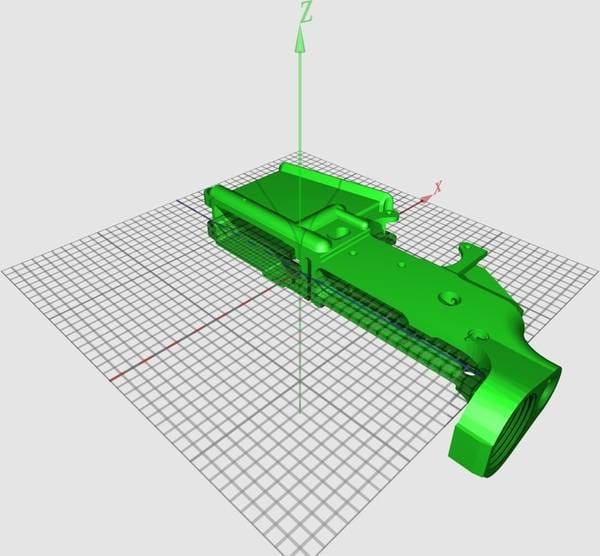

Back at Penn State one of my friends has had an interesting idea percolating in his head for a while. The machine shop on campus has some rapid prototyping machines where you feed it a 3D model of something in a computer file and it will happily “print” that object for you, turning a virtual rendering into a real world (and metal) object. My friend’s idea was to model a 1911 receiver using the software, print it, and then smuggle it off campus before the local cops got wind of a student using University machines to make guns. My friend eventually gave up on the idea (and now writes for TheFirearmBlog, actually), but it turns out someone else took the master plan to the next step. And then released the files online.

The widespread availability of cheap 3D printers has led to a boom in websites where people post models of things they’ve designed. Everything from intricate clocks to that one part that always breaks in Ikea furniture is available as a download, just grab the file and shove some plastic into your little printer and VOILA! Instant replacement part, often better than the original.

Something where this technology hasn’t really taken off is replacement parts for firearms. Currently, the methods available to those at home use plastic or metal with a relatively low melting point and build the object by layering the material and slowly building up the shape. The same characteristics that make the materials excellent for use in 3D printers (malleability and low melting point) make them not so good for holding up to the effects of recoil and the heat a firearm produces. Well, maybe something in .22lr, but definitely not a 5.56mm NATO rifle. And definitely not anything that’s not already made out of plastic.

Firearms parts are one thing, but what about the receivers themselves? With receivers, there are two very important considerations: one of the technical kind, and another of the legal kind.

If you were to fabricate your own AR-15 lower, there’s a very good chance that it will literally blow up in your face. Even though the recoil from a 5.56mm NATO cartridge is most decidedly on the “gentle” side of the spectrum that doesn’t mean that it’s light enough for plastic to handle. Smith & Wesson started making .22lr ONLY AR-15 clones not too long ago with plastic lowers, and one of the major concerns raised by those in the know was that if they were ever used for anything larger they might fail catastrophically and injure the shooter.

The reason for the safety concern isn’t specifically from the heat or the direct pressures around the chamber (even those would probably eventually kill the lower as well). The major concern is from the single greatest point of stress on the part: the threads that attach it to the buffer tube. Every time the gun goes off, those threads need to not only withstand the forces of the buffer going back and forth, but also the shooter’s shoulder pressing on the stock. After a few rounds the threads will most likely start stripping off, which could lead to a failure to seat malfunction or even a premature detonation blowing up the entire receiver assembly.

Not good. Very not good. Definitely wouldn’t want to be the EMT on duty for that one.

The other consideration we must, um, consider… is a legal one. Despite what Cory at BoingBoing may insinuate, it is perfectly legal for an American citizen who is legally allowed to purchase a firearm to make a firearm themselves. Some states may have regulations in place (like NY and CA’s assault weapons ban) that prohibit you from kitting out the rifle however you want, but as long as you stay within the letter of State and Local laws you’re fine. One of my friends just put the finishing touches on an MP5 he welded together, and I must say it looks (and shoots) fantastic.

You don’t even really need a serial number unless you want to make it into an SBR (like my friend) or plan to sell it, but it’s probably still a good idea. You can choose whatever serial number you want, so my friend chose ###0001 for this build. Leaving room for a few thousand more, I suspect.

The same general rule applies if you print your firearm instead of welding. The only issue you may run into is if you use one of those companies where you send them a design and they mail you a completed part — at that point THEY manufactured it and shipped it, making them illegal gun dealers. Technically.

Another legal serial number consideration is that according to the ATF, the serial number MUST be engraved in metal. A different crazy friend of mine used to work for Cavalry Arms, who made plastic AR-15 receivers with BUILT IN buttstocks, eliminating the issue with the threads stripping out of the stocks completely. They stamped their receivers the same way Glock stamps their frames — on an embedded strip of metal.

What’s the moral of this story? The best thing to take away from this development is to think before you act. Sure you could print your own AR-15 lower, but would it be useful? How about legal, especially if you live in Great Britain or Australia?

On the other hand, how great would it be to show up to a Brady Campaign rally with a 3D printer and just start churning these things out?

Click here for the design for the AR-15 Lower.

Click here for the design for the AR-15 Magazine.

Be safe, be smart.

[h/t: Martin]

You have some good crazy friends.

When Magpul developed the Masada, they “printed” the prototypes and shot them as well. I do not know the material that it was printed out of, nor do I know exactly what percentage of parts were printed.

The Masada uses a different lower receiver design that’s more well thought out for plastic components. Still not as good as an aluminum AR, but then again you can’t buy an ACR for less than my car is worth…

I have heard people talk about investing in CNC machines for exactly this purpose, so when the GGTs (Gun Grabbing Thugs – I just made that up, BTW) take over, they can still make an AR.

One problem I can see, though, is (and gunsmiths or metal workers, feel free to jump in here) AFAIK you don’t neccessarily put a block of aluminum into a CNC machine and then it spits out a complete lower. I’m pretty sure there’s a bit of gunsmithing that has to be done: Rough edges smoothed out, holes drilled, screw threads tapped/drilled, etc, and if any of those processes are done incorrectly you don’t have a receiver, you have a paperweight (and given the lgihtweight alloy construction, a pretty poor one.)

Finally, if your objective is to have an “E-Z Bild” gun, why even mess with an complicated First-world design like the AR? Better to make something like an AK, which uses a flat sheetmetal receiver. A few years ago there were even companies selling “receiver flats” that could be turned into actual, usable receivers with just a little bit of work but not anything that required experience as a machinist or expensive tools.

Don’t know if receiver flats are still available but if you really wanted a “do it yourself” gun that’d be the way to go IMO.

This is, in fact the interesting thing about this whole thing.

John Lott has made the point that a magazine is just a sheet of metal and a spring. Banning hi-cap mags is useless because they are so easy to make that if someone really wants one – they will just make it.

In the same vein, with increasing interest in 3D printers, stuff like this is going to happen… and don’t discount plastic just yet – how many major gun manufactures make polymer pistols? I know that many have metal embedded in the frame and it’s just a handgun, bit still.

In any case, even if the plastic does not work so what – you give that 3D render to a skilled machinist and they will have you an AR lower in no time.

And just wait tell we get our hands on replicators

CNC Gunsmithing sells something called “80%” lowers from a number of manufacturers.

Apparently, the legal standard for having manufactured a firearm only comes past this 80% complete point. So you can buy an AR with the majority of the complex work done (the forging/casting, magwell broached, buffer tube threads complete) and finish it yourself.

Interestingly, all you apparently need is a drill press, some common drills and a couple of jigs (designed by the folks at CNC Gunsmithing).

The real question, can you make an auto-sear? *Devilish grin*

According to Alito, if you don’t sell it and it doesn’t cross state lines, then maybe. I believe the other eight, and the BATFE&RBFs&GHs would disagree.

Why bother with an auto? For most purposes, semi auto is just the ticket, unless you watch too many of Arnold’s movies, where he sprays down the bad guys and they spray and hit nothing. I’ve fired an M14 and an M16 on full auto, essentially a waste of good ammo.

Why? Because paternalistic busy-bodies say I shouldn’t have one. Plus it would make a fun range toy.

“Because paternalistic busy-bodies say I shouldn’t have one.”

—–

This.

To answer my own question about the AK receiver flats:

http://www.brownells.com/.aspx/sid=78848/pid=42332/ttver=1/Product/AK_74_5_45X39_RECEIVER_FLAT?utm_medium=shoppingengine&utm_source=googlebase&mc_id=10000&gdftrk=gdfV21820_a_7c187_a_7c3466_a_7c100006760_d_100006760_d_11095

Ah, Internet. Is there nothing you can’t provide?

Any paranoid or prudent survivalist should have a few of these babies stashed in his bunker. Give him something to do while the radiation levels died down and/or the Zombies offed themselves.

Whoa. You,sir, are my new favorite human. The tooling looks like it would pay for itself in one or two builds tops as well. I think I’m going to have to get a stack of those.

It really is a revolution in gun ownership. In the future, regardless of gun bans or being a felon, you can get a gun. You can now make the lower and buy the upper without restrictions. Eventually when the 3d printer material is stronger you can print the whole gun and maybe the bullets and shells. You can also get the full auto blue prints and make a full auto lower.

What do you mean, “in the future.” Anyone with a basic machine shop can make a gun.

The Afghanis have been making rifles with medieval era blacksmithing techniques for years.

There are multiple web sites where you can by non-serial numbered 80% complete AR lower receivers along with the instructions and jigs to complete it with a drill press and a mill. It requires no transfer because it isn’t complete enough to be a gun yet. I have to personal experience with it other than internet browsing, but I like the idea.

Very cool stuff, especially the printers you can build yourself in your garage. One of these days I’ll have time to try my hand at building one. Maybe by then someone will have uploaded plans to print a Cavalry Arms style lower or a Glock frame. I’ve read that if you get a kiln as well, you can pack a freshly printed part in clay and fire it in the kiln. The plastic burns off, leaving a mold you can use to make cast aluminum parts. Exciting stuff, things like this are why gun control can never work in the long run.

take a look:

http://gpiprototype.com/services/eosintm280.html

I recall reading that Jay Leno had bought one of these to build parts for his classic car collection. From what I gathered he can scan a part and duplicate it or just enter the file of the parts that he wants to make. The military is also looking to purchase something like this to place aboard carriers that can not dock and require a part that is unavailable.

When did we develope a carrier that cannot dock? I spent the best part of 6 yrs on the biggest ones we have and they dock just fine……….

It seems like an easy way to fix the problem with the threads of the buffer tube would be to pin or rivet the the tube to the receiver.

Another slightly more complex fix would be to make a CAD model of the lower receiver that has a buffer tube already installed. This idea has actually got my brain working. Im going to fire up solidworks and see what happens.

Future anyone can buy weapons? Lol how about now, anybody can own a firearm, convert to full-auto, buy an 8 ball of coke I mean the list goes on and on lol, laws dont work…anybody now can buy a gun if they want but this will def make it easier my question is its plastic though? I dont get that part of it ill be more impressed once they figure out a way to make 3d replicate a metal one, a real one.

Does anyone know where to find blueprints now that the fearful censors are taking them off the net? Please reply to this post or send me an email directly.

Comments are closed.