updated as requested with the factory specs. Full catalog here:

http://viewer.zmags.com/publication/5fe0a3ac#/5fe0a3ac/27

Nice Post! Thanks for your brilliant.

This was an awesome and helpful article, thank you very much to everyone who contributed their advice and knowledge.

I haven’t seen anything on the sound difference between the 45m and the regular 45 suppressers. Are they the same better or worse because of the modular cap?

Comments are closed.