Lone Wolf Distributors, perhaps the oldest and largest manufacturer of aftermarket parts for GLOCK pistols, continues to increase its domestic production capacity. While most of its manufacturing capacity is not actually inside of its Priest River, Idaho headquarters, the facility continues to expand its R&D, prototyping, distribution, and, yes, manufacturing capability.

Last week Lone Wolf put on a dinner party for its employees and their families to celebrate a record year of growth. As I’m local to them, they extended an invitation to the wife and me. It was a pretty cool shindig, with good food, good beer, a [good] live band, and a Lone Wolf logo cake.

A couple of these lucite Timberwolf pistols graced the bar.

Eventually their Special Projects Manager and I got down to business, though, and we shot up the road from the event center to visit Lone Wolf HQ.

The plan was to grab the 460 R upper — chambered in .460 Rowland — that I’m borrowing for what should be some fun ballistics testing and shooting action (including through my Liberty Cosmic suppressor) on top of my G20SF frame with some Underwood ammo that’s showing up soon. This caliber is a beast!

We turned that into a quick tour of the manufacturing side of the HQ facility (which also houses offices, conference rooms, server center, photography studio, shipping and distribution area, etc.).

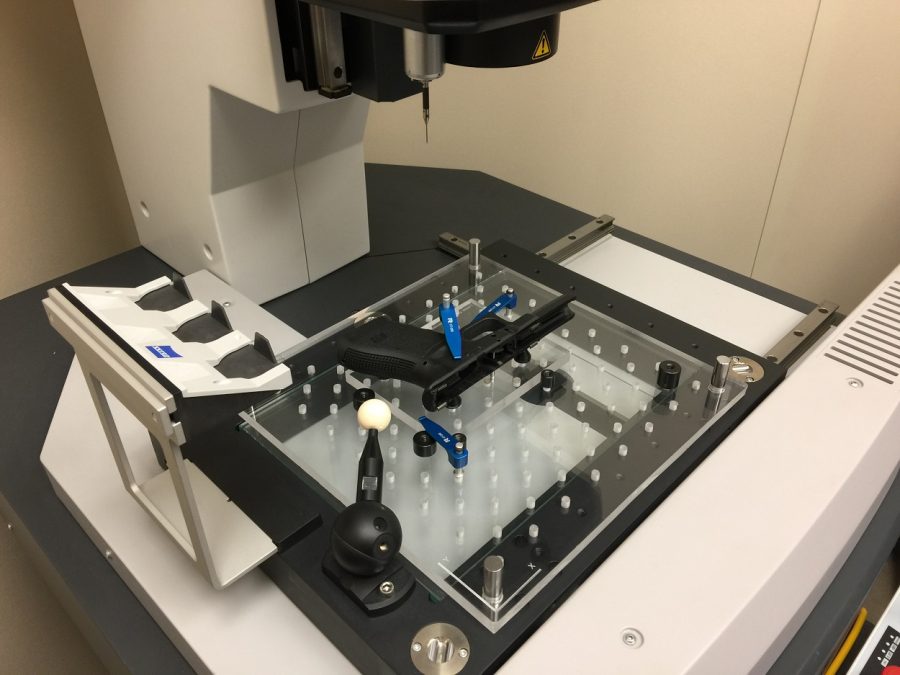

The first thing I noticed when entering the manufacturing floor was a very nice coordinate measuring machine made by a high-end optics manufacturer that I had no idea made this sort of stuff (and a whole freaking lot more). This is an expensive piece of equipment that’s glaringly missing from so, so many manufacturers — even “premium” brands with high-end CNC and wire EDM equipment.

It’s often stated by companies manufacturing parts with those sorts of modern machines that they’re accurate to within whatever tens of thousandths of an inch, but they have no meaningful way to verify that, verify that they’re maintaining that, or answer the question of, “accurate compared to what?” CMMs like this one measure and map, through multiple methods, down to the gazillionth of an inch, and I was happy to see this level of investment at Lone Wolf.

Lone Wolf has a handful of laser engraving machines and unique printing machines.

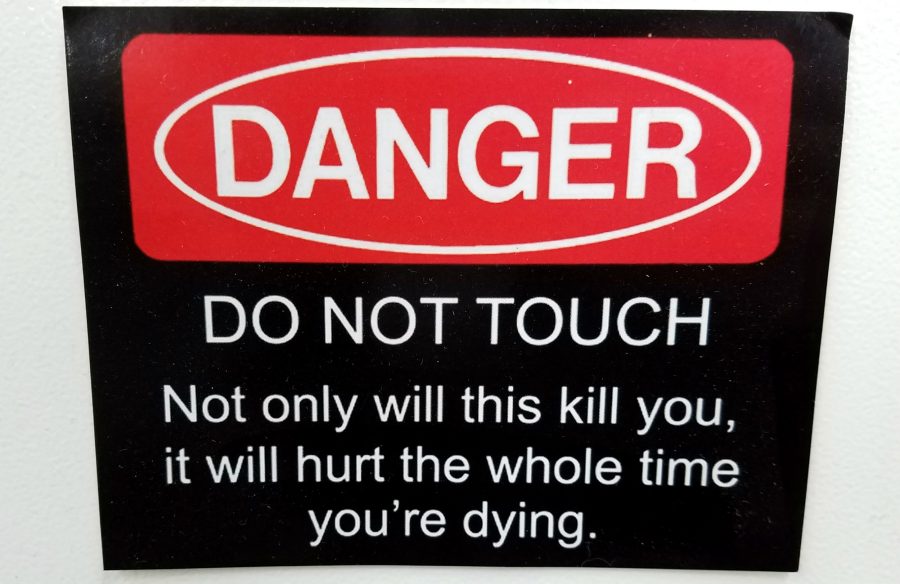

Some of them are dangerous.

There’s manual milling and machining equipment so Lone Wolf’s machinists can handle some one-off, custom jobs.

Whereas production is done on a handful of modern CNC mills of various types.

This guy automatically feeds in round stock from a hopper and can turn it into all sorts of finished products.

Flash hiders are one example.

This facility doesn’t manufacture Lone Wolf’s U.S.-made barrels — that’s done in a larger location — but a final step of QC plus engraving and packaging is done here.

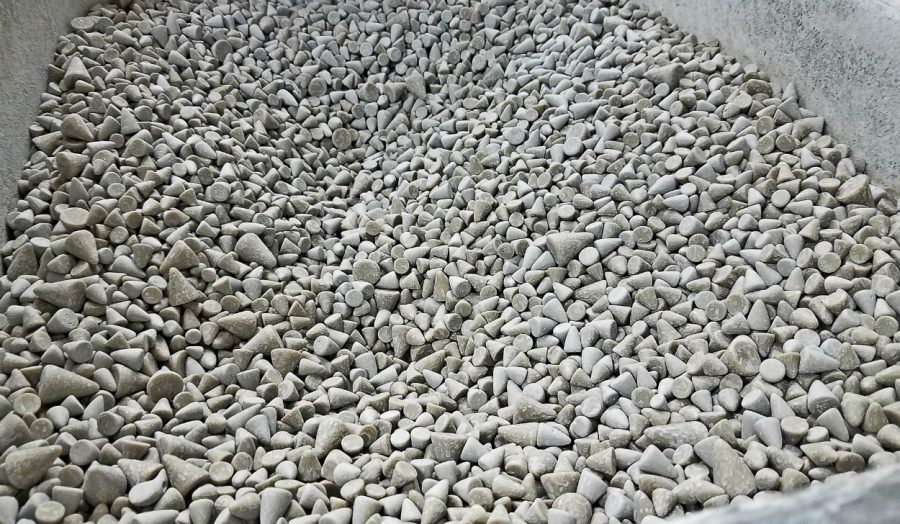

A box full of ceramic media used for tumbling and deburring.

Vibratory tumbler for parts finishing.

That’s all I got photos of, but there were parts washers, sand blasting cabinets, and product assembly lines, plus some other CNC, prototyping, testing, and printing equipment that was off limits to the camera. Considering the number one “gripe” I’ve seen about Lone Wolf parts –especially barrels — over the years is that they were made in SE Asia (Korea — the southern one), it’s nice to see them responding by continuing to increase their made-in-the-US product line.

Now if only they would make a plain jane glock slide that doesn’t cost an arm and a leg. I have a couple of 80% glock lowers and the thing that kills the wallet is find a slide that isn’t a piece of thousand dollar range bling.

Actually I think they have the most affordable aftermarket slides available (start at $175). Lots of options: https://www.lonewolfdist.com/Products.aspx?CAT=244 …the Alpha Wolf are made in the U.S. and that line is being expanded (right now it’s mostly blanks, which are often purchased by other ‘manufacturers’ and finished out with their fancy machining and sold under other brand names).

Of course, filling a slide with all of the necessary parts if you don’t have any of the OEM ones to use adds up.

If the LW stuff is still out of the budget, I’d hop on GunBroker and the like and search for used, OEM slides. There’s no shortage of them for sale out there. Going rate seems to be like $365 and up, though, so you could do something pretty sweet looking from LW or maybe other aftermarket companies for pretty similar $

I actually just picked up a brand-new (still had that weird coppery Glock grease) upper, complete with barrel and guide rod/spring from GunBroker for $325 plus shipping.

“The first thing I noticed when entering the manufacturing floor was a very nice coordinate measuring machine made by a high-end optics manufacturer that I had no idea made this sort of stuff…”

Leica? Nikon?

In some of these machine photos the manufacturer and/or model number has been photoshopped out for various reasons. I think you can sleuth out the maker of the CMM, though.

Ah, OK.

They want to avoid a competitor reverse-engineering their system, then?

Zeiss

I love that danger sign. I’ll be searching for one to buy after work.

My company had a Zeiss cmm machine. Wonderful and frustrating at the same time. It showed you how bad you were lol.

Have to admire an outfit that uses gallows humor to warn of impending danger!

I really like Lone Wolf. I bought a Glock 24 stainless upper from them and a bunch of parts for various projects. They have always had great customer service .

I own a few glocks. The nicest one I own is a stock 21 4th gen lower with a LWD slide and barrel assembly. Most of it is LWD and the lower is all glock. Has just the best trigger on it of the whole bunch. Amazing!

Comments are closed.