Savage has chambered several new rifles in 300 PRC that allow hunters and marksmen to make the most of the new round. Two of the new models are set up for left-handed shooters.

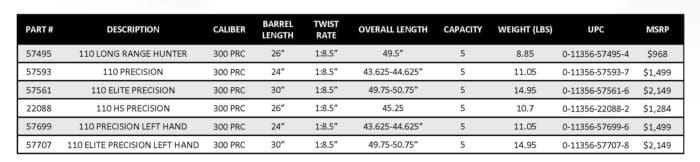

The new 300 PRC models are:

- 110 LONG RANGE HUNTER, 26-inch barrel, $968 (57495)

- 110 PRECISION, 24-inch barrel, $1,499 (57593 RH and 57699 LH)

- 110 ELITE PRECISION, 30-inch barrel, $2,149 (57561 RH and 57707 LH)

- 110 HS PRECISION, 26-inch barrel, $1,284 (22088)

While 300 PRC is capable of exceptional accuracy, the round is not simply a paper-puncher. The true potential of the 300 PRC comes with pairing heavy .30-caliber bullets with non-belted cases and temperature-stable powders. The 300 PRC’s projectiles achieve repeatable accuracy thanks to their high ballistic coefficients. The 30-degree shoulder of the case provides stable chamber alignment, while the non-belted cases stack efficiently and feed reliably from magazines.

“The 300 PRC has opened up new possibilities for extreme long range shooting,” said Jessica Treglia, senior brand manager at Savage Arms. “With their AccuTriggers and AccuStocks, Savage rifles offer the rugged stability needed for reliable accuracy at any distance.”

These rifles have several attributes to maximize the round’s potential, including Savage’s thread-in headspacing, floating bolt head, and button rifled barrels. Magazines are detachable AICS style boxes. The rifles come with a one‐piece 20-MOA rail and a serrated lock nut.

Would like to see these type of rifles chambered in Rimfire .17HMR – WSM and .22WMR.

Like the Ruger Precision Rimfire, or made specifically by Savage?

Check out Savage website. They have 27 rifles chambered in .22wmr alone, including a MDR chassis rifle and a varmint rifle.

Well if I hadn’t just bought a 700 pcr I would be interested in one of these. Down the road I will have to look into one.

Forgive my ignorance, but what do you mean “non-belted case”? I’ve never heard that term used before.

Google up “belted case.” A picture is worth a thousand words

.300 WinMag is a belted case. Take a look at pictures of one. The “belt” is the additional contour of the case head forward of the extractor groove. The cartridge headspaces off the belt instead of the case rim.

Thanks for answering my question instead of just telling me to “google it” like a condescending jackass.

Thank you. I’ll be here all week. Remember to tip your waitress.

God forbid you type two words into google instead of begging to be spoon fed.

Look up images of the old dangerous game cartridges such as .375H&H, 450NE (Nitro Express), or even 7mm Remington Magnum (from memory). The belt was used for extra strength around the base of the cartridge. The .375H&H also used the belt for headspacing because the cartridge had a small shallow shoulder. Other times, the belted case was a marketing ploy to suggest extra power over other similar cartridges.

Good for Savage.

I don’t understand this .300 PRC caliber: what is the point when .300 Winchester Magnum is virtually identical in just above every conceivable way? Case dimensions, velocities, and possible bullet weights all seem to be virtually indistinguishable. What am I missing in this new cartridge?

My understanding is that headspacing off the belt is less precise than headspacing off the base of the cartridge. Inconsistencies in headspacing limit accuracy potential when trying to maintain precise tolerances between the bullet and the rifling.

Would the thread in head spacing featured under attributes solve that issue With the belted magnum accuracy?

WARFAB,

So, why not measure headspacing off of the base of the brass case with .300 Winchester Magnum? Wouldn’t that yield the same consistency as with .300 PRC???

Headspace is set by the case feature that keeps the case from traveling further into the chamber, be it the rim, the shoulder, or the leading edge of the belt. 303 Brit headspaces off the rim, but has a ton of room before the shoulder in the chamber, so the cases stretch all to hell and don’t last long if you full length size when reloading. Similar can happen with belted, or you can have the shoulder too close if they try to make a match chamber.

Long range match shooters usually reload their ammo and belted cases can be a pain to deal with. The cases will tend to swell in front of the belt and traditional sizing dies don’t usually fix this. You can use special collet sizing dies like the one sold at http://larrywillis.com/ , but not having the belt is better.

Also, while the .300 Win Mag is a good cartridge that has been used successfully for many years, there are other improvements that can be made to the case design besides dropping the belt that will tend to increase accuracy.

Second that. Belts are a big ole pain in the ass to try and reload.

The 300 PRC can be loaded with longer, heavier, higher BC bullets, typically from 212gr to 250gr, and PRC barrels usually have a 1/8″ twist to better stabilize those bigger pills. The PRC has ~0.36″ greater OAL than the win mag. It only outshines the 300 win mag in extreme long range ballistics.

I’m going to have to take a good, close look at those two LH Precision models.

Thank you, Woody, for including the left-handed version information, and doing so prominently. Much appreciated. About 10% of all people are left handed, plus there are those like me who shoot long guns left handed because of eyesight issues.

OK, I see some folks are confused about headspacing issues in belted vs. non-belted cartridges.

This is going to be a long-ish reply here, and for that I apologize. I have something else to do tonight, and lack the time to make this shorter.

First, let us define “headspace” formally. “Headspace’ is the dimension between a datum on a cartridge case and the face of the bolt or breech of a gun. Since we’re talking about bolt-action rifles here, the ‘headspace” will be the measurement between the datum on the case (wherever that might be, which we’ll get into next) and the face of the bolt. Not the nose of the bolt, but the actual face – the flat surface that has a hole in it so the firing pin can come through it. That’s the face of the bolt.

Now, let’s talk about “belted magnums.” Let’s start with “what is a magnum, why did so many magnums have a ‘belt’ on them, what’s the belt for, and why?”

To answer all of these questions, we must go back over 100 years to the creation of the .375 Holland and Holland Magnum, the grandfather of all “belted magnum” cartridges, even if they don’t use the .375 H&H case as the parent for their case. The term “magnum” was used as a nickname for these new, large cartridge cases with a tapered neck, because they reminded someone of a champagne magnum bottle, which means nothing more or less in wine than “a large volume bottle.” That’s it. There’s nothing special about the champagne in the bottle, nor the powder in a ‘magnum’ cartridge, other than there is.a “lot” of it.

When Holland and Holland developed the .375, the market in dangerous game rifles in Africa was shifting on them. They had been used to making side-by-side double rifles, which used rimmed cartridges. In 1905, Otto Bock, a gunsmith in Berlin, Germany, had developed the 9.3×62 cartridge, and then other cartridges for dangerous game were appearing in bolt-action rifles – eg, the .404 Jeffery.

These Mauser-style (or actual Mauser action) rifles were far less expensive than the fine English SxS double rifles. Holland and Holland saw that there was a problem in their future unless they came up with a slick idea how to respond to these competitive developments. H&H wanted to keep producing double rifles, but they also figured if they could come up with a cartridge to feed in a bolt action rifle as well, they’d be able to sell more rifles because they’d have one ammo to feed both types of rifles.

Well, there are competing issues in double rifles vs. bolt action rifles. In a double rifle (or any break-action rifle, including a single barrel break action, or a lever action, or a falling block action, etc), you have a problem that you don’t have much extraction force. You need to make sure that your case has a good taper to it to insure that you can extract the cartridge, even from a dirty chamber, with little force. All of these action types of rifles would prefer to headspace off the rim on a rimmed cartridge, which would allow the case to have any taper you’d like. The reason why the taper for these non-bolt actions isn’t used for headspace is that they typically don’t have a shoulder region on the case, which would form a good datum for headspacing. Instead, they tend to have gradually sloped tapers over the entire case, to aid in extraction.

Now, let’s talk about a bolt action. On a magazine bolt-action rifle, you do not want rimmed cartridges, because the rims can interlock in the magazine, and leave you unable to feed a new cartridge at that most necessary of times, when you’re about to get your ass stomped by some dangerous game. So you want a rim-less cartridge case.

On a bolt action, you have terrific extraction forces – just huge. On a Mauser-style rifle, with the claw extractor, you can literally rip the case head off a cartridge if you have a mind to put that much force on a bolt (don’t try this on a Remington action – their bolt handles are soldered on, and you will rip off the handle. I mean on a genuine Mauser action, where the bolt handle is part of the bolt forging;..)

OK, so we have lots of extraction force. This means that we can put a lot less taper on the cartridge case, and get more volume with less length, and we can use that case diameter to keep the diameter of the case “fat” and give us a reason to create a fairly sharp shoulder taper, which gives us a surface off which we can headspace without a rim on the cartridge.

Ah, but now, if you’re tasked with creating a cartridge that will serve in both actions, how do you solve the headspace problem in both types of rifle actions, solve the magazine feed issue in the bolt guns, but have a shoulder-less case that will give you reliable exaction on non-bolt rifle actions?

You put a wide belt on the case, and you headspace off that. That, ladies and gents, is exactly what the boys at H&H did in 1912. They made a case that had lots of taper to it, no shoulder, a fat/wide belt forward of the extractor groove, which would prevent interlocking in a bolt action magazine, give a reliable headspace datum, while allowing for a long taper, etc, etc. Voila’! The belted magnum was born.

Over the decades after WWII, marketing guys started wanting to ship “magnum” cartridges in all manner of bore diameters. The marketing guys reckoned that “the first magnum had a belt, so our magnum needs a belt!” Technically, this was complete nonsense, but most all “magnum” cartridges developed in the late 50’s through the 70’s had belts on them.

Along comes Dakota and other custom riflamakers, and they start making “magnum” cartridges out of big volume cases with no belt on them. Nosler has recently introduced a line of “magnum” cartridges with no belt – and their parent case is the mighty .404 Jeffery, invented 1905, the same year that the 9.3×62 came out for the unmodified Mauser military 98 action. All these cartridges will headspace off the case shoulder. They assume you’re using a bolt action, so you have sufficient extraction force in case the chamber is dirty.

OK, with all that said, let’s talk about the concept of headspace. Remember headspace? It was why I started writing this up. I’ve already defined headspace, now let me tell you where/how various cartridges headspace (ie, “where is their datum?”)

– On straight-walled pistol cases, they typically headspace off the case mouth. The exception is the .38 Super, which used to headspace off the semi-rim, but now headspaces off the case mouth. The latter method is far preferred.

– On rimmed handgun cartridges, the headspace datum is the front of the rim.

– On rimmed rifle cartridges (eg, .30-30), the headspace datum is the front of the rim.

– On a belted magnum, the headspace datum is the front of the belt.

– On a non-rimmed, non-belted rifle cartridge, the headspace datum is a point on the shoulder. If you look at the drawings in the SAAMI publications, they call out exactly where on that shoulder the datum is.

– On a shotgun cartridge, the datum is just like a rimmed rifle or handgun case – it’s the front of the rim.

So: here’s what we’ve learned:

– There was a very specific reason why the .375 H&H had a belt – it was the way they created a cartridge that could work in both double guns and bolt guns. That’s it.

– There was never a need for a belt on the “modern” magnum cases, eg, 7mm RemMag, .338 WM, .300 WM, .264 WM, etc

– As long as we have a sufficiently wide, sharp shoulder (like most bottle-necked cartridges since the 7×57 Mauser), we headspace off that shoulder and need neither rim nor belt.

– Now we know why some cartridges have long tapers on their case, and why cartridges for bolt action rifles can get away with near-straight case walls: lots of extraction force available.

Now, when someone (eg a gunsmith) says that a rifle has “zero headspace” – what they really mean is that when a brand-new, to-SAAMI-specs cartridge is chambered in a rifle, and you close the bolt, that the bolt face comes into intimate contact with the case head – there is NO room for the case to wiggle forward/rearward in the chamber. This might be desirable in benchrest or other precision rifles, it is NOT a desirable condition in a semi-auto or hunting rifle. When. gunsmith cuts a chamber in a rifle barrel, and then checks the chamber with a “go” and “no go” gage, the bolt should close on a “go” gage, and NOT close on a “no go” gage.

I should make specific note here that when I, and most other gunsmiths, check headspace, we will strip out all the springs (eg, ejectors, extractors, etc) out of a bolt or breech face, so we can get a “true” reading. The bolt should close under gravity, not because I racked the bolt closed. It is possible to damage chambers with gages, so do not use anything but merest fingertip force to close an action when you have a gage in the chamber.

Typically, the difference between a “go” gage and a “no go” gage is 0.004″, or about the thickness of a piece of 20# paper. When the chamber is cut for “zero headspace,” it means that if the chamber is dirty, the bolt will be very hard to close.

What if a bolt closes on a “no go” gage? This is nothing to panic about. It means that the chamber or bolt face is worn, or that someone pulled the bolt out of the gun and replaced it with another bolt. If a rifle’s action closes on a “no-go” gage, it doesn’t yet mean that it is unsafe to fire, it means that it will be hard on the brass, because the brass will stretch more under firing.

Now, if you want to check to be sure whether or not a rifle is safe to fire, you use a “field” gage, which is anywhere from 0.006 to 0.012″ longer in headspace than a “go” gage – the exactly ‘field’ dimension depends on the cartridge we’re talking about.

If your bolt closes on a field gage, then you should NOT USE that gun until a gunsmith has a look at it.

There: belted magnums and headspace explained at the same time.

Read the whole thing and appreciate the explanations of both case belts and the chamber gauges. Thank you.

You really need to send an invoice to TTAG for posts like this. Only JWT’s articles approach this level of of thought and intelligence.

Comments are closed.