Reader Thundervoice writes:

I want to shoot as well as I can, if for no other reason than I’m detail-oriented and the engineer in me is always looking to make a process or system better. So I was never particularly satisfied with the accuracy of my MSR. It only produces about 2 MOA with the Federal factory ammunition I typically buy at Wal-Mart. Not bad, but nothing to write home about.

I once saw a gentleman at the range with a box of hand loaded ammo that varied in 0.2 grain increments and the results were my first indication of how much difference just a little bit of powder can make in downrange accuracy. Seeing that made me want to experiment on my own with powders and loads to get the most out of my MSR. So I did.

The Experiment

First, the equipment. For this experiment, I used a Stag Model 3T upper with a 16-inch barrel that has a 1:9 twist. The upper was matched with a lower I built that included a James Madison Tactical Saber single-stage trigger I selected based on a TTAG review. The buttstock is a Magpul ACS, which provides a better cheek weld than the mil-spec buttstock that came with the rifle.

The scope was a Bushnell AR Optics FFP Illuminated BTR-1 BDC Reticle AR-223 Riflescope with Target Turrets and Throw Down PCL, 1-4x 24mm. I supported the rifle barrel on a Caldwell Handy Rest Shooting Rest. The targets were 100 yards downrange. I did the experiment on a day when the temperature was 91 degrees and the humidity was 59 percent.

The basic concept of my load experiment was to create four loads for each of five powders and determine the resulting impact on accuracy. I started near the minimum load for each powder and increased the load by 0.5 grains, resulting in a total spread of two grains.

I used the same bullet for all of the loads, the X-Treme 223, 55 grain, full metal jacket. These bullets have a ballistic coefficient of 0.243 and are intended for target shooting, plinking, and varmint hunting. The five powders I used were all Hodgdon: Benchmark, CFE 223, H322, H4198, and Varget. Load data for all but the Varget were taken from the Hodgdon website.

I used the Lyman 49th Edition Reloading Manual for Varget, which had a starting load of 25.0 grains instead of the 25.5 grains shown on the Hodgdon site. For all five powders, the upper end load for my experiment was at or slightly below the maximum load.

As a control, I also included the Federal .223 55 grain FMJ factory ammunition (100 round box packaged exclusively for Wal-Mart) that I typically use for target shooting. The cases I used for reloading were mixed .223 brass recovered from previous shooting sessions (no military brass).

Results

I shot the loads in the following order: Benchmark, Varget, H322, CFE223, H4198, and Federal factory. After shooting the first two powders (Benchmark and Varget), I adjusted my scope to bring the point of impact down and to the right. I started with the lowest load in each powder, working my way up the load increments. For each load, I fired five shots.

The table indicates the maximum spread of five shots and the spread for the four tightest shots (assuming one flyer) for each powder and load. Powders are listed by burn rate, with the fastest burning powder at the top of the table. The burn rate values are from the Hodgdon website where #1 is fastest powder.

The maximum load is shown for information purposes only, as the maximum wasn’t used for any of the powders. For two of the loads, one of the five shots was off-target and the five-shot spread for these loads is indicated as >5 inches. Load values are in grains of powder. All of the spread measurements are in inches.

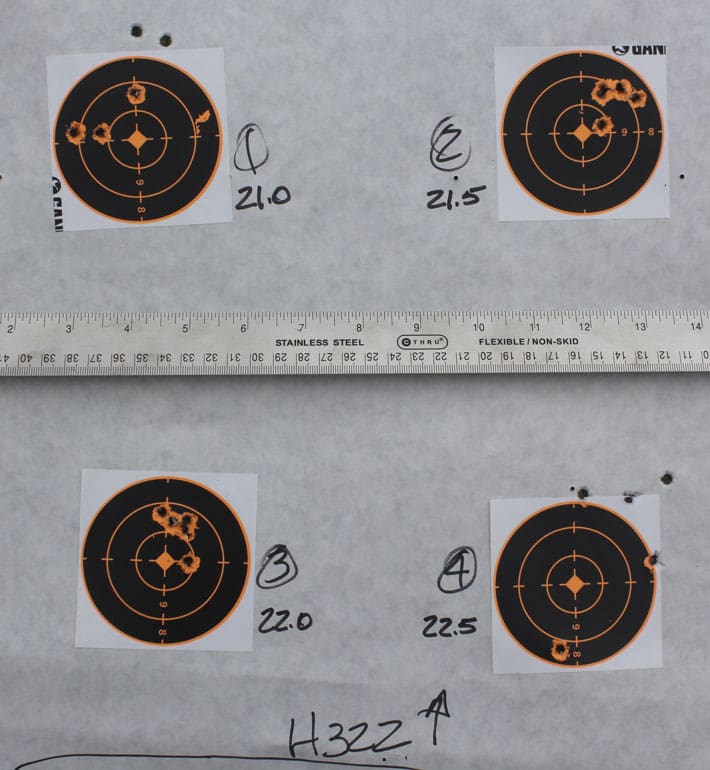

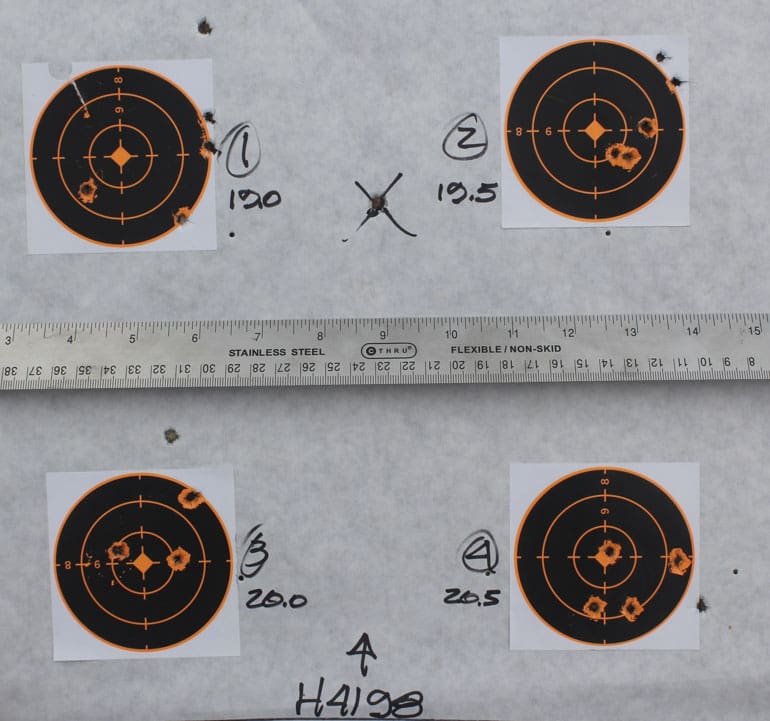

The photos illustrate the results for each of the powders and the Federal factory load that I typically shoot. The target rings are at 0.5 inch radius increments with outside circle having a diameter of 3 inches.

Lessons Learned

Overall, I learned several important lessons from this little experiment. The results indicate that both the powder and the load can make a difference in the accuracy of a rifle. My goal was to see if I could find a powder and load that would allow me to shoot a dime-sized group (~0.7 in) at 100 yards with my rifle.

If I base my results on the 4-shot group size, the H332, Varget, and CFE223 all provided that level of accuracy. Only the H322 powder provided a dime-sized 5-shot group. The most accurate load for each powder was one of the middle loads, not the smallest or largest used in the experiment.

There are some things I should have done differently. Given the limited number of shots for each powder (5), I should have used a more stable platform or rest for the rifle to minimize the impact of the shooter on the results. The differences between the 4- and 5-shot group sizes are likely due to the shooter more than the powder and/or load.

It would have been more informative if I had been able to chronograph the loads during the experiment. Unfortunately, I don’t have a chronograph and don’t know any fellow shooters that have one they would loan to me. I also should have sorted by brass and used the same brass for all of the loads.

I probably should have done the experiment over several days instead of all on one day. By the time I got to the last powder (H4198), I was starting to get tired and that may have affected the outcome for that powder. The H4198 powder had the largest groups, which may be due to being last in the order.

I plan to repeat this experiment at some point in the future and to include a different upper with a longer barrel and tighter twist rate as a comparison. Next time, I’ll implement some of the lessons learned and see if the results of the initial experiment are repeatable.

The bottom line for me is that I can improve the accuracy of my rifle by custom tailoring the loads I put through the barrel. If you don’t reload and want to improve your rifle’s accuracy, you may want to try some different types of factory ammunition to see which will provide you the best accuracy.

Probably what I would do at this point is re-test three or four of the best loads to verify the data. Use only one kind of brass, since different cases can have different volumes.

A good bench rest could help, but a dime-sized group at 100 yards with a 4x scope is a pretty tall order, regardless of other variables.

I agree about retesting.

I loaded 10 of each load initially so I could do 2 by 5 groups. Then 20 of the two best. Now into the thousands with final load.

Nice work, and nice writeup! Now you’ve started down the rabbit hole, and there’s no return!

One thing you might be interested to read through is the “Optimal Charge Weight” method of load development:

http://optimalchargeweight.embarqspace.com/

I like the idea of doing a “round robin” with your loads to minimize the effects of barrel heat and fouling (i.e. Shoot one round of Load 1 at Target 1, one round of Load 2 at Target 2, etc. and repeat) rather than shooting 5 at Target 1, 5 at Target 2, etc.

And, the “optimal” load is based on the center of the points of impact rather than overall group size.

These are some examples I created when trying to explain the concept to my dad. The first is a mockup of groups overlaid one one plot (where the “middle” three are the ones that were closest together.) The second is an actual plot of 75gr Hornady OTM / Varget / CCI-450 test results generated from the data

https://imgur.com/a/A0KB0Ka

That helped me settle on (or rather confirm) the “23.5 grains of Varget” load that seems to work for so many other people on the internet.

Another tool that’s helpful with this is the “On Target” app:

https://ontargetshooting.com/

I haven’t used the most recent one, but the basic idea is to take a picture of your target, and plot the impacts, and it will give you precise offsets. Which is much easier than using calipers or a ruler! And, that’s what gave me the “offset” data I plotted in the second image above.

I use 22.5 grains of ADI AR2207 sold in USA as H4198 with 55 gr Sierra Game King projectiles for 1/4 Moa groups in Remington 788 bolt action.

Drops foxes and kangaroos very well.

This load was ok in older book but is now too high in new manual. I went up in .2 grain increments to find sweet spot. Friend did the same thing and ended up with same load for his Tika bolt action. DO NOT try unless you know what to look for in pressure signs etc.

The goal with handload testing is to find a load that’s compatible with the barrel harmonics of the gun you’re shooting them with. What works for you is probably not what works for someone else. If there was a “sweet spot” that worked universally, then factory ammo would be loaded accordingly.

Definitely agree about the brass- it sounds like little energy was given to its consistency. If you had a mixed bag of different lengths and makes, that can certainly throw another variable into the equation. I always use new brass from the same manufacturer just to eliminate even the tiniest variables that might come from it. I’ve found Hornady’s brass to be very consistent. I run them through the sizing die to get the necks nice and straight, measure, trim, deburr, and measure again.

You say you plan to repeat this experiment with a longer barrel and tighter twist rate as a comparison. You might find some coincidental similarity, but you’re changing two variables at once, so you should expect all your results to change.

With a given barrel, you need to work up ladder loads for each bullet and for each powder.

If you get lucky, you might find different bullets of the same weight give similar results.

You’ll probably decide fairly quickly what powders you dislike, because they make it hard to get consistent throw weights on your equipment. The good news is, that reduces the size of your test grid!

Ahh, the beauty of handloading.

Try sticking with the same rifle and best loads. See if it’s repeatable. Then try a 62 or even 77 grain bullet with middle powder loads for those weights.

The heavier bullets should fly better in a 1:9 twist.

I like this article. At some point, the hobby of accurately hand-loading surpasses the shooting hobby. I’ve got thousands of lines of data in multiple spreadsheets and compare just about everything.

Yep! I buy a rifle work up a great load for it, get bored and then it’s time to buy a new rifle!

I will make an 8th point that you didn’t which is that ALL the reloads were more accurate than the factory loads were.

I think I’ve said repeatedly two things that were supported by the author’s testing:

1. Get a Lyman loading manual, as they call out accuracy loads as well as starting and maximum loads for a particular cartridge/bullet/powder combo.

2. The most accurate loads are almost never found at maximum powder charges. I’ve seen far too many new reloaders start at “max minus 10%” and then just work up to max velocities, then complain “this reloading business is a waste of time, look at how crappy my groups are…”

I like Lyman’s book(s) because:

a) they’re not hawking powders, and

b) they’re not hawking bullets (but Lyman does sell bullet molds and casting equipment).

Lyman also has a book specific to reloading for AR’s:

https://www.lymanproducts.com/brands/lyman/publications/ar-reloading-handbook.html

The next variables that could make a difference in group sizes tend to be a) how far the bullet is seated in the case off the lands and b) case neck tension, which is difficult to measure, and involves how much you crimp the bullet into the case as well as how concentric the case neck is.

To crimp or not to crimp in the AR? I don’t in my precision loads. Your thoughts?

Secondly, I removed the neck expander from my FL Resizer die. Groups have seemed to tighten. Thoughts?

PS: my 18″ Wylde SS 1-8″ likes Hornady 75 Gr HPBT, CCI 400 and Benchmark +/-2650 FPS in Lapua brass trimmed to 1.752″ with 2.258″ OAL. Best results are 5 shots in 0.430″ at 100 yds… so far. I weigh and measure everthing.

I’m also working up a Hornady 60 Gr VMAX and Varget load at +/- 3150 FPS. Results are intriguing. I like to have as many load combinations as possible, cuz you never know when that next component-drought will occur.

If you’ve found something that works, and you can attribute it to that one change, hey, run with it.

I could see how getting rid of neck expanders in a die might help – when you expand the neck, and then crush it back down you’ll be changing the neck tension – and perhaps not uniformly from round to round. When you’re just pushing in a pill and then crimping, you’re starting from the expanded dimension of that brass in your chamber – ie, a known starting point that isn’t changing. So I could see how not expanding the necks gives you more uniform neck tension – but I’d have to measure it to be sure.

I load for accuracy in a White Oak Varmint 24″ in a 1 in 8 twist. My favorites are Varget under a 77 gr Sierria Match. I use Lee dies. I full length resize then final clean. I use their neck sizer before priming and finish with a moderate crimp. So far I can get 1/2 moa all day long. There are days when I get lucky and there are some 1/4 moa groups. I have had good luck with Varget, CFE223, H335, and RL15. So far the best is Varget with RL15 close behind. Consistent neck tension is one of the biggest aspect I have noticed. That is why I use Lee dies. AR’s need full length resizing every time while my bolt gun just needs neck sizing. I have noticed two accuracy nodes with my rifles. I stay with the lower one as I can shoot longer.

i have a custom .243 built on a Yugoslav M98 action that does not like factory ammo at all. But it REALLY likes max charges of IMR4350 and H414 behind a 95gr Ballistic Tip loaded at a significantly longer OAL than factory ammo. Which means I’m not compressing the load, and the bullet is only about 0.010” off the lands. Almost certainly why the loads are so accurate. I just got a neck resizing die for it, but I haven’t had a chance to try it. Neck resizing made a big difference in my .30-06 and .338 Win Mag loads.

I’ve done similar experiments to optimize the accuracy of my AR. I understand doing this with a 55gr. FMJ for the sake of cheap shooting but I started my trials using 65gr. BTSP Sierra GameKings as I wanted to work up a hunting load. I had good results with H4895 with this bullet. For some reason my 1:9 seems to like heavier bullets, or maybe it was just because of a better quality bullet. Anyway I’ve been working on loads using bulk 62gr FMJ recently, but not really expecting the same groups with the bulk bullets.

I shot 30. caliber in competition, National Match Course of Fire for many years, long range too, virtually always with handloads. Only time that I remember when my handloads did not outshoot “factory” ammunition was in the rare instances when I was issued National Match Amunition from Lake City or Frankfort Arsenal, the latter many years gone. I have no experience with the 5.55 MM round though I suspect that rifles so chambered would benefit from “Properly Developed” handloads too.

Comments are closed.