Many years ago, my father in law bought one of the very first Savage LRPs chambered in .243 WIN. He topped it with a really nice Leupold scope and then started a new position at work that severely interrupted his ability to have free time for shooting. Fast forward a few years, and the rifle was still languishing in his safe. There were precious few factory loadings that the LRP liked, and the ones it did like were not very good at flying out to the 1000 yard line, the primary reason he bought the gun. A rebarrel was in order . . .

Many years ago, my father in law bought one of the very first Savage LRPs chambered in .243 WIN. He topped it with a really nice Leupold scope and then started a new position at work that severely interrupted his ability to have free time for shooting. Fast forward a few years, and the rifle was still languishing in his safe. There were precious few factory loadings that the LRP liked, and the ones it did like were not very good at flying out to the 1000 yard line, the primary reason he bought the gun. A rebarrel was in order . . .

Normally, I’m no big advocate of rebarreling a gun willy nilly. Truth of the matter though, the Savages have been notorious for being friendly to the hobbyist gunsmith. Where a Remington 700 patterned bolt gun almost requires a machine shop to work on, the Savages can be disassembled and reassembled with a minimum of tools thanks to their low cost manufacturing processes. That’s not to say the Savages aren’t shooters — they certainly are. Especially when you take their cost into account.

I was in the kitchen at my in law’s extolling the virtues of the various 6.5 Creedmoor chambered rifles I’ve been able to shoot in the last year when my father in law started to show signs of interest in the cartridge. I showed him several of the ballistics tables available comparing one of the 140 A-Max factory loads to something like the ~50 gr V-Maxs that his gun preferred. The difference was night and day. The deal was sealed when I showed him the results I was getting out of Hornady’s factory 6.5 Creedmoor loads and reminded him that he wouldn’t have to have his hunting buddy load up some hand rolled .243 WIN for him anymore.

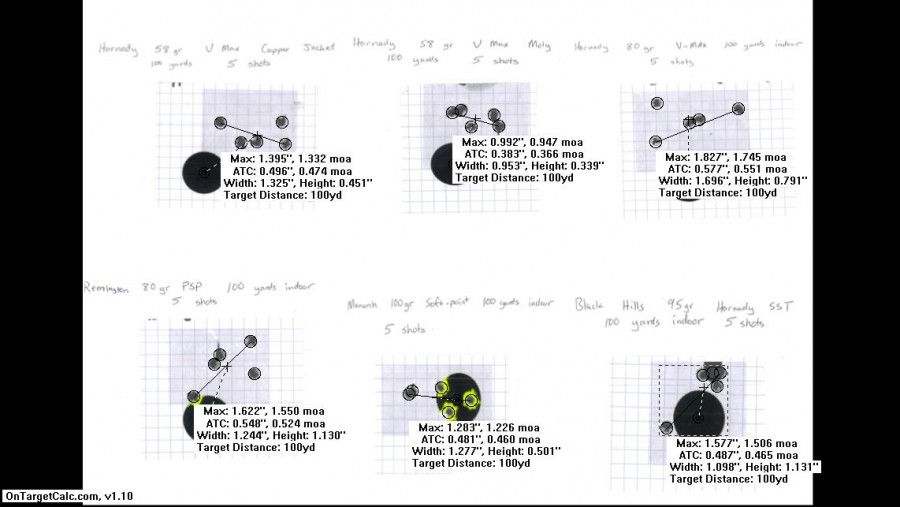

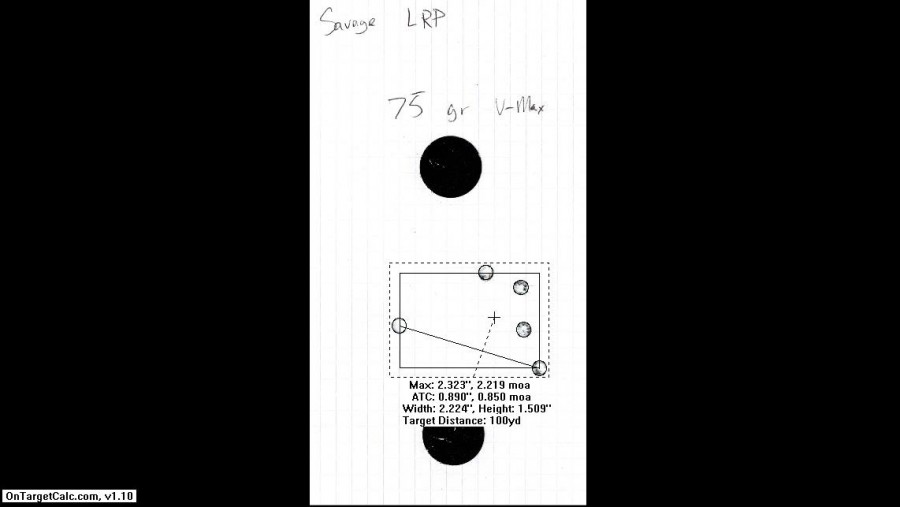

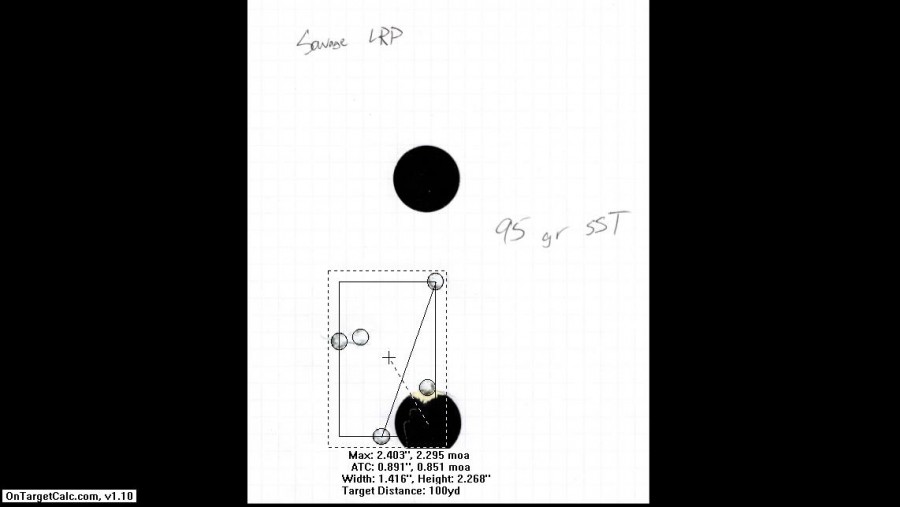

Ammunition availability aside, my father in law’s Savage had accuracy issues. I had (wrongly) declared it to be quite the shooter in my original review. Having time and an understanding of how to use OnTarget, I went back and evaluated my previous targets to find that the .243 chambered LRP never really shot better than 1 MOA with the exception of one factory load. To put the final nail in the accuracy coffin, I took the rifle back out to the range before I ordered any parts.

What I found was that it was still an erratic shooter giving preference to some loads, and hating others. Normally I’d call it confirmation bias, but I had the numbers staring me straight in the face. This gun simply wasn’t a shooter, and given that my father in law regularly has access to private land to shoot out to 1000 yards, something better really did need to be done.

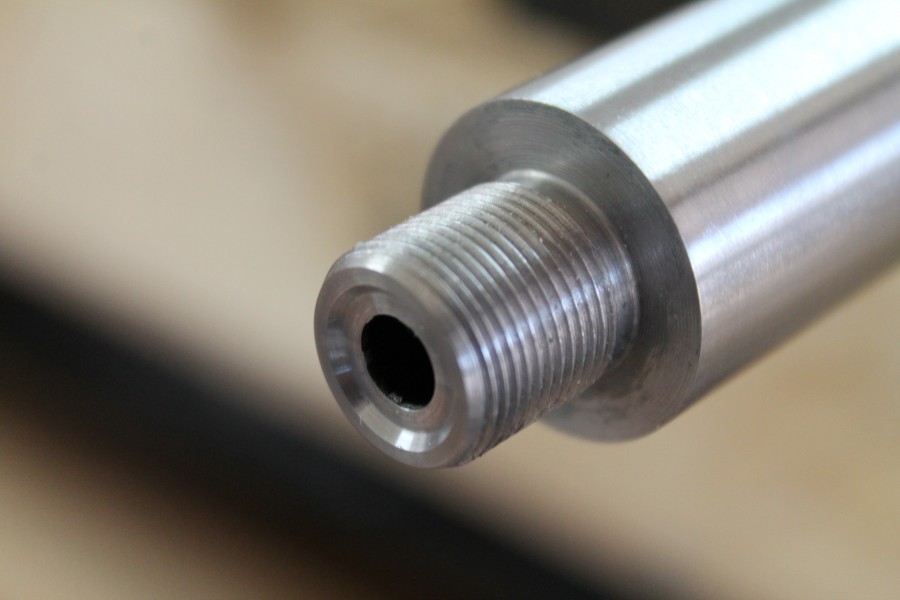

Rifle in hand, I made a call to Jim at Northland Shooter’s Supply. Jim is likely well known to those who have ever ordered parts for a Savage, but he was new to me. Jim still does business over the phone and spent the better part of an hour on the phone with me discussing the requirements I had for this rifle before making several suggestions on what I should order. Several items were non negotiable. Specifically, my father in law wanted a bull barrel. I wanted it chambered in 6.5 Creedmoor, threaded 5/8″-24 at the muzzle, and twenty-two inches long. From there, Jim counseled me on shank sizing and various other small parts I’d need. With few exceptions, the majority of Savages on the market are the small shank kind. The exceptions are the receivers chambered for the short magnums and the Model 12, the action I had in my hands.

Jim didn’t have the barrel in stock, so it had to be ordered direct from Shilen, an issue that moved my lead time up by several weeks. A quick review of Northlands recently updated website will show you the barrels they have in stock. While he had me on the phone, Jim counseled me on picking up their precision barrel nut and recoil lug. Given that I’ve seen some pretty horrendous stock parts come out of various guns and motorcycles, I opted to spend a bit more of my father in law’s money for the upgraded parts.

The last piece of the puzzle was tooling. I already had a barrel vise, but lacked an action wrench or the barrel nut tool specific to Savages. Jim has both in stock, and the prices were comparable to what I’d see on the market at large. Jim was sure to tell me several times that all of their tools, down to the allen wrench included with the action wrench, are made in the USA. Loaded up on tools and parts, Jim slammed my credit card for the better part of $700. Less than three days later, all the small parts and tools showed up. Four weeks later, a very heavy tube arrived direct from Shilen.

The first order of business was separating the action from the old barrel but only after removing the scope, rings, and bolt. Locked up in my fancy new barrel vise, I used the Northland barrel nut tool to break the old nut free which required a bit of grunting and a decent sized breaker bar for leverage. From there, the action spun off and the old barrel went into storage.

I completely degreased the action and got the new Shilen barrel mounted up in the vise along with the new barrel nut and recoil lug. I dabbed on a bit of moly grease and then threaded the action onto the barrel. At this point, I removed the ejector and extractor from the bolt, and closed the bolt on a 6.5 Creedmoor GO headspace gauge. I threaded the action down until it was tight against the gauge, and then threaded the barrel nut down hand tight.

At this point, I set my torque wrench for the correct specification, and attached it to Northland’s tool. I then mounted up Northland’s Action Wrench which helpfully features a relief cut for the recoil lug, and held it tight while I torqued the barrel nut down. Once at spec, I cycled the bolt on the GO gauge to confirm that the bolt closed without any stickiness. I then loaded up the NO GO gauge and confirmed that the bolt would not close. At that point, I reassembled the bolt and started putting the rifle back together.

Once reassembled, I took the gun to the range to sight it in. At this point, I found that the bolt would not close on a live round without quite a bit of force. Fearing that I’d somehow messed everything up irreparably, I went home, and tried things with the GO and NO GO gauges. I ended up only able to replicate the issues by using live rounds as the GO gauge worked fine. My first thought was that the chamber had been cut incorrectly and that the bullet ogive was being pushed against the rifle lands. I tested this by measuring the OAL of a loaded cartridge, loaded it, cycled the bolt, and then extracted it and measured the OAL. With it unchanged, I looked to the extractor which in retrospect should have been my first thought for two obvious reasons.

The first reason was that I had been having difficulty closing the bolt on a loaded round for the first “cycling” only. By uncocking the bolt, and closing it again, I had smooth bolt handle movement. I incorrectly chalked this up to the bullet being pushed further back in the case, a foolish assessment on my part. The second piece of evidence was that I wasn’t closing the bolt on the headspace gauge, instead choosing to load the headspace gauge into the bolt (held by the extractor), and then insert it into the chamber. Naturally, everything worked fine when I did it that way.

At roughly the same time I came to this conclusion, I launched the ejector spring across my shop whilst reassembling the bolt. Given that shipping was the same whether I bought one part or many, I elected to replace every part in the bolt face. I’m happy to report that the new extractor I purchased fixed my issue and the gun fed, extracted, and ejected with no issues.

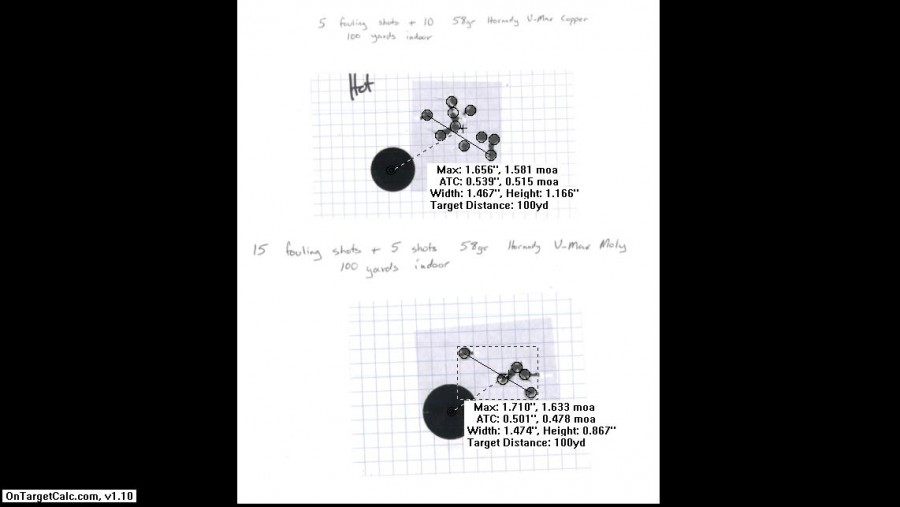

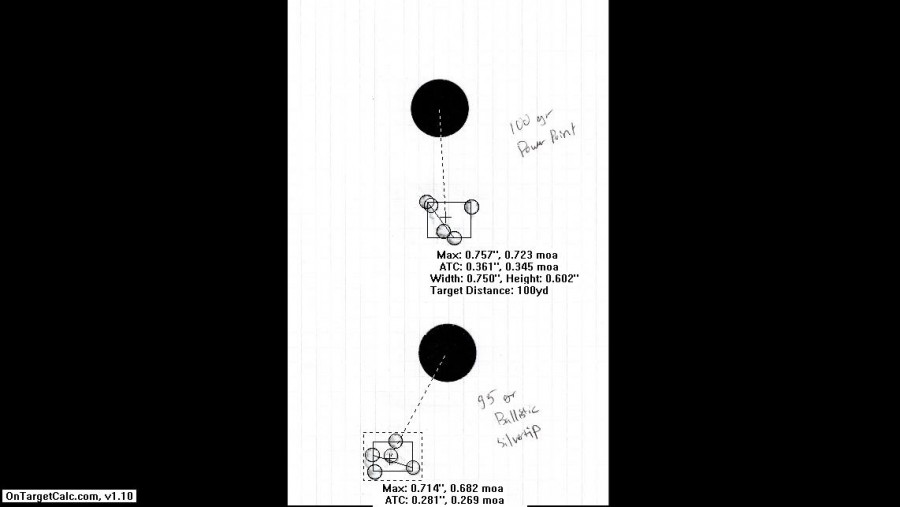

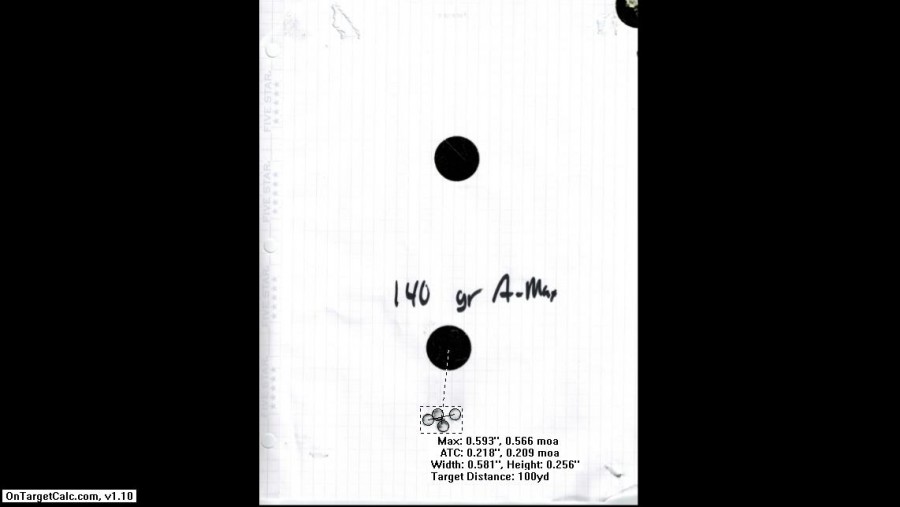

At the range with a functioning firearm and a calm day, the newly rebarreled Savage turned in some really impressive groups at the hundred yard line. It does not seem to like the 129 gr. SST factory load from Hornady turning in pretty consistent five shot groups in the 1.2 – 1.4 MOA range. Switching over to the 120 and 140 gr A-MAX loads from Hornady, this rifle consistently turns in sub MOA performance with my best group a ~.6 MOA five shot group (yes there’s five) from some 140 gr. A-MAX loads. Stepping it back to the quarter mile line and beyond, it performed as well as any of the other 6.5 Creedmoor chambered guns I’ve tested out, turning in sub MOA groups at well past the 500 yard line when I did my part.

Thanks to the beefy barrel, long strings of fire can be had without changing POI or group size. The group above was actually shot with a very hot, very dirty barrel. I put something like 120 rounds through the rifle to confirm that it worked fine, and then called up my father in law to let him know that his rifle was ready to go.

With a bachelor party at a private hunting ranch coming up before I was due back at the in laws, I took the rifle out along with the various ammo I had left. Among the fifteen or so guys assembled for the party, I was the only one who had ever shot past 200 yards. With nearly 900 yards to work with at the ranch, I set up an IPSC steel target at a laser measured 891 yards and managed to get everyone, including the bachelor, on target at least once in a pretty wicked little wind. Of all the guns we had out at the range, this one was easily everyone’s favorite, and the one that ran out of ammo first.

On the way back home, I stopped by the family ranch to drop off my steel target, and took the opportunity to take one of my parent’s friends out to my little spot under the big oak tree. He’d never shot anything with a silencer, and hadn’t done any shooting past 200 yards in his life. I set him up with a bit of ammo I’d squirreled away from the bachelor party and had him send three rounds. Pictured above are his first three rounds ever shot past the 200 yard line.

This rifle flat out shoots circles around its former incarnation and has been a crowd pleaser with everyone that’s shot it. Unfortunately, my father in law still hasn’t gotten the chance to take it out due to our combined work schedules. We’ll get out before it gets too hot to see if he likes it.

Specifications: Rebarreling of a Savage LRP

Specifications: Rebarreling of a Savage LRP

- Original Configuration

- Chamber: .243 WIN

- Twist: 1:9.25

- Length: 26 inches

- New Configuration

- Chamber: 6.5 Creedmoor

- Twist: 1:8

- Length: 22 inches

- Parts Cost: $471

- Barrel – Stainless Select Match – $339

- Muzzle Threading – $75

- Recoil Lug – $29

- Barrel Nut – $28

- Tool Cost: ~$250

- Barrel Vise – $59.99

- GO Gauge – $49.99

- NO GO Gauge – $49.99

- Barrel Nut Wrench – $28

- Northland Shooter’s Supply Action Wrench – $60

Ratings (out of five stars):

Ease of Installation * * * * *

Assuming you have the tools, and a bit of mechanical aptitude, rebarreling a Savage is fairly straightforward. Now that I’ve done one, I assume they can be knocked out fairly quickly from this point forward. The correct tools make life easier, so go ahead and pony up for them if you’re looking to do this yourself. As a nod to Shilen, the barrel threaded perfectly and the muzzle brake timed with a minimum of shims.

Accuracy * * * * *

I’m astounded at how good this rifle shoots. 6.5 Creedmoor is already a really great long range cartridge and one that can make a competent shooter look like he knows what he’s doing. Pair it up a with a gun that drives those bullets through the same hole, and you’ve got a winner. Mated up to a solid stock, and a good piece of glass, this is every bit of the 1000 yard rifle that my father in law wanted when he bought it originally.

Cleaning * * * * *

I have never owned a rifle that cleaned up this easily. I shot something like 200 rounds in total during my testing without a single cleaning. When it finally came time to return the gun to my father in law, I gave it a thorough once over. To my shock, a few patches soaked in KG 1 were all that were necessary to clean the carbon fouling from the barrel. No matter how much KG-12 I ran through it, I couldn’t get any copper fouling out of the bore. Shilen has done an excellent job with their hand lapping. This barrel can be shot all day and be clean after a few patches of quality carbon remover.

Overall Rating * * * * *

Less than $500 worth of parts and a few hours of work turned a safe queen into a bonafide shooter. I’ve always heard that Savages were the AR-15s of the bolt action world and this little project has firmly cemented it for me. So much so that I’m now trolling the pawn shop aisles for a donor Savage action.

“What I found was that it was still an erratic shooter giving preference to some loads, and hating others. “

That’s pretty much always the case. Why would this be a surprise?

You even found some loads were better than others after the barrel change.

Comments like this one are for sure head scratchers for me…

Um, yea.

I’ve said it many times on many threads: If a shooter really wants sub-MOA accuracy, and especially sub-half-MOA accuracy off the bench or rest, they must (it is not an option) learn how to reload.

I started reading this thread and saying “Hmmm. What, exactly, is wrong with this rifle? ‘cuz I’m not seeing it…”

I have entertained the idea of starting to reload but powder is still not available in my area. I have been lucky that my newest rifles (both in .300 blk) have shot very well with barnes 110 Vor-tx. The ruger American Ranch shoots well under 1/2 inch at 50 yards, 3 shot groups look like single holes, This while leaning against a truck. At 100 yards I was less than 2 inches, again, leaning on a truck, not using a bench. I would really like to see what these cheap things can do with hand loads.

Mail order primers and powder when one of the well-known reloading sites has a sale. Get as much as you can fit into one hazmat shipment, and that reduces your costs.

It shot some factory loads @ 2+ MOA. Now it shoots better than 1.4 MOA with everything. Most of the five shot groups I turned out with factory ammo were sub MOA.

Preference is perhaps not a strong enough word. The rifle absolutely wouldn’t shoot some factory loads before and now it likes pretty much everything I throw at it.

Adding the that, the prior rifles preferred bullets were lightweight varmint bullets. Now it shoots heavy(ish) high BC bullets very well. Everybody wins.

And now I’m going to tell you something that you might not have realized before:

You can change how a rifle shoots by changing the headspace. If it had generous headspace, well, the old barrel might not have shot as well as it could have.

One of the largest issues in rifle accuracy is the distance of the “jump” from the bullet starting to leave the case neck until it engages the lands of the rifling forward of the throat. In reloading, one of the things you can do to increase the accuracy of many rifles is to load your bullets to close up that gap a bit, or even seat the bullet into the lands. This latter issue needs corresponding reductions in powder loads. It is also a technique with a wide following in the accuracy pursuits (benchrest, f-class, etc).

“It is also a technique with a wide following in the accuracy pursuits “

Indeed.

One of the most useful tools I have for the calibers I load for accuracy is the RCBS Precision Mic, http://www.midwayusa.com/Product/574297/rcbs-precision-mic-308-winchester

One part of the tool allows measurement for “touching the lands.” Then, with another part, one can seat the bullet back consistently (provided the seating die is worth a darn) to a desired “thousandths off lands.”

(The third part is for measuring headspace…which I find useful when necksizing only to know when it is getting time to reset with a full length sizing operation).

Incidentally, since we are on the topic of factory load performance, I once had a box of Remington factory ammo that the differences in seating depth were so apparent one could easily discern them…no measuring tools were needed.

On another related story, a friend of mine was working on another guy’s hunting rifle that would not print worth a hill-of-beans with the factory ammo tried. Measurement of the throat revealed the problem was a weird cut chamber and we were able to develop a load for him that solved the problem.

That single ‘fix’ turned a rifle shooting 6+ MOA into a 1 MOA performer and saved the dude’s elk hunt. Thing is, he had spent a good chunk of change for that hunt in MT, and for a bit there, it was looking like he would not even get to TRY to take a shot – responsibly anyway.

There are so many variations in chamber details but this simple point is lost on too many folks. It saddens me that so many people seem to think rifles really ARE one size fits all, and all ammo should work the same.

” The rifle absolutely wouldn’t shoot some factory loads before”

But again, that’s normal. Every rifle is like that. So what?

Especially since you are talking about factory loads.

“and now it likes pretty much everything I throw at it. “

By your own data presented, that is simply not so. It may have crossed some arbitrary line you have set for “likes the load” but going from 2 MOA on “some” loads to 1.4 MOA on “some” loads has not really changed much.

If you are getting 0.5 MOA out of some loads and 1.4 MOA out of others, by MY criterion, that rifle HATES the 1.4 MOA loads and I for certain would not be making the claim that it “likes pretty much everything.”

Once you know the rifle is capable of doing 0.5 MOA (or whatever), nearly three times that spread should not really be considered an “acceptable” load. That’s my opinion, anyway.

I’d have to agree with that assessment. My best factory rifles will group into -.5″ at 200 yards, off the bench. Those are just off the shelf Remingtons, with some trigger tweaks. I’ve built up a couple of Mauser actions that will also do that. To me, any bolt gun that won’t do better than 1 moa at 100 yards, with almost any decent load, is probably destined for GunBroker.

With handloads, carefully worked up using a ladder technique, my Rem 700 SS 5R milspec will put them all into one nearly-caliber-sized hole at 200 yards. Not benchrest quality groups mind you, but certainly enough to keep me happy.

OK, a tip here:

When you’re checking headspace with go/no-go gages, you should strip the bolt. There should be no extractor, no ejector, no firing pin, no cocking piece, nothing but a bolt handle, the lugs and the main bolt body.

The rifle should be held in a horizontal position.

With the go gage in the chamber, you should be able to gently push the bolt forward into battery, and drop the handle. Don’t cam the handle downwards, just let go of the bolt handle. In a clean action, without burrs, the bolt handle should drop all the way down to the closed position.

If the bolt handle does not drop all the way down, do not apply force to close it. This is how you ruin chambers and/or gages. If the bolt handle doesn’t drop on a Savage, you need to unscrew the barrel a bit more. On any other rifle, it means you need to ream the chamber a little more. I’m not going to discuss that here or now, as it is involved. The central point here is that the camming action on a bolt gun is able to apply a ferocious amount of pressure to ram home an object into the chamber. That’s not proper measurement technique.

OK, now let’s check the no-go gage. Pull out (or blow out) the go gage from the chamber. Put in the no-go gage. Put the bolt back in, and once again, drop the bolt handle. It should not drop all the way down into battery.

When I screw a new barrel onto a Savage, I don’t screw the barrel back onto the gage, and then tighten things up. I screw the barrel down onto a piece of spent brass, make some timing marks, then remove the brass and start checking the headspace per the above, making small adjustments until I end up with a result where the bolt drops without assistance onto a go gage, and will not drop onto a no-go gage.

This helps prevent inaccurate readings, as well as damage to the chamber or the gages.

Great comment. Thanks.

That’s a publication-quality bit of advice, there. Thanks! Your advice is not unlike how to use a micrometer – you’re dealing with similar tolerances here, so it makes a lot of sense to gently use the measuring instruments (go/no-go gages) just as you don’t reef down on the micrometer thimble.

It is exactly like using a mic. When you’re using a mic, you should be using the ratchet on the end of the thimble, not the thimble, to close the mic onto the workpiece to be measured. You want light, but consistent, pressure.

Here’s the thing: most people probably don’t know that steel can “crush.” When a gunsmith re-barrels a more conventional bolt gun (ie, Mauser, Winchester, Remington), we budget 0.002″ of “crush” into the headspace when we finish torquing the barrel into the receiver. This crush doesn’t happen on a Savage, because you’re just screwing the barrel into the receiver, then you’re locking it in with the barrel nut.

Well, you can crush the go gage into the front of the chamber, and by so doing, could end up with a headspace setting that is at least 0.002″ too tight. The bolt has more than enough camming thrust to accomplish this, which is why you want to allow the bolt to drop into position on its own. To do that requires a stripped bolt – no springs pushing the bolt out of battery at all. If you’ve got the barrel set for minimum headspace, and you then cam the bolt down to crush the gage in there, you’re likely going to end up with a short chamber, which means closing the bolt on spec loaded ammo could be forcing the mouth of the case neck into the front of the throat, will will start crimping the neck into the bullet, which will in turn raise pressures in the case as well as damage the bullet jacket.

All of which are Not Good.

Even if you don’t have time to write stuff for TTAG, we should at least aggregate your comments and the wealth of knowledge therein into a single post that grows when you post info like this.

Maybe Ted Nugent can start something like Jay Leno’s Garage, but for guns! His mechanics are basically a dream team who know every nut, bold and oddball part, then know how to do it correctly.

Not like most of TV gun shows where the characters and the antics between them make the show, but the beautiful and extraordinary machines that are perfected and corrected are the stars. With some witty and insightful commentary, like the Forgotten Weapons youtube channel guy, this would be amazing.

I’m curious, Tyler, are there any recommended methods to blueprint a Savage before rebarreling? I’m pretty familiar with working on Remy 700 actions, where you true the action, true the bolt lugs, square the bolt face, etc. I also know the Savage has that floating bolt face, which presumably eliminates some of those Remington necessities. But, other than just screwing a new barrel in, what else do folks do to a Savage action for accurizing?

You could, it you wanted, re-cut the face of the action while it’s on a mandrel in a lathe. You could, if you wanted, then re-cut the threads while in an action fixture on a lathe. Then you might lap in the lugs on the bolt.

Blueprinting isn’t the cure-all for accuracy that some people think it is. I’d put it down the list of “where to spend money for accuracy in a rifle,” well after “reloading, examining the barrel you have, checking the stock you have, checking the bolt you have (and possible firing pin work)”, etc.

All that assumes a modern factory action, like a Savage or Rem700. If we’re talking of building up a milsurp rifle into a shooter, well then, printing might well yield some real improvements.

All said and done, if you want to pay someone to blueprint an action, you might come out ahead by simply buying a quality custom rifle action and building off that, rather than trying to get there whilst paying a ‘smith to re-machine a low-dollar action. People are amazed when I recommend this, but I try to be honest with people. Add up the hours you can sink into the “blueprinting” game and $1200 to $1400 for a custom action doesn’t look so expensive after all.

What’s a firing pin work? To reduce lock time? Or to prevent pierced primers or what?

The consistency with which the FP hits the primer, and the circular error with which the primer hits the primer (ie, away from being dead-center on the typical Boxer primer) all can result in changes in muzzle velocity, which result in at least vertical stringing.

The objective of this game is threefold:

1. Achieve the lowest possible standard deviations in MV of the bullet leaving the barrel. This is where the FP work comes in, as well as trickling powder by the grain into the case consistently, weights of powder charges down to 0.1 grain or less, trying to choose a load with powder that has very consistent results, high load densities, weighing your brass, checking your brass for volumetric consistency, etc.

2. Getting the bullet presented into the bore of a high-quality barrel in the most consistent and co-axial manner possible. This is where chambers with tight necks, neck-turning on your cases, etc comes in.

3. Everything else.

If the firing pin hits the primer inconsistently, you will get inconsistent results before you do anything else to the gun.

Thank you!

“2. Getting the bullet presented into the bore of a high-quality barrel in the most consistent and co-axial manner possible. This is where chambers with tight necks, neck-turning on your cases, etc comes in.”

Very, very important.

I’d add to that list a good run-out gage to measure concentricity of both the neck itself and the bullet when seated.

Great advice – and thanks! The reason I ask is that I do have a nice lathe and mill out in the workshop, and am slowly but surely learning what I can about the deeper aspects of rifle accuracy. Since (to me) time in the shop is hobby time well-spent, I have a lot of fun taking a few hours to set up for lathe work, etc. I also get a kick out of building fairly low-budget rifles that compete very favorably with some high-dollar customs that my friends have commissioned.

When you’re working on bolt actions, there’s a bunch of tools that are handy to have.

You will need to make mandrels to hold your action between centers to do some of the work. To make a mandrel that fits your action as closely as possible, you’ll need some gage pins to gage the front and rear bolt support holes. If you get gage pins from, oh, 0.697 up to 0.706 in half-thou increments, you should be OK. Gage your front and rear supports for the bolt, and machine your mandrel to fit precisely. Drill a hole through the mandrel in the region of the mandrel that lines up with the mag well. You’ll thread that for a 1/4-20 bolt, and bolt on a flat piece of stock across the bottom of the mag well to keep the action from turning on the mandrel.

Next, you will need a tube of some sort with set screws fore and aft to hold the action.

And you’ll need to make or buy a Labounty bolt fixture for working on the bolt itself.

If you want to jewel a bolt, you would be well served to make a widget that allows you to hold the lugs of the bolt in a super-spacer on a mill, and then an insert where the firing pin goes for support by the footstock of a spacer set.

There’s more tooling to make all the time, but that could get you going pretty well.

Sharpshootersupply will time and true your action, and make it much, much smoother to operate.

It sounds like I’ve been headspacing Savages, uh, “savagely”, and probably ought to follow those detailed steps listed here! Mine are probably on too far…

What, didn’t like the 6.8 SPC?

Although I am a big fan of the 6.8SPC, the 6.5Creedmore has about twice the energy at 300 yards, with a similarly weighted round. There’s really no comparison.

Most stock 243 barrels don’t have enough twist for 1k yard use. 243 and 6.5 creedmoor are two of the best factory 1k target rounds, but 243 u will need to reload. With the creedmoor you can buy sub moa ammo from Hornady for about a buck a round, shoot some, and then have the brass to start reloading. Win win win

Perhaps I am ill-informed, but I have never heard that a .243 can be a 1000 yard gun. I would think that those itty bitty little pills would be subject to any puff of air that came along, and past 200 yards it is dropping pretty hard.

.243 Win is well known in the long range community.

Some nice reading on the topic:

http://www.6mmbr.com/243Win.html

The .243 would be a 1,000 yard gun, if you reload. Again, the .243 isn’t loaded by the factory with the sorts of VLD bullets you need to keep the pill supersonic all the way downrange.

Berger makes some very nice 6mm (.243) pills, as does Lapua. The 1,000 yard group record was set by a 6BR cartridge (last I looked) and it is shoving less powder behind the bullet than a .243 can.

The wind call experience required to accomplish that with such a light round is impressive.

Well, from my noodling around with ballistics math, the #1 factor that improves a rifle’s ability to shoot in the wind is not the mass of the bullet, which I had assumed years ago would be the biggest factor.

Mass is a secondary issue to “bucking the wind.” What most improves a bullet’s performance in the wind the most is having a high Bc. If you have a high Bc bullet, you retain more of your starting velocity, which means that your bullet is exposed to the wind for less time, which means you drift less.

Now, as it so happens, higher Bc bullets are also higher mass, as a general rule, BUT… they’re mass+bullet form, meaning that just launching some heavy bullet with a flat or classic hunting rounded nose and low Bc isn’t going to buck the wind as well as a smooth, high-Bc bullet with a tangent or secant ogive and a tapered base.

There are 90 grain .224, and 105 to 115 grain .243 pills available with the required Bc’s to do long range shooting. Look at Berger’s web site for more info to start, then Lapua’s and you can branch out from there.

There are several cartridges that have been developed specifically to push the 6mm bullets to their best performance, starting with the 6mm PPC, then the 6BR, improved versions of the 6BR, then the 6XC. The 6XC is a very interesting wildcat, which is basically developed from a .243 chamber, with the reamer stopped short. There has been so much benchrest development around the 6mm projectiles for years, that it is one of the standards of accuracy shooting out to 600 yards since, oh, the 1970’s.

I keep telling people here on TTAG to check out what’s been going on in the benchrest community for decades past. That’s where the accuracy ‘smiths and shooters have been chasing the ultimate limits of accuracy for decades – and achieving stunning results. Most everything everyone really knows, not “thinks might work,” but stuff known to work, has been developed by the benchrest guys (OFWG’s shooting expensive custom rifles with loving hand-loaded ammo) for decades.

I don’t have near the expertise or experience with precision rifle shooting as most of the commenters in this thread.

But I see the .243 as a 2 stage round. For guys like me that need a multipurpose deer/coyote/medium game gun the .243 in factory loadings is near perfect. Mass produced rifles with moderate priced scopes give us a very decent “meat” rifle.

Go to the level that guys like DG are at and the .243 is still a very viable round. Quality actions, barrels, loadings and experienced shooters take the round into a whole other region.

You are ill-informed.

But as others have said, the factory barrels don’t have the right twist rate, and the factory ammo doesn’t use the best 6mm bullets for long range. As is almost universally the case, you gotta handload.

With that one major exception– 6.5 Creedmoor. You may be able to get away without handloading on that one. Maybe.

Fast twist 243 barrel with a 95 to 115 grain berger or amax, and the gun will shoot flatter than the 6.5 creedmoor out to 1k. In some competition they put a velocity cap ( i think 3100 fps)on the 243, now people are using the 6mm creedmoor….

Wish more people used 260 REM

Well, the reason why it really didn’t go anywhere with the accuracy crowd was that the quality of the factory .260 Rem brass was short of what was required. And, until recent bullet developments in the 6.5/.264 caliber products, the accuracy guys were focused like a laser on 6mm rounds. As more and more people started shooting 1K ranges, then people started fishing around for more Bc, and the 6.5 and 7mm bullet products started popping up.

The lack of quality brass in the .260 left the market open for both the 6.5×47 Lapua and the 6.5 Creedmoor.

Sadly true. That being said I love my 260. Lapua brass, 140 gr Amax or ELD, and some H4350 and steel plates are dinged out to 1,250 yds. As you have stated previously the key is to load your own. Especially with 260 as there is no decent factory load.

I love Lapua brass and bullets. Sadly, they’re often in limited supply. When I find good prices on Lapua brass or bullets, I snap them up, even if I might not get around to using them for quite some while.

The .260 could have been so much more than it was. If the .260 had been brought into the market as a wildcat with a large following (like the .22-250), then it could have been so much more than it became – which is now nothing but a footnote to the 6.5 Creedmoor, the 6.5×47, etc. Sadly, the 6.5-08 didn’t have a huge following – it was bracketed by the 6mm benchrest rounds below it, and the 6.5-284 above it. So it had to stand or fall based on Remington’s development and marketing, and we know what comes of that.

The rapid acceptance of the 6.5 Creedmoor shows that a manufacture can still introduce a new cartridge into the veritable blizzard of cartridges available in the US, and still gain ground. The 6.5 Creedmoor also shows that it takes quality ammo, quality rifles, etc to gain that ground, neither of which are Remington’s strong suit.

Where does the 22-250 fall in with this long range shooting.

In guns with properly fast twist rates to accommodate the necessarily heavy and long bullets required, it’s a blast out to a bit over 1000m but a little hard on barrels.

Too hard to get such a small caliber heavy enough. Drop is not an issue. The laser range finder makes everything KD. Wind is the enemy.

sorry( KD?)

Sorry, Known Distance. Too much time on .mil ranges for me.

You’d need to load it with VLD bullets. Most .224 bullets have pretty poor Bc’s until you get to the heavier weights – 75 grains and up. Many .22-250’s would need a new barrel to spin up the longer bullets – like 1 in 8 twists. Many .22-250’s I’ve seen have slower twists of like 1 in 12″ for light varmint-grenade pills of 40 grains to 50 grains.

Good article Tyler. The 12LRP has been the hidden gem of the Savage Target rifle line since it was introduced around 2010. They now come in less of a Sporter style stock and more of a Tac/Mil LR stock. Make sure you get your FiL some Dark Eagle 10 round mags and keep feeding it Hornady Match Ammo. 6.5 creedmore is hard to beat as an economical LR plinker and critter getter!

Comments are closed.