Round 2…

So Part I of Project Elk Slayer went off without a hitch, which is good news for me. I hate it when a monkey wrench gets thrown into my clockwork before I start a project. Part I testing showed that my refinished and refurbished 1967-made Remington 700 7mm Rem Mag had an average grouping of a little over 1” at 100-yards. Do I really consider this a 1-MOA gun? No, not even close. The best four of five shots showed acceptable groupings, but each group had at least one “wide” shot. If I took into account all 5 shots (and why wouldn’t I?), the average grouping opens up to roughly 2” to 2-1/2”. While certainly not bad, that definitely leaves plenty of room for improvement…

Before we start…

Originally, Part II of the Elk Slayer was going to be the pillared and bedded (“P&B” from here on out) LSS stock. However, I made the (incorrect) assumption that I was going to be able to get some of the supplies locally. Of the three “medical supply and equipment” stores in my town, not a single one had surgical tubing for sale. I sure hope I don’t need an emergency coronary artery bypass any time soon.

Also, of the 3 “big box” home improvement stores and one mom-&-pop shop, only the mom-&-pop shop knew what a Forstner bit was (don’t they teach wood shop in school anymore?). Unfortunately, none of the stores had one in the size that I needed in stock (9/16”). Thank heaven for Amazon Prime!

So, to keep this project moving forward, I decided to switch the testing order around a bit. I swapped the action out of the LSS stock and installed the Hogue Rubber OverMold stock in its place. For those who may not have installed or removed a stock before, the installation is quick and easy and only requires hand tools.

At the range…

Just like Part I, I started testing by firing 2 “fouling” shots with the purpose of removing any residual oil from the barrel and to verify POI. Everything again checked out and I waited for the barrel to fully cool. After 15 minutes, the barrel was the same temperature as the ambient air and I settled the rifle into my new Caldwell Lead Sled Plus.

Testing proceeded in the following order: 5 shots, 5 minute wait, 5 shots, 5 minute wait, 5 shots, about a 25 minute wait, and 5 more shots. For the first and last set of 5, the barrel was completely cooled. Each shot was loaded and shot individually, meaning I never had more than one cartridge in the gun at any one time.

Testing proceeded in the following order: 5 shots, 5 minute wait, 5 shots, 5 minute wait, 5 shots, about a 25 minute wait, and 5 more shots. For the first and last set of 5, the barrel was completely cooled. Each shot was loaded and shot individually, meaning I never had more than one cartridge in the gun at any one time.

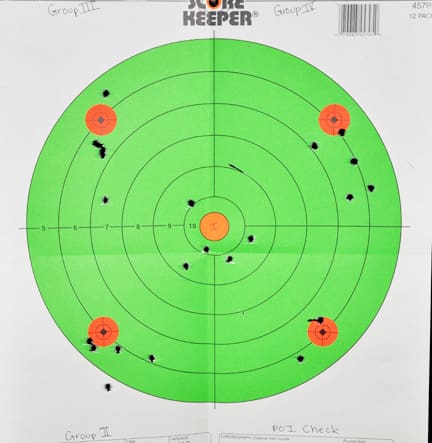

[Note: Group I is center, Group II is Bottom-Left, Group III is Upper Left, Group IV is Upper Right, and POI Verification is Bottom Right]

Accuracy was similar by my eye, but I ran the numbers anyways. Part I had a total average spread of 1.18”. Part II testing opened this average up to 1.47”. I want to post some statistics, but I’ll wait until we have all three data sets first. For now, I’ll just show the raw data before I start running variance modeling.

|

7mm Rem Mag Remington Core-Lokt 150-gr PSP R7MM2 |

Group 1* |

Group 2 |

Group 3 |

Group 4* |

Avg (rows) |

Std Dev (rows) |

|

Vertical Spread (in) |

0.966 |

1.529 |

1.779 |

1.966 |

1.560 |

0.435 |

|

Horizontal Spread (in) |

2.029 |

0.841 |

0.091 |

0.904 |

0.966 |

0.799 |

|

Extreme Spread (in) |

2.216 |

1.591 |

1.779 |

1.966 |

1.888 |

0.267 |

|

Avg Spread (in) |

1.737 |

1.320 |

1.216 |

1.612 |

1.471 |

NA |

|

Accuracy Testing – Best 4 of 5 rounds, 100 yards, 57F, slight gusts, Hogue Pillar Stock, (*) denotes a cold barrel |

||||||

Hogue OverMold Pillar Stock

As I said before, I like the Hogue stock more than I thought I would, and I even dig the “Ghillie Tan” coloring. Considering the price, the Hogue offers a durable, easy-to-install, and relatively stiff stock for the money.

I also like how quiet the Hogue is, particularly when compared to the factory SPS stock. Quiet? Can there be such a thing as a “loud” stock? Well, yes. Yes there can. For those who’ve never hunted with an SPS stock, imagine stalking prey with a hollow piece of plastic that echoes and amplifies the slightest twig scrape to sound levels normally reserved for rock concerts. Whatever Remington uses to make the SPS stock, they should sell it to Rockford Fosgate as an alternative revenue source.

While the Hogue recoil pad isn’t quite as nice as the one on the OEM LSS stock, it does help some. The tackiness of the “overmold” offers a secure grip, even when using fleece-covered gloves or mittens. The only suggestion I’d make to Hogue to improve this stock would be adding an extra swivel stud to allow the use of a bipod and sling. Most of my bipods are Harris made and all of them offer an extra “stud” to allow sling usage, but I’ve always preferred having a dedicated stud. But maybe that’s just me.

Observations so far…

So far, there are a few things that stand out from testing. First, the Nikon ProStaff 3-9×40 BDC scope is holding zero very well. Including this set of tests, I’ve probably shot 200-220 rounds through this gun so far. Other than the day I mounted the Nikon and sighted the rifle in, I haven’t touched the turrets. So much for the “internet chatter” about the Philippine-made Nikon scopes not being of acceptable quality. I haven’t yet tested the BDC Concept, but plan on doing a write-up shortly, so keep an eye out.

The second item that stands out to me is how the gun reacts as it heats up. Although I don’t report it in my write-ups, I keep track of each shot fired. I found that the first shot of each string is the most “accurate” (remember, accuracy and precision aren’t the same thing), meaning that its POI is the closest to POA. Each subsequent shot in each string tends to deviate more and the POI shifts from POA. Even with the LSS stock, the first shot of each string is either on the target dot, or in the “10-ring.”

I’m sure there are many TTAG readers that know more than I do about this, but I was told by those “in the know” that the recoil lug, and more specifically the “fit” of the recoil lug in the stock, has the biggest impact on repeatability. Hopefully, the bedding job and pillars will limit movement and will tighten these groups up. Keep an eye out for the complete “bedding job” write-up, as well as Part III of Project Elk Slayer.

How’s your cheek weld on that stock? It looks like the scope is a tad high compared to where the cheek piece is, and if you’re not getting a good and consistent cheek weld then you may have some parallax issues contributing to the large groups.

My weld isn’t as good on the Hogue as on the LSS stock. Actually, it is more like a chin weld on this stock, which I agree would normally contribute to some consistency issues. However, I’m using the Lead Sled which makes short work of alignment.

To be honest, I don’t know how I’ve ever lived without it (the Lead Sled that is). When I align the scope, I aim at the target and make sure there is nothing touching the rifle, with the exception of my chin/cheek/face. Once I’m satisfied with the alignment, I back off the rifle, then get back into it to verify alignment and make the shot. This is probably why shooting a box of 20+2 takes an hour!

Patrick,

How may rounds have gone down the barrel of your 7mm Magnum? I’ve read that barrel washout is a real problem with the 7mm. Generally, 700 to a 1,000 rounds and accuracy suffers, if I remember correctly.

Did you purchase the standard Hogue over molded stock or the Hogue stock with the full bed block?

This rifle was made in 1967 as verified by Remington Service, so I don’t know what the history before me was. Since I’ve had the gun, less than 300 have made it down range. I shot 30-40 rounds with the scope that came with the rifle, then 20-30 with open sights. I had the gunsmith at my local range scope the barrel (for $20) and it checked out O.K. By OK, I mean that it wasn’t “alligator skinned”, roughened, or cracked. Paul, my gunsmith, said that it looked great and should make a great gun to make a hunting-gun/project out of. After that, I sent it off to Remington to be refinished and to have the trigger replaced. Why Remington for refinish work? They are surprisingly cheap and fast! The gun has a carbon-steel receiver and a stainless steel barrel, all of which was bead-blasted and refinished.

You are correct in that most magnums generally wear out after 1000 rounds or so. Of course, “wear out” is a general term and it means different things to different people. From what I’ve been told, the quickest way to crack or “skin” a magnum barrel is to shoot too quickly. I haven’t found any empirical data proving this theory, but it makes sense. The rule of thumb I follow with magnum rifles is that you should always be able to “hold” the barrel, meaning that it shouldn’t get too hot to touch.

The stock I purchased is the OverMold stock with pillars – NOT the full-length bedding channel. If this were a true precision rifle, I would have considered that stock. Since this truly is a hunting rifle, I picked the lightest stock I could get away with.

Ah, okay, original barrel. I wasn’t sure if refurbishing included a new barrel.

Thanks for the information on barrel wear. I suspect barrel wear and heating are related. Only makes sense, now that you mention it.

I think the Hogue Overmolded stocks are great. Nothing like putting a stock on a rifle that really cannot be hurt. The Hogues aren’t as pretty as the laminated stocks but you sure don’t worry about the finish.

Interesting project. I’m looking forward to the conclusion.

HURRY UP!! 🙂

I have a 700 SPS Varmint and am enjoying this series – thank you.

You could probably save yourself a lot of time and money by trying some different ammo. Maybe the gun just doesn’t like Remington Cor Lokt 150 gr and you won’t get good groups no matter what you do.

@chuck – when I got this rifle back from Remington, I mounted the Nikon and checked accuracy with 4 different loads (2 manfacturers and 2 different weights). The Remington Premier Core-Lokt 150-gr showed the best groups, but it was only by less than 1/4′-1/2″ over the regular Core-Lokt’s. At $46/box vs $21/box, I picked the standard Core-Lokt cartridges because, well, we still do this stuff for free 🙂

Comments are closed.