By Scott Conti

While enjoying a lovely dinner in Newport, RI with TTAG’s impresario, the conversation drifted to firearm technologies that could still use some improvement. We agreed that the magazine has always been one of the weak points of any semi-auto pistol platform. Feed lips get bent, springs weaken and can rust, schmutz can enter and cause all sorts of long- and short-term problems with functioning and reliability. Anyone who is serious about their carry equipment knows that you need to maintain your mags and should have a spare close at hand. Even then, they screw up occasionally. So what can be done about this state of affairs? . . .

I consider myself an inventor – after a long and torturous career in IT, I started my own prototype machining business. My first products “reinvented” armorer tools for handguns (insert shameless plug here). So RF suggested I take a look at the current state of the art of magazine technology and blue sky how to make it better.

Most magazines for semi-auto pistols are pretty similar – they consist of a body made out of metal or plastic, a baseplate, a follower and a spring. This, of course, means the potential failures are the same.

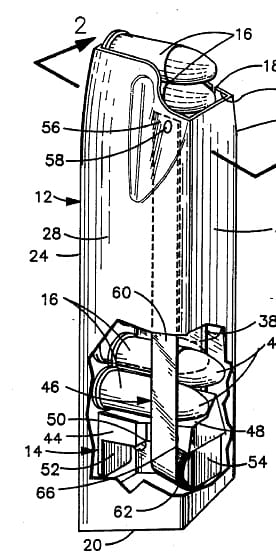

A cursory search of Google Patents will bring up hundreds of magazine-related filings. Most of the creative minds looking to improve gun feeding seem to focus on changes to the spring. Ram-Line seems to hold the lead in innovative patents to basic magazine technology with several patents that use a spirally wound flat coil spring that winds and unwinds to “pull” the follower up instead of the conventional spring that pushes the follower up. This technology is in common use for .22 rifles in the ubiquitous 30 and 50 round Ruger 10/22 mags.

Among the claims of US Pat #4888899 is that additional capacity is gained by reducing the space needed underneath the rounds for spring compression. In the early 1990’s, Ram-Line produced magazines like these for handguns. I have at least one Sig P226 variation on this theme that will hold 18 rounds. Mine works fine, but the plastic baseplate doesn’t look like it will survive many magazine drops and I don’t normally use it. This drawback can certainly be overcome but there must be the reasons the idea never caught on.

But why limit feeding to springs? Is it possible (or desirable) to use, say pneumatic or hydraulic force to push cartridges up in a mag? Indeed, we find US Patent #4033227 which is hydraulically operated – only it’s for for a “tank with large-calibre firearm.” As expected this uses a telescoping hydraulic cylinder to push the rounds up from below. Could this be adapted and miniaturized to a handgun?

A pneumatic magazine is described in patent application US2007/0215137 A1 – however it is for paintball guns. Could the follower be a piston in a pressurized magazine? The basic implementation problems to overcome with either of these would be the space required for the mechanisms and pressure reservoirs and of course leak-detection and prevention.

What other forces could be used? Other ideas that come to mind – expandable foams or maybe a miniature cable drive. Or how about using magnetic force to propel a follower up the magazine? Magnets are a great source of energy but also have their limitations. Neodymium magnets can to lose their properties over 180F. They also attract all sorts of “ferrous junk” – (run a magnet along the ground outside and see how much stuff sticks to it).

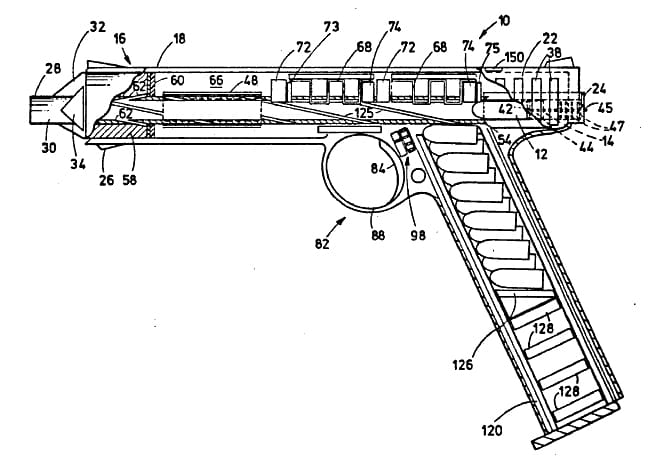

Regardless, US Patent #5074189 describes such a mechanism but it is used for electrically-fired cartridgeless ammunition in a firearm that appears to use magnets for both recoil reduction and to generate the electricity required to fire the cartridge. The description says it has one moving part, no springs, fires at a higher velocity than a conventional handgun and will work in “any environment.” This would appear to be The Perfect Gun. Sign me up! However, it looks like the patent for the cartridge was never actually filed. If a working example of this contraption exists, I’d love to check it out.

Some would say the problem has already been solved…it’s called a “revolver.” A good friend of mine – a self-educated inventor who holds many patents and is now in his 90’s – is still solving problems he has worked on for decades. I don’t expect to solve this one quickly, as many others have worked on this problem for over 100 years and yet we all know most handgun magazines work – and fail – about the same. So what’s your bright idea?

Kahr mags are the worst. I have a PM9. The rounds pop out all the time. I was told by Kahr, that the magsw were designed that way, because of operation of the pistol.

They have a design flaw, which they are unwilling to fix.

Does any one want mine? I will sell it at a good price. I am disabled. My left arm is paralyzed, and I can’t deal with lost rounds in my pocket.

Honestly I can’t really think of any. I haven’t had any mag related problems in my short shooting career (~2 years, 20,000 rounds). Mostly Glock factory mags, but also Ruger LC9/LCP mags, PMAG AR mags, and Chip McCormick, Checkmate, and Wilson Combat 1911 mags.

How about some sort of air bladder?

An air bladder would be prone to leak and would be too variable in the force it uses. As it expands, it would reduce the force substantially.

The same thing happens with a spring. As it un-compresses, its force reduces.

Magazine manufacturers/designers overcome this property by pre-compressing the spring inside the magazine. When you re-assemble a magazine (after disassembling it to thoroughly clean it), you have to force the spring to compress as you are putting it back into the magazine. This ensures that the spring will supply sufficient force even when pressing against only one cartridge at the top of the magazine. One could achieve the same result by pre-compressing an air bladder, but then the bladder would be more prone to leak down.

Is that the old HK ad? Pretty funny. I actually like the plastic ones that you can kind of see through as an idea, though I’ve never used them.

Oh, I just clicked t the article and I see it is the ad. See how I can edit now instead of making a new post? Nice!

Add some pic rail to the magazine, a laser, and a flashlight, and some wavy lines injection molded on it.

Or just continue to enhance metallurgy and design of springs.

-D

You won’t make any progress without a few trolls to tell you how stupid it all is.

I would revamp the PMAG to allow those awesome dust covers to lock onto the bottom of the magazine after being removed… Have lost one or two that way already… I think Tango Down may already offer that feature on thier polymer mags?

>I would revamp the PMAG to allow those awesome dust covers to lock onto the bottom of the magazine after being removed.

That is already a feature.

The dust covers snap onto the bottom of the pmags I have, bought all this year though. Maybe a recent design change?

A magazine designed to look like a three-foot high walking cane. The cane-mag would hold about one hundred fifty rounds. This will make, when out for an evening of dinner and opera or going to the grocery store, the carrying and re-loading of extra mags probably unnecessary in the event of a self-defense shooting.

How Would You Improve Magazine Design?

I’d put the centerfold on the outside and get rid of the ads.

And cue the rimshots… zing!

Ralph wins the Internets for the day.

And also offers the best idea on the topic yet.

wait…people still buy magazines?

Ralph will be here all week, don’t forget to tip your waitress!

Perhaps some sort of rotating cylinder that advances after each round is fired. BOOM!

if i remember correctly the tokarev 33 pistol did away with one point of failure on mags by doing away with the mag lips and machining them into the pistol. i had an old tok with old mags back in the early 70’s and never had a hitch with it or the suspect ammo i had to use for it. the mags for the tok and my current makarov appear to be overbuilt as well. seems to head off any problems and i’m not real big on mag cleaning and maintanence, but i have zero problems with original mags.

That’s what I was thinking. Why keep feed lips on the magazine, when you can machine them into the frame.

Because you need something to retain the rounds in the magazine when it’s not in the gun? Replacing a fairly simple mechanism with a complex mechanism to accomplish the same thing is not an advancement.

The most reliable magazine ever made is a revolver’s cylinder…

My wife’s .22 Beretta Neos has a way to compress the spring to load in the rounds. I like that and have always thought it would be a good idea on other magazines.

What I’d really want is a magazine that can be reloaded quickly. Strips are one attempt, but they don’t really work well. If I’m in combat and I need to reload magazines, I don’t want to be futzing with strips and such, and then find a hard surface to push the rounds in. I want to compress the spring, have it held down, and then slide the rounds in easily.

I’ve never had inordinate problems with feeding. It’s filling that is my beef.

“I’ve never had inordinate problems with feeding. It’s filling that is my beef.”

This. Shooter’s Thumb hurts like hell after a few hundred rounds on a stiff new mag. Hell, even on a well used mag the old digits start to sting after a few reloads. I know some .22LR handguns have a little thumb slider to compress the spring. Why not in .380 and up?

Single-stack Makarov magazines have an interesting follower design. There’s a small metal tab which sticks out through the window in the side of the magazine, and while its main purpose is to engage the slide lock when empty it also functions as a magazine loader but it’s fairly sharp. (It helps if you use your thumbnail to depress it.) The Makarov combination tool does this even better, and saves your thumbnail.

Look up the Ultimate Cliploader for the Ruger MkIII’s…I can testify that it works.

regarding reloading; what about a magazine where the follower could be pushed all the way down to the bottom, (with say, a slide on the side of the magazine) and you could reload without any pressure, and then release the follower spring when finished. That would be nice.

That’s how the mags on a Ruger Mark III work.

The Sig Mosquito also has an opne slot on both sides, and there is a fastener holding the follower in that you can use to hold the follower down for reloading. Covering these protrusions with a small square of thin plastic would make them quite useful as a reloading tool.

If anyone omes up with a design for a pneumatic mag, I’ve got the product name: The Mae West. “You just put your lips together and blow.”

I think a magazine with no feed LIPS, but a full arch over the top. That is, bullets are pressed down and slid in from the front, and slide out through the front, with the bullets pressed forward.

Sounds like a PEZ dispenser.

I can’t wait to see your breechface design.

What’s the real problem we’re trying to solve here? Most magazines work, and work well. And magazines really need to be cheap. It’s no good coming out with a magazine that gives you 1% better performance if it doubles the cost.

The only genuine advance in magazine design I’ve seen recently is the change Beretta made to the 92 desert magazines: Ridges indented in the sides of the magazine form rails for the rounds inside to ride on, instead of sliding directly on the sides of the magazine. This gives dust and dirt room to move aside, reducing friction. Serves a similar purposes as the dust grooves inside a FN-FAL receiver. The 9mm Beretta Px4 magazines also have this, as do the Walther PPQ/P99 magazines. As a bonus, it probably increases the strength of the magazine a little too.

I think he has some good points. Trying to think outside the box is great.

Here is my take on things.

One is economy of scale. A pneumatic system or something that doesn’t use a standard spring is great, but it is more expensive, and might be partial to other failures which are more complex. It sort of falls in line with the KISS theory. Springs are cheap, easily replaceable by the owner, and well magazines as we know them today are simple. Also cheap, so when one goes bad we can replace the internal parts or toss it for a new one.

I am not saying there is room for improvement. I would like to see magazines which are easy to clean and maintain, make dis-assembly easy. Maybe put in some access ports for compressed air of something so folks can blow the out quickly and keep on going. Also some standardization would be nice too. Not just within a single manufacturer, but possibly across multiple. I know wishful thinking.

Now improving springs to hold up better under various conditions, feeders which work better etc all make sense.

I’m disenchanted with all mags never owned one that has been 100% reliable. The bigger the caliber the problems are more apparent.

My only complaint about mags is I own a couple of firearms that will be next to useless if anything ever happens to the one mag I have for each. Nothing worse than owning a gun for which there are no aftermarket parts for, and the original manufacturer is long gone. I have an AMT “Backup” in .22LR that shoots ok, but I treat the magazine as if it was a delicate precious piece of art, because otherwise, I’ll have a very awkward single shot pistol. Apparently I bought one of the 11 or so in .22 and everyone else got theirs in .380 for which there are magazines available.

Colors.

-D

Good idea!

I like to rotate my mags occasionally, letting the spring rest on one mag at a time. I also have labeled each mag with a number, so I can know which mag had that one feed failure at the range. That would be easier to keep track of if each mag was a different color.

Doesn’t any one want to buy my PM9 with it’s crappy mags?

Standardized sizes.

I know its a pipe dream, too much difference between guns, etc. But it’d be great to live in a world were all you do is pick the caliber, capacity, and single or double stack and you’re good to go.

Though it probably will never happen that is a nice dream.

If in a gas powered system I would guess with some sort of integration of the magazine operation into that flow there might be enough kinetic energy available to cycle the bolt, drag the line of rounds up and line the next one up for the bolt to come forward. I can’t think of any simple way to do that, one that would be less mechanically complex than what already exists for reliability’s sake, but the energy is there in each shot to get it done somehow.

You’re not wrong. In fact, you’re very, very right. You were just born a little bit too late to be the first to invent the belt-fed.

I like the line of thought Jake has made and I don’t think it would require a belt feed. It could be more like a conveyor, or elevator powered by the bolt movement. Or, think like a revolver with a column of bullets instead of a cylinder.

I’m not sure what you’d gain by it, but it’s a very interesting idea.

That’s called a harmonica pistol. Google it.

I don’t see any compelling reason to totally throw away the current magazine approach. I do see good reasons to refine them slightly.

Designers could use slightly thicker steel for increased strength which would alleviate the lip problems that people encounter. I imagine the manufacturers could use slightly better quality steels for the springs so that they don’t lose too much spring force when compressed for a long time. And for people that have 15+ round magazines, load them two rounds short of maximum capacity so that the spring isn’t at maximum compression all the time. And how about using stainless steels?

Finally, I believe it is an unreasonable expectation that a magazine function properly without ever cleaning or maintaining them — just as unreasonable as expecting a firearm to work properly without ever cleaning or maintaining them. After all every device needs care and maintenance. Fortunately I have yet to encounter a magazine that is difficult to disassemble or clean.

Not really a magazine change but bringing back the Tround concept is a thought. My idea uses an internal box mag where you remover a spring loaded base plate of some kind, pour in the shells, and replacing the plate would compress the spring. Being rounded triangular shells the trounds would self stack to fit.

The mechanism of the gun would be like the Dardick 1500 pistol that never caught on. It was a working fusion of semi-auto and revolver design and is a shame it never caught on; if only the gun wasn’t ugly as sin.

There are really only two changes I’d make to magazines, and neither one would have anything to do with the spring(s).

1. Make the feed lips out of a material other than sheet metal. Whether it’s a machined block of metal (preferably steel) or some composite, #1 cause of feed problems in most semi-autos I see has to do with the magazines and the feed lips. They’re bent, they’re dinged, they have a burr on them, they’re at the wrong angle, Mr. MacShooterific has “adjusted” them with his Leatherman MUT tool… on and on.

Magazines should either be so cheap that people simply THROW THEM AWAY when they quit working correctly, or they should be made with proper materials so that they don’t malfunction after they’ve been dropped once. Pick one, I don’t care which.

2. The follower could be made from UHMW or some similar self-lubricating plastic/composite, and ride on grooves or rails inside the box to prevent mis-alignment.

Last change which would apply to only some magazines: Make it easy to pull the bottom off so the inside of the mag can be cleaned and/or the spring replaced.

a racheting system would eliminate the need for a spring and would ensure consistent feeding pressure round to round. the downside is it would be more complex.

What you want is a dardik ;D

A sliding sleave to relieve the spring for loading then is recompressed and locked in when the mag is reseated in the well

Talking purely about what I would like, without think about how it would be designed:

1. I would like to load the bullets into the mag directly down. I don’t like having to compress the spring with the primer end of the casing, then slide it to the rear of the mag, then make sure I got it all the way back. When loading the last bullet, the friction on the side of the casing makes it very difficult to slide it in and to the rear. This friction as the cartridge slides to the rear is the cause of that blister on my thumb. You should be able to just push the cartridges straight down into the top of the mag.

2. I hate how difficult it is to remove the baseplate of the mag. You have to stick something through a hole on the bottom, then carefully slide the baseplate off the bottom of the mag. Be careful, or the spring and/or follower will go flying across the room into who-knows-where-it-is-hiding. Performing this operation in reverse to re-assemble the mag is way too difficult too.

How dare Congress limit magazine size……..I paid good money for those Playboys

Comments are closed.