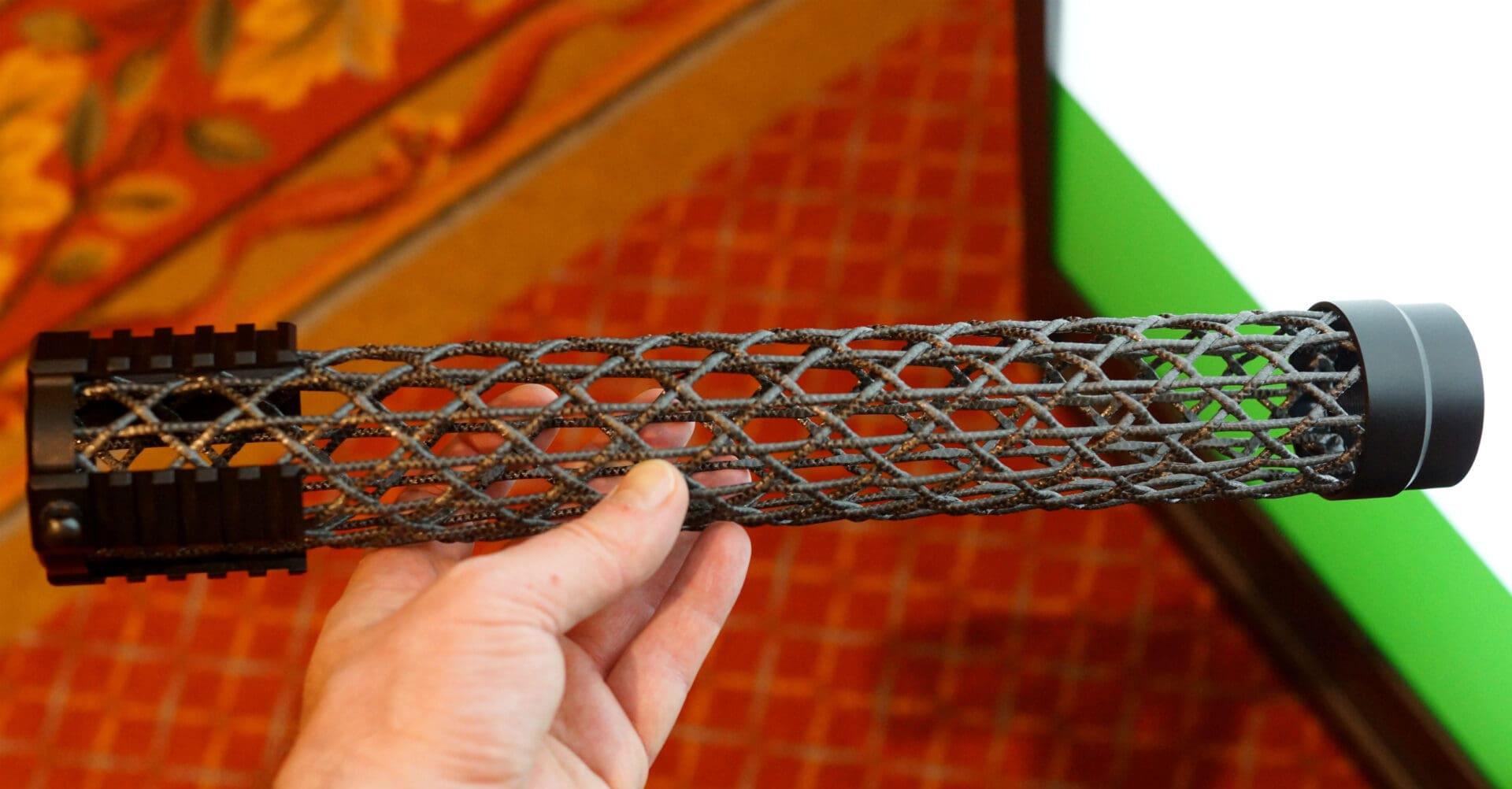

Made from braided carbon fiber tubes shrouded by a protective jacket, Brigand Arms‘ AR-15 handguards are stiffer and stronger than you might expect given their airy, lattice design. In a way, it’s actually all of that airspace that you’re paying for. These bad boys are the lightest handguards anywhere, with the 15″ Edge (no rails) model clocking in at an astonishing 3.9 ounces. Yet, it’ll support 100 pounds of weight in any direction. Read on for more info and photos . . .

https://youtu.be/qZCgM6N2BiE

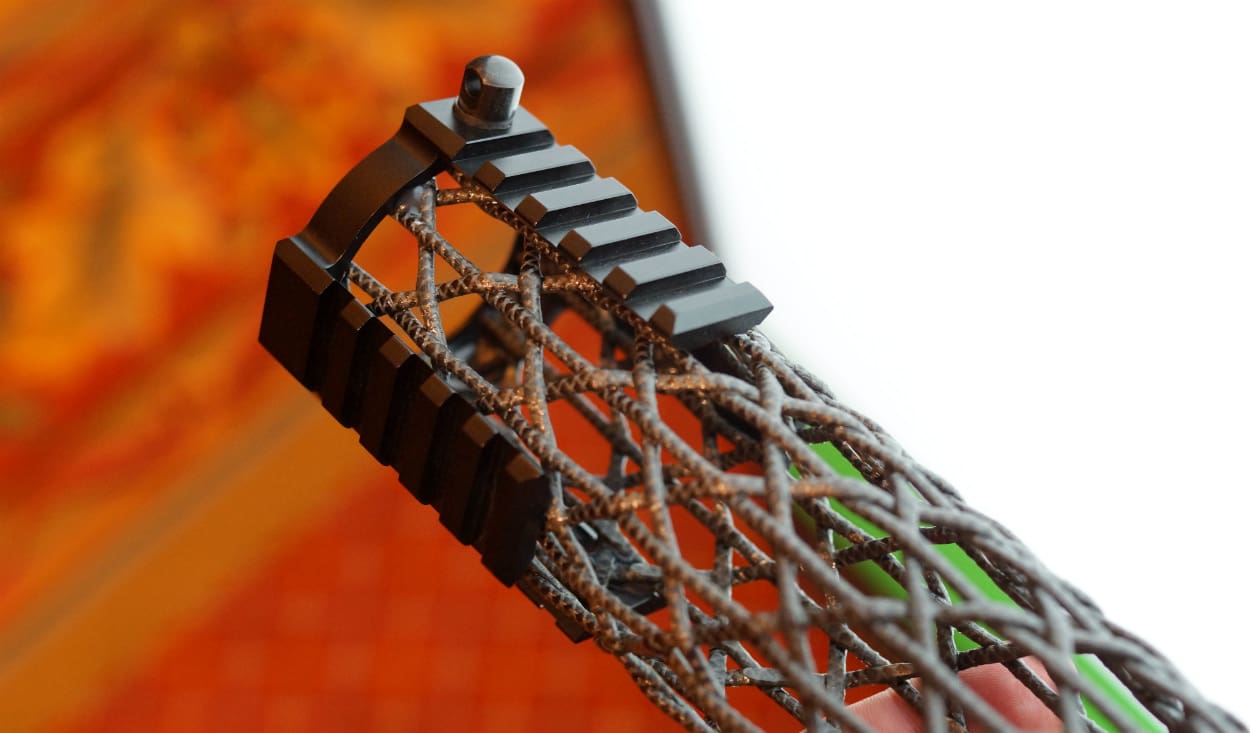

A giant loom braids these T700 carbon fiber tubes around a mandrel. 6061 aluminum, hard anodized end caps are then added. The muzzle cap comes either unadorned or with a short quad rail for accessory mounting.

With this much air space, barrel cooling is excellent. Brigand’s SHOT Show booth has a handguard with a 40 lb weight hanging off the end of it, and its stiffness is very apparent. Again, it’ll handle 100 lbs of pull force on the muzzle end without issue, and 400 lbs of compressive force along its length.

T&E sample has been requested. Not gonna lie, I’m pretty excited to put it through its paces. I already have a few points of feedback for Brigand, and am interested to see this product progress into the future.

My main concern is that if I buy one, I’m going to need a prettier barrel.

At first, I thought it was woven out of basket material. I think it would looked better if they dyed it black.

They have the ability to do that, and these things can also be cerakoted.

I wonder if they could do a nice wicker pattern. Everybody loves the baskets and chairs, it would be so very non-threatening. I bet if a few of the CA folks saw them, they’d be deemed so cute that ARs would become all the rage throughout the state.

You can get your prettier barrel here: http://riflebarrels.com/product-category/drop-in-barrels/ar/ar15/

🙂

O2

Sure, it’s plenty strong in ways it’s strong, but is it going to bust if the middle of the tube impacts a corner with some force? Most handguards would take that in stride, but here that would focus all that energy into a very small portion of a single strand.

Valid point. TTAG guys need to head back to the booth and ask the rep to smack it against the edge of the counter top a few times.

Depends. If you’re talking about full-swing smacking it on the sharp edge of a granite counter top and hitting just one strand – maybe. Maybe not, but maybe. It’s not a solid tube. Cooler looking than a tube, but lacks the structural integrity.

The next generation will be made by somebody out of a cf/kevlar tube, with KeyMod/M-LOK lasered/water jetted right into the tube.

The stuff is pretty freaking strong. No way can I deflect it at all, whatsoever by hand no matter how hard I press. If you did impact a single strand with a corner that hit with enough force to break it there, you’d end up breaking a small part of the strand. It’s not like the whole thing would crumble to dust at that point. If I can, I’ll try talk my way into a section of the lattice without the aluminum and stuff on it so I can see what it actually takes to do some damage to it. My impression of it from handling it and pushing and pulling on it, etc, is that it’s pretty freaking strong. No real reason for me to believe it’s any more susceptible to what Sian is describing than the myriad aluminum forends that are mostly air with thin, lattice-like webbing-style structures either. I wouldn’t be surprised if it’s actually stronger than those under sharp impact.

Good to know, hard to tell exactly how thick it is without actually handling it. It’s CF, so if it is done worth a flying eff (which by your description it is) it should be a no brainer.

Still though, should be a hex/octa tube with the fittings for KeyMod and MLOCK just cut right in. No time, or I’d build them myself.

No real shortage of those. Lancer systems, etc. This is different in a handful of ways.

All I’ve seen is cf with add-on rails. Does someone make a kevlar/cf hex/octagon with keyslots actually cut into the unit itself?

Not sure on KeyMod or KeySlot. M-Lok though yes.

There are some guys who made racing bicycles with tubing like this – including mountain bikes – and they work just fine with a whole person on top.

Plenty strong!

Thing about carbon fiber is that it is directionally strong. Thus why any time you need rigidity and strength, you need layers with the weave going different directions.

It could well be that the cables they’re manufacturing these out of has that licked internally, at a glance, each one seems to be a weave of its own, so it might be all good.

I need this for MAXIMUM COOLING!

Wait…is that a normie sling swivel? Needs moar QD! Normal sling swivels are not tactical in the least.

I still prefer them for mounting a bipod. The rail adapters tend to be large.

Yeah but with all areas of the barrel exposed, how hot do your hands get???

Take it from an engineer. That won’t be a problem.

I’d rather take it from an engineer who has fired an AR-style rifle fast and long enough to get the barrel good and hot; do you qualify?

The primary purpose of a handguard is not to cool the barrel; it’s to protect the shooter’s hand from the radiated heat of the barrel during and shortly after the firearm has been fired rapidly enough to get the barrel good and hot. A solid or near-solid carbon fiber tube handguard will not get hot due to heat transfer; but any heat from the barrel has almost nothing to stop it from directly heating the shooter’s hand in this design, so as a handguard, this seems to be a “fail”, in my book. It’ll keep your hand from touching the barrel, but that’s all.

Of course, all serious operators who are operating operationally will be wearing gloves, but still…

“The primary purpose of a handguard is not to cool the barrel; it’s to protect the shooter’s hand from the radiated heat of the barrel during and shortly after the firearm has been fired rapidly enough to get the barrel good and hot.”

The whole point is to radiate the heat, and so it will radiate it most quickly with a rig like this. Will it be hotter if you grab it? That barrel would have to be red-hot to feel anything more than an annoying warmth from what appears to be at least half an inch. And as you said, operating operators…

Hey good question- I’m happy to refer you to Brigand Arms’ technical brochure,

https://brigandarms.com/wp/wp-content/uploads/2015/11/Brigand-Arms-Technical-Brochure.pdf

where you will see data collected for BA handguard heat transfer, from the engineer who designed the handguard, (you’ll be pleased he also has experience firing rounds).

Maggie, thanks for the link, but if one needs any but the most basic science knowledge to understand the cooling of a barrel…

Sure if were talking about heat rejection of technically coated S/S v. polished S/S I could see explaining to the lay people. But if ya gotta explain “airflow is good”, we are truly doomed in STEM.

Unbelievably, I’m going to have to say it again, as both of you seemed to miss my clearly emphasized point, even though I understand your point completely.

Hand-guard: A device that guards (protects) the hand from the heat of the barrel during sustained firing.

This is NOT a handguard; it is a well-ventilated barrel shroud (and a fine one, at that).

“The whole point is to radiate the heat, and so it will radiate it most quickly with a rig like this.”

Wrong. The point is to stop that same radiated heat from reaching the hand, through direct conduction, or radiation. You’re right, this will not conduct heat (that’s good). However, it will not in any way stop radiated heat (this is bad for the hand, but good for the barrel).

Maggie, the test chart shows how fast the barrel cools, not how hot the shooter’s hand gets during and after the firing, and I gotta say, 50 rounds (less than two common 30-shot magazines) is not a serious test for hand comfort in any case. In my experience, most recreational AR shooters will fire more ammo than that in a short timespan on a semi-regular basis, and if they do, this “handguard” will be found wanting. Once again, yes, I know, it allows the barrel to cool faster, and this is good. It is also the primary function of a ventilated barrel shroud, NOT a handguard.

Folks, it’s pretty obvious that neither of you has ever fired 3 to 6 mags back-to-back of .223/5.56mm ammo rapidly in a semi-auto AR, let alone fired bursts through a full-auto M16/M16A1, as I have. Under either of these circumstances, this device WILL NOT protect a bare hand from the radiated heat of the barrel, so it IS NOT a handguard, by definition.

It is, however, a very nice ventilated barrel shroud that would look cool while protecting the hands/arms/body from inadvertent contact with a hot barrel, while still allowing the maximum amount of cooling airflow and heat radiation to minimize the amount of time that the barrel remains hot. It may serve as a substitute handguard for those folks who will NEVER fire their rifle/carbine rapidly for more than 3 to 4 magazines, or will always wear heat-resistant gloves, even in August in Florida/Arizona.

TL;DR?

Summary: Not. A. Handguard.

I know a gent with more than a few auto-guns. Among them an M16, and yes, I have fired it full auto.

As to spraying a bunch of rounds out of it…

The Ground Precautionary Message ACALA #97-031, from November 1996, clearly states that if an M4 barrel reaches just 737 degrees C, the barrel will be weakened to the point where it will burst.

(B) FIRING 140 ROUNDS, RAPIDLY AND CONTINUOUSLY, WILL RAISE THE TEMPERATURE OF THE BARREL TO THE COOK-OFF POINT. AT THIS TEMPERATURE, ANY LIVE ROUND REMAINING IN THE CHAMBER FOR ANY REASON MAY COOK-OFF (DETONATE) IN AS SHORT A PERIOD AS 10 SECONDS.

…

(D) SUSTAINED RATE OF FIRE FOR THE M16 SERIES RIFLES AND M4 SERIES CARBINES IS 12-15 ROUNDS PER MINUTE. THIS IS THE ACTUAL RATE OF FIRE THAT A WEAPON CAN CONTINUE TO BE FIRED FOR AN Indefinite LENGTH OF TIME WITHOUT SERIOUS OVERHEATING.

After 280 rounds, the plastic “handguard” is 120F-275F depending on location. You gonna hold on to that for 5 minutes? Didn’t think so. I very much understand your question, but you are ascribing attributes to the plastic hand guard that it simply doesn’t have. It would be far better to get that heat off the barrel as soon as possible, because that plastic isn’t going to be touchable with bare hands either. The radiant heat being about an inch away may be though.

*sigh*

Still locked-in on how hot the barrel is getting. Wow. Like a bulldog on a bone.

‘Twas a nice “Look, a squirrel!” moment, though.

– No one was talking about shooting until the barrel got hot enough to burst.

– No one was talking about shooting until the barrel got hot enough to cook-off chambered rounds.

– No one was talking about shooting at any given rate of fire and/or how hot the gun/barrel gets during sustained fire.

– And no one was talking about how hot a (non-specified; M16 triangular w/heat-shields? M16A1 round w/heat-shields? Gau/GUU carbine w/ single heat-shields? M4 w/double heat-shields? Commercial DPMS Glacier Guard w/no heat shields?) plastic handguard gets when the cyclic firing rate is kept up for 280 rounds.

The subject was: this “handguard” is not going to protect the shooter’s hand from the heat of the barrel IN ANY WAY, once the barrel gets hot enough to cause radiant heat burns. This will happen long before you reach the barrel bursting point, the cook-off point, or even the “Ow, the plastic handguard is hot enough to burn me!” point. It may even happen after a long string of sustained fire (sustained doesn’t mean the barrel is barely warm; it just means the rate of fire can be sustained by the weapon nearly indefinitely, but the barrel is still pretty dang hot), but that would have to be investigated with a controlled test.

The point, which is apparently is written in invisible ink, is that the barrel gets hot after only a couple of mags. If you’ve even dumped one 30 rounder, the bbl is hot. It is not a bull bbl, it is a flimsy lightweight bbl. for light duty. By the time you’ve dumped 3, that barrel is smokin’…

That heat is going to…

A: radiate into a ‘handguard’ which will then absorb it, and re-radiate it. That heat will be hot.

B: radiate directly into the atmo, without much of it transferring to the space-frame that keeps you from directly touching the barrel. As the bbl is radiating much more quickly, there is less heat transferred to your hand, as the bbl is radiating directly, rather than through an intermediary. Even hold your hand an inch from a 120F metal plate? Not that hot. Hold your hand on a 120F metal plate? Very different outcome.

Bottom line, by the time there is too much heat coming off the bbl for you to hold it with the space-frame, there’s also too much heat coming off a plastic shroud to hold it. Difference being, that mesh space-frame will dissipate heat far faster as there is no intermediary step (ie, transferring it into the plastic guard).

As to the heat figures art 280 rounds, that’s gov issue stats, easy to find, and not done on aftermarket parts.

I am an engineer…

Let’s see someone put this through it’s paces without gloves on the range. In summer. In Texas. Mag dumps. That should settle it.

And hold on to it, with the support hand in position on the “handguard” for 5 minutes AFTER firing has been completed.

Not. Gonna. Happen.

Not gonna happen with plastic either. For someone who has fired one in anger, you seem to forget how quickly that plastic gets untouchable.

Nineshooter,

I want to take care in answering your last post, but do find 16V’s response quite brilliant for now..

Locke-

I’m an engineer as well, cheers!

Here is a field test that was done this past summer. It ain’t Texas, but it is southern Alabama,…

https://m.youtube.com/watch?v=POIOcOjfLrI

Keep in mind it’s trial #7, so nineshooter, the thermocouple readings were obtained every 50 and 100 shots, that was not a total for rounds fired.

One 30-shot mag? Puh-leeze.

Do it with 4 mags (even at half that rate of fire), then hold it for 3 minutes in a horizontal “low ready-rifle” position, bare hand centered on the handguard. Even 2-3 30-shot mags may make it too hot to hold on the mesh; not because the carbon-fiber mesh is getting hot, but because nothing is stopping the heat from passing through the holes in the mesh to the hand.

Re-reading that last line, I’m not sure what you mean by “trial #7”; was that the seventh mag fired through the weapon? If that’s the case, then how long the weapon was allowed to cool between mags will make a HUGE difference.

And where did you have the thermocouple attached? The barrel? If so, once again, I’m not saying this is bad for the barrel; in fact, it’s probably GREAT for the barrel!

“Handguard”. It’s the support hand I’m concerned about.

Do your next shooting test with a old-fashioned bulb-type thermometer laid alongside the mesh, on the outside, and let the radiant heat from the barrel register on the body and bulb of the thermometer (bulb centered in one of the mesh holes). Let me know how hot it gets after mag #1, #2, #3, and #4, and every 30 seconds after the last round fired in mag #4 (up to the 3-minute mark).

If you have a laser-aimed digital temperature sensor (as used by engine/motor testers), attach a small piece of metal in one of the holes in the mesh, so it can be directly heated by the radiant heat coming off the barrel, and check its temp after every mag and every 30 seconds after the last mag, until it starts to decline. THOSE the readings I want to see.

“…not because the carbon-fiber mesh is getting hot, but because nothing is stopping the heat from passing through the holes in the mesh to the hand.”

So please, for the last time, tell us all where that heat energy actually goes then? You are aware of the law of conservation of energy, and that the heat has to either be dissipated, or change forms, no? The heat is going to be more rapidly dissipated by the space-frame, or it is going to heat-soak into whatever “handguard” you chose, to be re-dissipated more slowly. By the time that bbl is radiating too much heat to hold, you can bet your ass that the plastic guard is also going to be scalding.

Also, Type J or Type N thermocouples are generally used for lab work in that range. Ir and lasers are for service techs, or weird apps where you can’t apply a thermocouple. Not for general lab work.

Oh, and by the end of your mythical ‘mag #5″ you are at the point where rounds will cook off – which was why I put that up there in the first place.

By 5 mags, that plastic is just as hot as hell, attempting to re-radiate heat from the bbl. The suggestion that it’s somehow “better” than a frame is specious at best.

So, the metal heat shield in a plastic handguard makes no difference at all in blocking/re-directing radiant heat away from the hand?

And the double-heat-shield in the latest M-4 handguard is no better at controlling/slowing heat buildup or re-directing radiant heat away from the hand than the single-heat-shield handguards?

And the plastic in a conventional handguard has absolutely NO insulative value? As soon as any single point on the inside surface reaches a specified temperature, the entire handguard, inside and out, instantly becomes the same temperature (despite your previous comment on the “range” of temperatures as a handguard gets heated-up)?

No, all these things are provably untrue. All the handguards described above sacrifice barrel cooling ability to re-direct heat back toward the barrel or into the air surrounding the barrel, to better protect the support hand from heat on the outside of the handguard. They are better at keeping the hand cool, and worse at allowing the barrel to dissipate heat and get/stay cool. That is the trade-off of a handguard in barrel heat management.

The device in question has maximized barrel cooling, at the cost of protecting the support hand from radiant heat for a longer period as the barrel heats up, under certain firing conditions.

If you NEVER shoot until your barrel gets hot, then this is the “handguard” for you.

If you shoot until your barrel gets hot, but ALWAYS wear a heat-resistant glove on your support hand, no matter what the weather conditions are or how uncomfortable it is, then this is the “handguard” for you.

If you DON’T always wear a heat resistant glove on your support hand, and DO occasionally shoot until your barrel gets quite hot (as many (most?) AR shooters do), and you DON’T like your support hand getting hot/burned, then this is probably NOT the best “handguard” for you.

Continue to chatter all you want; it changes nothing for the rest of us in the real world.

Seriously, get some science education.

It doesn’t matter how many layers you have, in the end it’s gonna still be re-radiated on the handguard. Conservation of energy and all that. No, the layers mean nothing, because sooner (rather than later) it will all mean nothing.

You really are just trying to disprove a scientific principle that has been proven about a million times.

Get an education, despite it all, go out and dig up a thermocouple and learn for yourself.

The good thing is you no longer need M-Lok or Keymod. There are plenty of places for you to just zip tie your accessories onto.

ZT-Mod0 – New mounting standard!

Zip-lok? Z-mod?

How, exactly, does it attach to the barrel nut?

That’s the weak link in a lot of otherwise good free float tubes, in my opinion.

If I were to guess from looking, the collar probably screws onto it directly. I don’t see any set screws or the like.

Looks like extruded metal from a homemade bbq grill. heyyyyyyyyy DYI redneck grips. BUT for serious weight reduction this would be ideal.

how much $$$$

Click the link. Looks like they all come in at over $340.

And that’s all I need to know to back out

Yeah, but does it come in keymod…?

there is more to rail than weight. no thanks. how on earth would you get the additional rail segments to line up properly leveled? would seem nearly impossible

I’d use one on a bench gun because its unique.

I like it! Add a nice paracord cover on the pistol grip, and maybe a macrame, single-point sling. Perhaps a tie-dye cerakote finish too! (just kidding – I actually do like the handguard. Does Windham still make the Carbon-15?)

Oh you guys, anything different you throw a fit over.

im very interested in the price and the barrel nut design.

i hope the weights listed are with the barrel nut included.

As an engineer, I aspire to one day make unique, new ideas like this handguard a reality. Props to the engineers, I want to be like you when I get out of school.

“Props to the engineers, I want to be like you when I get out of school.”

If you were to see that 15 years from now, you will be doing an epic face-palm.

Just wait until you’re handed your first impossible to obtain specifications on a fantasy schedule.

🙂

If he’s still in school, he better learn Mandarin as a kicker.

There will be nothing left of US engineering in 20 years to lament. The Chicoms steal all the IP they want from ‘partnership’ deals, and the outright espionage of US companies not doing those deals. Chinese engineers are filing a ton of patents, which of course, we will be the only ones who honor.

How about torsion? Is that little bit of rail out front (that looks like it’s begging for an iron sight) going to stay true if you twist the thing up, or is it better suited for use with scopes or red dots only?

Makes me think of a Chinese finger trap. 🙂

This would be cool for my varmint rig with a stainless fluted barrel.

Marks for innovation. Ugly as sin, but I’d buy one for a dream-set up.

That’s awesome!

Now make a super light buttstock…

“…it’ll support 100 pounds of weight in any direction…”

Great so when I put this on my lightweight run and gun rifle and accidentally get a little too low on the low crawl sections, I get carbon fiber splinters all up inside me… you first.

I’ll buck the trend and say that it actually looks pretty. Very un-gun-like, more like a handwoven piece of art or something, but pretty.

I see they splurged on the Barska red dot for the promo pics. Well played…. Well played….

Surely the best way to subtly demonstrate “outside the tactical box” thinking…

Interesting,

My experience with Carbon Fiber handguard came in the Army. There was an attempt to use them on the SPR rifles. While it is some really light weight stuff it is not the most durable when it comes to abrasion. Once the surface of carbon fiber gets cracked or scraped the fiber begins to fray. I have personally seen it on one such rifle but was told it was common place. I think with something like this you have to keep in mind the intended application. This is obviously not designed for a weapon with multiple rails and devices attached to it. This would

not be used on a rifle that is going to be bounced around the floorboard of a truck or stacked with other rifles in a parol base. This would be great on a 3gun build though. It would also be nice for a super lightweight build for a female or youth.

Contrary to what the title says, this is not the lightest handguard. A standard clarks custom carbon fiber sleeve is lighter and roughly 1/3rd the cost. it is more akin to a bcm kmr with a v7 nut weight wise but you lose all the functionality of the kmr. These are really cool looking but unless you need the strange combo of ultra light with massive open air venting its really just novelty handguard for if you want something different.

And the carbon fiber will actually insulate your hand from the heat. This thing is a barbecue grill for your hand.

Careful, 16V will be down to tell you there’s no difference between this handguard and other handguards in keeping your hand cool…

…no, really. See above.

Yup, I will be. Since the actual science is in my favor, Your nonsense? Not so much…

“A standard clarks custom carbon fiber sleeve is lighter…”

I’m not sure about that. It’s hard to say as Brigand is looking at new barrel nut designs to ensure that’s as light as humanly possible, and Clark’s stats are with their aluminum nut and Brigand’s are without the nut. However, the weight difference in the Clark between 4″ handguard and 16″ handguard is 4 ounces (so that’s 4 ounces to add 12″ of carbon fiber tube length), whereas Brigand’s entire 15″ handguard weighs 3.9 ounces. Tube-to-tube, the Brigand is pretty clearly lighter. Heck, Nick has farts that weigh more than 3.9 ounces.

Go with a Ti barrel nut like the V7, and the Brigand’s total weight at 15″ would be 4.68 oz (~5.9 w/ an aluminum nut). The Clark’s is 7 oz. at 16″ length.

I’m not sure I actually like the idea of an aluminum barrel nut no matter what, though. Also keep in mind the Clark’s tube has to be permanently epoxied to the nut. If you want to swap your barrel or can’t access your gas block underneath the handguard (to replace it or swap the gas tube, etc), then you’ll have to cut the carbon fiber tube off and the barrel nut will be trash as well. Of course, they’re pretty darn affordable in comparison.

Does it come with an oven-mit?

I don’t foresee an issue, but will definitely be putting this to the test. Especially after all of the insanity above. I’m expecting that the airspace between barrel and hand is going to provide some insulation (at least from convective and conductive heat transfer) and that there’s going to be way more fresh airflow through it than any other handguard, which should help to keep my hand (and the barrel) cooler. As for radiant heat and how long it takes for my hand to get uncomfortably hot and how much ammo and how quickly fired is needed for that to happen, and how much the airflow over my hand helps, etc etc, there’s one easy way to find out. And I’ll find out.

BTW the times when I’ve gotten a rifle too hot to hold, I feel like it has been the metal or plastic of the handguard that made it too hot to hold, not the slots or windows or other gaps in the handguard. It’s like grilling a steak. What makes the grill marks? It’s the metal grill, not the spaces between the grill. Whether that metal is actually hotter than the grill air temp or not, it does transfer its heat a lot more rapidly. I very well may be able to hang onto a gun more comfortably if my hand is 1″ away from a 500* barrel than gripping a 180* handguard.

Actual testing; that’s the spirit!

And I trust you to do it right.

But do be careful, I don’t want to be smellin’ any medium-well-done Jeremy S…

I’d opine that a side-by-side test with a normal-handguarded AR, with both guns having the same barrel weight and configuration, shot at the same rate to see which one got too hot to hold first, would tell the tale.

Or three guns; one with the tested “handguard”, one with a conventional plastic w/metal heat shield handguard, and one with a vented railed free-float tube and rail covers.

I’m sure the carbon tube is strong. I’m concerned about the strength of the connection to the end caps. Because if the tube disconnects from the end caps then it won’t matter how light or strong the tube is.

They said the bond there is the strongest part of the system. The aluminum will shear or the carbon will crack before that bond will break. This is not unlike cars (e.g. Lotus) and aerospace stuff where carbon fiber and/or aluminum panels are bonded together with an epoxy adhesive. All of the manufacturers who do that state that the bond is the strongest area and the aluminum will tear or crack away elsewhere before the bond degrades.

I have a suggestion for TTAG – please consider doing your own AR build with a carbon fiber lower, carbon fiber upper (if there is one), carbon wrapped barrel, and the Brigand handguard. Torture-test it for academic reasons / your readers’ benefit, and, if possible, do a comparison-test with a conventional AR of good quality, please! Would be interesting to see what happens, and it would conclusively end some of the acrimony here.

Good shooting!

Comments are closed.