I recently visited BLACKHAWK!‘s Manhattan, Montana accessories operation along with a gaggle of other gun writers. BLACKHAWK! is part of publicly traded Aliant Techsystems, also known as ATK. In case you have a life and aren’t familiar with ATK’s corporate structure, the conglomerate is a firearms-related and outdoor juggernaut (they’ll actually be spinning off the sporting group, soon to be called Vista Outdoor). In addition to BLACKHAWK!, the ATK umbrella encompasses names you know like Federal Premium, Speer, CCI, Savage Arms, Bushnell, Weaver, Outers, RCBS, Gunslick, Hoppe’s, Uncle Mike’s and more. Their Montana plant used to be located in beautiful Bozeman. But when the company outgrew that facility and wanted to expand, rather than accommodating a growing business, the city fathers, in their infinite wisdom, made the process difficult enough that ATK decided to build a new 80,000 square foot operation 20 miles west on I-90 in Manhattan. It’s a beehive of activity, working to meet the demands of their military, law enforcement and gun owning customers . . .

Manhattan is where they design and produce a lot of their injection molded items, everything from BLACKHAWK’s Serpa and Epoch holsters to those little trays that hold the cartridges in the boxes of Federal ammo you just bought. And the plant’s 24/7 operations make this Manhattan a city that never sleeps, too, feeding the constantly hungry maw of gun owner demand.

Chris Michael gave us a quick and dirty overview of their product design process, in this case a Serpa holster for a new pistol.

Once he’s finalized a design they produce a 3D-printed version to make sure the prototype works as, well, designed.

Once the design is finalized, they need to produce a mold. Our tour guide and master of ceremonies, Birten Todd, described how the plant produces their own molds on CNC equipment for the 30 injection molding machines they have cranking away, day in, day out.

Here, freshly formed GLOCK 17 Serpa holsters are cooled.

Here, the Serpas are completed and packaged for shipping.

Given the Manhattan plant’s size and capacity, they don’t just turn out BLACKHAWK! gear. They also produce other items like some of the plastic trays that end up in boxes Federal Premium, Speer and CCI ammunition. Here are some for .22 LR rolling out of the molding machine. Not that any of us is likely to actually find much of that it in stores.

Holsters aren’t the only BLACKHAWK! SKUs made in Manhattan, either. Here, Night-Ops weapon-mounted lights are completed.

And while most of ATK’s web gear is assembled in Puerto Rico, here shoulder harnesses for CQC Serpa holsters are sewn.

And these are tactical drop-leg holsters being assembled.

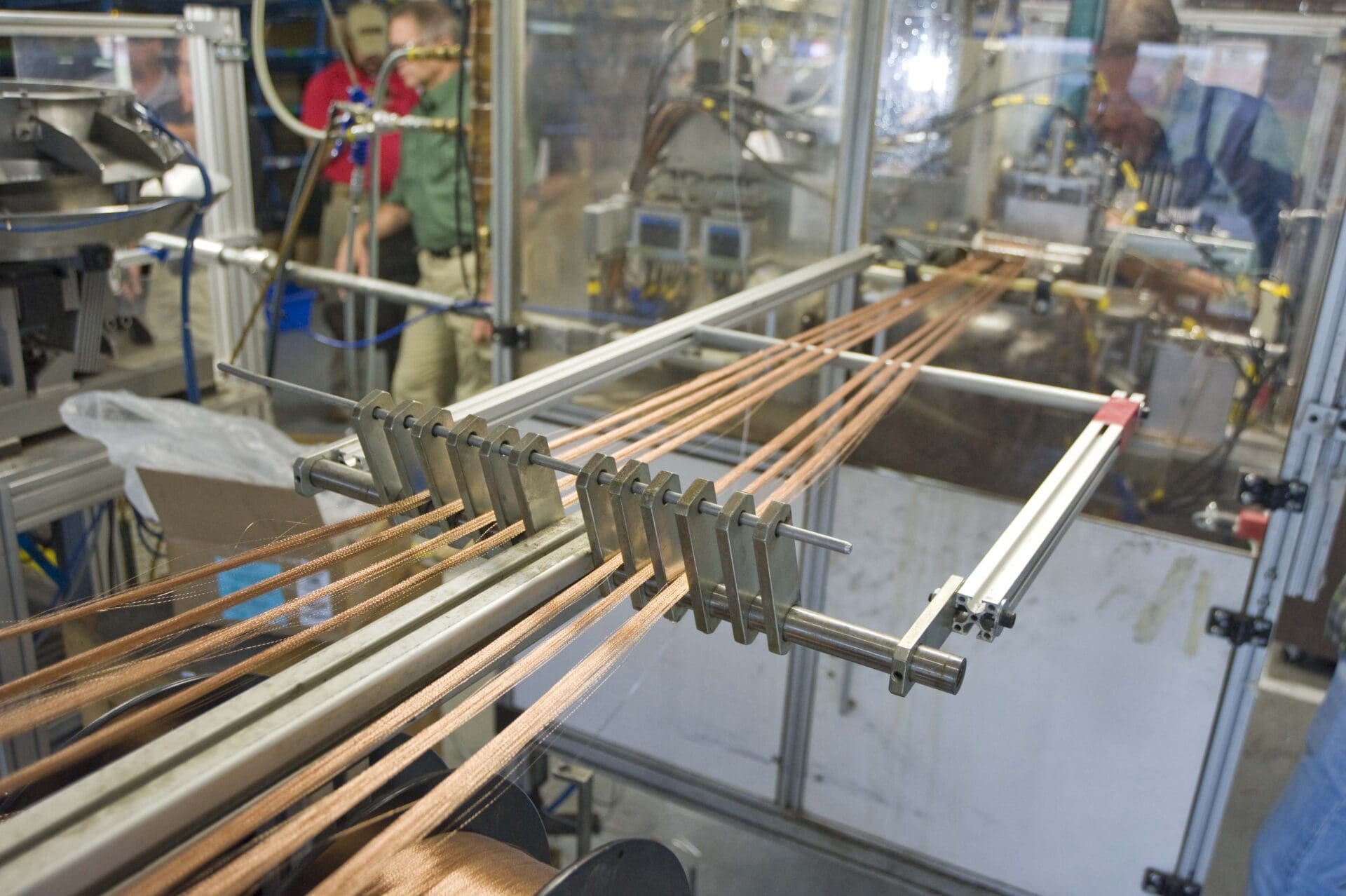

Up on the factory’s mezzanine level, they produce a variety of cleaning products you’ve probably used if you’ve ever swabbed out a gun. Items like bronze brushes.

And cleaning mops.

Oh, and don’t forget patches. You’ll need those, too.

Here’s where they package up a lot of that cleaning gear into the Outers and Hoppe’s kits you see hanging on displays at retailers like WallyWorld and Bass Pro.

Sample cleaning kit configurations:

So there you have it. A thumbnail sketch of what 200 people do every day deep in the heart of beautiful Big Sky Country to help you pack your piece, feed it and keep it pristine.

Nice tour! I’ve been using Outer’s and Hoppe’s stuff for nearly 45 years. Decent stuff and I’m glad to see it is made in the USA.

This is like an episode of “how it’s made”

I love it. Very cool

I was hearing that maddening loop of music in my head as I read the article…

I’d love to see a “How’s It Made” type series with popular firearms (ak,ar, etc) as the main theme

Love to see America hard at work making useful stuff!

I am pleasantly surprised to see this made in the USA! I really thought bh! stuff was all imported. Good to know!

I’m glad to see some of their products made in the country they sell them. But oftentimes I see the “made in china” on most of the webgear, and such I’ve purchased from them. Am I in the wrong here?

If you find BLACKHAWK! web gear made in China, it’s counterfeit. They do not sell any web gear that was made in China.

Bozeman city fathers are a bunch of bozos for letting this plant get away. I use alot of their products and will continue to. Nice job on the tour.

Id like to hear the inside story on that one.

Bozeville’s full of PRK & celebrity transplants, gunstuff doesn’t relate to their new age lifestyles…if they’d been making crystals or prayer rugs instead of holsters, the tax breaks & subsidies would’ve been rolled out for their expansion.

That was a nice tour and it’s good to see that at least some portion of their manufacturing is done in the US, but don’t be fooled. This is a company that makes a large portion of their wares in China. On top of that, they make some products in China that are cheap ripoffs of products by companies like Harris Bipods and others that actually make those products in the USA.

One of the great things about the firearms industry is that so many products can be found that are made here in the US. I love spending my money on companies that employ hard working, talented Americans. So, if you find a good Blackhawk product, flip it over and see where it’s made. If it doesn’t say “Made in USA”, maybe consider a different product that is. If it does, pick it up and let Blackhawk know you bought it because it’s made here.

Jobs are hard to find in Montana.. 200 lucky people get to working the firearms industry.

Nice. Makes me want to move to Montana.

A “gaggle” is two, a.k.a. 2. Who was the other person? 😉

Comments are closed.