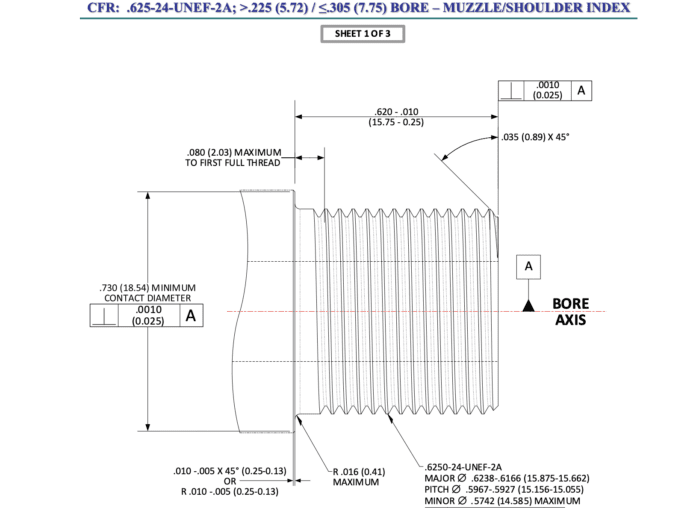

SAAMI, the Sporting Arms and Ammunition Manufacturers’ Institute, has existed since 1913 with standardization of cartridge and chamber dimensions (and cartridge maximum pressures) as its primary focus. With hundreds of ammunition manufacturers and hundreds of barrel manufacturers, it’s critically important that a shared standard exists for everyone to follow. Now, SAAMI has weighed in on a standard for barrel threads. You know, the threads at the muzzle onto which one screws a muzzle device like a brake, compensator, flash hider, or silencer.

As a firearm manufacturer myself (Black Collar Arms) and what you might call a “heavy user” of muzzle devices and suppressors over the last decade+, this was music to my ears. When we began making barrels at Black Collar, we had to decide on all of the specifications of the muzzle threads. There’s way more to it than just calling out 5/8×24 and hitting “go.”

How thick are the threads, what’s the pitch angle of the walls of the threads, how deep are the grooves, how tall are the tips, do the tips come to a sharp point or do you knock them down a little, how much threaded length is necessary from the muzzle to the shoulder, do you undercut in front of the shoulder, etc.? (Yes, there are technical terms for each of these things that I’m not using here.)

Ultimately it’s a balancing act. Thin threads with deep grooves and short tips will be compatible with the most muzzle devices from the most manufacturers, but the fit will be looser. Larger threads will result in a more precise fit, but may be too tight for accessories from some manufacturers to screw onto the barrel.

We consulted with experts, like the team at Silencer Shop who probably field more silencer and muzzle device compatibility questions than anyone else in the country. We searched for and requested technical drawings (or at least thread specs) from barrel and muzzle device manufacturers. Ultimately, we chose what we felt was as close to the industry norm as possible. What we felt was the best balance of compatibility and precision.

To be completely candid, the end result was pretty much an arbitrary choice. There’s a massive difference between 1/2×28 threads on the loose end of the spectrum vs. 1/2×28 threads on the tight end of the spectrum, but from both ends of the scale and everywhere in-between, it’s all 1/2×28 threads. Choosing some spot somewhere in the middle is . . . well, it’s just a choice. It’s an opinion.

While SAAMI makes it clear in the description that their specifications and drawings aren’t yet approved as the official, final standard, this is a huge step in the right direction for everyone making barrels and every sort of muzzle device.

I’d highly encourage all manufacturers to review these technical drawings and consider cutting their threads to these specs.

Good on SAAMI for recognizing the importance of setting and maintaining a standardization system for this critical component of a firearm, and for taking a major step toward setting that standard.

Now, if we could encourage them to publish a standard for a taper before the threads, we’d be all set.

this manly not seem like it but it is a really big deal.

If it were me I would probably use something at least compatible with mil spec whatever that may be.

Maybe barrel makers will stop with weird threads like my 1/2-36 ar9 or whatever my 450 Bushmaster is in too. Doubt that for liability though.

There’s no milspec for silencers or their thread pitch, at least not across differing weapons platforms. It’s not as a big of a concern with military arms, as the silencer model is married to a particular weapon model. Uncle Sugar doesn’t need to buy one silencer for multiple firearms, they buy one for one.

Thank Colt for the 1/2×36 9mm thread. They did this 40 years ago with the 9mm AR15 sub gun so someone couldn’t screw a .22 caliber AR15 flash hider on and shoot a 9mm ruining the barrel. I worked on a Diamond back DB9R 9mm AR style pistol that was muzzle threaded 5/8×24! Go figure? At least you could machine off the threads and re-thread it 1/2×28. I ended up replacing the barrel with a Faxon 9mm barrel threaded 1/2×28. Less labor & machine time $.

yay!

Does Europe have a set standard, as in NATO?

No, in fact early british cars and motorcycles even have THEIR own “standard”. Restore one of them and you’ll learn about Whitworth nuts, bolts, sockets and wrenches. You’ll also learn how to swear with a fokkin accent and a distrust of Lucas, the Lord of Darkness.

Lucas electrics and their famous leaky smoke.

*Shudder*… 🙁

There is no MIL-STD, US or NATO either one.

foam ear plugs are a whole lot easier.

“foam ear plugs are a whole lot easier.”

So is not bothering to swerve when your kin are napping on the centerline.

30 seconds with a garden hose to wash off the guts, and no one’s the wiser.

*Snicker* 😉

(I’m teasing. We like marsupials ’round here…)

And cheaper, at least for now. If it weren’t for the NFA I’d have probably made up one for most of the rifles I own at this point, perhaps even played with some research on it.

Yep

IMO as good as silencer tech has gotten, and as popular as shooting has become, I’d imagine that without the NFA most firearms would be integrally suppressed by now. Most entry to mid level air rifles already seem to be.

… “foam earplugs are a whole lot easier.”

Not really, they’re a bastard to insert down the barrel and really slow down follow-up shots.

I’ll respond below to this technical article on the same level nitwits responded to yesterday’s article about sonic cleaning firearm components with such silliness as, use a rag to wipe it down.

Use a Heli-Coil.

If we could all be so wise as Debbie

never. time- sert.

Have to wonder whether those 5 victims in Cleveland TX would be alive if the killer had had easy access to a suppressor so there would have been no noise complaint.

Likely not, as 5.56 well-exceeds supersonic velocity.

It’s still gonna sound like a rifle in the neighborhood…

I have to admit that I just assumed that these threads were already standardized and the pitch and diameter spec was just the shorthand to refer to the standard everyone used. Live and learn (and I hope to do both for much longer).

So how close was your previous educated best guess/compromise to what SAAMI eventually came up with? Will your previous work be close enough to work with the new standards and be somewhat forward-compatible?

back when u.s. bikes meant ignatz, we toyed with raleigh, peugeot, frejus.

limey, frog, ‘tralian would not play nice. fuji neither.

Then the Japanese came along using metric and screwed everything up.

Someone put together a master chart of what derailleur driveline components would work with different manufacturers, and there were some surprise matchups, but it’s been over 20 years back. Like Campy and Shimano, maybe? It was handy for poor folks like me back then trying to get various bits and pieces to play nice together…

I liked to take a quality English butted 532 Reynolds racing frame and put on higher-end Shimano 8-speed driveline and wheel components like Ultegra or Dura Ace on it mated Dia Compe cantilever brakes. Best of all worlds and things at the time. Indexing shifting that just plain worked was something the Japanese really contributed much to the bicycle world.

Before my bike and lower leg was crushed by a car’s bumper, my ride had a Dura-Ace 8-spd. driveline and Ultegra brake levers. All of them were cast-offs from someone else upgrading. Bought the bike new in 1989 with the RX-100 group.

Put around 100 miles a week on them, at a moderate pace. I rode for the aerobic benefits…

A lot of non machinist & non mechanical engineers don’t realize that there are different classes of threads which are standardized by ANSI. 1/2x28RH can be several class depending on the fit & precision, 1A,2A,3A even thought it’s all national standard 60 degree. At least we don’t have Whitworth (55 degree), square or Acme (common on lathes & mills) threads on muzzles. When cutting threads on a lathe with a 60 degree single point tool I ALWAYS have a standard to check the fit before I remove the barrel from the faceplate. One thing I noticed is some companies thread their .22LR barrels with way too long lengths of thread. Most .22 rimfire suppressors are designed for 0.400 length of thread and if you install it on an AR15 length of thread (approx. 0.620 +_ 0.015) the muzzle hits the first baffle. Thankfully some companies make precision spacers that screw on to shorten the length of thread.

“Thankfully some companies make precision spacers that screw on to shorten the length of thread.”

Or park a thin jam nut behind it?

Isn’t it a bit late in the day, after at least 4million gun mufflers are in use already?

And millions of threaded gun barrels already produced?

… aah bullshit. Mark it with chalk, cut it with a torch, thread it with a hex die, and assemble it with a pipe wrench. Those bullets will self-align the baffles after a minimal number of shots fired.

“Mark it with chalk, cut it with a torch, thread it with a hex die, and assemble it with a pipe wrench. Those bullets will self-align the baffles after a minimal number of shots fired.”

Oh, right. Forgot about that.

Nice to see a standard published. Should I ever decide to get a silencer/Suppressor I now have the information to the thread angles etc to put on the barrel. Wouldn’t mind a muffler for a couple of firearms. But too cheap to pay the tax and cost of something I could theoretically make myself.

THANKS INFOR , NEVER THOUGHT OF STUFF LIKE THAT

Hmmmm…. seems like I’ve seen a lot of thread specs from barrel makers where

there is no radius at the shoulder or even a relief cut there. Seems like that 0.016 radius could keep some cans from mating to the shoulder.

Nice article and well constructed. However the author could easily have left out the nod to “Silencer Shop” and been fine. As a dealer for them and a type 07 I can think of no worse can retailer in America.

Nice folks but they couldn’t manage their way out of a wet paper bag.

SAAMI offering some standardization isn’t unwelcome.

Comments are closed.